Product description

- Workbench and product design independently developed by KRRASS. 4000W Fiber laser cutting machine is mainly used for cutting stainless steel, carbon steel, aluminum, copper, aluminum alloy, iron, gold, silver and other plates with a thickness of 1.0~25mm

- The cutting accuracy reaches +-0.03mm. The maximum acceleration speed: 1.5G. Maximum air running speed: 120 m/min. Machine net weight: 3.5 tons.

- Laser power: 4000W

4000W Fiber Laser Cutting Machine Design

The 4000W laser cutting machine uses precision German IPG, SPI, Rofin or domestic Raycus lasers. Combined with the gantry CNC machine tool designed by our company, it has undergone high-temperature annealing treatment and high-precision processing. Has good stiffness and stability.

4000W Fiber Laser Cutting Machine Features

- The weight of a single table: >3 tons, and the total weight of the machine >4.8 tons.

- The body is welded by 18-20mm thick steel plate and 8mm square steel. Workbench load-bearing> 1.2 tons

- Maximum running speed: 100m/min (120m/min optional)

- The weight of a single table: >3 tons, and the total weight of the machine >4.8 tons.

- The body is welded by 18-20mm thick steel plate and 8mm square steel. Workbench load-bearing> 1.2 tons

- Maximum running speed: 100m/min (120m/min optional)

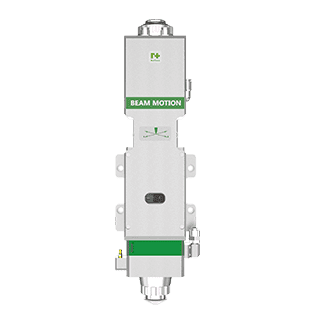

Raytools cutting head with automatic focusing system

4000W Fiber laser cutting machine functional advantages

- Excellent beam quality: smaller focused spot, finer cutting lines, higher work efficiency and better processing quality;

- Extremely high cutting speed: 2 times of the same power CO2 laser cutting machine;

- Very high stability, extremely high electro-optical conversion efficiency;

- Very low use cost: the power consumption of the whole machine is only 20-30% of that of similar CO2 laser cutting machines;

- Very low maintenance cost: no laser working gas; optical fiber transmission, no need for reflective lenses; it can save a lot of maintenance costs;

- Convenient product operation and maintenance: optical fiber transmission, no need to adjust the optical path;

- Super flexible light guide effect: small size, compact structure, easy to flexible processing requirements;

- Gantry type double drive structure, high damping machine tool, good rigidity;

- It adopts imported AC servo system drive and imported transmission system. The movement structure of the machine tool adopts imported rack and pinion transmission and linear guide rail as the guide, ensuring high speed, high precision and high reliability;

- The rack and guide rail adopt completely enclosed protective devices to prevent oil-free frictional movement and dust pollution, improve the life of transmission components and use accuracy to ensure the movement of the machine tool;

- The professional laser cutting machine, numerical control system, and computer operation can ensure the cutting quality and make the cutting work more convenient;

- The configuration of the automatic switch meter shortens the standby time and effectively improves the work efficiency by more than 30%.

The main technical parameters

[wptm id=43]

Application field

4000W fiber laser cutting machine is mainly used for cutting stainless steel, carbon steel, aluminum, copper, aluminum alloy and other metals. Applicable to industries such as kitchen utensils, cabinets, steel pipes, lamps, metal utensils, hardware, precision machinery, auto parts, elevators, nameplates, advertising, electronics, toys, etc. Suitable for cutting different thickness plates

Learn more about our products, please visit and subscribe to our Youtube channel