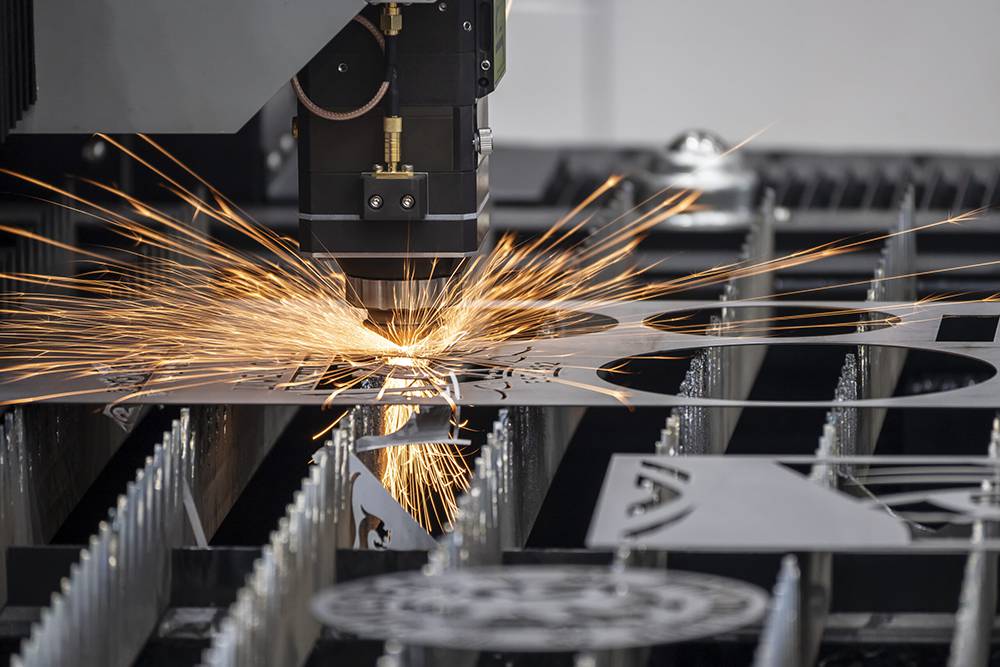

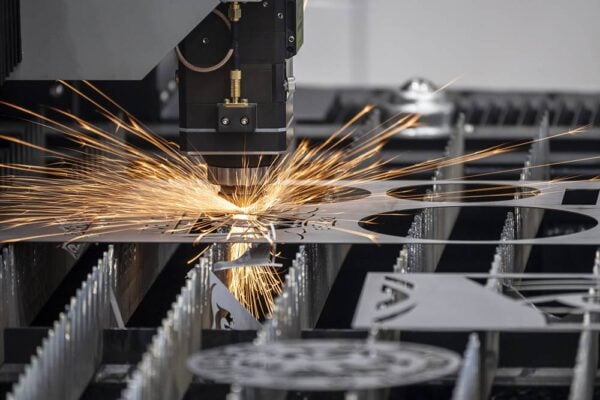

Nowadays, many metal processing companies have begun to replace new processing equipment in order to improve their competitiveness. So, what kind of processing equipment is more suitable for processing companies? Here, the 1000W fiber laser cutting machine is definitely a device that cannot be missed! Why do you say that? Let us introduce to you the capabilities of the 1000W fiber laser cutting machine.

Advantages of 1000W Fiber Laser

Laser cutting technology has been used in sheet metal processing for a long time. What are the advantages of fiber laser cutting machine as a rising star?

Excellent cutting performance. Because the fiber laser cutting machine has excellent beam quality, small spot, and continuous light output, the cutting quality effect is better than the previous two generations of laser equipment, and the cutting speed is more than twice the power of the same CO2 laser cutting machine.

Low processing cost. The photoelectric conversion rate of the fiber laser cutting machine can reach about 30%, which is 3 times that of the CO2 laser cutting machine and 10 times that of the YAG solid laser cutting machine. The power consumption is only 20-30% of the CO2 laser cutting machine. And the maintenance cost is low, no reflective lens is required, and the loss of consumables is much less than YAG.

Long service life. The fiber laser cutting machine uses imported lasers, which are very stable in performance and have a service life of up to 10W hours, which is much longer than the previous two generations.

For a 1000W fiber laser cutting machine, it is no problem to cut stainless steel, carbon steel, iron plate, galvanized plate, copper and aluminum and other materials. The thickest carbon steel that can be cut is 12mm, and the stainless steel is 8mm. It can meet all metal categories and some processing thicknesses covered by processing companies! Therefore, to meet the processing needs, a 1000W fiber laser cutting machine is enough!

Parameters of 1000W Fiber Laser

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

File from provided URL is empty.

Maximum Cutting Thickness of a 1000W Fiber Laser Cutting Machine

If it is simply calculated in accordance with the theoretical situation, the fiber laser cutting machine can cut an extra 1mm thickness of sheet metal for every additional 100w of power. But this is not the case. Let’s take a 500w fiber laser cutting machine as an example. It can cut 5mm sheet metal. But when the equipment is in operation, electrical energy is converted into light energy and then converted into heat energy, there will be a certain amount of energy loss, so the actual cutting thickness value is not a theoretical value.

1. The thickness of the sheet metal cut by the 500W fiber laser cutting machine: the maximum thickness of aluminum plate is 2mm; the maximum thickness of copper plate is 2mm; the maximum thickness of stainless steel is 3mm; the maximum thickness of carbon steel is 6mm;

2. The thickness of the sheet metal cut by the 1000W fiber laser cutting machine: the maximum thickness of aluminum plate is 3mm; the maximum thickness of copper plate is 3mm; the maximum thickness of stainless steel is 5mm; the maximum thickness of carbon steel is 10mm;

3. The thickness of the sheet metal cut by the 2000W fiber laser cutting machine: the maximum thickness of aluminum plate is 5mm; the maximum thickness of copper plate is 5mm; the maximum thickness of carbon steel is 16mm; the maximum thickness of stainless steel is 8mm;

4. 3000W fiber laser cutting machine cutting sheet metal thickness: aluminum plate maximum thickness 8mm; copper plate maximum thickness 8mm; stainless steel maximum thickness 10mm; carbon steel maximum thickness 20mm;

Applications of 1000W Fiber Laser

1000W fiber laser cutting machine is used to cut many kinds of metal signs, such as stainless steel, carbon steel, aluminum, copper, brass, gold, and silver.

1000W fiber laser cutting machine is mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and other metal materials.

1000W fiber laser cutting machine applied industries: sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing, various manufacturing processing industries.

How to Choose Right Power Fiber Laser Cutting Machine?

There are some considerations for you to select the right laser cutting strength.

First, select according to the processing material and cutting thickness

Laser has different effects on different metal materials. The laser power varies depending on the metal material. For example, under the same thickness, the laser power for cutting carbon steel is lower than that of stainless steel, and the laser power for cutting stainless steel is lower than that of yellow. Copper power is small. In addition to the properties of the metal itself, the thickness is also closely related to the laser power. For the same metal pipe, the cutting power of 10mm is lower than that of 20mm.

Secondly, choose according to the finish of the cut surface

Whether there are burrs on the laser cutting surface is mainly related to the cutting thickness and the gas used. There is no burr when cutting below 3mm. Nitrogen is the best gas, followed by oxygen, and the air is the worst. The metal laser cutting machine has few or no burrs, the cutting surface is very smooth, the speed is relatively fast, and the material deformation is relatively small.

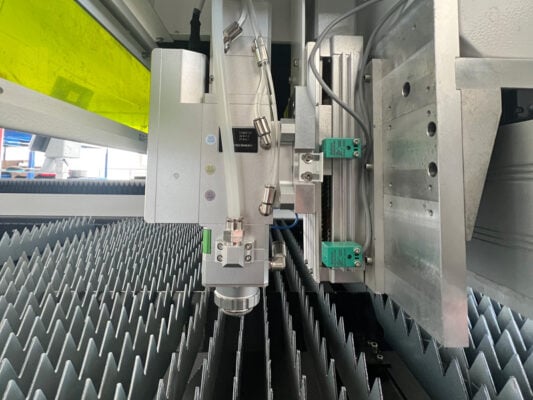

Third, Selection of core components for laser cutting

The laser and laser head are imported or domestically produced. Imported lasers generally use IPG, and domestic lasers generally use Raycus. At the same time, pay attention to other parts of laser cutting, such as whether the motor is an imported servo motor, guide rail, bed, etc., because they affect the cutting accuracy of the machine to a certain extent.

Fourth, power selection

There are many mainstream laser pipe cutting machines on the market, ranging from 1000W to 20000W. The thickness of the pipes of most manufacturers is between 8mm-12mm. If cutting this thickness for a long time, it is recommended to choose a 4000W-6000W laser pipe cutting machine. If it is brass with high reflection characteristics, it is recommended to use a laser pipe cutting machine with a power of 8000W or more. 2000W-4000W laser pipe cutting machine is recommended for the thickness of 5mm-8mm. A lower thickness of 1000W is usually sufficient. It should be noted that if you buy a 6000W laser pipe cutting machine, you can reduce the output magnification and adjust it to 2000W for cutting when cutting small thickness materials of about 4mm, which saves energy and saves electricity and costs.

Conclusion

In conclusion, a 1000W fiber laser cutting machine offers remarkable cutting capabilities and precise parameters that are essential for a variety of industrial applications. This machine is particularly suited for cutting thin to medium-thickness materials with high speed and accuracy, ensuring high-quality finishes and minimal material waste. By leveraging advanced technology and robust design, these machines provide significant operational efficiencies and cost savings.

Krrass, a renowned brand in the metalworking industry, stands out with its exceptional range of fiber laser cutting machines. Their 1000W fiber lasers are engineered to meet diverse manufacturing needs, offering unparalleled performance, reliability, and ease of use. Investing in a Krrass fiber laser cutting machine means investing in cutting-edge technology and exceptional customer support, ensuring your business stays ahead in the competitive landscape.