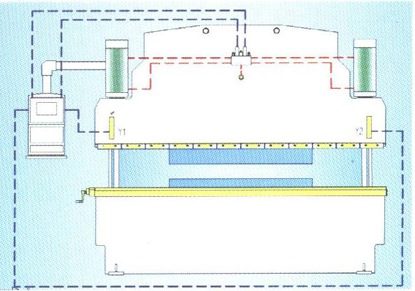

Normally Hydraulic press brake two cylinders synchronization method includes ELECTRIC-HYDRAULIC synchro and MECHANIC synchro.

In General we call electric-hydraulic synchro press brake, CNC press brake. According to Chinese GB/T standard, model number is WE67K.

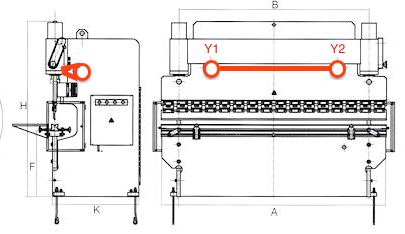

MB8/PBS/PBE model CNC hydraulic press brake works with two optic scalers to measure Y1, Y2 position during bending. CNC controller will control proportion valve exactly according to feedback of Y1, Y2. So that two hydraulic cylinders will move parallel. Y1, Y2 accuracy is 0.001mm.

The advantage of electric-hydraulic synchronized type CNC hydraulic press brake:

- First is Fast speed. Because CNC system control approaching/working/return speed;

- Then, Full bending procedure is adjustable, Including return height, speed, mute point and holding time;

- Because back gauge is on side wall frame, moving is high and accurate;

- Obviously that this type machine’s Y1, Y2 bending accuracy is high;

- At same time, the machine has good unbalance-bending performance. We can install different punch/die over working length;

Conventional hydraulic press brake is mechanic synchro press brake. Normally It is with torsion bar style. The machine has a big solid bar to force Y1, Y2 to work at same time. There can be moving difference according to speed, friction, workpiece. Y1, Y2 works with the torsion bar.

In Chinese GB/T standard, call conventional press brake WC67Y model. Also can install NC controller over same structure to make program on Y, X. It is called WC67K, NC hydraulic press brake.

The advantage of the torsion bar press brake is cost lower; normally can work with general workpiece. the short coming is speed lower, accuracy lower.