Are you in the market for an electric press brake but overwhelmed by the options available? Choosing the right electric press brake is crucial for the efficiency and productivity of your operations. With various models, features, and brands on the market, making the best choice can be challenging. But worry not! In this comprehensive guide, we'll walk you through everything you need to know to select the best electric press brake for your needs.

Introduction

In today's rapidly evolving manufacturing landscape, precision, efficiency, and flexibility are paramount. At the heart of many metal fabrication processes lies the electric press brake, a crucial tool for bending and shaping metal sheets with accuracy and consistency. But what exactly is an electric press brake, and why is it indispensable in modern manufacturing operations?

What Is An Electric

Press Brake

An electric press brake is a machine tool used to bend sheet metal into various shapes and angles. What sets it apart from its hydraulic or mechanical counterparts is its reliance on electric motors for power transmission, offering distinct advantages in terms of precision, speed, and energy efficiency.

Importance In Modern Industry

In manufacturing, whether you're producing automotive parts, electronics enclosures, or architectural components, the ability to precisely bend metal to exact specifications is vital. This is where the electric press brake shines. By utilizing electrically-driven mechanisms, these machines offer unparalleled control over the bending process, resulting in accurate bends, consistent angles, and high repeatability.

Now, more than ever, choosing the right and best electric press brake equipment is critical for staying competitive and meeting customer demands. Selecting the best electric press brake tailored to your specific needs can significantly impact your production efficiency, quality standards, and ultimately, your bottom line.

From small job shops to large-scale manufacturing facilities, having the right electric press brake can streamline operations, reduce setup times, minimize material waste, and improve overall productivity. But with numerous options available in the market, understanding what factors to consider is key to making the optimal choice for your business.

How To Understand "Best Electric Press Brake"

In the world of metal fabrication, a best electric press brake for workshop should be with precision, efficiency, and versatility. Like Krrass Machine Tool, Best electric press brakes should have below features and advantages that can meet your needs.

Precision Control

Electric press brakes are renowned for their exceptional precision and control. Featuring advanced technology and sophisticated control systems, these machines offer precise and accurate bending capabilities. By utilizing electric power, they ensure consistent regulation of the force applied during the bending process, resulting in high-quality and repeatable bends. This precision enables fabricators to achieve intricate shapes and angles effortlessly, reducing the need for rework and ensuring top-notch product quality.

Energy Efficiency

In today's focus on sustainability, electric press brakes excel in energy efficiency. Unlike traditional hydraulic models, electric press brakes use electric motors for operation, leading to significant energy savings. Through intelligent power management, these machines minimize energy waste, promoting a greener manufacturing process. Not only does this benefit the environment, but it also translates into cost savings for businesses, making electric press brakes a smart investment choice.

Versatility in Metal Fabrication

Electric press brakes offer unmatched versatility in metal fabrication applications. Designed to handle various materials, thicknesses, and bending requirements, they accommodate stainless steel, aluminum, copper, and more with consistent and precise results. Their versatility allows fabricators to tackle a wide range of projects, from intricate components to large-scale structures, making them indispensable in any metalworking workshop.

Ergonomic Design and User-Friendly Interface

Electric press brakes prioritize user convenience with ergonomic design and intuitive interfaces. Engineered for operator comfort and safety, these machines feature adjustable working heights and user-friendly control panels. Every aspect is designed to streamline the bending process, minimizing fatigue or injury risks. Advanced technology combined with user-centric design ensures operators can work efficiently, maximizing productivity and reducing downtime.

Advanced Features and Automation

Beyond their core advantages, electric press brakes come with advanced features and automation capabilities. These include programmable bending sequences, intelligent back gauges, and sophisticated software interfaces. Such features allow fabricators to automate tasks, enhance efficiency, and minimize errors. With the ability to store and recall bending programs, electric press brakes ensure consistency across production runs, delivering high-quality results effortlessly.

In summary, the features and advantages of the best electric press brakes establish them as essential assets for metal fabricators. Their precise control, energy efficiency, versatility, ergonomic design, and automation capabilities offer significant benefits in terms of product quality, cost savings, and operational efficiency.

How Electric Press Brakes Achieve Energy Efficiency

- Electric press brakes operate using electric motors, which consume power only when needed. Unlike hydraulic systems that run continuously, electric motors activate only during bending operations, significantly reducing energy wastage during idle times. This on-demand power usage is a key factor in enhancing energy efficiency.

- Some electric press brakes are equipped with regenerative systems that capture and reuse energy during braking or deceleration. Instead of dissipating this energy as heat, it is recycled within the system, further reducing overall energy consumption. By harnessing energy that would otherwise be lost, regenerative systems enhance the efficiency of electric press brakes.

- Modern electric press brakes utilize efficient drive systems such as servo-electric or hybrid drives. These systems optimize power usage by adjusting motor speed based on the required bending force, ensuring energy is used efficiently. Additionally, intelligent power management systems monitor the load and adjust power consumption accordingly, minimizing energy waste throughout the bending process.

Electric press brakes not only reduce energy consumption during operation but also contribute to lower standby power consumption, thanks to their ability to be put into standby mode without significant energy usage. Overall, these features make electric press brakes a sustainable choice for manufacturers aiming to reduce energy costs and minimize environmental impact.

How To Find Best Electric Press Brake

1. Understanding Different Types

Understanding these different types of electric press brakes allows you to choose the one that best suits your specific application requirements, whether it's precision, speed, capacity, or automation.

1. Servo-Electric Press Brakes:

- Description: Servo-electric press brakes use electric servo motors to drive the ram, providing precise control over the bending process.

- Advantages:

- High precision and accuracy.

- Energy-efficient operation.

- Quiet operation and low maintenance.

- Suitability: Ideal for applications requiring high precision and versatility, such as aerospace, electronics, and fine sheet metal work.

2. Hybrid Press Brakes:

- Description: Hybrid press brakes combine hydraulic and electric technologies, utilizing hydraulic systems for high-force applications and electric servo motors for bending accuracy.

- Advantages:

- High bending force combined with precise control.

- Energy-efficient operation.

- Faster cycle times compared to purely hydraulic machines.

- Suitability: Suitable for a wide range of applications, including medium to heavy-duty bending tasks in industries like automotive, machinery, and general fabrication.

3. Fully Electric Press Brakes:

- Description: Fully electric press brakes operate entirely on electric power, including both the ram and back gauge movement.

- Advantages:

- High precision and repeatability.

- Energy-efficient with minimal maintenance requirements.

- Fast setup and bending speeds.

- Suitability: Best suited for applications requiring high-speed bending and precision, such as small parts manufacturing, electronics, and job shops.

2. Assess Your Requirements

(1)Determine the Types of Materials

Understanding the materials you’ll be working with is essential to selecting the appropriate press brake.

- Material Types:

- Mild Steel: Commonly used due to its flexibility and cost-effectiveness.

- Stainless Steel: Requires more force due to its higher tensile strength.

- Aluminum: Easier to bend but can be more prone to damage if not handled properly.

- Copper and Brass: Softer materials that need careful handling to avoid marks and deformation.

- Material Thickness:

- Thin Sheets (up to 2mm): Requires less force and can be managed with most electric press brakes.

- Medium Sheets (2mm to 6mm): Requires moderate force; a mid-range press brake is typically suitable.

- Thick Sheets (over 6mm): Requires significant force; ensure the press brake has sufficient tonnage capacity to handle thicker materials without strain.

(2) Evaluate Bend Lengths and Angles

The typical bend lengths and angles required for your parts will influence the specifications of the press brake you choose.

- Bend Lengths:

- Short Bends: For small components, ensure the press brake can accurately perform short, precise bends.

- Long Bends: For large components, consider the maximum bed length of the press brake. Tandem press brakes might be necessary for extremely long parts.

- Bend Angles:

- Simple Bends: Most press brakes can handle basic angles.

- Complex Bends: If your parts require intricate angles, look for a press brake with advanced control systems and programmable features to ensure precision.

(3) Consider Production Volume and Throughput

Your production volume and throughput requirements will determine the speed, efficiency, and durability needed from your press brake.

- Low Volume Production:

- If you have a lower production volume, you might prioritize precision and versatility over speed. A fully electric or servo-electric press brake might be ideal due to their precise control and energy efficiency.

- High Volume Production:

- For high production volumes, speed and efficiency become critical. Look for press brakes with fast cycle times, quick setup features, and robust construction to handle continuous operation without frequent downtime.

- Throughput Requirements:

- Cycle Time: Assess the speed at which the press brake can complete a cycle, including the approach, bending, and return movements. Faster cycle times improve throughput.

- Automation Capabilities: Advanced features like CNC control, programmable bending sequences, and automated tool changes can significantly enhance throughput by reducing manual intervention and setup time.

3. Choose A Reliable Manufacture

When looking for the best electric press brakes, it's essential to consider manufacturers known for their innovation, quality, and reliability. Here are ten leading manufacturers along with some recommended models:.

| Manufacturer | Recommended Model | Country of Origin |

| Amada | EG-6013AR | Japan |

| Trumpf | TruBend Series 5000 | Germany |

| Bystronic | Xpert 40 | Switzerland |

| LVD | Dyna-Press 24/12 Plus | Belgium |

| Salvagnini | B3.AU-TO | Italy |

| SafanDarley | E-Brake 100-3100 | Netherlands |

| Prima Power | eP Series | Italy |

| Durma | AD-ES Series | Turkey |

| Krrass | WE67K Series | China |

| Accurpress | Accell E Series | USA |

| MC Machinery Systems (Mitsubishi) | BH Series | Japan |

What Is Best Electric Press Brake Price

The price of the best electric press brake can vary widely depending on several factors, including the brand, model, specifications, features, and additional options. Here’s a general overview of the price range for high-quality electric press brakes:

Price Range Overview

- Entry-Level Models:

- Price Range: $50,000 to $100,000

- Features:

- Suitable for small to medium-sized shops

- Basic automation and control systems

- Limited bending capacity and length

- Mid-Range Models:

- Price Range: $100,000 to $250,000

- Features:

- Advanced control systems with CNC capabilities

- Higher bending capacities

- Enhanced precision and speed

- Suitable for more demanding applications

- High-End Models:

- Price Range: $250,000 to $500,000+

- Features:

- State-of-the-art automation and advanced software

- Maximum precision and speed

- High bending capacities for thick and complex materials

- Suitable for large-scale production and high-volume operations

Examples of Specific Models and Their Approximate Prices

- Amada EG-6013AR:

- Price Range: $250,000 to $350,000

- Features: Servo-electric drive, automatic tool changer, high precision.

- Trumpf TruBend Series 5000:

- Price Range: $200,000 to $400,000

- Features: Advanced CNC control, servo-driven ram, high productivity.

- Bystronic Xpert 40:

- Price Range: $100,000 to $150,000

- Features: Fully electric drive, high-speed bending, compact design.

- LVD Dyna-Press 24/12 Plus:

- Price Range: $80,000 to $120,000

- Features: Compact, fully electric, energy-efficient, high-speed ram movements.

- Salvagnini B3.AU-TO:

- Price Range: $300,000 to $450,000

- Features: Hybrid technology, automated tool change, high precision.

- SafanDarley E-Brake 100-3100:

- Price Range: $150,000 to $250,000

- Features: Servo-electronic drive, advanced safety features, energy-efficient.

- Prima Power eP Series:

- Price Range: $200,000 to $300,000

- Features: Servo-electric drive, high precision, user-friendly interface.

- Durma AD-ES Series:

- Price Range: $80,000 to $150,000

- Features: Energy-efficient electric drive, high precision, advanced CNC controls.

- Accurpress Accell E Series:

- Price Range: $100,000 to $200,000

- Features: Full electric drive, robust construction, advanced control system.

- MC Machinery Systems (Mitsubishi) BH Series:

- Price Range: $150,000 to $250,000

- Features: Electric drive, high speed and accuracy, advanced safety and ergonomic features.

- Krrass WE67K Series:

- Price Range: $50,000 to $100,000

- Features: Reliable electric drive, suitable for small to medium-scale operations, user-friendly controls.

Hydraulic vs Electric Press Brake: Which One Is Better

When choosing between a hydraulic press brake and an electric press brake, it’s essential to understand their unique characteristics and how they align with your application needs, budget, and production volume. Here is a detailed comparative analysis of these two types of press brakes.

Structural Differences

Hydraulic Press Brake:

- Components: Workbench, hydraulic system, control system, and frame.

- Hydraulic System: Includes the main oil cylinder, oil tank, oil pump, and directional valve.

- Mechanism: Utilizes hydraulic pressure generated by pumping hydraulic oil to move the ram up and down, achieving the bending of sheet metal.

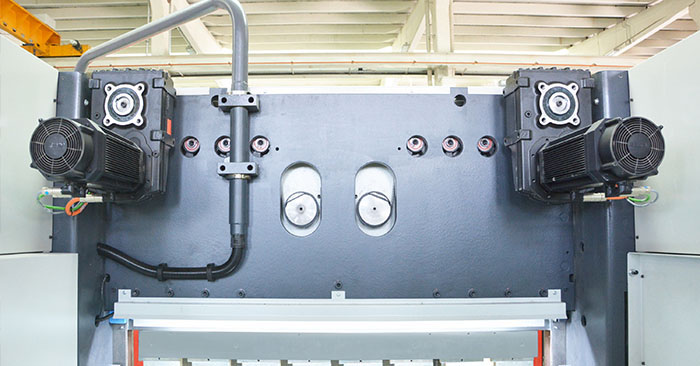

Electric Press Brake:

- Components: Ram, workbench, electric motor transmission mechanisms, cantilever devices, and electronic control systems.

- Mechanism: Driven by an electric motor that moves the ram and workbench through gears and reducers, enabling the bending process.

Working Principles

Hydraulic Press Brake:

- Operates by pumping hydraulic oil into the cylinder, causing the piston to move upwards. This action pushes the ram down and the workbench up, bending the sheet metal.

- Known for its stability and reliability due to the controlled movement of hydraulic oil.

Electric Press Brake:

- Uses an electric motor to drive the transmission mechanism, moving the ram and workbench up and down to bend the sheet metal.

- Provides a simpler and more direct method of operation compared to hydraulic systems.

Performance Differences

Hydraulic Press Brake:

- High Bending Accuracy: Achieves precise bends by controlling parameters such as oil flow rate and piston stroke.

- High Bending Force: Capable of exerting strong pressure and torque, suitable for processing thicker metal sheets.

- Fast Bending Speed: Utilizes hydraulic direct drive for adjustable and rapid bending speeds, ideal for high production volumes.

- Good Stability: The adjustable hydraulic pressure allows for better control over bending angles and accuracy, ensuring consistent results.

Electric Press Brake:

- Simple Operation: User-friendly and does not require highly skilled operators, reducing training and labor costs.

- Automation: Can be programmed for automatic multiple bends, minimizing manual intervention.

- Low Noise: Operates quietly due to the absence of hydraulic oil pumping.

- Easy Maintenance: Features a simpler transmission mechanism with fewer moving parts, leading to easier and less frequent maintenance.

- Energy Efficiency: Consumes less energy, as electricity is only used when the ram is in motion.

- Cost-Effective: Generally less expensive than hydraulic press brakes and well-suited for small to medium-scale production.

Conclusion

Choosing between a hydraulic press brake and an electric press brake depends on your specific needs. Hydraulic Press Brakes are ideal for heavy-duty applications requiring high force and precision, particularly for bending thicker materials. Electric Press Brakes are advantageous for operations seeking energy efficiency, low maintenance, and automation, especially suitable for small to medium-scale production with less intensive bending requirements.

Where To Buy Best Electric Press Brake?

When looking to purchase the best electric press brake, it's crucial to consider both the quality of the machine and the reputation of the manufacturer. Electric press brakes offer numerous advantages, including energy efficiency, low maintenance, and high precision, making them an excellent investment for any metal fabrication operation. One highly recommended brand in the industry is KRRASS.

KRRASS has established itself as a trusted manufacturer of high-quality electric press brakes. Their machines are known for their reliable performance, advanced technology, and user-friendly interfaces. KRRASS electric press brakes feature robust construction, ensuring durability and long-term operation even in demanding production environments. With a focus on innovation, KRRASS provides electric press brakes that incorporate the latest advancements in automation and precision, making them suitable for a wide range of applications from small-scale workshops to large manufacturing facilities.