In the previous article, we explained the tool configuration of the delem da53t cnc press brake to you. After the preparations are ready, we need to check the control system of the machine before use. In this article, we will explain how to perform a reference point check on a CNC press brake using the Delem DA-53T. The following are basic guidelines for doing this process in general:

Turn on each power switch of the machine in turn

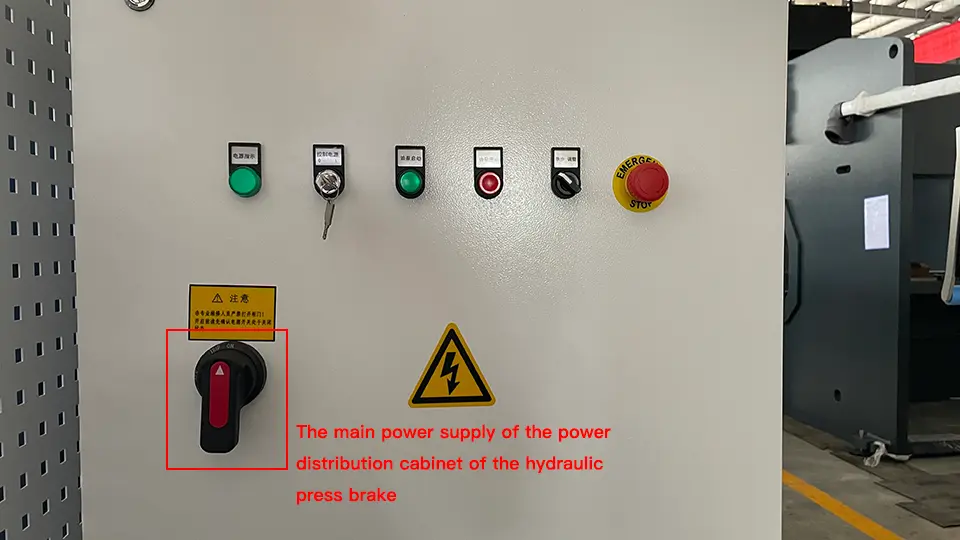

1. Turn on the main power supply of the power distribution cabinet: Before we turn on the machine, we need to close the door of the power distribution cabinet of the hydraulic press brake and turn the handle of the electric cabinet clockwise to make it in a locked state. At this time, the power supply of the main electrical cabinet will also be turned on.

2. Turn on the control power supply: Insert the control power key and turn it to the right. At this time, the control power will be turned on and the control power indicator will light up.

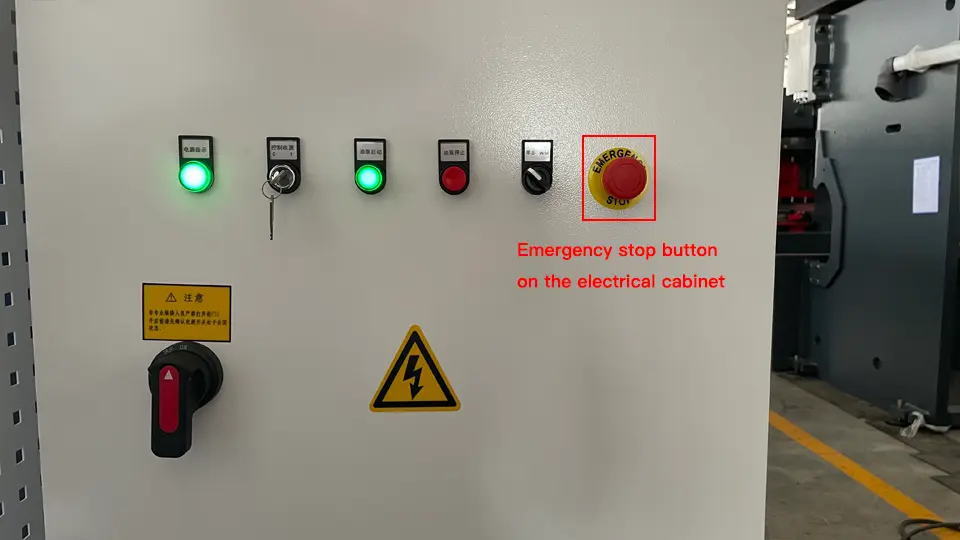

3. Check all emergency stop buttons: check the emergency stop buttons on the electric cabinet, controller, and foot switch, and bounce them back to the open state.

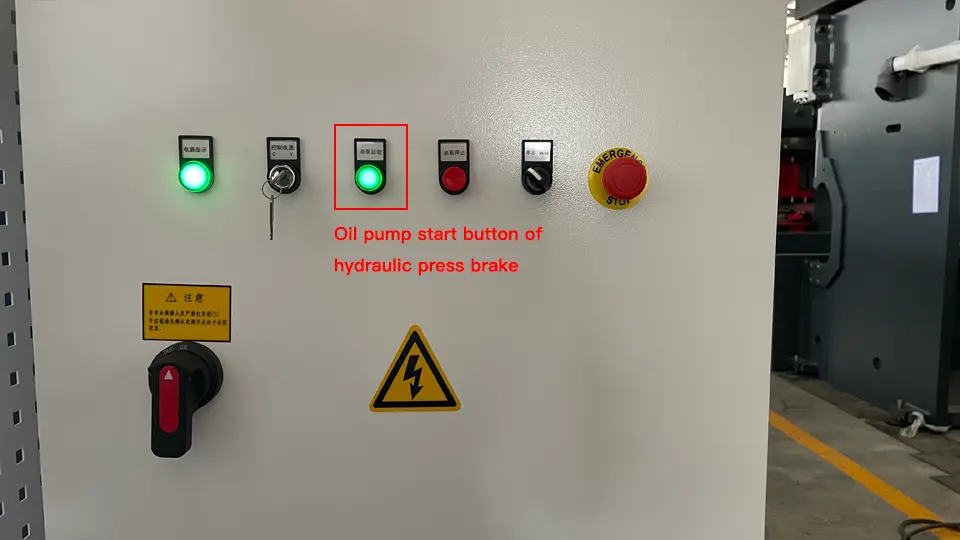

4. Start the oil pump: press the start button of the oil pump, the green indicator light on the button is on, at this time the main oil pump of the hydraulic press brake is powered on and starts to work.

So far, the circuit system of the hydraulic press brake has been fully started, and the Delem DA-53T controller has also started to start and check the system. Wait for a while, the controller enters the system standby state. At this point, we need to check the reference point of the cnc press brake.

Perform a reference point check

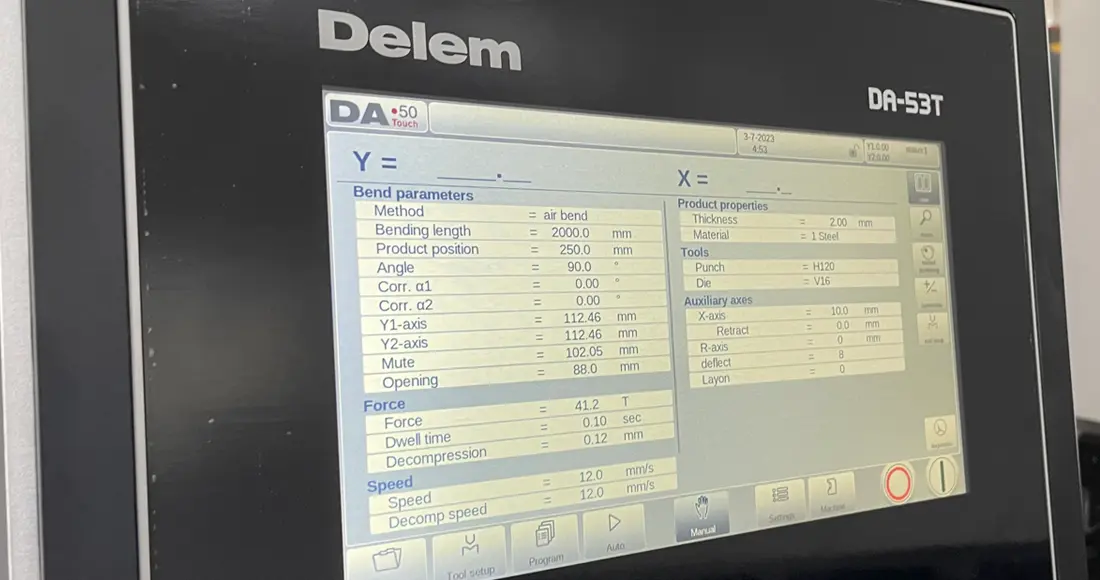

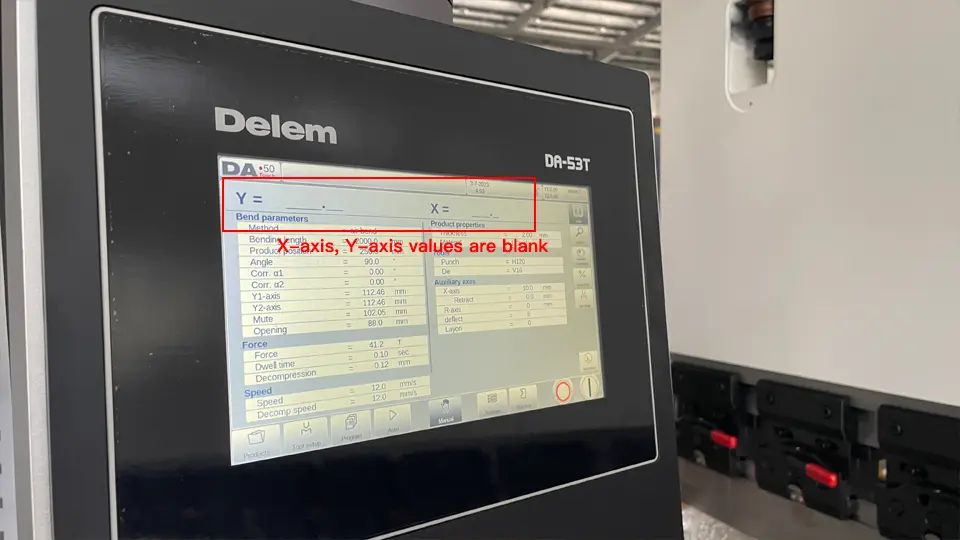

1. In the Delem DA-53T controller, click the manual button at the bottom to switch to the manual operation page. At this time, you can see that the parameters corresponding to the X-axis and Y-axis are blank values;

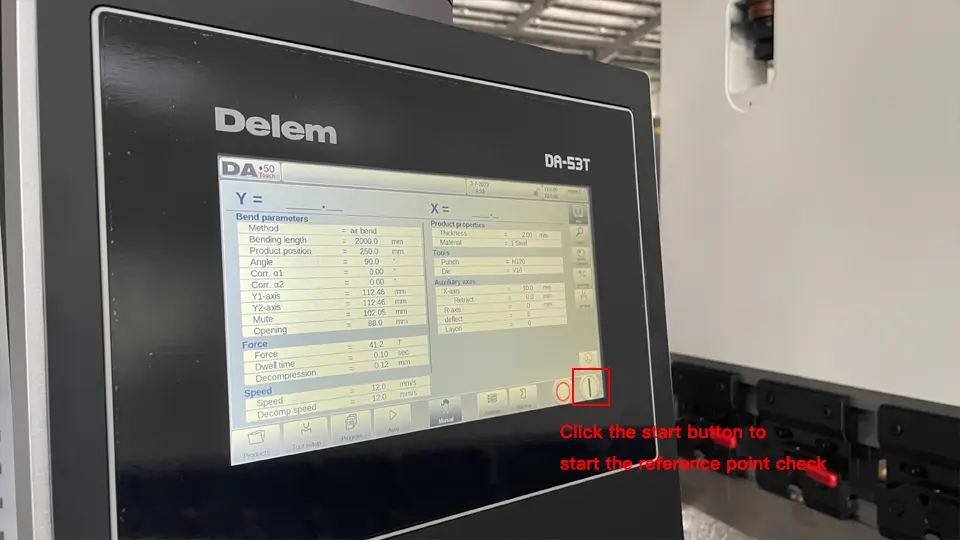

2. Click the start button in the lower right corner of the screen, the hydraulic press brake will automatically start the inspection program, and start to check the related operations of the X-axis and R-axis;

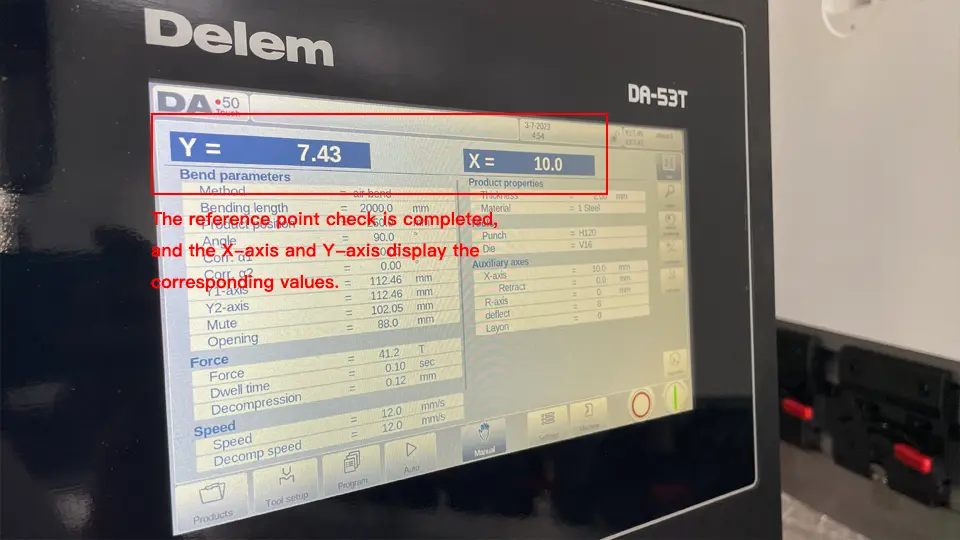

3. After the X-axis and R-axis inspection procedures are completed, lightly step on the foot switch to press the slider down to check the reference point of the Y-axis. After the slider reaches the lowest point, it will automatically return to the top, and the Y-axis is completed at this time. Reference point check;

4. After all the reference point checks are completed, the reference values of the Y-axis and X-axis will be displayed on the screen. So far, the reference point check of the press brake has been completed.

The above is the specific operation of how to perform a reference point check on the CNC Press Brake, I hope it can help you. If you have completed the above operations, you can continue to read our next article:

DELEM DA53T china press brake installation – I

DELEM DA53T china press brake installation(Tool configuration)- II