This table lists 4000W fiber laser cutting machine cutting parameters, cutting data about carbon steel, stainless steel,etc.

Carbon Steel 1 40-50 4.000 N2 / Air 10 2.0 Single 0 0.6 Carbon Steel 2 15-20 4.000 N2 / Air 10 2.0 Single -1 0.6 Carbon Steel 3 10-12 4.000 N2 / Air 10 2.0 Single -1 0.6 Carbon Steel 3 4.0-4.5 2.500 O2 0.6 1.0 Double +4 0.6 Carbon Steel 4 3.5-4.0 3.000 O2 0.6 1.0 Double +5 0.6 Carbon Steel 5 3.0-3.5 3.300 O2 0.6 1.0 Double +5 0.6 Carbon Steel 6 2.6-3.2 3.500 O2 0.6 1.0 Double +6 0.6 Carbon Steel 8 2.0-2.3 4.000 O2 0.6 1.2 Double +6 0.8 Carbon Steel 10 1.8-2.5 4.000 O2 0.6 1.2 Double +6 0.8 Carbon Steel 12 1.5-1.7 2.600 O2 0.8 4.0 Double +5 1.0 Carbon Steel 14 1.2-1.4 2.600 O2 0.8 4.0 Double +5 1.0 Carbon Steel 16 1.0-1.2 2.600 O2 0.7 4.0 Double +5 1.0 Carbon Steel 18 0.7-0.8 2.600 O2 0.7 4.0 Double +5 1.5 Carbon Steel 20 0.6-0.7 2.600 O2 0.7 4.0 Double +5 1.5 Carbon Steel 22 * 0.5-0.6 * 2.600 O2 0.6 * 5.0 Double * +5 * 1.5 * Carbon Steel 25 * 0.4-0.5 * 2.600 O2 0.6 * 5.0 Double * +5 * 1.5 * Stainless Steel 1 50-60 4.000 N2 10 2.0 Single 0 0.5 Stainless Steel 2 20-25 4.000 N2 10 2.0 Single -1 0.5 Stainless Steel 3 10-13 4.000 N2 12 3.0 Single -1.5 0.5 Stainless Steel 4 8-10 4.000 N2 13 3.0 Single -2 0.5 Stainless Steel 5 4-5 4.000 N2 14 3.0 Single -2 0.5 Stainless Steel 6 3.5-4.0 4.000 N2 15 3.0 Single -2 0.5 Stainless Steel 8 1.5-2.0 4.000 N2 16 4.0 Single -3 0.5 Stainless Steel 10 1.2-1.5 4.000 N2 18 4.0 Single -4 0.5 Stainless Steel 12 0.7-1.0 4.000 N2 18 5.0 Single -5 0.5 Stainless Steel 14 * 0.6-0.8 * 4.000 N2 18 * 5.0 Single * -8 * 0.5 * Stainless Steel 16 * 0.3-0.5 * 4.000 N2 20 * 5.0 Single * -8 * 0.5 * Aluminium Alloy 1 30-50 4.000 N2 10 2.0 Single 0 0.6 Aluminium Alloy 2 20-24 4.000 N2 12 2.0 Single 0 0.6 Aluminium Alloy 3 10-13 4.000 N2 14 3.0 Single -1 0.6 Aluminium Alloy 4 4-5 4.000 N2 14 3.0 Single -2 0.5 Aluminium Alloy 5 3-4 4.000 N2 15 3.0 Single -3 0.5 Aluminium Alloy 6 2-3 4.000 N2 15 3.0 Single -3 0.5 Aluminium Alloy 8 1.4-1.8 4.000 N2 16 4.0 Single -3 0.5 Aluminium Alloy 10 * 0.8-1.1 * 4.000 N2 16 * 4.0 Single * -5 * 0.5 * Aluminium Alloy 12 * 0.6-0.8 * 4.000 N2 18 * 5.0 Single * -5.5 * 0.5 * Brass 1 30-35 4.000 N2 10 2.0 Single 0 0.5 Brass 2 15-20 4.000 N2 10 2.0 Single -1 0.5 Brass 3 8-10 4.000 N2 12 3.0 Single -1 0.5 Brass 4 5.0-6.0 4.000 N2 13 3.0 Single -2 0.5 Brass 5 2.0-3.0 4.000 N2 13 3.5 Single -2.5 0.5 Brass 6 2.0-2.5 4.000 N2 14 3.5 Single -3 0.5 Brass 8 * 1.0-1.2 * 4.000 N2 14 * 4.5 Single * -3.5 * 0.5 * Copper 1 26-30 4.000 O2 10 3.0 Single -1 0.5 Copper 2 10-13 4.000 O2 12 3.0 Single -1 0.5 Copper 3 5.5-6.5 4.000 O2 12 3.0 Single -2 0.5 Copper 4 2.0-3.0 4.000 O2 14 3.5 Single -4 0.5

Note:

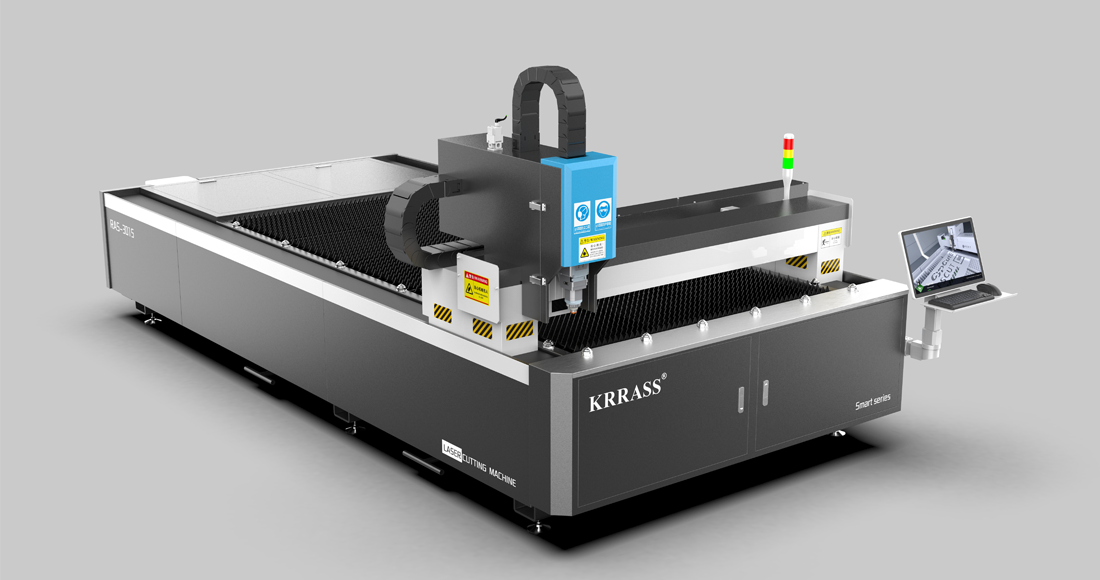

In the cutting data, the core diameter of the 4000W laser output fiber is 50 microns; The cutting data adopts Jiaqiang cutting head with an optical ratio of 100/125 (collimation/focus lens focal length); Cutting auxiliary gas: liquid oxygen (purity 99.99%) liquid nitrogen (purity 99.999%); The air pressure in this cutting data specifically refers to the monitoring air pressure at the cutting head; Due to differences in the equipment configuration and cutting process (machine tool, water cooling, environment, cutting nozzle, gas pressure, etc.) used by different customers, this data is for reference only. The 4000W fiber laser cutting machine produced by KRRASS basically follows these parameters.

Learn more about our products, please visit and subscribe to our Youtube channel