High Standard CNC Press Brake 6-8 Axis

High Standard CNC Press Brake 6-8 Axis

MB8 Series High Standard CNC Press Brake is an affordable CNC press brake with impressive features and options. Paired with an advanced Delem DA-66T or Delem DA-69T control system supporting 3D graphic controls and at a competitive price, the High Standard Series is your first choice for Y1/Y2 machine technology.

Simple and solid press brake

Work area can be customized and all types of tool clamping can be installed

Tailored-made sheet metal press brake

- Controller: DELEM DA-66T

- Electrics: Schneider Electric - France

- Main Motor: Siemens Motor - Germany

- Servo Motor: ESTUN

- Foot Switch: KACON - South Korea

- Hydraulic System: Bosch Rexroth - Germany

- Oil Pump: Sunny - USA

- Sealing Ring: PARKER - America

- High Efficiency Motor - Class IE3

- Tube Connector: EMB - Germany

- Backgauge: Hiwin - Taiwan

- Grating Ruler: Fagor

Standard Equipment

Introduction to Configuration

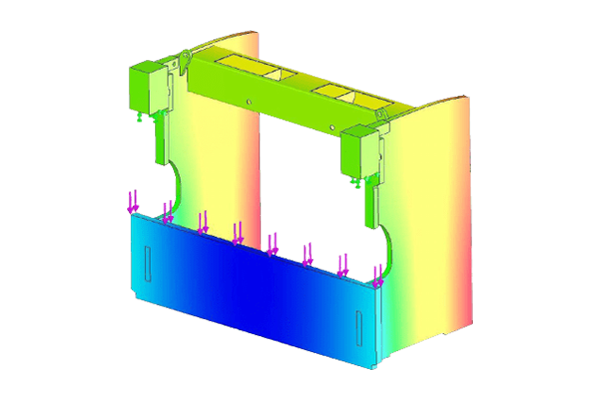

FEA & Stress Analysis

Stress Analysis & Finite Element Analysis

The CAE software SOLIDWORKS used as the method to analyze the linear static construction, stress and deformation for press break and laser cutting machine frames. So for complicated structures, highly complex loading’s, transient modelling and combination of the above, FEA makes sense.

DELEM CNC Control System

DELEM DA-66T Control

- 2D graphical touch screen programming mode

- 17" high resolution colour TFT

- 3D graphics acceleration

- Colour LCD display

- 1280 x 1024 pixels, 16 bit colour

- Full touch screen control (IR-touch)

- Sensor bending & correction interface Profile-TL offline software

- Full Windows application suite

DELEM CNC Control System

DELEM DA-69T Control

- 3D and 2D graphical touch screen programming mode

- 3D visualisation in simulation and production

- 17" high resolution colour TFT

- 1280 x 1024 pixels, 32 bit colour

- 3D graphics acceleration

- Full touch screen control (IR-touch)

- Sensor bending & correction interface

- Profile-T3D offline software

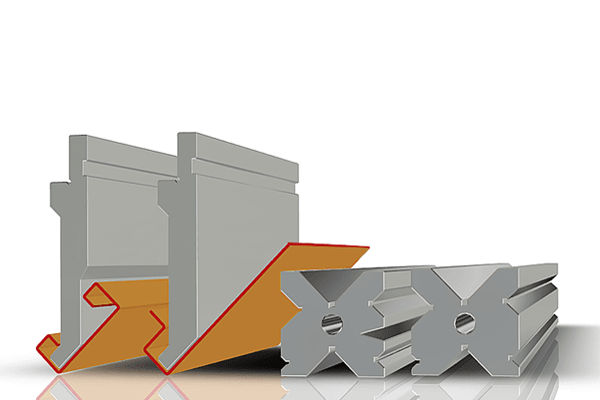

Manual Upper Tool Clamping

The CNC Press Brake Machine use all Raw material is provided by qualified suppliers and chemical composition corresponds to international standards. Therefore, raw material yield and tensile strength are guaranteed, are standardized with a 8.4 x 3.5 mm safety groove, which keeps the tool from falling out.

Advantage:

- Safe and fast tool change

- Can be used without modifying Europe type punches

- Front clamp - vertical tool change

- Rear clamp - horizontal tool change

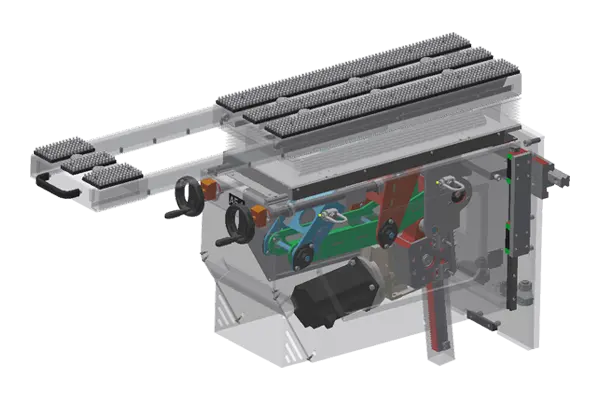

KRRASS® BGA-6 BackGauge

Press Brake 6-Axis CNC BackGauge with X1, X2, R1, R2, Z1, Z2-Axis

- Ball screws and linear guide on X, R-axis.

- Mechanical accuracy ± 0.03 mm.

- Mechanical accuracy ± 0.03 mm.

- Axes Z1‐Z2 speed 1000 mm/s.

- Axis X1-X2 speed 500 mm/s.

- Axis R1-R2 speed 500 mm/s.

- Load capacity – 300 kg per support.

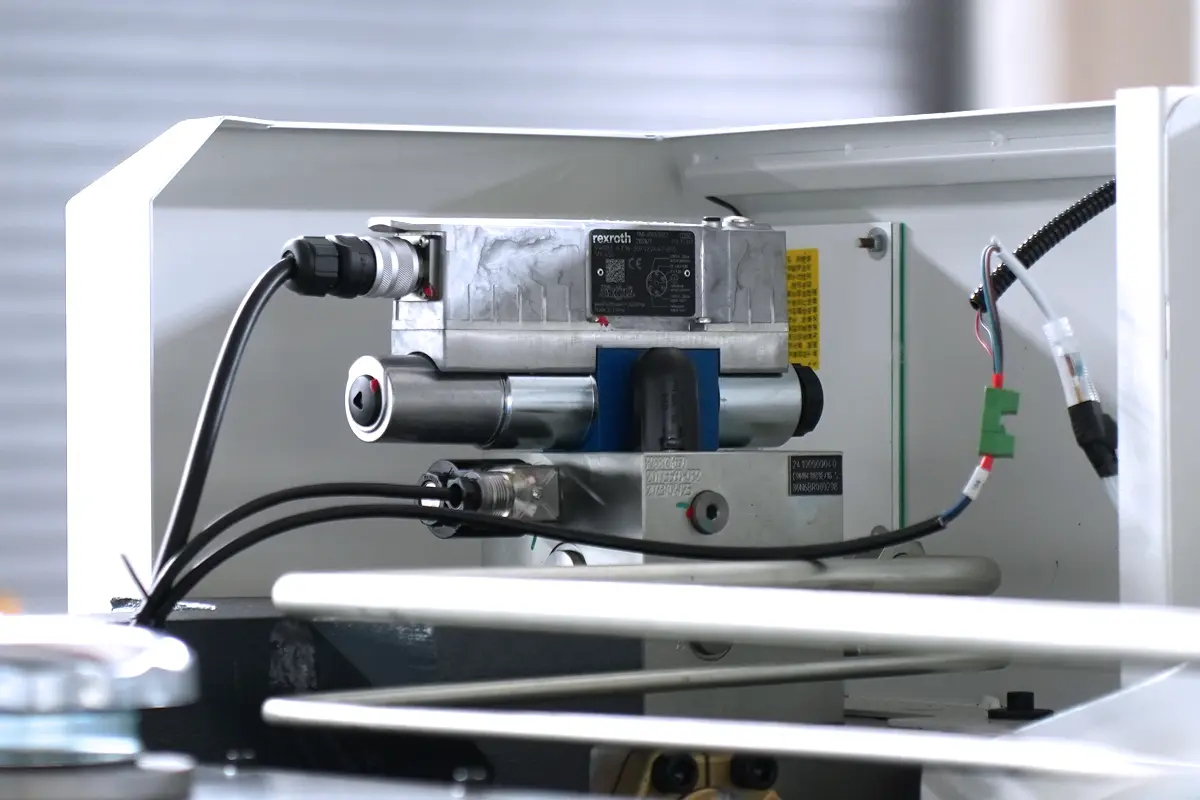

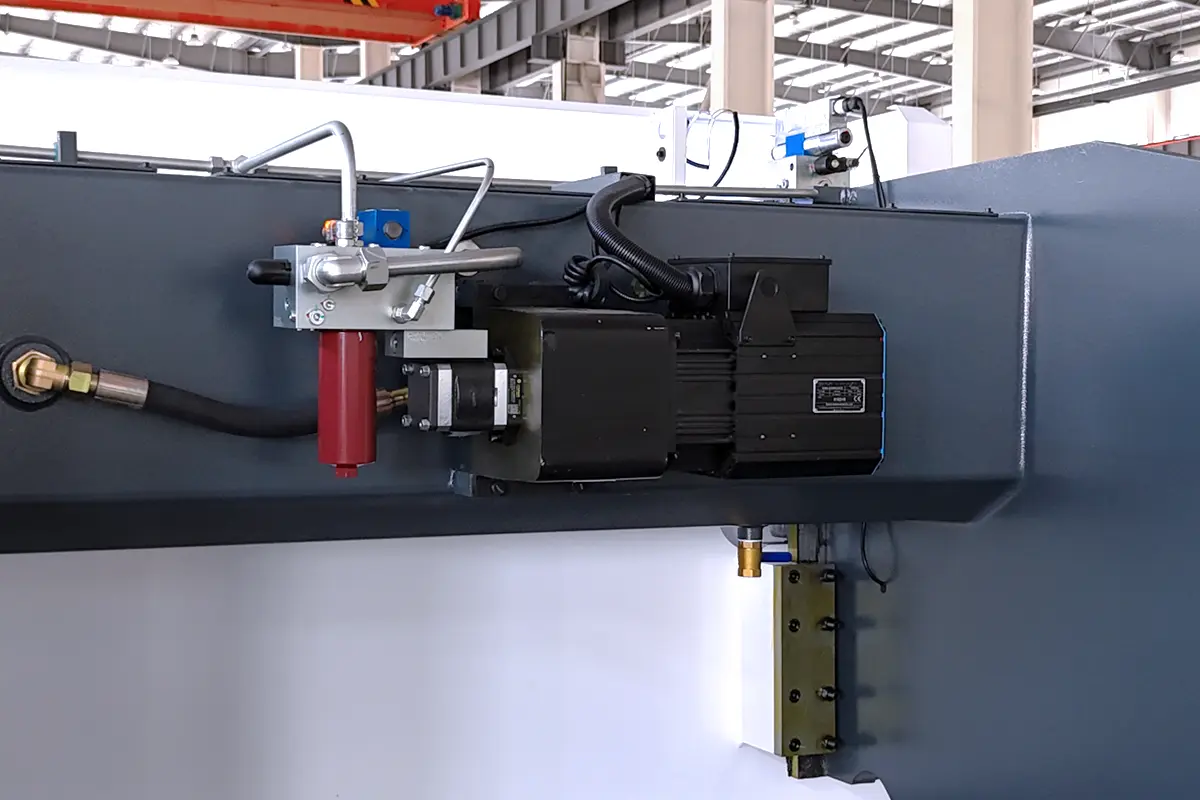

Proportional Valve

The German Rexroth fully closed-loop electro-hydraulic servo high-frequency synchronous control system is adopted to ensure that the machine tool has high stability and high precision in the process of high-speed operation.

Advantage:

- The frequency response (response frequency) is higher and can be as high as 200Hz.

- It can continuously and proportionally control the pressure and flow of the hydraulic system, control the position, speed, and force, and reduce the impact of pressure changes.

- Closed-loop control, signal feedback.

- Original German imported products, longer service life.

KRRASS® family Electric Crowning

- Very precise bending angles

- Europe type dies with 60 mm and 90 mm

- Base can be clamped as well as single dies with 13 mm tang

- Electric crowning with a controller

- Precise positioning and alignment of the crowning table

- Easy and fast usage

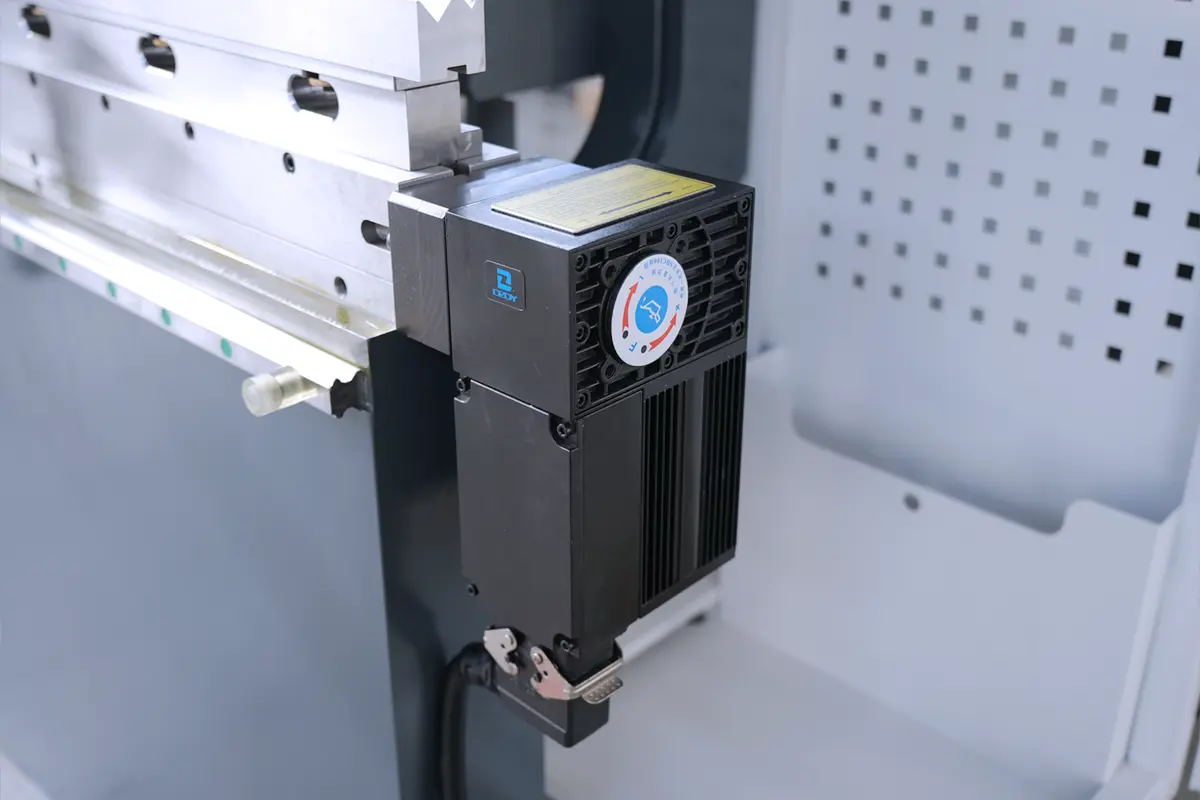

Italy DSP Laser Protection (Optional)

DSP® laser protection will be necessary if you have a high requirement for the safety.

Advantage:

- Laser protection, Multi beam Receiver

- Pretective areas, Front, center and rear

- The safety level is CAT.4 and SIL3

- Detection Case protection degree: IP 65

- Laser classification: class 1 M

- Response time: 5 ms

- Change Speed Point : 5mm + Stopping Space

- The maximum protective distance is up to 15M

- LED indicators show various states

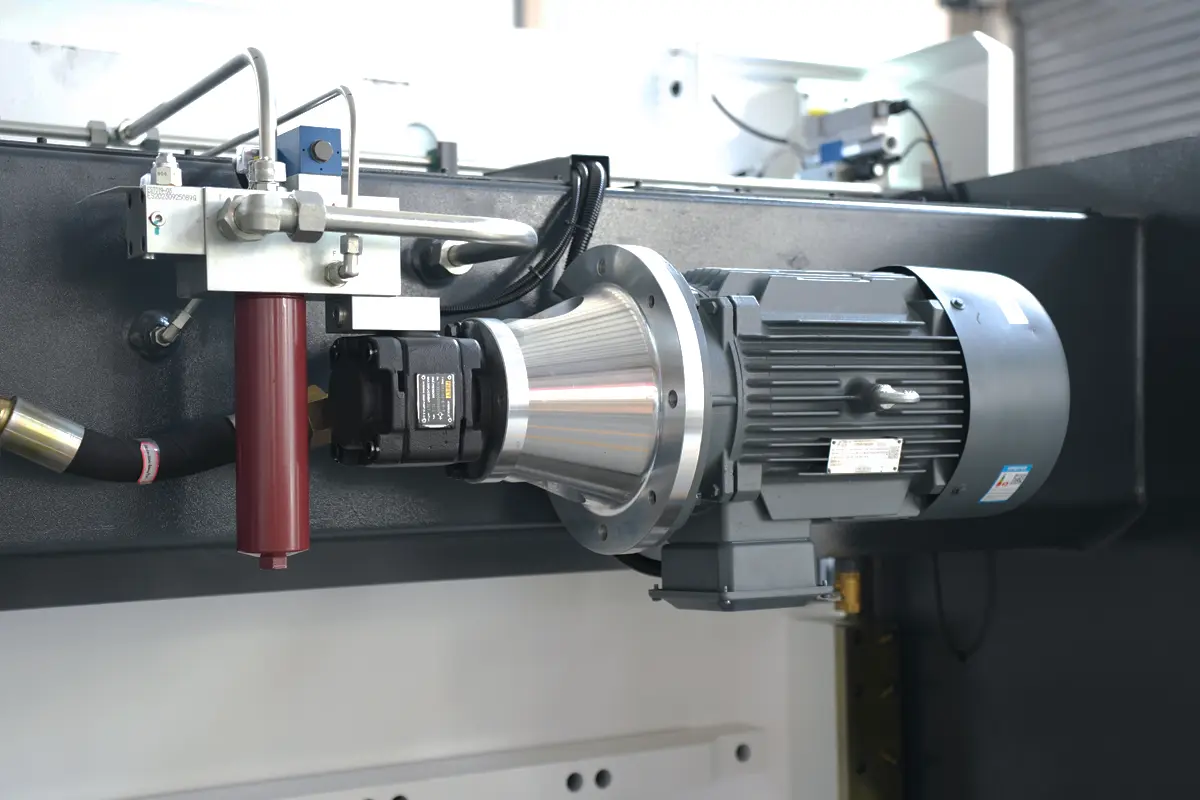

German Siemens Main Motor

The German famous brand motor increases the service life of the press brake machine and keeps the machine working in a low-noise environment.

Hybrid Servo ECO Function

KRRASS® New Hybrid Servo ECO Function (Optional)

KRRASS® promotes a friendly environmental policy, and as such all our equipment features the Hybrid ECO Function. Our hybrid servo-drive positioning system provides accuracy at any position.

Advantage:

- Operating cost is min due to low energy consumption. Thus, it gives advantages to the user with high efficiency & low operation cost.

- High dynamic for a higher productivity of the machine.

- Compliance with EU Directives.

- Lower energy for a green Machine.

- Lowered sound pressure level at 50 dB.

- The servo-motor, with closed loop speed control.

- Energy efficiency of up to 35 % compared to conventional systems.

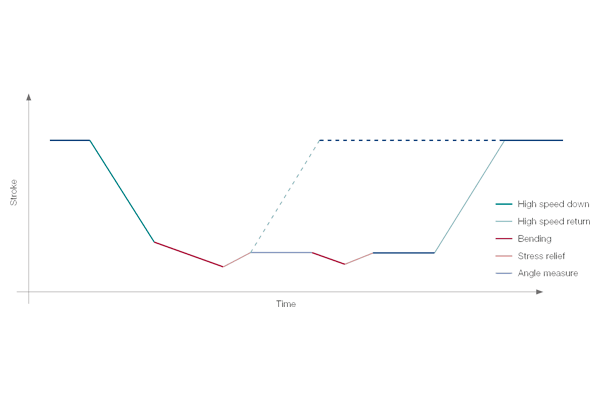

Laser Check Angle Measurement System

The iMeasure Laser angle measurement system with Data-M Engineering for an accurate bend angle after only one bending operation.

The iMeasure are fully-automatic laser-assisted bend angle measurement systems for CNC press brakes. Irrespective of the properties or thickness of the material, the LaserCheck enables an exact determination of the bending angle with an accuracy of better than 0.1°. This represents precision which has never been available before.

- Automatic angle correction

- A laser beam is projected on the sheet metal surface

- The camera detects the laser beam

- The angle between the beam and the camera axis determines the bend angle

- Force reduction + calculation of the springback

Front Sheet Follower Supports System

The hydraulic press brakes with Sheet supports follower system for bending long and thin sheets,It basically consists of a pair of sheet supports placed on the front of the machine at the height of the bending line (bottom tool). Supports are controlled by the CNC, following and supporting the sheet during the bending process.

- Brush and support shaft dim 350x900 up to 1200 mm

- Automatic bending follower supports

- AP1 - AP2 CNC-controlled interpolated axes

- Ecommended for heavy parts or large thin plate

- Bend as closed as 70°

- Load capacity – 180 kg per support

Punches & Dies

CNC Press Brake punches and dies will be one of the most important topics we discuss before you place the order. Any bending shape will be completed by a suitable set of punch and die. We can provide appropriate toolings according to different bending requirements of customers.

Bending Offline Software

Indispensable Tool To Increase Profitability

DELEM DA-Offline software maximises machine efficiency and production output of press brakes. The Profile-T3D software facilitates offline programming and simulation the bending process.

Profile T3D Offline Programming

The Bending offline software is an indispensable tool to increase the profitability of any CNC press brake machine. The offline software Profile T3D enables in a quick, easy and efficient way, importing and unfolding 3D files, finding automatically solutions for tooling and bend sequences and simulating dynamically in 3D for checking collisions.

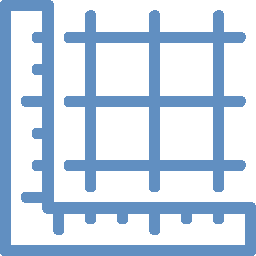

CNC Press Brake Machine Technical Parameter

| Model | Bending Pressure (kn) | Bending Length (mm) | Column Distance (mm) | Throat Depth (mm) | Slider Stroke (mm) | Max. Opening Height (mm) | Y1,Y2-axis Down Speed (mm/sec) | Y1,Y2-axis Back Stroke Speed (mm/sec) | X-axis Max.Distance (mm) | Main Motor (kw) |

|---|---|---|---|---|---|---|---|---|---|---|

| 50T1600 | 500 | 1600 | 1250 | 205 | 160 | 540 | 230 | 140 | 600 | 4 |

| 80T/2500 | 800 | 2500 | 2000 | 350 | 170 | 570 | 230 | 140 | 600 | 7.5 |

| 100T/2500 | 100 | 2500 | 2000 | 410 | 200 | 570 | 220 | 140 | 600 | 7.5 |

| 100T/3200 | 1000 | 3200 | 2700 | 410 | 200 | 570 | 220 | 140 | 600 | 7.5 |

| 100T/4000 | 1000 | 4000 | 3500 | 410 | 200 | 570 | 220 | 140 | 600 | 7.5 |

| 110T/3200 | 1100 | 3200 | 2700 | 410 | 200 | 570 | 220 | 140 | 600 | 7.5 |

| 110T/4000 | 1100 | 4000 | 3500 | 410 | 200 | 570 | 220 | 140 | 600 | 7.5 |

| 125T/3200 | 1250 | 3200 | 2700 | 410 | 200 | 570 | 200 | 140 | 600 | 11 |

| 125T/4000 | 1250 | 4000 | 3500 | 410 | 200 | 570 | 200 | 140 | 600 | 11 |

| 135T/3200 | 1350 | 3200 | 2700 | 410 | 200 | 570 | 200 | 140 | 600 | 11 |

| 135T/4000 | 1350 | 4000 | 3500 | 410 | 200 | 570 | 200 | 140 | 600 | 11 |

| 160T/3200 | 1600 | 3200 | 2700 | 410 | 200 | 570 | 200 | 140 | 600 | 11 |

| 160T/4000 | 1600 | 4000 | 3500 | 410 | 200 | 570 | 200 | 140 | 600 | 11 |

| 160T/5000 | 1600 | 5000 | 4100 | 410 | 200 | 570 | 160 | 90 | 600 | 11 |

| 160T/6000 | 1600 | 6000 | 5100 | 410 | 200 | 570 | 160 | 90 | 600 | 15 |

| 175T/3200 | 1750 | 3200 | 2700 | 410 | 200 | 570 | 160 | 140 | 600 | 11 |

| 175T/4000 | 1750 | 4000 | 3500 | 410 | 200 | 570 | 160 | 140 | 600 | 11 |

| 175T/5000 | 1600 | 5000 | 4100 | 410 | 200 | 570 | 160 | 90 | 600 | 11 |

| 175T/6000 | 1600 | 6000 | 5100 | 410 | 200 | 570 | 160 | 90 | 600 | 15 |

| 200T/3200 | 2000 | 3200 | 2700 | 410 | 200 | 570 | 160 | 140 | 600 | 15 |

| 200T/4000 | 2000 | 4000 | 3500 | 410 | 200 | 570 | 160 | 140 | 600 | 15 |

| 200T/5000 | 2000 | 5000 | 4100 | 410 | 200 | 570 | 160 | 90 | 600 | 15 |

| 200T/6000 | 2000 | 6000 | 5100 | 410 | 200 | 570 | 160 | 90 | 600 | 15 |

| 210T/3200 | 2100 | 3200 | 2700 | 410 | 200 | 570 | 160 | 140 | 600 | 15 |

| 210T/4000 | 2100 | 4000 | 3500 | 410 | 200 | 570 | 160 | 140 | 600 | 15 |

| 210T/5000 | 2100 | 5000 | 4100 | 410 | 200 | 570 | 130 | 90 | 600 | 15 |

| 210T/6000 | 2100 | 6000 | 5100 | 410 | 200 | 570 | 130 | 90 | 600 | 15 |

| 250T/3200 | 2500 | 3200 | 2700 | 410 | 250 | 420 | 160 | 140 | 600 | 18.5 |

| 250T/4000 | 2500 | 4000 | 3500 | 410 | 250 | 620 | 160 | 140 | 600 | 18.5 |

| 250T/5000 | 2500 | 5000 | 4100 | 410 | 250 | 620 | 130 | 90 | 600 | 18.5 |

| 250T/6000 | 2500 | 6000 | 5100 | 410 | 250 | 620 | 130 | 90 | 600 | 18.5 |

| 320T/3200 | 3200 | 3200 | 2700 | 450 | 300 | 670 | 150 | 130 | 600 | 22 |

| 320T/4000 | 3200 | 4000 | 3500 | 450 | 300 | 670 | 150 | 130 | 600 | 22 |

| 320T/5000 | 3200 | 5000 | 4100 | 450 | 300 | 670 | 130 | 90 | 600 | 22 |

| 320T/6000 | 3200 | 6000 | 5100 | 450 | 300 | 670 | 130 | 90 | 600 | 22 |

| 400T/3200 | 4000 | 3200 | 2700 | 500 | 300 | 670 | 150 | 130 | 600 | 30 |

| 400T/4000 | 4000 | 4000 | 3500 | 500 | 300 | 670 | 150 | 130 | 600 | 30 |

| 400T/5000 | 4000 | 5000 | 4100 | 500 | 300 | 670 | 130 | 90 | 600 | 30 |

| 400T/6000 | 5000 | 6000 | 5100 | 500 | 300 | 670 | 130 | 90 | 600 | 30 |

| 500T/4000 | 5000 | 4000 | 3500 | 500 | 300 | 670 | 150 | 130 | 600 | 30 |

| 500T/5000 | 5000 | 5000 | 4100 | 500 | 300 | 670 | 130 | 90 | 600 | 30 |

| 500T/6000 | 5000 | 6000 | 5100 | 500 | 300 | 670 | 130 | 90 | 600 | 30 |

Reviewed by 21 users

The MB8-175/12 feet press brake offers high precision bending .It’s performacne evaluation is cool.

i like krrass company cause it is good !

I feel the high quality of KRRASS bending machines like never before

very very good quality,very very good service

This is my second Krrass folder. I love this brand.