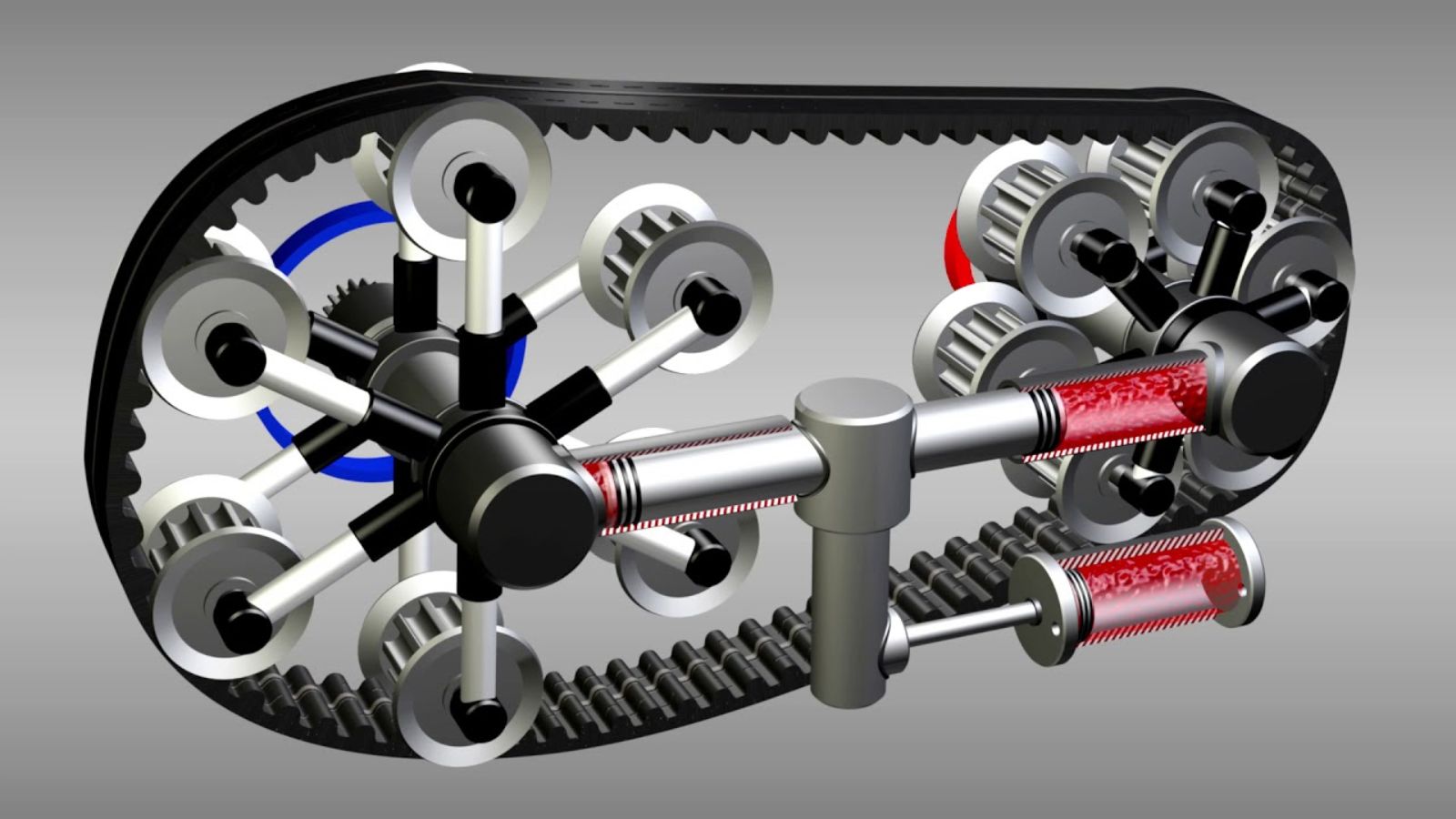

Hydraulic transmission is a transmission method that uses liquid as a power transmission method. It has the advantages of simple structure, smooth transmission, and overload protection. It is widely used in engineering machinery, machine tools, ships, and other fields. However, hydraulic transmission also has some shortcomings, such as lower efficiency, higher cost, sensitivity to pollution, etc., which need to be paid attention to in design and application.

1. Introduction to hydraulic transmission

Hydraulic transmission plays an important role in many fields with its unique advantages, but it also has some shortcomings that cannot be ignored. This article will deeply explore the main shortcomings of hydraulic transmission and propose corresponding solutions, aiming to help readers better understand and apply hydraulic transmission technology.

2. Main disadvantages of hydraulic transmission

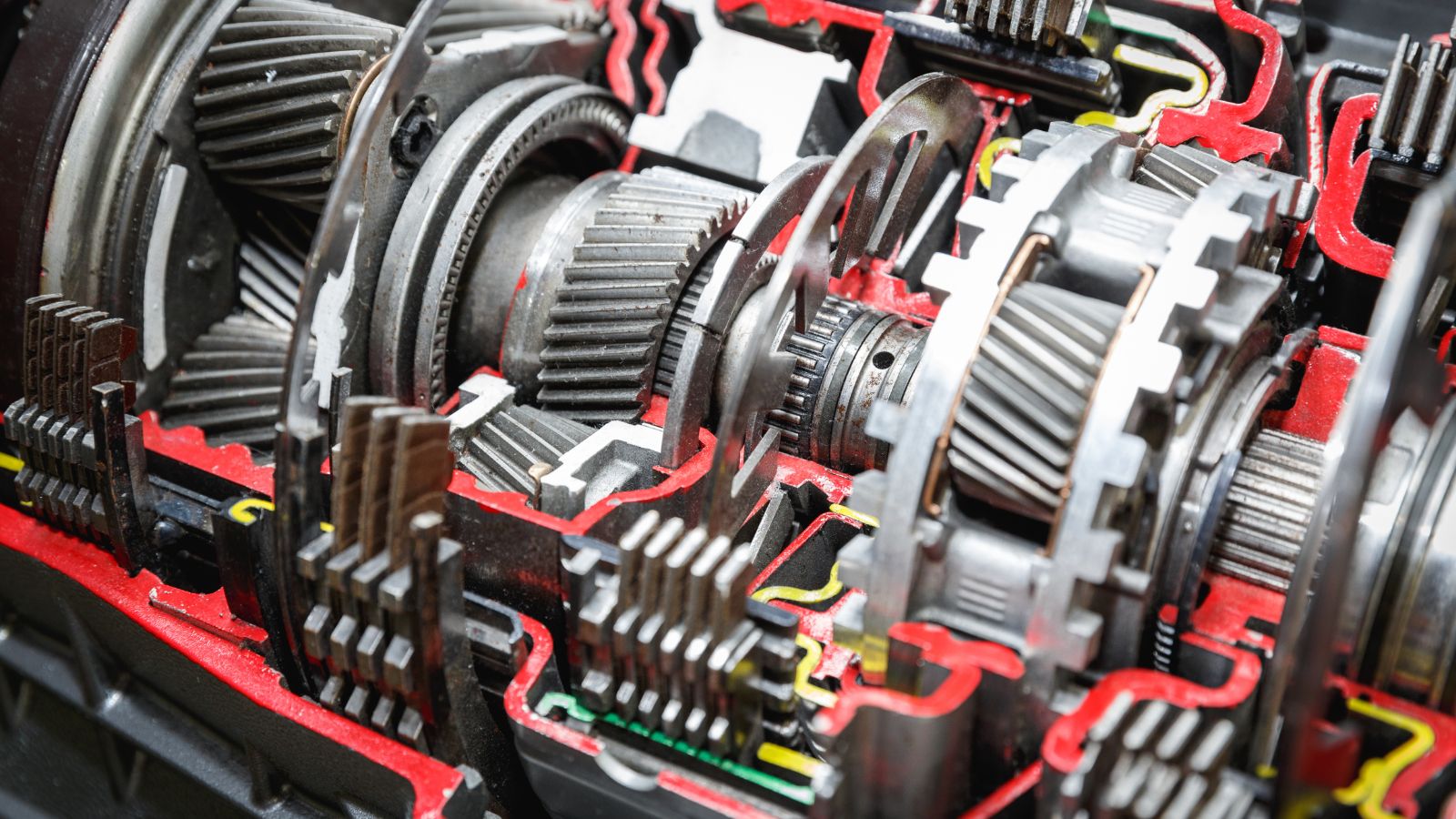

2.1 Low efficiency

In the energy transmission process of hydraulic transmission, there are two conversions of mechanical energy-hydraulic energy-mechanical energy, which inevitably causes energy loss. The efficiency of the hydraulic system is generally 75%-85%, which is lower than other transmission methods.

2.2 Higher cost

Hydraulic components require high manufacturing precision and complex materials and processing techniques, resulting in high cost of the hydraulic system. In addition, the hydraulic system also needs to be equipped with auxiliary equipment such as hydraulic oil, oil tanks, and oil filters, which further increases the cost.

2.3 Sensitive to pollution

Hydraulic oil in hydraulic systems is very sensitive to contamination. Contaminants such as dust and impurities will accelerate the wear of hydraulic components, reduce system efficiency, and even cause malfunctions. Therefore, the hydraulic system needs to be equipped with a precision oil filter and the hydraulic oil should be replaced regularly.

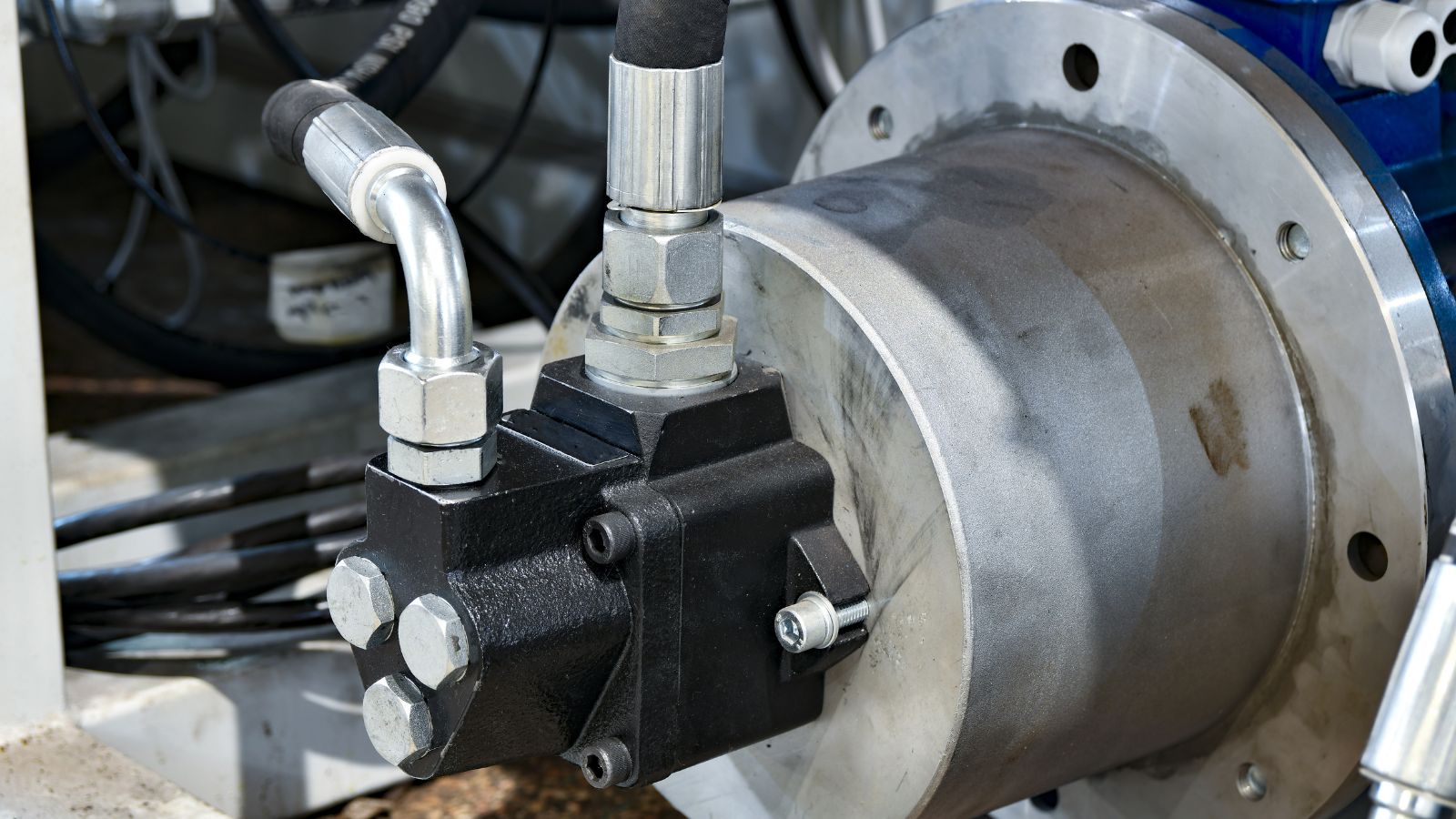

2.4 Leakage problem

There is a risk of leakage in the hydraulic system, and leaked hydraulic oil will pollute the environment and cause safety hazards. To reduce leakage, the manufacturing accuracy of hydraulic components needs to be improved, and the hydraulic system needs to be inspected and maintained regularly.

2.5 Effect of temperature

The viscosity of hydraulic oil changes with temperature. If the temperature is too high or too low, it will affect the performance and efficiency of the hydraulic system. Therefore, the hydraulic system needs to be equipped with a temperature control device to ensure that the hydraulic oil works within the appropriate temperature range.

2.6 Noise problem

Hydraulic pumps, motors, and other components will produce noise when working. If no measures are taken, noise pollution will result. Therefore, it is necessary to install mufflers in hydraulic systems to reduce noise levels.

3. Solution

To address the main shortcomings of hydraulic transmission, the following measures can be taken:

Improve the design and manufacturing level of hydraulic systems and use high-efficiency hydraulic components to reduce energy loss.

Choose appropriate hydraulic oil, and replace and maintain it regularly to reduce the impact of contamination on the system.

Use advanced sealing technology to reduce leakage in the hydraulic system.

Equipped with a temperature control device to ensure that the hydraulic oil works within a suitable temperature range.

Install mufflers to reduce noise levels in hydraulic systems.

4. Conclusion

Hydraulic transmission is a mature transmission technology with a wide range of applications. Understanding the main shortcomings of hydraulic transmission and taking corresponding measures can improve the efficiency of the hydraulic system, reduce costs, extend its service life, and improve its environmental protection and safety.