What is your processing project, metal or non-metal, metal uses fiber laser cutting machine, non-metal uses carbon dioxide laser cutting machine or other.

- If it is non-metallic, please refer to other answers.

- If it is metal, then what metal, how thick to cut, how large the parts, how high the accuracy, which determines the machine power you want to choose, processing format, accessories configuration and other factors of fiber laser cutting machine.

Power

The higher the power, the greater the thickness that can be cut and the faster the fiber laser cutting machine’s speed. There is a misunderstanding here, that is, some people think that no matter how thick the plate is, the more power the better. In fact, it is not. High power is suitable for cutting thick plates, such as 12000W can cut more than 50mm carbon steel stainless steel. If it is a thin plate, then choose the corresponding medium power. Good cutting for fiber laser cutting machine is not to see the power, but to see the optical quality. Nowadays, more and more manufacturers, both large and small factories are desperately trying to reach the power, which is actually to look at the psychology of people. In fact, some equipment known as 15000W, 20000W, the cutting effect of fiber laser cutting machine is not necessarily better than 8000W.

Of course, if you cut the thick plate, you must choose high power, if the power is too low, it’s difficult to cut through the plate by fiber laser cutting machine.

Machine size

The size of the fiber laser cutting machine bed determines the amount of work you can do with it. The size of the bed is a permanent feature and cannot be changed. So before making a decision, you should be clear about the amount of cutting you plan to do with the fiber laser cutting machine. For example, if you have plans to deal with large projects, you should obviously go for a large processing format fiber laser cutting machine.

Large fiber laser cutting machine tools can save a considerable part of the time of loading and unloading, and this time cost is also considerable.

Optical quality

As mentioned above, the performance and working quality of the fiber laser cutting machine largely depend on the quality of the optical components. Many people believe that power consumption is an important factor in determining the efficiency of a fiber laser machine. But the most important thing is not the power, but the quality of the optics. One of the best lasers in the world is German IPG and British SPI. The domestic ones are making continuous progress, but there is still a long way to go in terms of optical quality and stability with fiber laser cutting machine.

Another aspect we should consider is the head of fiber laser cutting machine, whether the optical lens group can output high-quality laser and is there precision adjustment system in fiber laser cutting machine are very important.

User-friendliness

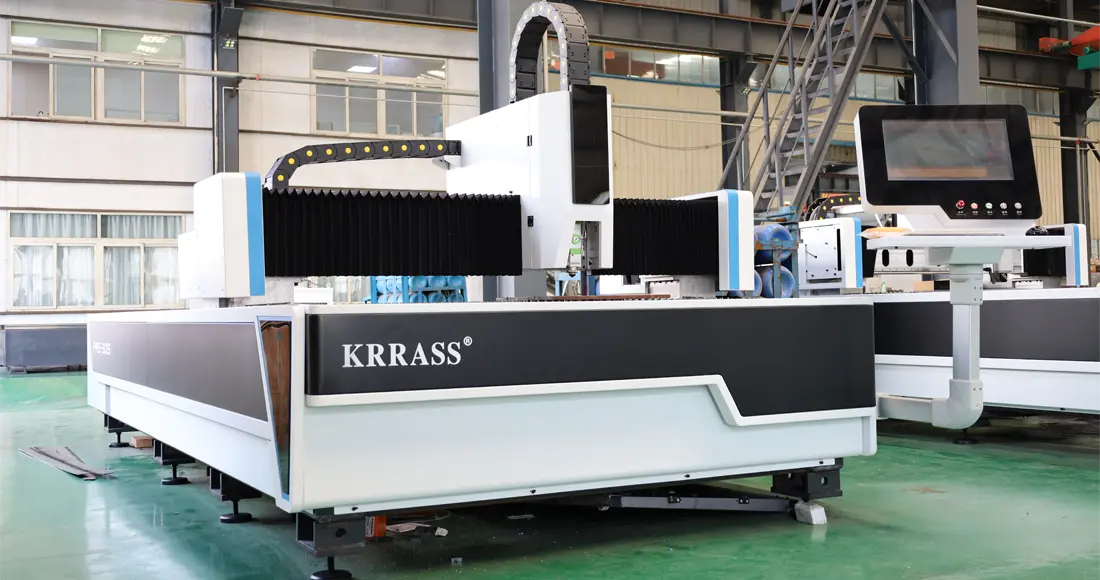

Fiber laser cutting machine operating system in the country choose KRRASS, each factory will carry out a certain optimization to better adapt to their own equipment. This should be actually operated when making samples and testing machines. It's all relatively simple.

Accessories Configuration

Good accessories determine the accuracy and stability of the fiber cutting machine. For example, the fiber laser machine tool system, the thickness of wall, the method of welding, and the annealing process. These determine whether the fiber laser cutting machine can be maintained without deformation for a long time. Furthermore, the manufacturer of the servo motor, the rack and pinion , and the cold water slag extraction system, these should be understood clearly.