In today’s competitive market, finding the best price for laser cutting services is crucial for businesses and hobbyists alike. Max laser cutting technology offers high precision and efficiency, making it a popular choice for various industries. However, navigating the costs associated with these services can be challenging. This article will explore the factors that influence the Max laser cut price, how to compare quotes effectively, and tips for getting the best value for your money. Whether you're a manufacturer looking to optimize production costs or a DIY enthusiast aiming to bring your creative projects to life, understanding Max laser cut price will help you make informed decisions.

Technical Overview

Definition and Principle

Max laser source refers to a high-performance laser technology known for its exceptional power, stability, and precision. It operates by emitting a concentrated beam of light through an optical system, which is then focused onto a specific point on a material to cut, engrave, or mark it with high accuracy.

The core principle behind Max laser technology is the stimulated emission of radiation, where electrons in a material are excited to a higher energy state and then release photons as they return to their ground state. These photons stimulate other excited electrons to emit additional photons, resulting in a coherent and highly focused laser beam. Key technologies involved include advanced optical components, precision control systems, and robust power sources, all designed to optimize the performance and reliability of the laser.

Development History

The development of Max laser source technology has seen significant advancements over the years. Initially, lasers were limited in power and efficiency, suitable only for basic cutting and engraving tasks. However, with ongoing research and technological innovations, the capabilities of laser sources have expanded dramatically.

Major milestones in the evolution of Max laser sources include the introduction of fiber lasers, which offer higher power and better beam quality, and the development of solid-state lasers, known for their efficiency and compact design. Advances in control software and cooling systems have further enhanced the performance, making Max laser sources a preferred choice for high-precision applications across various industries.

Technical Advantages of Max Laser Cut

Max laser sources offer several advantages over traditional laser sources, making them a superior choice for many applications:

- Higher Power: Max laser sources can deliver higher power outputs, allowing for faster cutting speeds and the ability to work with thicker and tougher materials. This is particularly beneficial in industrial settings where efficiency and productivity are critical.

- Better Stability: Enhanced stability in Max laser sources ensures consistent performance over extended periods, reducing downtime and maintenance costs. This stability is achieved through advanced cooling systems and robust design, which prevent overheating and degradation of laser components.

- Accuracy: The precision of Max laser sources is unmatched, thanks to their high-quality optical systems and precise control mechanisms. This allows for intricate designs and fine details to be executed with exceptional accuracy, making them ideal for applications requiring tight tolerances and high-quality finishes.

- Efficiency: Max laser sources are more energy-efficient compared to traditional laser sources, resulting in lower operating costs and reduced environmental impact. The efficient conversion of electrical energy into laser light minimizes waste and optimizes performance.

- Versatility: These laser sources are versatile and can be used across a wide range of materials, including metals, plastics, ceramics, and composites. This versatility makes them suitable for diverse applications, from industrial manufacturing to medical devices and consumer electronics.

Applications of Maxphotonics Laser Source

Max laser technology, with its superior precision, power(from 500W to 60KW), and versatility, finds applications across a wide range of industries. Its ability to deliver high-quality results efficiently makes it an invaluable tool for various sectors. Here are some key application areas:

1. Industrial Manufacturing

- Cutting and Welding: Max lasers are extensively used for cutting and welding metals and other materials with high precision and speed. This is critical in automotive, aerospace, and machinery manufacturing, where accuracy and durability are paramount.

- Marking and Engraving: Used for marking serial numbers, barcodes, and logos on products, ensuring traceability and branding. This is common in the electronics, medical devices, and consumer goods industries.

- Micromachining: Employed in the production of small and intricate components, such as microchips and miniature mechanical parts, where extreme precision is required.

2. Medical Field

- Surgical Procedures: Max lasers are used in various surgical applications, including eye surgeries (e.g., LASIK), tumor removal, and cosmetic surgeries. Their precision allows for minimally invasive procedures with faster recovery times.

- Dental Treatments: Utilized in procedures such as cavity preparation, gum reshaping, and teeth whitening, offering patients less discomfort and quicker healing.

- Dermatology: Effective for skin treatments like tattoo removal, scar reduction, and skin resurfacing, providing high accuracy and reduced risk of damage to surrounding tissues.

3. Automotive Industry

- Part Manufacturing: Employed in the cutting and welding of automotive parts, ensuring strong and precise joints. This includes body panels, frames, and exhaust systems.

- Marking and Identification: Used for engraving identification marks on parts, which is crucial for quality control and traceability in the supply chain.

4. Aerospace Industry

- Component Fabrication: Max lasers are utilized in the fabrication of complex aerospace components, including turbine blades and structural parts, where precision and reliability are critical.

- Surface Treatment: Applied for surface treatments like drilling cooling holes in turbine blades, enhancing the performance and lifespan of aerospace components.

5. Jewelry and Fashion

- Design and Customization: Max lasers enable the creation of intricate designs and customization in jewelry, allowing for unique and high-quality pieces.

- Engraving: Used for engraving detailed patterns and personal messages on various fashion accessories, including watches, rings, and bracelets.

Cutting Performance of Max Laser (10KW Power)

With the popularization of the 10,000-watt laser concept, many domestic equipment manufacturers have successively upgraded to 10,000-watt systems. As a result, the demand for high-performance and advanced technology in 10,000-watt fiber lasers is becoming increasingly urgent. Here draws on the actual experiences of light source manufacturers (such as Maxphotonics), equipment manufacturers, and end users to elaborate on the cutting advantages—such as cutting ability, cutting efficiency, and cutting quality—as well as the process characteristics of 10,000-watt lasers. This comprehensive analysis will be highly beneficial to you.

10KW Cutting Characteristics By Adopting Max Laser

1. Cutting ability is greatly improved.

Cutting ability | 6000W | 12000W | 15000W | |

Carbon Steel | Stable processing | ≤22mm | ≤35mm | ≤40mm |

Sample thickness | 25mm | 50mm | 50mm | |

Stainless Steel | Stable processing | ≤14mm | ≤22mm | ≤25mm |

Sample thickness | 30mm | 50mm | 70mm | |

Aluminium Alloy | Stable processing | ≤12mm | ≤20mm | ≤22mm |

Sample thickness | 20mm | 40mm | 50mm | |

Brass | Stable processing | ≤12mm | ≤20mm | ≤22mm |

Sample thickness | 20mm | 40mm | 50mm | |

Note: Carbon steel cutting capacity refers to the use of oxygen cutting; stable processing refers to cutting plates with cutting speed greater than 1m / min. (except carbon steel) | ||||

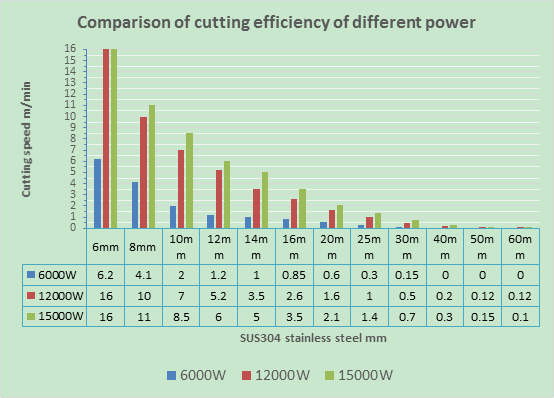

2.Cutting efficiency is doubled

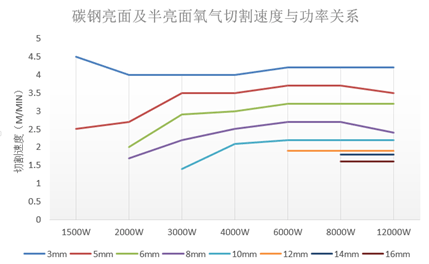

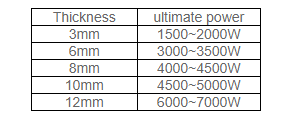

Key point: When carbon steel is cut on the bright side, there is a limit power when the thickness of the board is determined.

If the actual power is less than the limit power, as the power increases, the cutting speed will increase accordingly;

If the actual power is greater than the limit power, the cutting speed will remain unchanged as the power increases, and there will be no improvement; at the same time, the cutting effect will not change.

Carbon steel oxygen bright surface cutting: relationship between sheet thickness and ultimate power.

2. Process Analysis of Oxygen Cutting Carbon Steel Bright Surface

(1) The three major functions of laser

1 Preheating before the start of cutting—Before the start of cutting, the temperature of the steel plate is heated to above the ignition temperature (>1000 °C) to enable high temperature oxidation reaction with oxygen;

2 Preheating during the cutting process—heat the steel plate in a certain area at the front of the slit to a temperature above the ignition temperature to ensure that the surface energy can rapidly undergo oxidation reaction when the cutting gas flow passes.

3 Heat compensation at the slit—compensate the heat loss caused by heat conduction, radiation, slag removal, etc. at the slit to ensure the temperature of the cutting zone;

(2) The role of oxygen

Cutting action—The oxygen and high temperature iron undergo a violent oxidative exothermic reaction, melting the metal, and blowing off the slag.

Glossy cutting condition

1 Suitable for cutting with small nozzles, small airflow diameter;

2 In order to ensure that the spot diameter of the sheet surface is large enough, a large defocusing amount is required for cutting;

3 The thicker the plate, the larger the spot diameter and the greater the amount of defocus;

4 Ensure that the spot on the surface of the plate can be heated to a temperature above the ignition temperature (>1000 °C) in a very short period of time. Excessive power will increase the heat input and cause the plate to overheat. The cutting effect is unfavorable;

It can be seen that when the carbon steel is cut on the bright side, for the medium-thin board, the 10,000-watt power cannot exert its due advantage. The solution is to use air cutting to cut carbon steel like stainless steel, and to fully utilize the energy of a 10,000-watt laser to achieve high-speed cutting of carbon steel.

When the 10,000-watt laser uses air to cut carbon steel within 12mm, it can achieve full-power slag-free cutting effect, and the cutting efficiency is comparable to stainless steel.

(3) The bright surface cutting ability is greatly improved

When carbon steel is cut with oxygen, the 10,000-watt laser can achieve small taper cutting of thick plates. Green indicates a bilateral taper<0.1 mm; a colorless area indicates a bilateral taper of 0.3 to 0.7 mm.

Thickness(mm) | 6000W | 12000W | 15000W |

Oxygen cutting speed(m/min) | |||

| 4 | 3.5~3.7 | 3.3~3.6(2000-3000W) | 3.3~3.6(2000-3000W) |

| 6 | 2.7~3.0 | 2.7~3.0(3000-3500W) | 2.7~3.0(3000-3500W) |

| 8 | 2.4~2.5 | 2.4~2.5(4000-4500W) | 2.4~2.5(4000-4500W) |

| 10 | 2.2~2.3 | 2.2~2.4(4000-5000W) | 2.2~2.4(4000-5000W) |

| 12 | 1.8~2.0 | 1.8~2.0(5500-6500W) | 1.8~2.0(5500-6500W) |

| 14 | 1.3~1.5 | 1.6~1.7(6500-7500W) | 1.6~1.7(6500-7500W) |

| 16 | 0.8~0.9 | 1.5~1.7(8000-9000W) | 1.5~1.7(8000-9000W) |

| 18 | 0.7~0.8 | 1.2~1.4(9000-12000W) | 1.2~1.4(9000-12000W) |

| 20 | 0.6~0.65 | 1.1~1.3(9000-12000W) | 1.1~1.3(9000-12000W) |

| 22 | 0.55~0.6 | 0.8~0.9(10000-12000W) | 0.8~0.9(10000-12000W) |

| 25 | 0.5~0.55 | 0.6~0.8(12000W) | 0.6~0.8(13000-15000 |

Thickness(mm) | Nozzle outlet diameter | Defocusing amount(mm) |

| 12 | 1.2 | +9~+10 |

| 14 | 1.2 | +9.5~+10.5 |

| 16 | 1.4 | +10~+11 |

| 18 | 1.4 | +10~+11 |

| 20 | 1.6 | +11~+13 |

| 22 | 1.6 | +11~+13 |

| 25 | 1.6 | +13~+14 |

| 30 | 1.8 | +13~+14 |

3. Advantages of Maxphotonics 10,000-watt Laser

(1) Using 4000W single module for power synthesis, the number of modules is small, and the reliability of the whole machine is high;

(2) The optical module is separated from the electrical module, which is convenient for maintenance and short maintenance time;

Due to the high power of the 10,000-watt laser, the traditional QBH output head, whether it is the power carrying capacity or the heat dissipation performance, can no longer meet the requirements of the stable output of the 10,000-watt laser. The Maxphotonics 10,000-watt laser class adopts the self-developed LOE output head. When used with the cutting head, the cutting head fiber interface needs to select the corresponding lock.

4. Customer Usage

Guide For Max Laser Cut Price

In today's competitive market, understanding the pricing of Max laser cutting services is crucial for both businesses and hobbyists. This guide will help you navigate the various factors that influence the cost of Max laser cutting, compare quotes effectively, and provide tips for securing the best deal.

Factors Influencing Max Laser Cut Price

1.Material Type and Thickness

- Common Materials: Different materials such as metals, plastics, wood, and ceramics have varying cutting complexities and costs.

- Material Properties: Harder or thicker materials require more power and time, increasing the overall cost.

2.Complexity of Design

- Simple vs. Intricate Designs: Intricate designs with detailed patterns take longer to cut and may require higher precision, thus costing more.

- Cutting Path: Longer or more complex cutting paths increase the time and effort required, impacting the price.

3.Cutting Speed and Precision Requirements

- Speed Settings: Faster cutting speeds may reduce costs but can compromise quality. Conversely, slower, more precise cuts may increase costs due to longer machine use.

- Precision Levels: Higher precision requirements necessitate advanced equipment and skilled operators, which can drive up costs.

4.Volume of Work

- Bulk Orders: High-volume orders often benefit from economies of scale, reducing the cost per unit.

- Single or Custom Pieces: One-off or highly customized pieces may cost more due to the setup and specialized attention required.

Raycus, JPT, Max, and IPG fiber source: How to Choose

Raycus

This brand is cheap, and this is the main reason most of the companies use it, is not famous for a quality engraving and also have less warranty than other fiber power sources. This brand also has a small range frequency between 20 to 80 kHz, which makes it have a short range of engraving materials. In comparison with other brands, Raycus doesn't offer too much advantage to the customer, but it can be very cheap, and as a result, machines build with this power source are low cost.

JPT

This Singaporean brand has a different laser power source, some of them are limited by 20 to 80kHz (low-cost JPT), and other models offer less warranty. This brand is famous because it provides excellent quality, excellent engraving, and stability at the time of work with their premium models, as JPT-X or MOPA.

Max

Max is another fiber power source known for being inexpensive, but unlike Raycus, MAX laser generators have better stability than Raycus. The MAX fiber optic sources also have the same Raycus disadvantage with an engraving range between 20 to 80 kHz, which makes them share the same engraving drawbacks: little or no engraving capacity on plastics and low capacity for doing different effects on metal materials. The other significant disadvantage of the Max laser sources is their lack of clarity about the warranty. Sometimes, it is one year, and other times if the damage occurs within the first ten months, the warranty and repairs are users' responsibility.

IPG

Being the world leaders in fiber optic laser technology, IPG is the best brand for its high-quality engraving, stability, and guarantee. The main advantage over other brands, is the high-quality engraving jewelry and small electronic components compared to Chinese brands. They also have a wide variety of technologies, which allows us to choose the best source of laser power for engraving specific materials. If you have materials that no other laser machine can engrave, IPG laser has the solution. Which is why at Barch Laser, we work hand in hand with IPG Photonics, to be able to build machines capable of engraving on any material with high-quality results.

Price of each brand

Max Photonics

- 10,000-Watt Fiber Laser: Approximately $30,000 - $50,000

- Max Photonics is known for offering competitive pricing without compromising on quality and performance. Their 10,000-watt lasers are widely used in industrial applications and are appreciated for their reliability and cost-effectiveness.

JPT Opto-Electronics

- 10,000-Watt Fiber Laser: Approximately $35,000 - $55,000

- JPT provides high-quality laser sources with a strong focus on innovation and customer support. Their pricing reflects the advanced technology and customization options available, making them a popular choice for specialized applications.

IPG Photonics

- 10,000-Watt Fiber Laser: Approximately $60,000 - $100,000

- IPG Photonics is a market leader in fiber laser technology, known for its cutting-edge research and superior product performance. Their higher price point is justified by their extensive R&D, exceptional precision, and robustness, catering to high-end industrial requirements.

Raycus

- 10,000-Watt Fiber Laser: Approximately $25,000 - $45,000

- Raycus offers a balance between affordability and high performance. As a prominent player in the fiber laser market, Raycus lasers are often chosen for their cost efficiency and reliable performance, especially in medium to large-scale manufacturing environments.

Key considerations for pricing when choose a laser brand

- Power Output: Higher wattage typically means higher cost, but it also allows for cutting thicker materials and faster processing times.

- Beam Quality: Lasers with better beam quality (e.g., lower M^2 values) can cut more precisely, which might come at a premium.

- Warranty and Support: Extended warranties and comprehensive customer support can add to the cost but provide peace of mind and reliability.

- Geographical Factors: Prices can vary based on import duties, shipping costs, and regional market demand.

- Additional Features: Integrated cooling systems, advanced control software, and other features can influence the price.

Differences between JPT, IPG, MAX, and Raycus Laser Source

The difference between the four laser sources comes from properties like their engraving outcomes, warranty, the number of materials they can mark, and frequency range. Below is a comparison between the laser sources.

Stability

Stability is essential for the accuracy of the laser marking machine. IPG and JPT laser sources are more stable than MAX and Raycus.

· Cost

Based on a budget: When comparing the prices from the highest to the lowest prices, IPG laser sources >JPT laser sources > MAX laser sources > Raycus laser sources. As a result, if you are looking for a cheaper laser source to buy, go for a Raycus laser marker.

· Engraving result and compatible material

All the laser sources have good engraving results. However, some are better than others. For example, JPT and IPG lasers can handle high-reflective materials like aluminum, steel, and stainless steel better than MAX and Raycus laser sources.

In summary, below is a table showing the properties of each laser source.

| Laser source | IPG | MAX | JPT | Raycus |

| Cost | High | Low | Average | Low |

| Level of stability | Very high | Low | High | Low |

| Beam property | High | Good | Good | Fair |

| Engraving results | Excellent | Good | Good | Fair |

| Range of frequency | Very high | Low | High | Low |

| Metal materials | Great | Effective | Good | Effective |

| Plastic | Great | Poor | Effective | Poor |

| Warranty | Two years | One year | One year | One year |

Conclusion

Max laser cutting technology offers unparalleled precision and efficiency, making it a valuable tool across various industries. With the insights provided in this article, you can navigate the pricing landscape more effectively and ensure that you get the best value for your investment. By leveraging this knowledge, you can maximize the benefits of Max laser cutting services and achieve superior results for your projects. Whether you are enhancing your manufacturing processes or embarking on a new creative venture, a clear understanding of Max laser cut pricing will empower you to make cost-effective and high-quality choices.