The bending of sheet metal refers to the processing of changing the angle of the sheet or plate. Such as bending the plate into a V shape, U shape, etc. In general, there are two methods for bending sheet metal: One method is die bending, which is used for sheet metal structures with complex structures, small volumes, and mass processing; The other is bending with a bending machine, such as NC press brake, which is used to process sheet metal structures with relatively large structure sizes or with low output. At present, the company's products are mainly processed by bending machines.

These two bending methods have their own principles, characteristics and applicability.

1. Mold bending:

For structural parts with an annual processing volume of more than 5,000 pieces and the part size is not too large (in general, it is 300X300), generally consider opening a stamping die for processing.

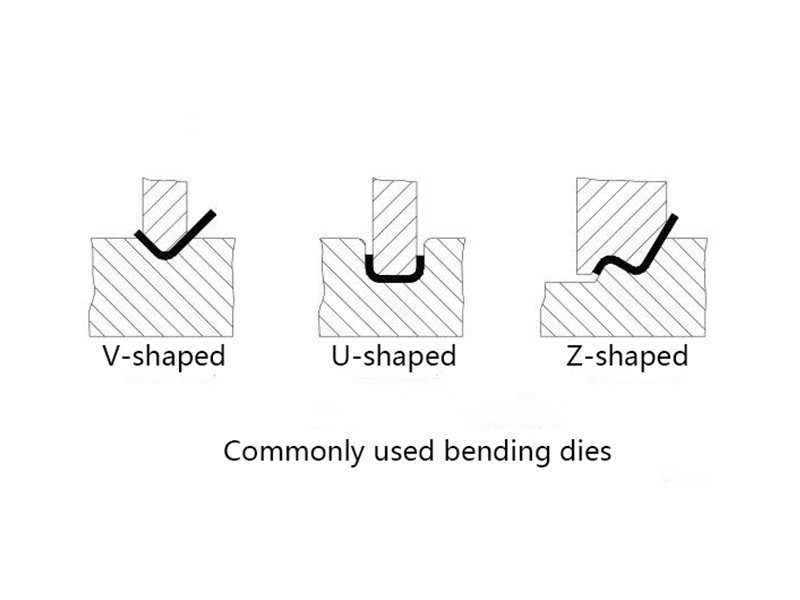

1.1. Common bending dies

Commonly used bending molds, as shown in Figure 1-1: In order to extend the life of the mold, round corners should be used as much as possible when designing parts.

If the flange height is too small, even if the bending die is used, it is not conducive to forming. Generally, the flange height L≥3t (including wall thickness).

1.2 Bending by bending machine

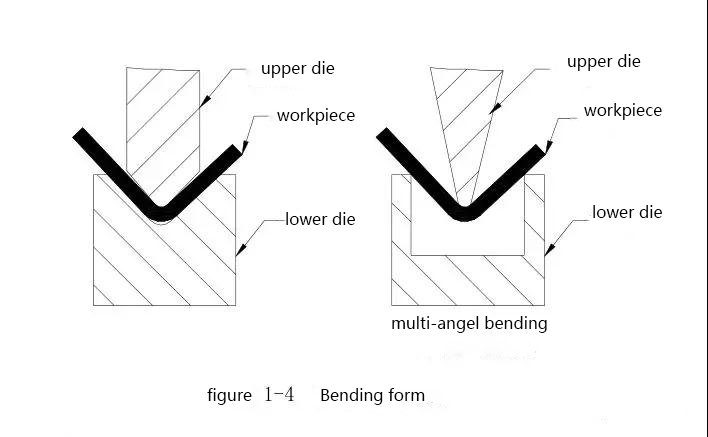

There are two types of bending machines: ordinary bending machines and NC press brake. The precision requirements are high. The bending of sheet metal with irregular bending shapes is generally bent with a NC press brake. The basic principle is to use the bending knife (upper die) and V-shaped groove (lower die) of the bending machine. Sheet metal parts are bent and formed.

Advantages: convenient clamping, accurate positioning, fast processing speed;

Disadvantages: low pressure, only simple forming can be processed, low efficiency.

1.2.1. Basic principles of forming

The basic principle of forming is shown in Figure 1-2:

1) Bending knife (upper die)

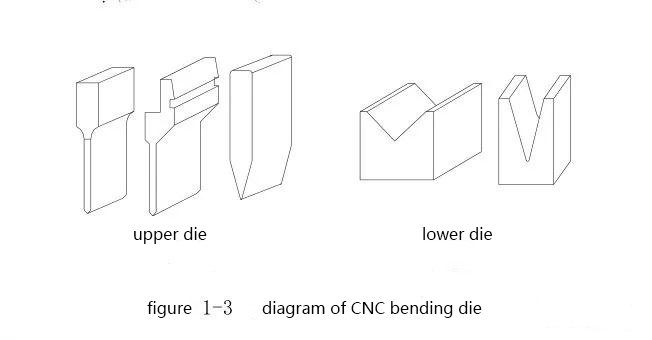

The form of the bending knife is shown in Figure 1-3. It is mainly selected according to the shape of the workpiece during processing;

2) The lower mold generally uses V=6t (t is the material thickness) mold.

There are many factors that affect the bending process, mainly including the upper mold arc radius, material, material thickness, lower mold strength, and lower mold die size. See Figure 1-3. The upper mold is on the left and the lower mold is on the right.

The basic principles of bending processing sequence:

- Bending from inside to outside;

- Bending from small to large;

- First bend the special shape, then the general shape;

- After the previous process is formed, it will not affect or interfere with the subsequent process.

The bending forms seen by current outsourcing factories are generally as shown in Figure 1-4.

1.2.2. Bending radius

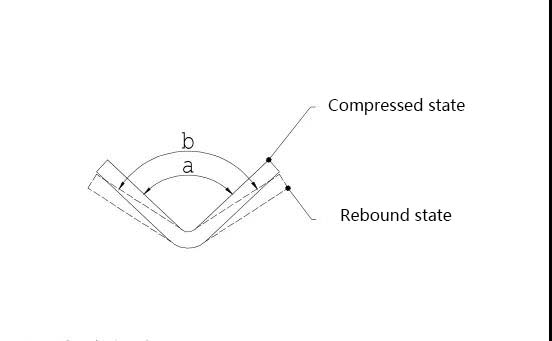

When the sheet metal is bent, a bending radius is required at the bending position. The bending radius should not be too large or too small, and should be selected appropriately. Too small a bending radius will easily cause cracks in the bending part, and too large a bending radius will make the bending easy to rebound.

1.2.3. Bending springback

1) Rebound angle: Δα=b-a

Where

b——The actual angle of the part after springback;

a—The angle of the mold.

1.2.4. Interference phenomenon during bending

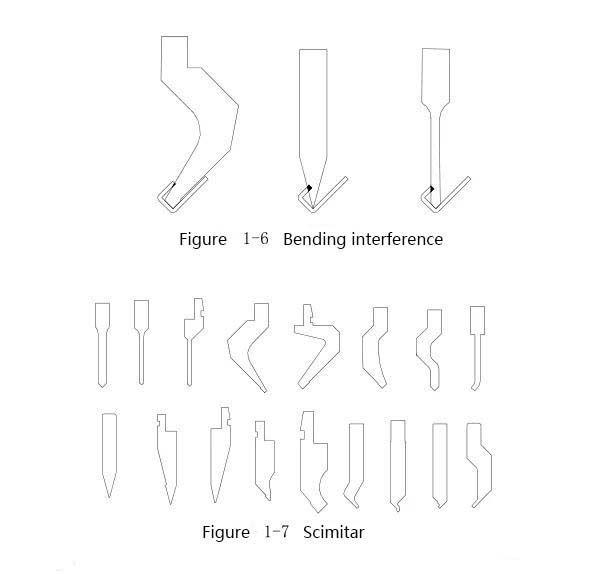

For two or more bends, interference between the bent workpiece and the tool often occurs. As shown in Figure 1-6, the black part is the interference part, so the bending cannot be completed, or because of bending interference Causes bending and deformation.

1.2.5. Crush the edge at one time

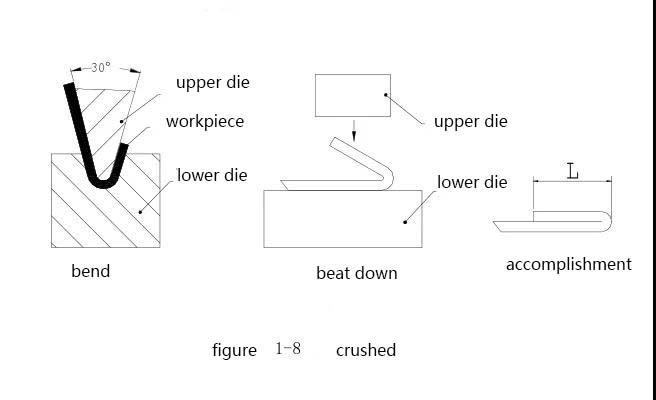

The method of pressing the dead edge at a time: as shown in Figure 1-8, first use a 30-degree bending knife to fold the plate to 30 degrees, and then flatten the bent edge.

The minimum bending edge size L in the figure is based on the minimum bending edge size described in 1.3.2.2 plus 0.5t (t is the material thickness). The dead edge is generally applicable to stainless steel, galvanized sheet, aluminum-zinc clad sheet, etc. Electroplating parts should not be used, because there will be acid liquid in the place where the dead edge is pressed.

1.2.6. 180 degree bending:

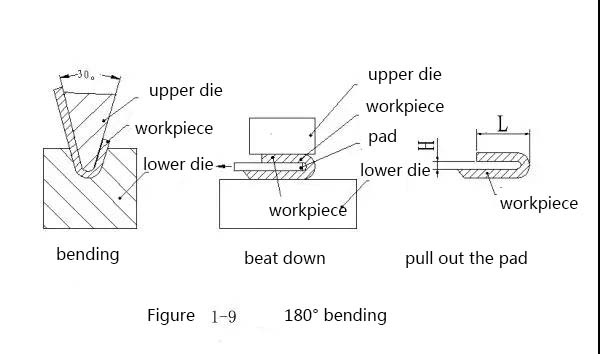

180-degree bending method: as shown in Figure 1-9, first use a 30-degree bending knife to fold the board to 30 degrees, then flatten the bent edges, and then pull out the backing board.

The height H should be a commonly used board, such as 0.5, 0.8, 1.0, 1.2, 1.5, 2.0. Generally, this height should not be a higher size.

1.2.7 Triple folding dead edge:

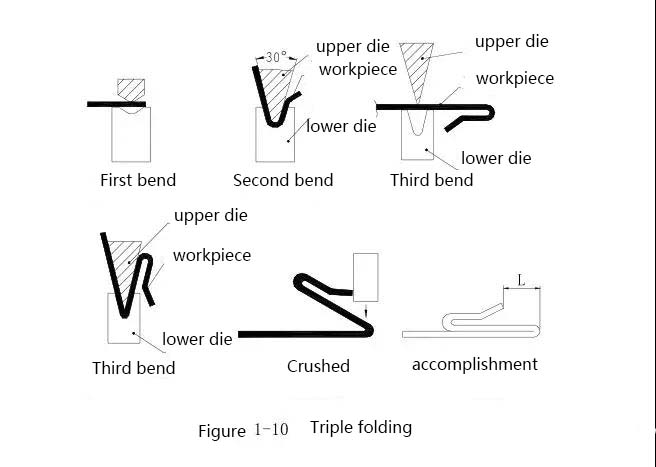

As shown in Figure 1-10, fold the shape first, and then fold the edges.

Learn more about our products, please visit and subscribe to our Youtube channel