Handheld Laser Welding Machine

KRRASS Handheld Laser Welding Machine

The handheld laser welding machine adopts fiber laser welding technology, a welding technology that creates a strong joint between several metal components with a fiber laser. This machine welds metal plates and metal tubes. Fiber laser produces a high-intensity beam concentrated into one spot. This concentrated heat source enables fine, deep welding with high welding speed.

High Efficiency

Increased by 2 to 10 times

High Quality

Smooth welding seam, no subsequent grinding needed

Low Cost

Spare at least 2 welders, 80% to 90% power saving

Welding Thickness

- 1kw handheld lasr welder can weld 0.5-2mm steel

- 1.5kw handheld lasr welder can weld 0.5-3mm steel

- 2kw handheld lasr welder can weld 0.5-4mm steel, 0.5-3mm aluminum

The above data is based on the triangular light spot. Due to the plate and labor difference, please refer to the actual welding.

Laser Welding Source Selection

- IPG Fiber Laser Welding - Germany

- MAX Fiber Laser Welding - China

- Raycus Fiber Laser Welding - China

Introduction to Configuration

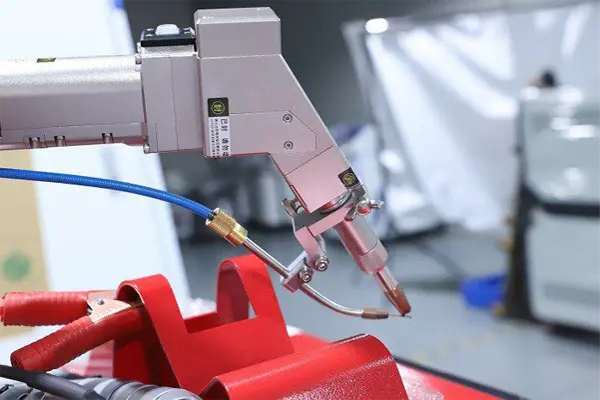

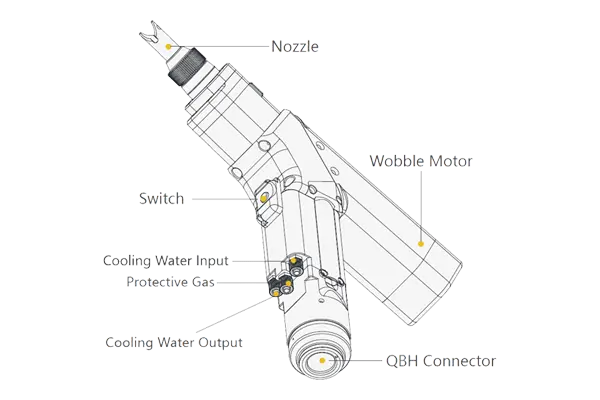

Double pendulum laser welding head can weld aluminum materials

Double wobble weld head technology

The Handheld Laser Welding Machine has a beautiful welding seam, fast speed, no welding marks, no discoloration, and no need for later polishing. It can perfectly replace traditional argon arc welding and electric welding by welding thin stainless steel plates, iron plates, aluminum plates, and other metal materials: lightweight, small size, ergonomic design, and comfortable grip. The operation is easy to start, and the operators’ requirements are shallow. Strong anti-interference.

Infrared Precise Positioning

With the welding head position proofreading and verification function, the welding position is more accurate, and the welding seam is smooth and beautiful.

Control System

The control system comes with a few modes: CW model and PWM model Arc model. The control screen directly digitally sets the parameters of the wire feeder. The system monitors the operating status in real-time and monitors and collects the active quality of the laser, chiller, and control board. Support Chinese, English, Korean, Japanese, Russian, French, Spanish, and Israeli language systems.

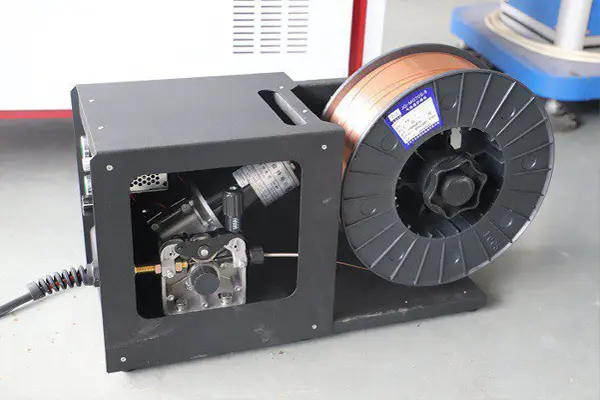

Wire Feeder

The Handheld Fiber Laser Welding Machine of 1000W and 1500W support 0.8mm 1.0mm 1.2mm wire, 2000W support 0.8mm to 1.6mm. Wire send and back speed adjust through the touch panel. If two weld metal gaps are more than 0.2mm, that needs filler wire.

Technical Parameter of Handheld Laser Welding Machine

As the laser welding equipment manufacturer, KRRASS supply 1kw/1.5kw/2kw Handheld Laser Welding Machines for sale.

| Model | Handheld Laser Welding Machine |

|---|---|

| Laser Power(kw) | 1/1.5/2 |

| Welding Speed(mm/s) | ≤120mm/s |

| Welding range(mm) | 0.5~4 carbon steel; 0.5~4stainless steel; 0.5~3 aluminum |

| Fiber Length(m) | Standard 10 |

| Cooling Mode | Water cooling |

| Electromechanical | 380V/50HZ 220V optional |

6 Main Features of Handheld Laser Welding Machine

High Efficiency

Increased by 2 to 10 times, reduce costs and increase efficiency.

High Quality

Smooth welding seam, no subsequent grinding needed.

Low Cost

Spare at least 2 welders 80% to 90% power saving.

Flexible Operation

360-degree flexible movement, every welders can do it well.

Multifunction

6 welding mode with or without wire function as cutter for thin steel.

Multiple languages

Multi-language support to serve global customers

How does a KRRASS Laser Welding Machine Work?

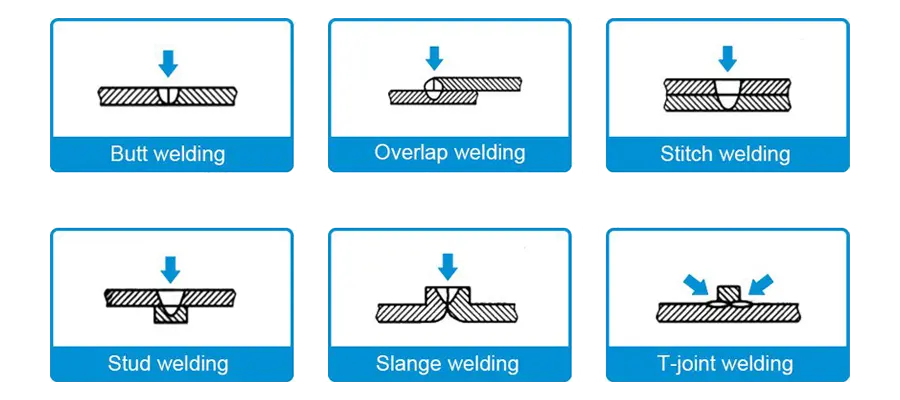

The head of Handheld Fiber Laser Welding Machine is light and portable. It can weld any part of the workpiece, and has various welding methods such as butt welding, stack welding, tailored welding.

Equipment Using Advantages

- Easy to operate for both beginners and professionals to save your labor cost!

With the help of visual touch scree, the machine operation is simple and convenient, which will save your time on personnel trainning and save your budget on operator recruitment. Also, the hand-held fast positioning welding process requires no need to move the workpieces to improve working efficiency. - No deformation and rupture, causing no harm to your materials!

Fast laser welding technique to connect and stick the seams efficienctly, which cause no structure distortion to your design and style! - Clean and hygienic work, make your work environmental-friendly!

Use the laser to melt down the metal so to realize welding, this hand-held laser welding machine works with no smoke, glare and ultra-low noise. And regardlessof the metal size, it can always process well accurately and efficienctly.

| Comparison item | Laser welding | Argon arc welding |

|---|---|---|

| Welding method | Spot welding or continuous | Spot welding |

| Applicable materials | Stainless steel, carbon steel, galvanized sheet,aluminum, etc. | Stainless steel, carbon steel, galvanized sheet |

| Thickness requirements | 0.5—4mm | 1—12mm |

| Workpiece deformation/undercut | Small | Big |

| Welding speed | 0—8m/min | 0—1m/min |

| Subsequent processing | Light or no sanding | Need polishing |

| Operation difficulty | Simple | Complex |

| Safety and environmental protection | Relatively safe and environmentally friendly | Not safe and environmentally friendly |

| Labor costs | General workers (can operate after simple training) | Professional welder |

| Wearing parts | Lens, nozzle | Argon |

| Supplies | Argon/Nitrogen | Argon |

Application

Laser welding can be applied to various materials like titanium, nickel, tin, zinc, copper, aluminum, chromium, niobium, gold, silver, and other metals and their alloys, steel, Kovar, and other alloys. Various dissimilar metals are available, such as copper-nickel, nickel-titanium, titanium-molybdenum, brass-copper, and low-carbon steel-copper. At the same time, the welding machine is widely used in industries of mobile phone communications, electronic components, glasses and watches, jewelry, hardware products, precision equipment, medical equipment, auto parts, craft gifts, and other design areas.

Reviewed by 3 users

The machine is of good quality, fast delivery, high work efficiency, and the welding surface is smooth

The welding machine heats up quickly and maintains a consistent temperature throughout the welding process, resulting in strong and durable welds

Welding machine

This welding machine produces clean and precise welds, and I have been able to complete my projects with ease.