Plate rolling is a process used in metal processing, which directly affects product quality, cost and production efficiency. Plate rolling is one of the core links in metal processing, and its success is related to the smooth operation of the entire production chain.

Different from general metal processing technology, plate rolling involves complex mechanical principles, material science and process technology. Achieving the desired rolling results is not easy and requires a series of practical skills and experience. These tips cover everything from equipment selection to process parameter setting to quality control and troubleshooting.

This article will provide you with a comprehensive guide on how to achieve the desired results in plate rolling through appropriate equipment selection, process parameter settings, quality control and troubleshooting. Whether you are working in the metal processing industry or are interested in plate rolling, this article will provide you with valuable reference and guidance.

Table of contents

I. Basic knowledge of plate rolling

II. Introduction to common plate rolling machines and their processes

III. Material selection during plate rolling process

IV.Parameter setting of plate rolling machines

V. Quality control during plate rolling process

VI. Troubleshooting methods for plate rolling machines

I. Basic knowledge of plate rolling

A. Overview of plate rolling:

Plate rolling refers to the process of compressing and deforming a metal blank through the gap between a pair of rotating rollers in order to reduce the cross-section, increase the length and change the shape. This process is of great importance in industrial production, as it is one of the most common ways of producing steel. Plate rolling has a wide range of applications and is mainly used to produce various metal products such as profiles, plates and pipes.

B. Basic process of plate rolling:

The basic process of plate rolling includes raw material preparation, preheating, rolling and cooling. First, the raw material preparation stage includes material selection and preparation of metal blanks to ensure that the material quality meets the requirements. Then, the metal blank is preheated to improve its plasticity and facilitate subsequent rolling operations. Next comes the rolling stage, in which the metal blank passes through the gap between a pair of rotating rollers and is plastically deformed under the action of pressure and friction, eventually reaching the required size, shape and properties. Finally, the rolled product needs to be cooled to stabilize the material structure and achieve the required hardness and properties.

C. Common terms for plate rolling:

Rollers are rotating tools used to press metal blanks, and their clearance determines the final size of the rolled piece. The rolled piece is the finished product produced from the metal blank during the rolling process. Its shape and size depend on the design and adjustment of the rolls. The rolling direction refers to the direction of movement of the rolled piece as it passes between the rolls. This direction has an important impact on the performance and shape of the final product.

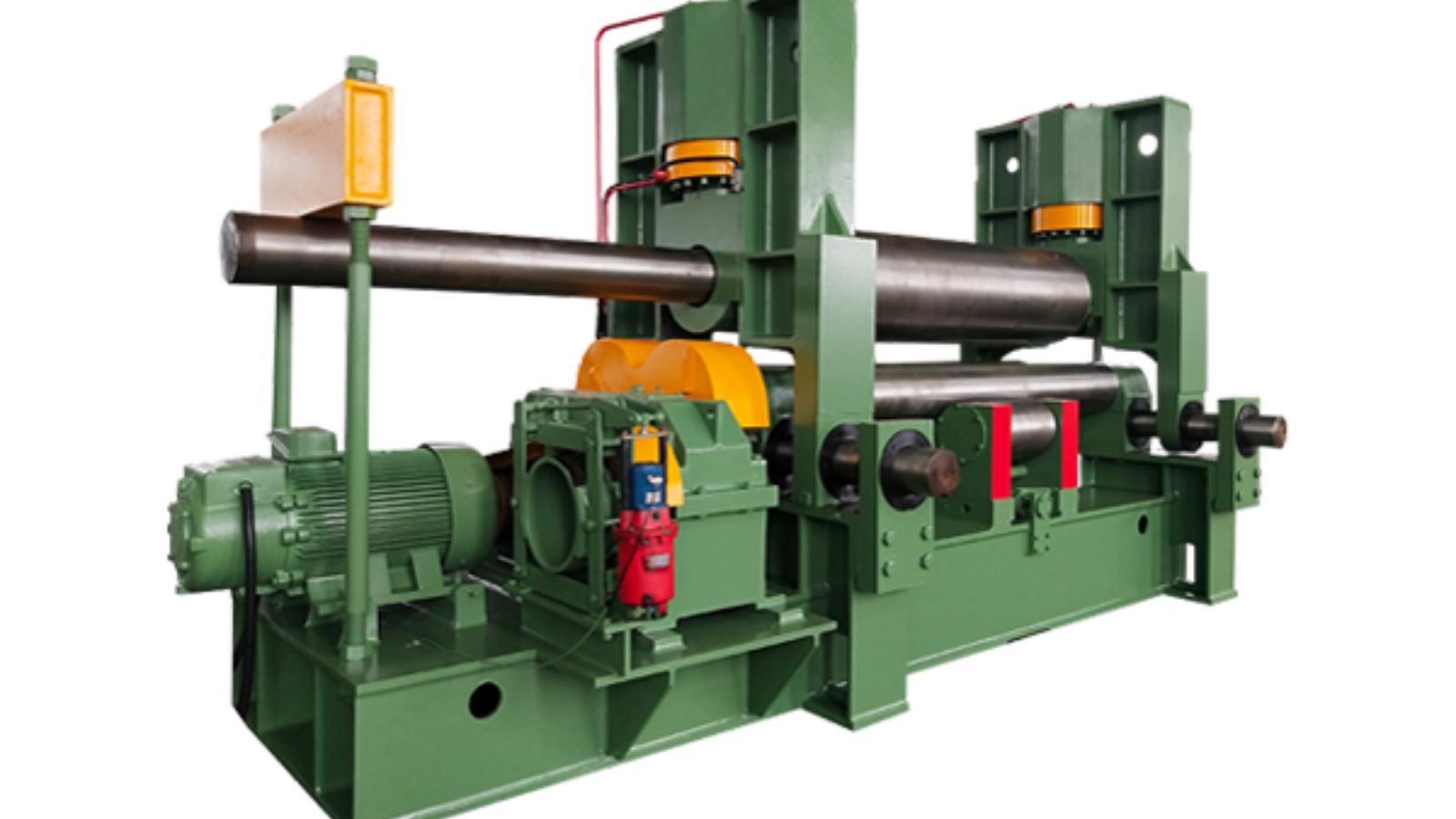

II. Introduction to common plate rolling machines and their processes

A. Different types of plate rolling machines and their characteristics:

- Hot rolling mill: Hot rolling mill is mainly used to heat metal billets to high temperatures and then roll them. Its characteristic is that it can effectively reduce the hardness of metal and improve its plasticity, thereby achieving a wide range of pressing and forming. Hot plate rolling machine are suitable for producing products such as thicker plates and profiles.

- Cold rolling mill: The cold rolling mill rolls metal blanks at room temperature. Its characteristic is that it can maintain the hardness and strength of the metal while improving surface quality and dimensional accuracy. Cold plate rolling machine are suitable for producing thin sheets and high-precision plate products.

- Hot tandem rolling mill: Hot tandem rolling mill is a rolling mill that combines hot rolling and cold rolling processes. It realizes the cooling and shaping of hot-rolled finished products through rapid cooling, thereby obtaining the cold-rolled properties while maintaining the plasticity of the metal. Advantages, suitable for producing high-strength, high-hardness plate products.

B. Process factors affecting plate rolling results:

- Temperature control: Reasonable temperature control can affect the plasticity and fluidity of the metal, thereby affecting the size and surface quality after rolling.

- Pressure setting: Pressure is the force exerted on the metal blank, which directly affects the compression deformation and forming effect of the metal. Reasonable pressure settings can ensure the dimensional accuracy and surface quality of rolled parts.

- Roll configuration: Parameters such as roll type, arrangement and size will affect the rolling results. Different roll configurations can achieve different forming effects. For example, adjusting the crown, tilt angle and gap of the rolls can change the shape and size of the rolled piece.

III. Material selection during plate rolling process

A. The influence of different materials on rolling results:

Different materials will have different effects during the plate rolling process, and these effects directly affect the quality and performance of the rolling results. For example, for stainless steel, due to its higher hardness and plasticity, higher rolling temperatures and pressures are required to ensure the forming effect and surface quality. For aluminum alloys, due to their large thermal expansion coefficient, stricter temperature control is required to avoid plate deformation or surface quality problems.

B. Comparison of properties of common plate materials such as steel and aluminum:

- Steel: Steel has good mechanical properties and processing properties and is widely used in the manufacturing of structural parts, mechanical parts, automobile parts and other fields. Features include high strength, wear resistance and corrosion resistance.

-

Aluminum: Aluminum has a lighter density, good thermal conductivity and electrical conductivity, and is widely used in aerospace, automobile manufacturing, architectural decoration and other fields. Its characteristics include good plasticity, oxidation resistance and surface finish.

IV.Parameter setting of plate rolling machines

A. How to set appropriate rolling parameters based on expected results:

In the plate rolling process, appropriate rolling parameters are key to achieving the desired results. First, the rolling parameters, including temperature, pressure, rolling speed, etc., need to be determined based on the requirements of the target product and the expected finished product quality. For example, for products that require high surface finish, the rolling speed can be appropriately reduced and the rolling pressure can be increased to reduce the generation of surface defects. Secondly, parameters need to be adjusted according to the material characteristics and the performance of the rolling equipment to ensure that the rolling process is stable and reliable. Finally, through real-time monitoring and adjustment of rolling parameters, possible problems can be discovered and solved in a timely manner to ensure that the rolling results meet expectations.

B. Adjustment methods for rolling speed, steel pass rate, roll diameter and other parameters:

- Rolling speed: The selection of rolling speed should consider factors such as material hardness, rolling mill type and product requirements. Generally speaking, higher rolling speed can improve production efficiency, but may affect product surface quality. Therefore, when determining the rolling speed, production efficiency and product quality need to be comprehensively considered and adjusted according to the actual situation.

- Steel pass rate: Steel pass rate refers to the number of steel billets processed by the rolling mill per minute and is an important indicator to measure the production capacity of the rolling mill. The adjustment of the steel pass rate can be achieved by adjusting parameters such as rolling speed, roll gap and feeding speed to meet production needs and equipment performance requirements.

- Roll diameter: The selection of roll diameter should be determined based on factors such as plate thickness, material hardness and rolling process. Larger diameter rolls can improve rolling efficiency and product surface quality, but will also increase rolling mill costs and maintenance difficulty. Therefore, when selecting the roll diameter, it is necessary to comprehensively consider the production requirements and equipment performance, and make reasonable adjustments.

V. Quality control during plate rolling process

A. How to ensure product quality through testing:

The key to ensuring the quality of plate rolling products lies in effective detection methods. First of all, for the detection of dimensional accuracy, commonly used methods include dimensional measuring instruments, laser measurement systems, etc. to ensure that the length, width and thickness of the product meet the specified standards. Secondly, for the detection of surface quality, visual inspection, optical microscope, surface roughness tester and other equipment can be used to detect whether there are defects, oxides, unevenness and other problems on the product surface. In addition, the chemical composition of the product also needs to be analyzed to ensure that it meets the required chemical composition.

B. Control methods for product dimensional accuracy, surface quality, etc. during plate rolling process:

- Dimensional accuracy control: Through reasonable setting of rolling parameters, maintenance and adjustment of rolling mill equipment, and the use of high-precision dimensional measuring instruments, the dimensional accuracy of products can be effectively controlled. In addition, regular inspection and maintenance of the rolling mill to ensure the consistency and flatness of the roll gap is also an important measure to ensure dimensional accuracy.

-

Surface quality control: Corresponding control methods can be adopted for different surface defect problems. For example, the problem of surface oxides can be controlled by controlling the rolling temperature and atmosphere, surface treatment, etc.; for the problem of uneven surfaces, appropriate roll configuration, rolling parameter adjustment, and surface treatment technology can be used to improve it. . At the same time, strengthening the monitoring and management of rolling mill equipment and processes, and timely discovering and solving problems are also the key to ensuring product surface quality.

VI. Troubleshooting methods for plate rolling machines

A. How to identify common faults:

Deflection of the rolled piece: The deflection of the rolled piece during the rolling process may be caused by uneven gaps between the rolling mill rolls, uneven surface of the rolled piece, uneven material properties of the rolled piece, etc. The identification method includes observing whether the shape of the rolled piece shows abnormal changes, measuring whether the size of the rolled piece meets the requirements, checking whether the roll gap is uniform, etc.

Surface defects of rolled parts: Common surface defects of rolled parts include surface oxidation, unevenness, scratches, etc. Identification methods include visual inspection of the surface of the rolled piece for abnormalities, detailed observation of the surface of the rolled piece using an optical microscope or magnifying glass, and surface quality inspection using equipment such as a surface roughness tester.

B. Solutions and preventive measures:

The problem of rolling stock deflection can be solved by adjusting the gap between the rolling mill rolls, adjusting the feeding position of the rolling stock, and checking the surface quality of the rolling stock. Preventive measures include regularly checking the operating status of rolling mill equipment and ensuring uniform quality of rolled materials.

The problem of surface defects of rolled pieces can be solved by adjusting rolling mill parameters, adopting appropriate roll configuration, and improving the material quality of rolled pieces. Preventive measures include strengthening the maintenance and upkeep of rolling mill equipment, regularly cleaning the roll surface, and ensuring uniform roll gaps.

VII.Conclusion

This article introduces in detail the basic knowledge, equipment and processes, material selection, parameter settings, quality control, troubleshooting and other practical skills of plate rolling, aiming to help readers fully understand and master the key points of plate rolling. As an industry-leading manufacturer of plate rolling machines, KRRASS has established a strong reputation worldwide with its strong brand strength, technological innovation and customer service. For any design and production request, KRRASS can supply plate plate rolling machines to suit the requirements and offers a comprehensive selection of metal processing equipment. Readers are encouraged to apply the knowledge and techniques introduced in this article in practical operations to achieve better rolling results, and are welcome to learn more about KRRASS products and services.