Welcome to the comprehensive guide on hydraulic press brakes, where precision meets innovation in metal fabrication. As a cornerstone tool in modern manufacturing, understanding the nuances of a hydraulic press brake—from its functionality and components to the considerations in choosing the right machine and manufacturer—is vital. In this article, we delve into the world of hydraulic press brakes, offering insights into their operation, maintenance, and the cost factors that influence their selection. For businesses and professionals in the metalworking industry, this guide illuminates the path to informed decisions and successful outcomes.

- What is a Hydraulic Press Brake?

- How Does a Hydraulic Press Brake Differ from Other Press Brakes?

- What are the Key Components of a Hydraulic Press Brake?

- How Does a Hydraulic Press Brake Work?

- What is the Basic Working Principle of a Hydraulic Press Brake?

- What are the Advantages of a Hydraulic Press Brake?

- How Much Does a Hydraulic Press Brake Cost?

- What Factors Influence the Cost of a Hydraulic Press Brake?

- What are the Ongoing Costs of Operating a Hydraulic Press Brake?

- How to Maintain a Hydraulic Press Brake?

- How to Choose a Right Hydraulic Press Brake?

- How to Choose a Press Brake Manufacturer?

1.What is a Hydraulic Press Brake?

A hydraulic press brake is a vital tool in the world of manufacturing and metal fabrication. It's a machine that uses hydraulic pressure to bend and shape metal sheets into desired forms and angles. This versatile equipment, essential in the arsenal of any press brake manufacturer, leverages the power of hydraulic fluid and cylinders to create precise and consistent bends.

The applications of a hydraulic press brake are diverse, ranging from automotive and aircraft manufacturing to heavy machinery and construction equipment production. Its ability to handle various metal thicknesses and lengths with precision makes it a preferred choice for custom and mass production metalwork.

One of the key advantages of using a hydraulic press brake is its efficiency and consistency. The hydraulic system allows for smooth, controlled motions, resulting in high-quality bends and minimal waste. Additionally, the versatility of these machines, combined with their ability to produce complex bends, makes them invaluable to manufacturers looking to optimize their fabrication processes.

2.How Does a Hydraulic Press Brake Differ from Other Press Brakes?

Hydraulic press brakes stand out in the press brake landscape due to their unique operating mechanisms and advantages over other types. Compared to mechanical and pneumatic press brakes, hydraulic models offer enhanced control, precision, and versatility.

Unlike mechanical press brakes, which rely on a flywheel and crank mechanism, hydraulic press brakes use hydraulic fluid to move the ram. This allows for more precise control over the bending process, as the hydraulic system can be finely adjusted to modify the force and angle of the bend. This precision is particularly beneficial for complex or delicate metal forming tasks.

Pneumatic press brakes, on the other hand, use air pressure for operation. While they are known for their speed, they lack the force and control that hydraulic press brakes provide. Hydraulic systems can generate much higher pressure, making them suitable for thicker and harder materials. This is a critical factor for manufacturers needing to work with a wide range of metal types and thicknesses.

Additionally, hydraulic press brakes often come with advanced features like CNC (Computer Numerical Control) which further enhances their precision and efficiency. This integration allows for automated, repeatable bends at high accuracy, which is less feasible with mechanical or pneumatic types.

3.What are the Key Components of a Hydraulic Press Brake?

Understanding the key components of a hydraulic press brake is essential for appreciating its functionality and efficiency. Each component plays a critical role in ensuring the machine operates with precision and reliability.

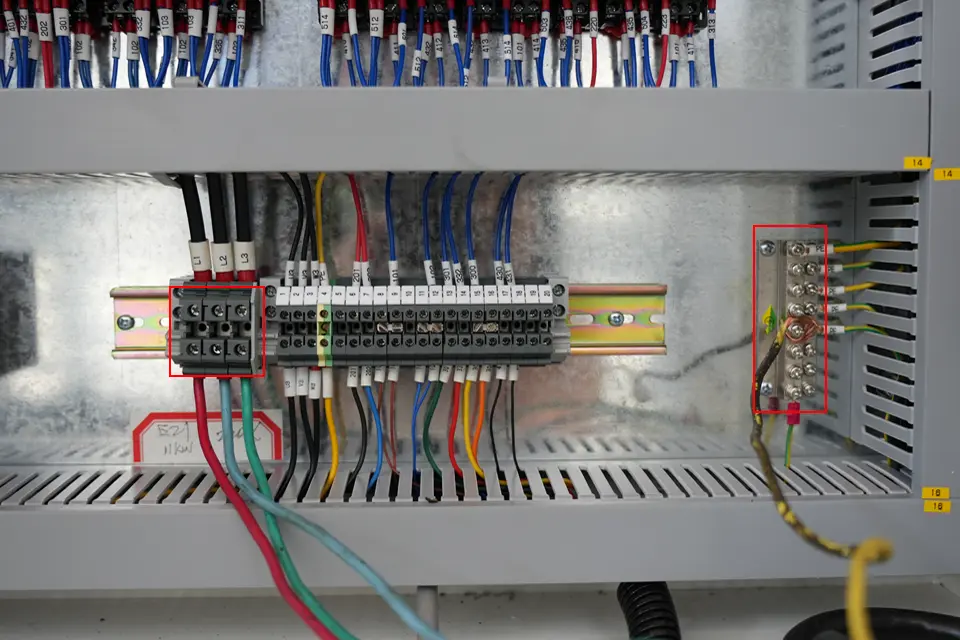

Hydraulic System: At the heart of a hydraulic press brake is its hydraulic system, comprising a motor, hydraulic pump, and valves. This system generates the force needed to bend metal sheets. The precision of the hydraulic system directly impacts the accuracy of bends and the overall efficiency of the machine.

Ram: The ram is the moving part of the press brake that comes down to apply force to the metal for bending. It's connected to the hydraulic system and can be precisely controlled for depth and pressure, ensuring accurate bends.

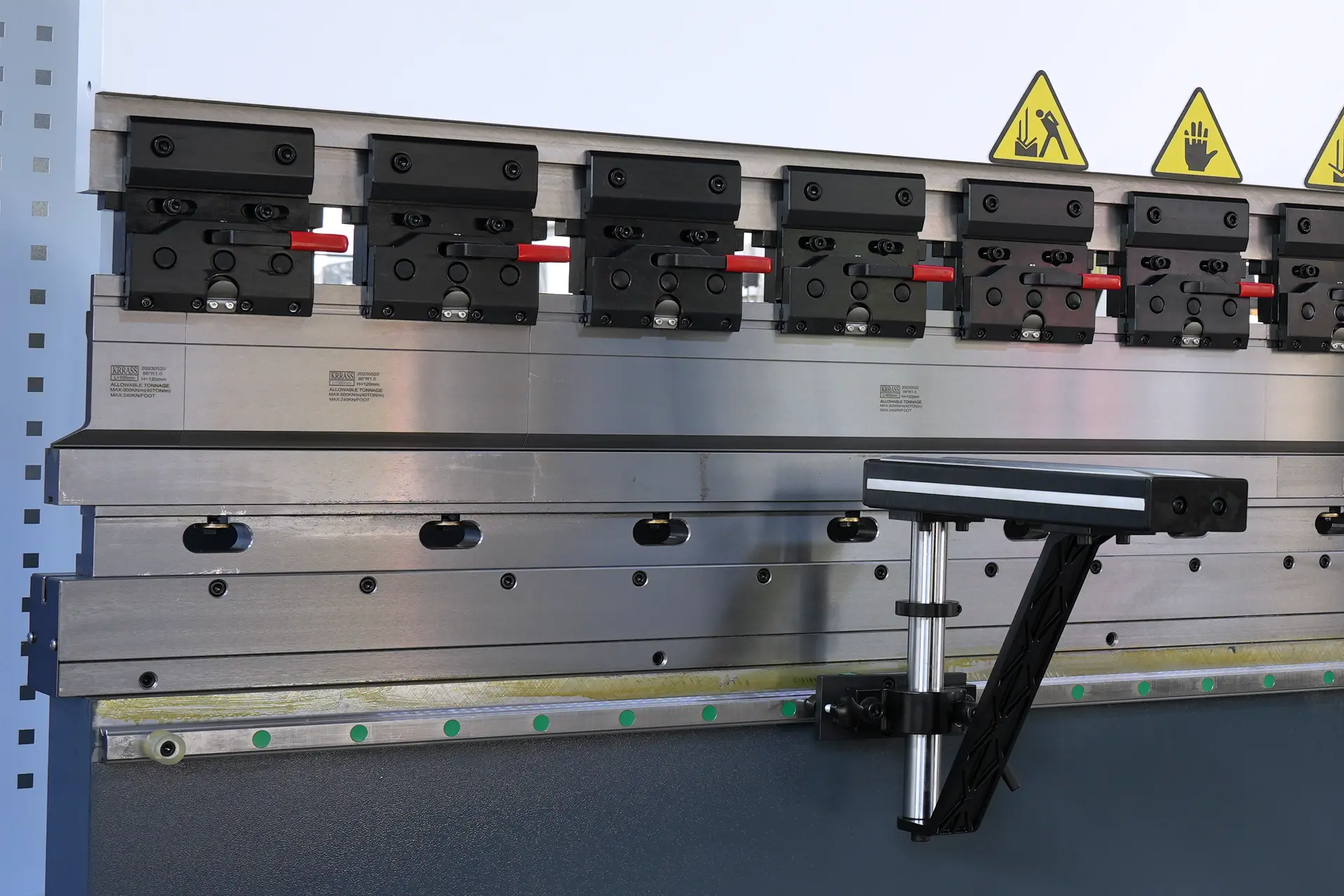

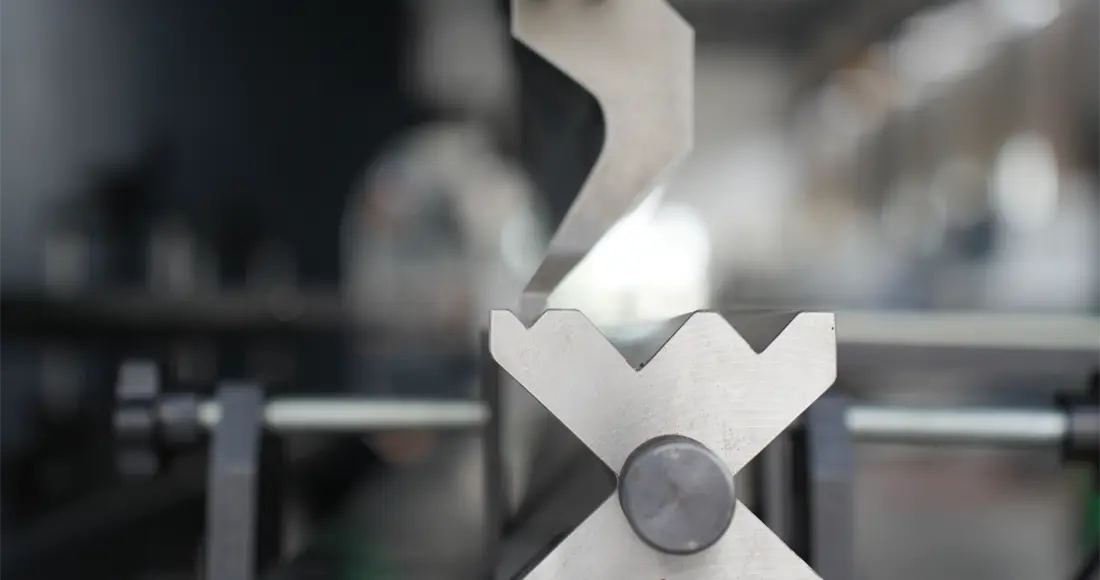

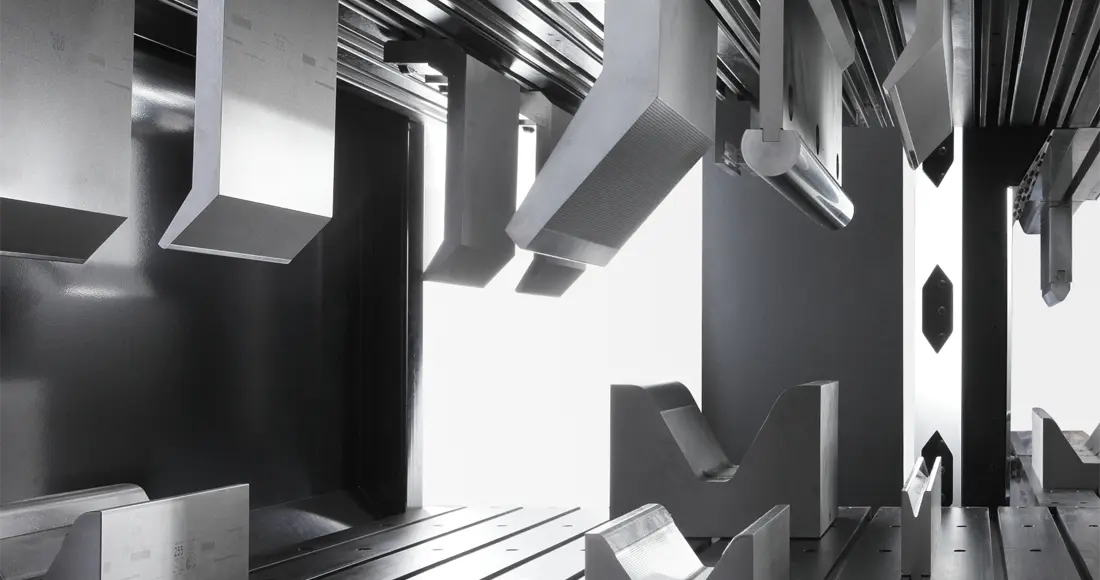

Die and Punch: These are the tooling components of the press brake. The punch is attached to the ram and presses the metal into the die, which is fixed on the table. The shape and size of the die and punch determine the angle and type of bend.

Back Gauge: An essential component for precision work, the back gauge controls the positioning of the metal sheet. It's adjustable and allows for accurate placement of the workpiece, ensuring consistent bending operations.

Control Panel: Modern hydraulic press brakes are equipped with sophisticated control panels, often featuring CNC technology. This allows operators to program the machine for automated bending processes, increasing both precision and productivity.

Frame: The frame of the hydraulic press brake provides the necessary stability and support for the entire operation. It's designed to withstand the significant forces involved in metal bending and is a critical factor in the durability of the machine.

4.How Does a Hydraulic Press Brake Work?

The operation of a hydraulic press brake is a fascinating blend of power, precision, and technology. Understanding its working mechanism is key to appreciating its capabilities in metal fabrication.

The process begins with the hydraulic system, which consists of a motor, a pump, and hydraulic fluid. When the machine is activated, the motor drives the pump, which circulates the hydraulic fluid under high pressure. This fluid then moves to the cylinders connected to the ram.

As the hydraulic fluid enters the cylinders, it creates pressure that moves the ram downwards. The ram, equipped with a punch, presses the metal sheet against the die set on the machine table. The pressure exerted by the ram, along with the shape of the die and punch, determines the angle and radius of the bend.

Precision in a hydraulic press brake is achieved through the control system, often a CNC interface, allowing operators to set parameters such as the force, depth, and angle of the bend. These settings ensure that each bend is consistent, accurate, and meets the specific requirements of the project.

The back gauge plays a crucial role during the operation by positioning the metal sheet accurately. It adjusts the distance of the workpiece from the die, ensuring that bends are made at the correct locations along the metal sheet.

5.What is the Basic Working Principle of a Hydraulic Press Brake?

The basic working principle of a hydraulic press brake revolves around the conversion of hydraulic energy into mechanical energy to accomplish precise bending tasks. This process involves several key steps and components working in harmony.

It all starts with the hydraulic system, which is the driving force behind the press brake. The system consists of a motor, a hydraulic pump, hydraulic fluid, and cylinders. When the motor is activated, it powers the pump, which then circulates the hydraulic fluid under pressure through the system.

This pressurized fluid is directed into the cylinders that are connected to the ram. The pressure exerted by the fluid causes the cylinders to extend, pushing the ram downward with great force. The ram, which holds the punch tool, descends onto the metal sheet that is positioned over the die on the machine's table.

The controlled descent of the ram determines the bend's angle, radius, and depth. This precision is made possible by the adjustable nature of the hydraulic system, allowing for fine-tuning of the pressure and movement of the ram.

Once the desired bend is achieved, the hydraulic pressure is released, causing the ram to retract and return to its original position. This retraction allows the operator to remove the bent sheet and set up for the next bending operation.

6.What are the Advantages of a Hydraulic Press Brake?

Hydraulic press brakes are preferred in many metal fabrication settings due to their numerous advantages. These benefits not only enhance the efficiency and quality of metal bending processes but also contribute to overall productivity and safety. Here are some key advantages of using a hydraulic press brake:

Precision and Control: Hydraulic press brakes offer superior control over the bending process, allowing for precise adjustments in force and angle. This precision is crucial for achieving consistent and accurate bends, especially in complex or delicate operations.

Versatility: These machines can handle a wide range of metal types and thicknesses, making them suitable for various applications. The ability to easily adjust settings also allows for quick changes between different jobs.

Energy Efficiency: Modern hydraulic press brakes are designed to be energy efficient, reducing operational costs. They consume power only during the bending cycle, unlike other types that may require continuous power.

Operational Safety: With built-in safety features and controlled operations, hydraulic press brakes enhance safety for operators. The risk of accidents is significantly reduced compared to mechanical press brakes.

Low Maintenance: Due to fewer moving parts and a robust hydraulic system, these machines generally require less maintenance, leading to lower downtime and maintenance costs over their lifespan.

Longevity: The durable construction and the nature of hydraulic operations contribute to the long service life of these machines, making them a valuable long-term investment for businesses.

These advantages make hydraulic press brakes a preferred choice for businesses looking for reliable, efficient, and high-quality metal bending solutions.

7.How Much Does a Hydraulic Press Brake Cost?

The cost of a hydraulic press brake can vary significantly based on several factors, making it a key consideration for businesses in the metal fabrication industry. Understanding these factors can help in making an informed investment decision.

Firstly, the size and capacity of the press brake play a crucial role in determining the price. Larger machines with higher tonnage capabilities, designed for heavy-duty operations, generally come at a higher cost. The range can vary from tens of thousands to hundreds of thousands of dollars, depending on the specifications.

Another significant factor is the level of automation and control technology. Hydraulic press brakes equipped with advanced CNC systems and features like programmable back gauges and ram speeds add to the cost but also offer higher precision and efficiency.

The brand and quality of the press brake are also influential. Reputable manufacturers known for their quality and after-sales service often price their machines higher, reflecting the reliability and longevity they offer.

Additionally, customizations and special features tailored to specific manufacturing needs can impact the final price. Options such as specialized tooling, increased safety features, or additional hydraulic functions can contribute to a higher cost.

8.What Factors Influence the Cost of a Hydraulic Press Brake?

When it comes to purchasing a hydraulic press brake, two major factors that significantly impact the cost are the size of the machine and its complexity. Understanding how these elements affect the price can guide buyers in making an informed decision that aligns with their production needs and budget.

Size: The size of a hydraulic press brake is a primary determinant of its cost. This includes the overall dimensions of the machine, its tonnage capacity, and the length of the bed. Larger press brakes with higher tonnage and longer beds are designed for bending larger or thicker materials and, consequently, are more expensive. These machines require more material for construction, more powerful hydraulic systems, and often more sophisticated control mechanisms, all contributing to a higher cost.

Complexity of the Machine: The complexity of a hydraulic press brake is another crucial factor influencing its price. Complexity refers to the level of technology integration, automation features, and the capability to perform complex bending operations. Machines equipped with advanced CNC systems, programmable features, and sophisticated safety mechanisms are typically at the higher end of the price spectrum. The complexity extends not just to the operational aspects but also to the ease of maintenance and adaptability to various production environments. The more complex the machine, the more capable it is of handling intricate and precise bending tasks, which adds to the cost.

9.What are the Ongoing Costs of Operating a Hydraulic Press Brake?

While the initial investment in a hydraulic press brake is substantial, it's also crucial to consider the ongoing costs associated with its operation. These include regular maintenance and energy consumption, which can impact the total cost of ownership over the machine's lifespan.

How Much Does Regular Maintenance Cost?

Regular maintenance is essential for keeping a hydraulic press brake in optimal working condition and prolonging its service life. The cost of maintenance can vary, depending on the machine's usage intensity, the environment in which it operates, and the quality of the initial build. Generally, a well-maintained hydraulic press brake requires periodic servicing of its hydraulic system, including changing hydraulic fluids, filters, and seals. These services can range from a few hundred to a few thousand dollars annually, depending on the machine's size and complexity.

What are the Typical Energy Consumption Costs?

Energy consumption is another ongoing cost factor for hydraulic press brakes. These machines, particularly those with larger capacities and more sophisticated control systems, can consume a significant amount of electricity. The cost will depend on the machine's efficiency, the frequency of its use, and local energy prices. On average, a mid-sized hydraulic press brake might consume between $500 to $2000 worth of electricity annually. It's important to note that newer models are often more energy-efficient, potentially offering savings in long-term operational costs.

10.How to Maintain a Hydraulic Press Brake?

Proper maintenance is key to ensuring the longevity and optimal performance of a hydraulic press brake. Regular and effective maintenance not only prevents machine downtime but also ensures consistent quality in metal fabrication processes. Here are essential steps for maintaining a hydraulic press brake:

Regular Inspection: Conduct routine inspections to check for any signs of wear and tear, especially in critical components such as the hydraulic system, ram, dies, and punch tools. Look for leaks, unusual noises, or any irregularities in operation.

Hydraulic Fluid Maintenance: Regularly check and maintain the hydraulic fluid. This includes checking the fluid level, ensuring it's clean, and replacing it according to the manufacturer's guidelines. Contaminated or low hydraulic fluid can lead to inefficient operation and damage to the hydraulic system.

Lubrication: Ensure all moving parts are properly lubricated. Regular lubrication reduces friction and wear, extending the life of the machine’s components.

Die and Punch Care: Regularly inspect and maintain the dies and punch tools. This includes cleaning them and checking for any damage or wear. Sharpening or replacing the tools when necessary is crucial for maintaining the quality of bends.

Software and Control System Updates: For hydraulic press brakes with CNC controls, ensure that the software is regularly updated and that the control system is functioning correctly. This is crucial for maintaining precision in bending operations.

Professional Servicing: In addition to regular in-house maintenance, schedule professional servicing periodically. This allows for a comprehensive examination and maintenance of the machine by experts.

11.How to Choose the Right Hydraulic Press Brake?

Selecting the right hydraulic press brake is crucial for achieving optimal performance and efficiency in metal fabrication. The choice depends on several factors, each aligning with specific production needs and goals. Here are key considerations for choosing the right hydraulic press brake:

Determine Your Bending Needs: Assess the type of work you will be performing. Consider the thickness, type of materials, and the complexity of the bending operations. This will help in determining the tonnage, bed length, and type of press brake you require.

Machine Capacity: Ensure the press brake has the right tonnage and bed length for your materials and projects. Choosing a machine with a capacity that matches your most common tasks can enhance efficiency and precision.

Control System: Consider the type of control system the press brake uses. For high precision and complex jobs, a CNC-controlled press brake may be the best choice, offering greater flexibility and accuracy.

Quality and Reliability: Opt for a press brake from a reputable manufacturer. High-quality machines offer better performance, longevity, and often come with better support and warranty conditions.

Future-Proofing: Consider future needs and potential growth. A press brake that can be upgraded or has the capacity to handle a broader range of jobs can be a wise investment for growing businesses.

Cost vs. ROI: Balance the initial cost of the press brake with the return on investment it offers. While higher-end models may be more expensive, they can offer greater efficiency, lower operational costs, and better quality output in the long run.

After-Sales Support: Consider the level of after-sales support and service available. Good support can be invaluable in ensuring the machine continues to operate efficiently and any issues are promptly resolved.

12.How to Choose a Press Brake Manufacturer?

Selecting the right press brake manufacturer is as crucial as choosing the machine itself. The manufacturer's reputation, expertise, and service quality can significantly impact the efficiency and longevity of your hydraulic press brake. Here are some key factors to consider when choosing a press brake manufacturer:

Industry Reputation: Research the manufacturer's standing in the industry. Look for companies with a proven track record of reliability and customer satisfaction. Industry reviews, testimonials, and case studies can provide valuable insights.

Quality of Products: Evaluate the quality of the press brakes offered. High-quality materials, robust construction, and adherence to safety and performance standards are indicators of a reliable manufacturer.

Technological Innovation: Consider manufacturers who invest in research and development to incorporate the latest technology and innovations in their machines. This can translate to improved efficiency, precision, and capabilities in your operations.

Customer Support and Services: Good customer service and technical support are crucial. Ensure the manufacturer provides comprehensive after-sales support, including maintenance, repairs, and technical assistance.

Customization Options: If you have specific requirements, look for manufacturers who offer customization options. The ability to tailor a press brake to your unique needs can be a significant advantage.

Warranty and Spare Parts Availability: Check the warranty terms and the availability of spare parts. A strong warranty and readily available parts can reduce downtime and maintenance costs.

Price vs. Value: While price is an important factor, it should be weighed against the overall value offered. Consider the long-term benefits in terms of machine performance, durability, and operational costs.

Embracing the Future with Krrass: Your Trusted Press Brake Manufacturer

In conclusion, the journey through the realm of hydraulic press brakes is one of discovery and strategic decision-making. As we've explored the key aspects of these machines, it becomes clear that choosing a reliable and innovative press brake manufacturer is crucial. Krrass, a leading press brake manufacturer in China, exemplifies this with its commitment to quality, technology, and customer satisfaction. Embrace the future of metal fabrication with Krrass and discover how our expertise can elevate your production standards. Visit us at https://www.krrass.com/ to learn more about our cutting-edge solutions and services.