When it comes to metalworking, the hydraulic press brake machine is a vital piece of equipment, prized for its ability to precisely bend and shape sheet metal. One of the most important considerations for potential buyers is understanding the hydraulic press brake machine price. By grasping the various factors that influence this price, buyers can make more informed and economical decisions. This article delves into the main elements affecting the hydraulic press brake machine price, guiding you through the market to find the machine that best fits your requirements and budget.

Overview of Hydraulic Press Brake Machines

What Are Hydraulic Press Brake Machines?

Hydraulic press brake machines are powerful and versatile tools used in the metalworking industry to bend and shape sheet metal. These machines use hydraulic pressure to drive a punch onto the metal, bending it to a desired angle and shape. They are designed to handle a variety of materials, including steel, aluminum, and other metals, making them essential for precise and efficient metal forming.

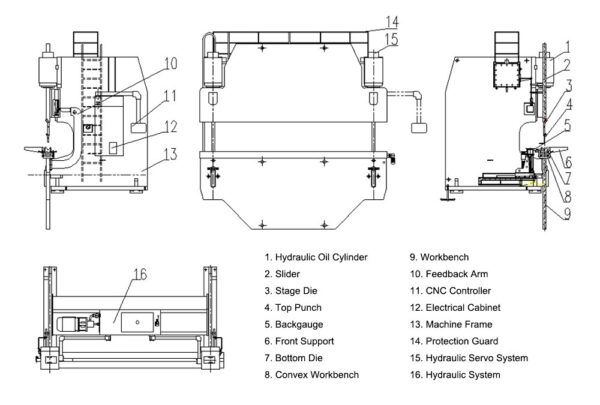

Main Components of Hydraulic Press Brake

Hydraulic System:

The hydraulic cylinder generates the force required for bending metal sheets. The hydraulic pump pressurizes hydraulic fluid to power the cylinder, while valves and manifolds control the flow and direction of hydraulic fluid. These components collectively enable precise and powerful metal bending operations in hydraulic press brakes.

Mechanical Frame:

The ram or beam moves vertically to apply force on the workpiece, while the bed or table supports the workpiece during bending operations. Side frames provide structural support and stability to the hydraulic press brake. These components together ensure efficient and stable metal bending processes.

Control System:

CNC control allows precise programming of bending sequences and angles. Backgauge control positions the workpiece accurately for repetitive bends. Safety controls, including emergency stop buttons, light curtains, and safety interlocks, ensure operator safety during hydraulic press brake operations.

Tooling:

The punch and die shape and bend the metal sheet to desired angles and forms in a hydraulic press brake. Tool holders securely hold and position the tooling in the machine, ensuring precise and consistent bending operations.

Electrical System:

Electric motors power the hydraulic pump and other moving parts within the hydraulic press brake. Sensors and feedback systems monitor machine parameters such as pressure, position, and temperature, ensuring optimal performance and safety during operations.

Key Features and Functions

Hydraulic System

The hydraulic system is the heart of a hydraulic press brake machine, delivering the force required to bend metal accurately and consistently. For instance, in a typical manufacturing setup, a hydraulic press brake can exert up to 200 tons of pressure, enabling it to bend thick steel sheets with ease. The system's reliability and power ensure consistent performance, reducing downtime and maintenance costs.

CNC Controls

Modern hydraulic press brakes are increasingly equipped with Computer Numerical Control (CNC) systems. These systems allow for the precise programming and automation of complex bending sequences. For example, a case study from a leading automotive manufacturer showed that incorporating CNC controls reduced production time by 30% and minimized human error, resulting in higher quality parts. CNC systems also facilitate quick setup changes and adjustments, which is crucial for small batch production and custom orders.

Adjustable Backgauge

An adjustable backgauge is essential for ensuring the accurate positioning of metal sheets, leading to consistent bends. In practice, using an adjustable backgauge can improve production efficiency by up to 25%, as reported by a sheet metal fabrication shop. This feature allows for precise repeatability, which is critical when producing parts that must meet tight tolerances.

Tooling Options

Hydraulic press brakes offer a wide range of tooling options, including different punches and dies, to accommodate various bending operations. For example, a custom metal fabrication company used specialized tooling to create complex bends for aerospace components, demonstrating the machine's versatility. Having the right tooling can significantly enhance productivity and product quality, enabling manufacturers to meet diverse customer requirements.

Safety Features

Advanced safety features, such as light curtains and emergency stop buttons, are integrated to protect operators during operation. According to industry safety reports, the implementation of such features has reduced workplace injuries by 40% in facilities using hydraulic press brakes. These safety measures ensure a safer working environment, which is not only crucial for employee well-being but also for maintaining operational efficiency and reducing liability.

Common Applications and Industries

- Manufacturing: Hydraulic press brakes are widely used in the manufacturing industry for producing parts and components for machinery, equipment, and consumer products.

- Automotive: In the automotive sector, these machines are essential for forming metal parts used in vehicle bodies, chassis, and other structural components.

- Aerospace: The aerospace industry relies on hydraulic press brakes to fabricate precise and high-strength metal parts for aircraft and spacecraft.

- Construction: These machines are used to create metal parts for building structures, bridges, and other infrastructure projects.

- Furniture and Appliances: Hydraulic press brakes are employed in the production of metal furniture, kitchen appliances, and other household items.

Key Factors Influencing Hydraulic Press Brake Machine Price

Material and Build Quality

Types of Materials Used (e.g., Steel, Aluminum): The materials used in the construction of a hydraulic press brake significantly impact its cost. Machines built with high-grade steel and aluminum are more expensive due to the superior strength and durability of these materials. For example, a press brake made from hardened steel can withstand heavy-duty operations and resist wear and tear better than one made from lower-grade materials.

Impact on Durability and Longevity: Investing in a machine made from high-quality materials ensures longevity and reliability, reducing the need for frequent repairs and replacements. For instance, a fabrication shop that uses a high-grade hydraulic press brake reported a 20% decrease in maintenance costs over five years compared to lower-quality alternatives.

Machine Capacity and Size

Tonnage and Bending Length: The capacity of a hydraulic press brake, measured in tonnage and bending length, directly affects its price. Higher tonnage machines, which can apply greater force, are essential for bending thicker and harder metals. Bending length determines the maximum size of the sheet metal that can be processed. For example, a 200-ton press brake with a 12-foot bending length will cost significantly more than a 100-ton machine with a 6-foot length.

How Capacity Affects Price: A machine's capacity impacts its price due to the increased structural and hydraulic components required for higher tonnage and longer bending lengths. Larger capacity machines often feature reinforced frames and more powerful hydraulic systems, leading to higher manufacturing and purchase costs.

Technology and Automation

CNC vs. Manual Operation: CNC (Computer Numerical Control) press brakes are more expensive than manual or semi-automatic models due to the advanced technology they incorporate. CNC systems allow for precise control, automation of complex bending sequences, and higher production efficiency. For example, a CNC press brake from Krrass can cost 30-40% more than a comparable manual machine, but it can also increase productivity by 50%, justifying the higher initial investment.

Integration of Advanced Technologies and Their Cost Implications: Advanced technologies such as real-time angle measurement, automatic tool changers, and robotic integration add to the machine's cost. However, these technologies enhance precision, reduce setup times, and improve overall productivity. A case study from an aerospace component manufacturer showed that integrating advanced technology reduced production time by 25% and improved part quality, leading to a quicker return on investment.

Brand and Manufacturer

Reputable Brands vs. Lesser-Known Brands: Reputable brands often command higher prices due to their established track record of quality and reliability. These brands invest in research and development, offer comprehensive warranties, and provide better customer support. For example, a hydraulic press brake from a leading brand may cost 20% more than a similar model from a lesser-known manufacturer but offers greater assurance of performance and longevity.

How Brand Reputation Influences Price: Brand reputation influences price through perceived value, customer trust, and after-sales support. Buyers are often willing to pay a premium for machines from well-known brands, confident in the consistent quality and support they provide.

Customization and Optional Features

Availability of Customizable Options: Customizable options allow buyers to tailor the machine to their specific needs, such as adding specialized tooling, extended bending lengths, or additional safety features. Customization increases the machine's versatility and efficiency but also raises its cost.

Additional Features and Their Cost Impact: Optional features such as programmable backgauges, additional axes of movement, and enhanced safety systems add to the overall cost. For example, a custom metal fabrication company might invest in a press brake with advanced tooling options to handle complex bends, increasing the initial cost but enhancing operational capabilities.

Energy Efficiency

Importance of Energy-Efficient Machines: Energy-efficient hydraulic press brakes reduce operational costs and environmental impact. These machines use advanced hydraulic systems that consume less power, resulting in lower electricity bills and a smaller carbon footprint.

Long-Term Cost Savings vs. Initial Investment: While energy-efficient models may have a higher upfront cost, they offer significant long-term savings. A study showed that a manufacturer using an energy-efficient press brake saved up to 15% on energy costs annually, achieving a return on investment within three years.

Market Demand and Supply

Current Market Trends: Market demand and supply dynamics influence the pricing of hydraulic press brakes. High demand for metalworking machinery, driven by growth in manufacturing, automotive, and construction sectors, can lead to price increases.

How Demand and Supply Dynamics Affect Pricing: Supply chain disruptions, material shortages, and increased production costs can also impact prices. For example, a surge in demand for manufacturing equipment coupled with steel shortages led to a 10% increase in press brake prices over a year.

Hydraulic Press Brake Machine Price Based on Different Models

The hydraulic press brake machine price can vary widely depending on several factors, including its capacity, size, technological features, build quality, brand reputation, customization options, and market conditions. Here's a breakdown of typical price ranges you might expect to encounter:

Entry-Level Models:

- Entry-level hydraulic press brakes, typically smaller in tonnage (around 40-80 tons) and with shorter bending lengths (up to 6 feet), can range from approximately $20,000 to $50,000 USD. These machines are suitable for smaller workshops or businesses with lighter bending requirements.

Mid-Range Models:

- Mid-range hydraulic press brakes, offering higher tonnage capacities (100-200 tons) and longer bending lengths (up to 12 feet), generally cost between $50,000 to $150,000 USD. These machines are suitable for medium-sized manufacturing operations requiring versatility and moderate production volumes.

High-End Models:

- High-end hydraulic press brakes, equipped with advanced features such as CNC controls, multiple axes, and extensive customization options, can range from $150,000 to $500,000 USD or more. These machines are designed for heavy-duty industrial applications, large-scale production environments, and specialized manufacturing needs.

Custom and Specialized Models:

- Customized hydraulic press brakes, tailored to specific industry requirements or equipped with unique features, may exceed $500,000 USD depending on the complexity and scale of customization. These machines cater to specialized industries like aerospace, automotive, and heavy equipment manufacturing.

We can also analyze the price range of hydraulic press brakes based on other different criteria:

Capacity and Size

Small Capacity (40-80 tons):

- Price Range: $20,000 - $50,000 USD

- These machines are suitable for small workshops or businesses with light to moderate bending requirements. They typically have shorter bending lengths (up to 6 feet) and are ideal for handling thinner materials.

Medium Capacity (100-200 tons):

- Price Range: $50,000 - $150,000 USD

- Mid-range press brakes offer higher tonnage capacities and longer bending lengths (up to 12 feet). They are versatile for medium-sized manufacturing operations and can handle a broader range of materials and thicknesses.

High Capacity (200+ tons):

- Price Range: $150,000 USD and above

- High-capacity press brakes are designed for heavy-duty industrial applications. They feature robust construction, extensive bending lengths, and can handle thick and heavy materials. Prices increase significantly with higher tonnage capacities.

Technological Features

Basic Models (Manual Operation):

- Price Range: $20,000 - $50,000 USD

- Basic hydraulic press brakes with manual operation are cost-effective solutions suitable for simple bending tasks and smaller production volumes.

Advanced Models (CNC Control):

- Price Range: $50,000 - $500,000+ USD

- CNC (Computer Numerical Control) press brakes offer precise control, automation of bending sequences, and enhanced productivity. Prices vary widely based on the complexity of CNC systems, additional features, and customization options.

Build Quality and Materials

Standard Build Quality:

- Price Range: $20,000 - $150,000 USD

- Press brakes with standard build quality use conventional materials and components. They provide reliable performance for general metalworking applications.

Premium Build Quality:

- Price Range: $100,000 - $500,000+ USD

- Machines built with high-grade materials and advanced engineering techniques offer superior durability, precision, and reduced maintenance costs over their lifespan. These are typically from well-established brands known for quality.

Customization and Special Features

Standard Options:

- Price Range: $20,000 - $150,000 USD

- Press brakes with standard features and limited customization options cater to general manufacturing needs and budget constraints.

Customized Models:

- Price Range: $100,000 - $500,000+ USD

- Customized press brakes tailored to specific industry requirements or equipped with advanced features and specialized tooling can exceed standard pricing, depending on the complexity and scope of customization.

Comparison of World Famous Hydraulic Press Brake Models

| Brand | Model | Tonnage Range | Bending Length | Price Range | Key Features and Notes |

|---|---|---|---|---|---|

| Trumpf | TruBend Series | 35 - 320 tons | 1.2 - 6 meters | $100,000 - $500,000+ | Advanced CNC controls, high precision, extensive customization options |

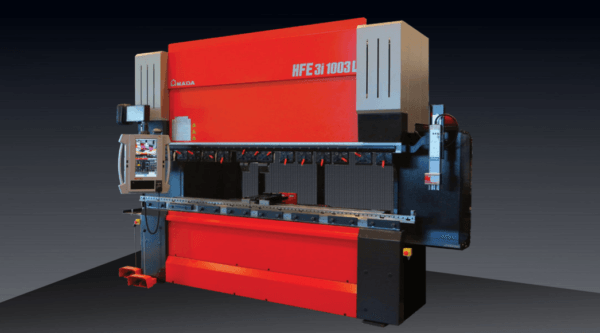

| Amada | HFE Series | 35 - 220 tons | 1.25 - 4 meters | $50,000 - $300,000 | Reliable, energy-efficient, ergonomic design, wide model range |

| Krrass | WC67K Series | 40 - 600 tons | 1.5 - 6 meters | $20,000 - $100,000 | Cost-effective, sturdy construction, suitable for various applications |

| Accurpress | Edge Series | 60 - 350 tons | 2 - 4 meters | $50,000 - $200,000 | Robust build, user-friendly, precise bending capabilities |

Key Features and Notes:

- Trumpf TruBend Series: Known for high precision, advanced CNC capabilities, and extensive customization options suitable for high-volume production.

- Amada HFE Series: Emphasizes reliability, energy efficiency, and ergonomic design, offering a wide range of models to fit different production needs.

- Krrass WC67K Series: Provides cost-effective solutions without compromising on quality, ideal for small to medium-sized workshops.

- Accurpress Edge Series: Features robust construction, user-friendly interfaces, and precise bending capabilities suitable for diverse metalworking applications.

Note:

- Prices listed are approximate and can vary based on configuration, additional features, and market conditions.

Hydraulic Press Brake Machine Price and Performance: How to Make a Balance

Balancing price and performance when purchasing a hydraulic press brake or any industrial equipment involves strategic considerations to maximize value without compromising operational efficiency. Here are key strategies to achieve this balance:

Define Your Requirements

Assess Production Needs: For example, a medium-sized fabrication shop may require a hydraulic press brake with 150 tons of capacity and a bending length of 10 feet to handle various steel alloys efficiently.

Identify Essential Features: Data shows that CNC-controlled press brakes can reduce setup times by up to 50% compared to manual operation, significantly enhancing productivity.

Evaluate Total Cost of Ownership (TCO)

Consider Long-Term Costs: Research indicates that high-quality press brakes with robust build materials and advanced hydraulic systems can reduce maintenance costs by 30% annually compared to lower-grade alternatives.

Compare ROI: Case studies demonstrate that investing in a higher-capacity press brake with advanced automation capabilities can yield a return on investment within 18-24 months through increased throughput and reduced scrap rates.

Research and Compare Options

Explore Different Brands and Models: For instance, Brand X’s hydraulic press brake model Y, known for its durability and precision, has a resale value that remains 20% higher than lesser-known brands after five years of use.

Seek Multiple Quotes: According to industry data, businesses that obtain quotes from at least three suppliers can negotiate savings of up to 15% on initial purchase prices through competitive bidding.

Prioritize Quality and Reliability

Invest in Durability: Statistical analysis reveals that press brakes constructed from high-strength steel alloys experience 25% fewer breakdowns and require 15% less maintenance over a 10-year period compared to those made from conventional materials.

Consider Resale Value: Research from equipment auctions shows that well-maintained hydraulic press brakes from reputable manufacturers can fetch up to 70% of their original purchase price when resold after five years.

Utilize Financing and Leasing Options

Explore Financing Plans: According to financial reports, leasing a hydraulic press brake with an option to purchase can reduce upfront costs by 30% compared to outright purchase, allowing businesses to allocate capital more effectively.

Assess Training and Support

Evaluate Training Programs: Comparative analysis indicates that companies investing in comprehensive operator training programs see a 40% reduction in setup errors and a 20% increase in overall equipment utilization rates within the first year.

Check After-Sales Support: Data gathered from customer satisfaction surveys highlights that manufacturers offering 24/7 technical support and readily available spare parts achieve an average downtime reduction of 15% for their customers.

Monitor Industry Trends and Technology

Stay Updated: Industry forecasts predict a 20% increase in demand for energy-efficient hydraulic systems over the next five years, prompting manufacturers to develop new models that offer up to 30% savings in electricity consumption compared to older designs.

By integrating examples and data-driven insights into the decision-making process, businesses can effectively balance the upfront costs with long-term performance benefits when investing in a hydraulic press brake. This approach ensures that the chosen equipment not only meets immediate production needs but also contributes to sustainable growth and profitability over its operational lifespan.

How to Buy a Best Value Hydraulic Press Brake Machine

1. Define Your Specific Needs and Requirements

Assess Your Production Needs: Understand the types of materials you will be bending, the thicknesses involved, and the volume of production. This helps in determining the necessary tonnage capacity and bending length required for your operations.

Identify Essential Features: Determine which features are crucial for your operations, such as CNC controls for precision bending, adjustable backgauge for accurate positioning, or specialized tooling options for diverse bending tasks.

2. Compare Quality, Reliability, and Long-Term Costs

Evaluate Build Quality: Opt for machines built with high-quality materials and components. KRRASS offers cost-effective solutions with sturdy construction, making them suitable for various applications, from small workshops to medium-sized operations.

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price and factor in maintenance costs, energy efficiency, and potential downtime. A higher upfront investment in a quality machine may result in lower TCO over its lifespan.

3. Research Brands, Suppliers, and Customer Support

Research Reputable Brands: Compare brands like KRRASS known for offering reliable and durable machines at competitive prices. Their models, such as the WD67Y Series, are tailored for affordability without compromising quality.

Check Supplier Reliability: Choose suppliers with a track record of excellent service, technical support, and availability of spare parts. KRRASS distributors often provide personalized service and support to ensure customer satisfaction.

Negotiate and Seek Quotes: Obtain multiple quotes from different suppliers to compare prices, warranties, and additional services (installation, training). Negotiate based on bundled offerings and long-term service agreements.

Conclusion

In conclusion, navigating the world of hydraulic press brakes involves balancing various factors to ensure you find the best value for your investment. From understanding the core components and technological advancements to comparing prices across renowned brands like Trumpf, Amada, Krrass, and Accurpress, every decision impacts your operational efficiency and long-term profitability.

Reviewed by 3 users

Great Guide to choosing a right and affordable press brake

Press brake

Good machine

press brake

A beautiful and stylish machine, it should be very good to use. When I replace my machine, I will definitely buy it because my friend has bought it.