320Ton Press Brake Machine for Sale, MB8-320T4000 DA53T 4+1 Sheet Metal Press Brake price

$45,050.00 Original price was: $45,050.00.$41,550.00Current price is: $41,550.00.

Model: MB8-320T4000

Axis: 3+1 Axis

Category: CNC Press Brake

Brand Name: KRRASS

Bending Pressure: 4000KN

Bending Length: 3200mm

Controller: DELEM DA-53T

HS Code: 8462299000

Application: CNC Press Brake Press Brake Machine Price MB8-320T3200 3+1 Axis With DELEM DA53T controller

Technologyies

| Bending Pressure: | 3200KN |

| Bending Length: | 4000mm |

| CNC Control Axes: | Y1+Y2+X+W Crowning |

| Main Motor: | 22KW |

| Operating Voltage: | 380V/220V 50HZ/60Hz |

| CNC System: | DA-53T |

| Length* Width* Height: | 4500mm * 1700mm * 3350mm |

Configurations

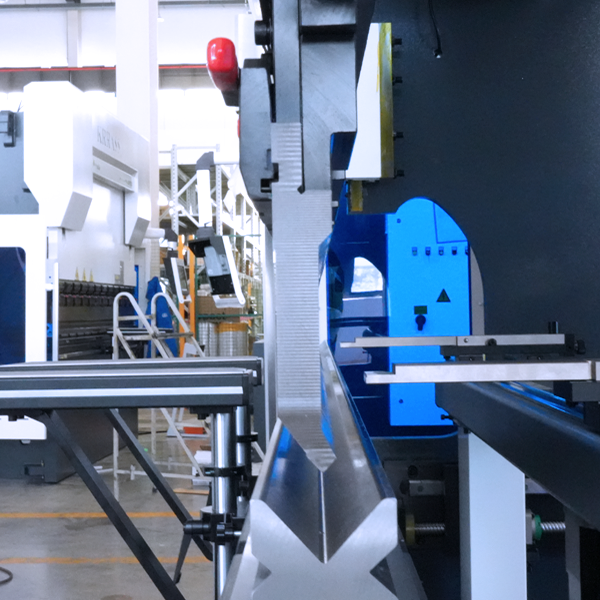

Main Feature

320Ton Press Brake Machine for Sale with DA-53T Controller with its easy-to-use control unit, rigid body frame, flawless design, high efficiency, multiple tool usage solutions, top CE safety standards, and a suitable price range make it the best-in-class world leader. It is ideal for bend-sensitive, energy-efficient solutions.

- Simple and solid Hydraulic Press Brake

- Work area can be customized and all types of tool clamping can be installed

- Tailored-made Hydraulic Press Brake

DELEM DA-53T Control

- 10.1″ high resolution colour TFT

- “Hot-key” touch navigation

- Up to 4 axes (Y1,Y2 + 2 aux. axes)

- Tool / material / product library

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- CNC Crowning control

- USB memory stick interfacing

- Profile-53TL offline software

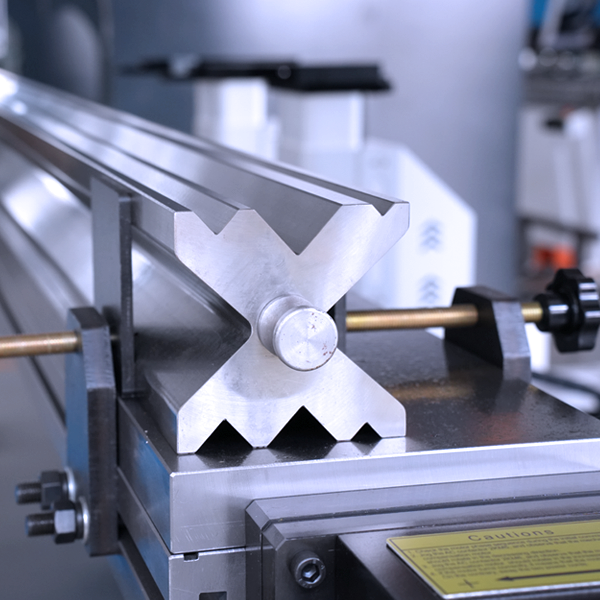

Electric Crowning System

- Very precise bending angles

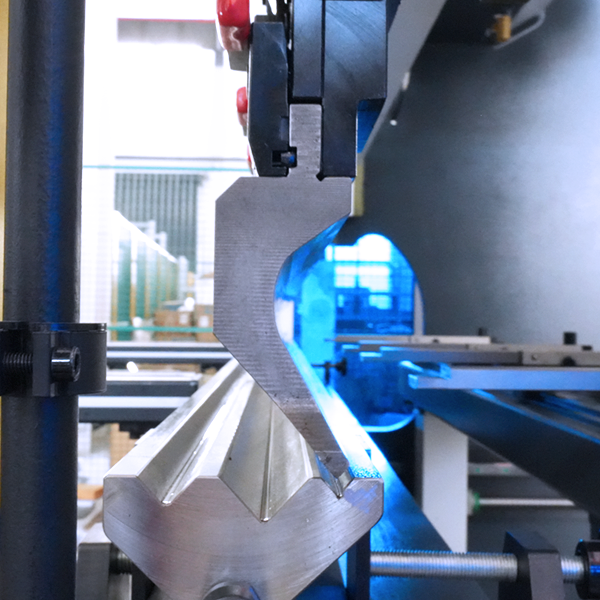

- Europe type dies with 60 mm and 90 mm

- Base can be clamped as well as single dies with 13 mm tang

- Electric crowning with a controller

- Precise positioning and alignment of the crowning table

- Easy and fast usage

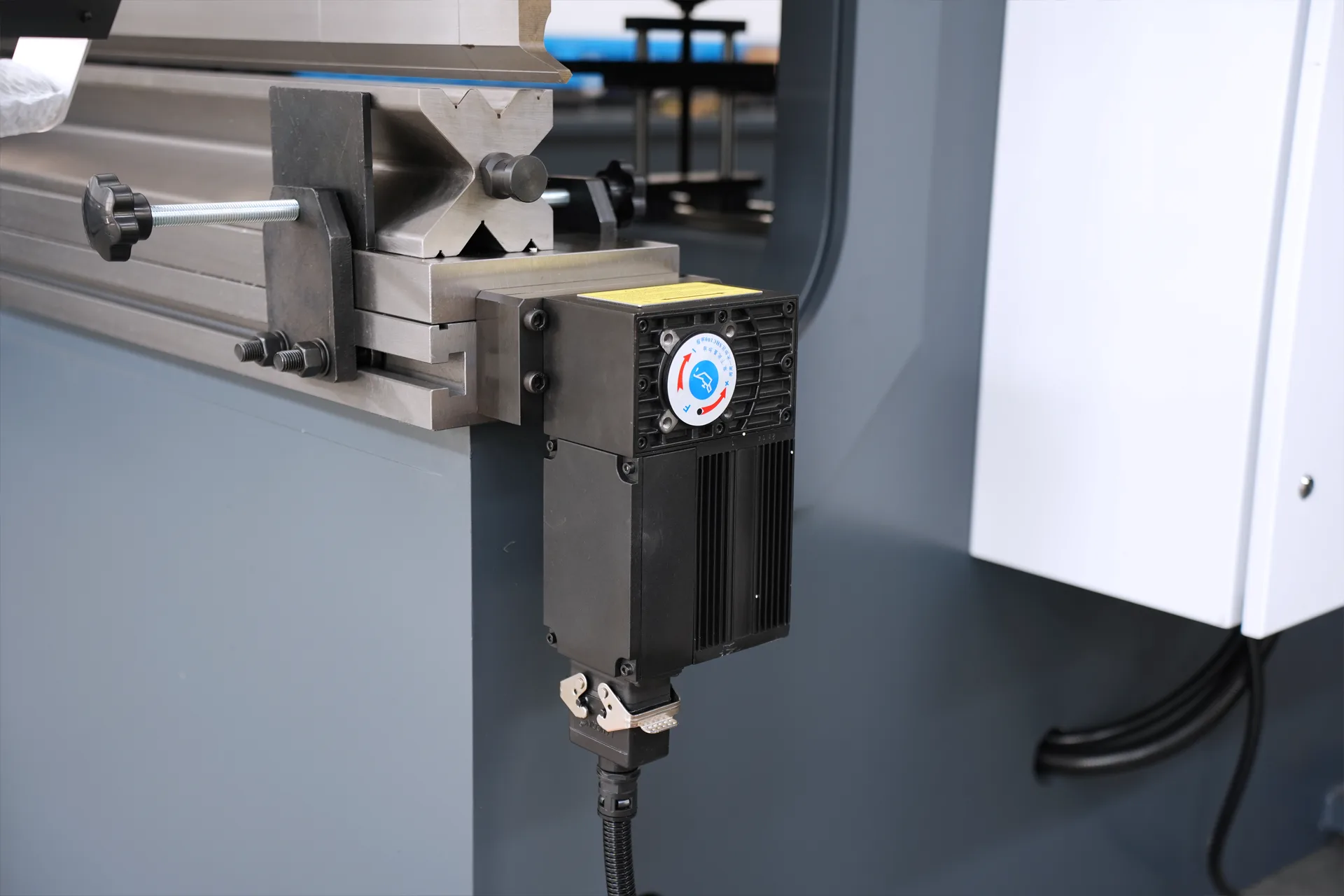

Fagor Grating Ruler

Slider position signal is feedbacked to controller by Spain FAGOR Grating ruler , then the CNC controller adjusts the amount of fuel tank by changing the synchronous valve opening size.

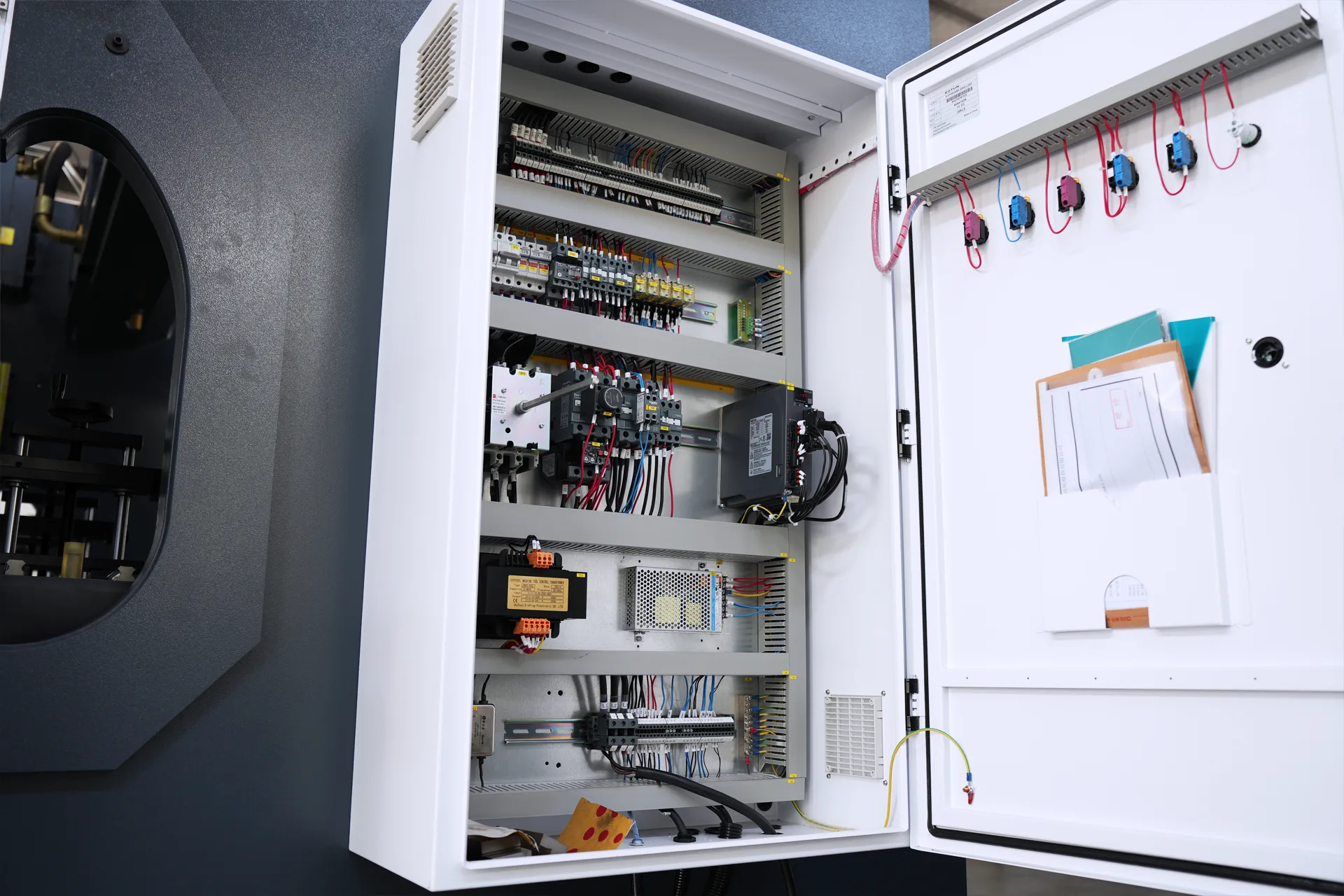

Schneider Electric

High quality electric parts can perform well even the electricity is not stable and customers can easily get the replacement anywhere in the word.

X-axis Servo Motor

In addition, the advantages of servo motors include:

- High reliability: Highly reliable

- High ratio of torque to inertia: Can provide as much as 50% more torque in many applications

- High precision: Can precisely actuate, hold, and speed up positions, torque, and speeds in fractions of seconds

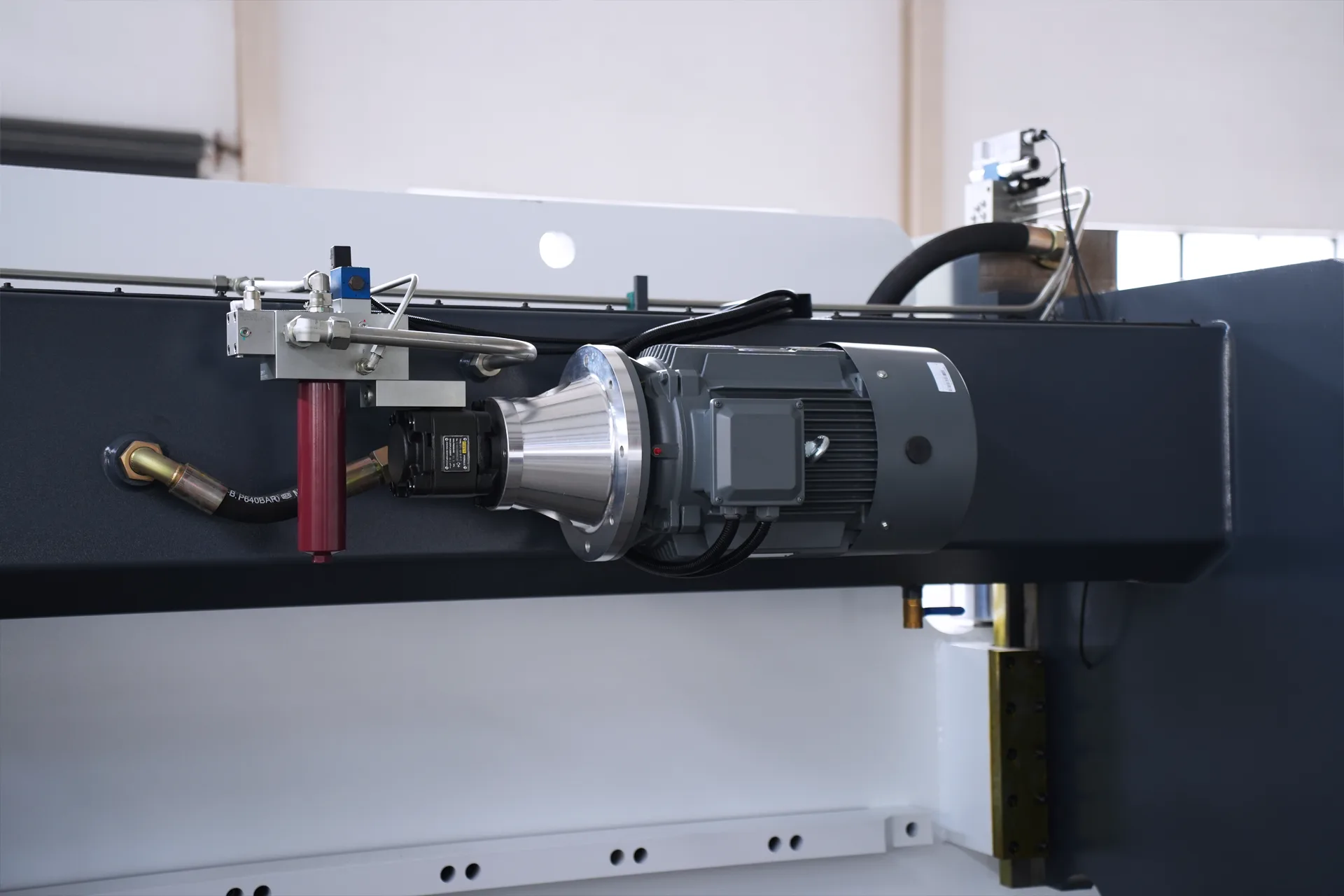

German Siemens Main Motor

The German famous brand motor increases the service life of the machine and keeps the machine working in a low-noise environment.

Rexroth Proportional Valve

The German Rexroth fully closed-loop electro-hydraulic servo high-frequency synchronous control system is adopted to ensure that the machine tool has high stability and high precision in the process of high-speed operation.

Liftable Backgauge

High-precision backstop means that customers can input the size into the system according to the product’s dimensions, and it can be positioned accurately with an accuracy of 0.01mm.

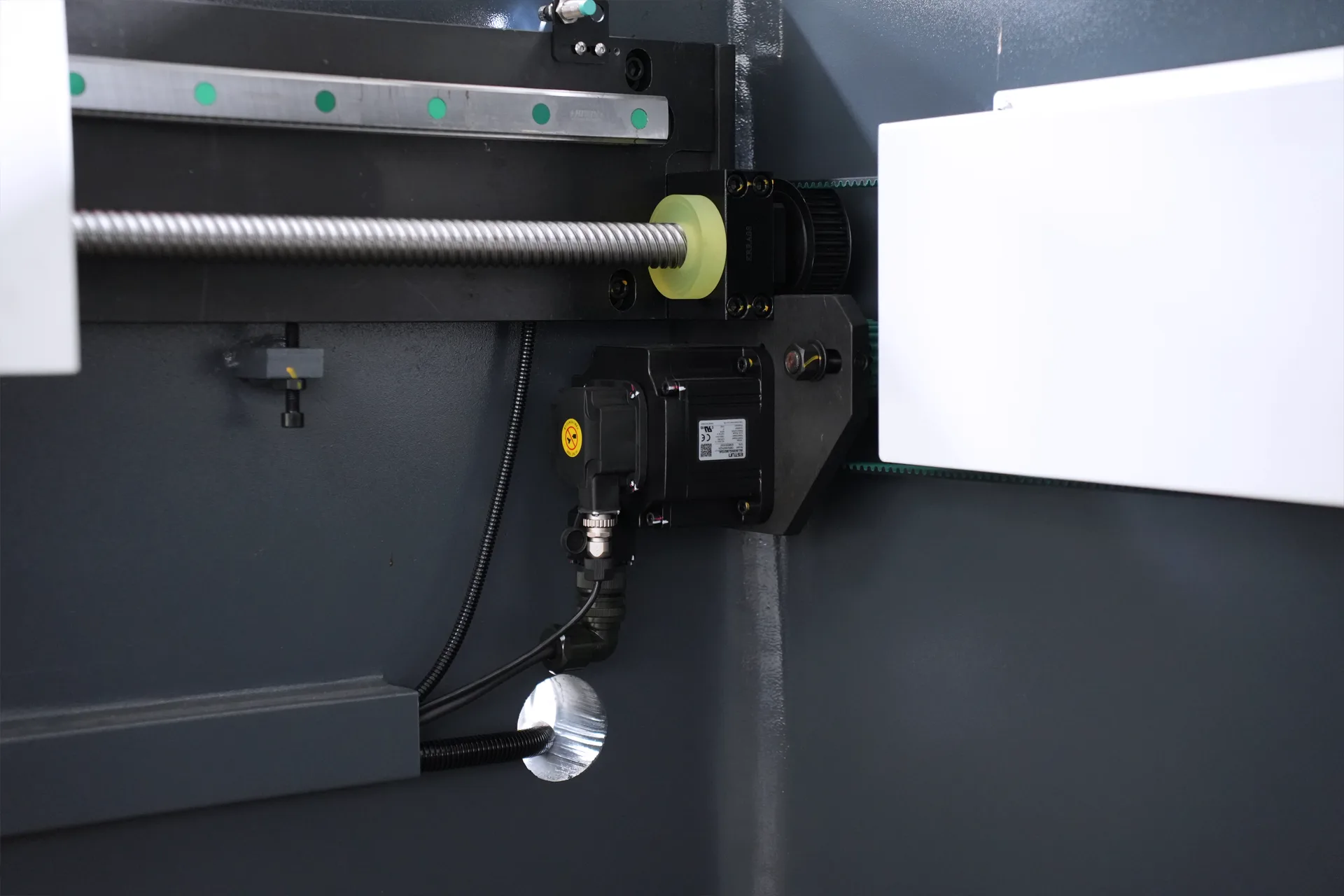

X-axis Guide Rail and Lead Screw

- Hiwin Ball screws and linear guide on X, R-axis

- Axis X speed 500 mm/s

- The backgauge can be manually adjusted for R-axis height

- Mechanical accuracy ± 0.01 mm

- Fingers with double stop and micrometric adjustment

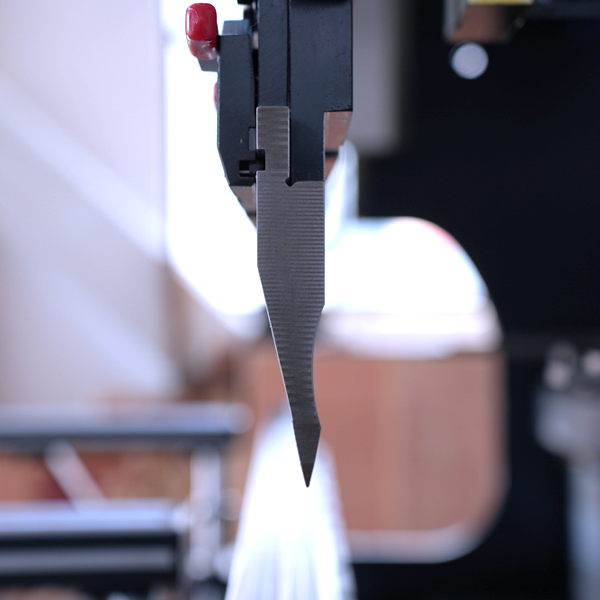

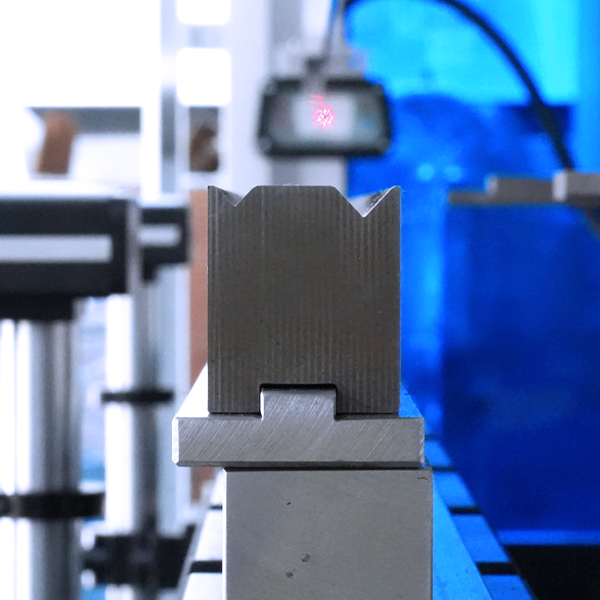

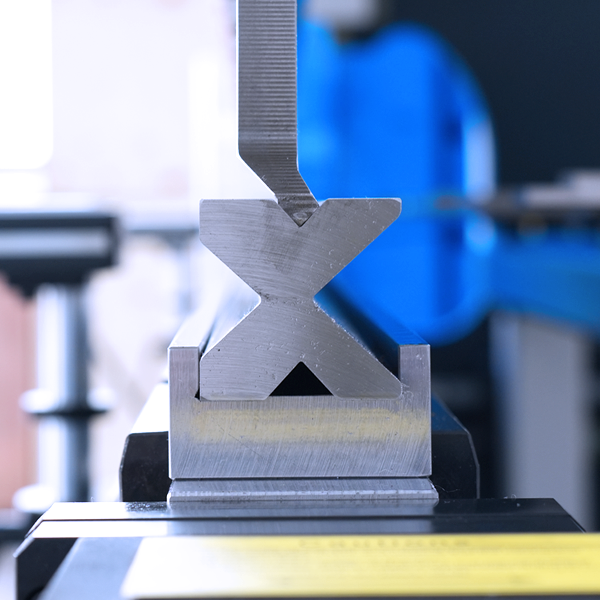

High-precision Quick Mold Change Device

The upper mold is divided into different gold sizes and can also be cut according to customer requirements.

The lower mold adopts a Single-V concentric mold, which can adapt to customers’ bending of materials with different thicknesses. The mold can also be modified according to customer requirements. To meet the best needs of customers.

Front Material Support

The front support can be raised and lowered and rotated. When you want to bend larger metal sheets, it can effectively help you and reduce your burden.

South Korea KACON Foot Switch

South Korea brand foot switch is movableand can stop the machine anytime by theemergency button.

Back Of The Fuselage

The whole machine has a clean and neat structure design, regular lines and is easy to operate, making it an ideal choice for bending metal sheets.

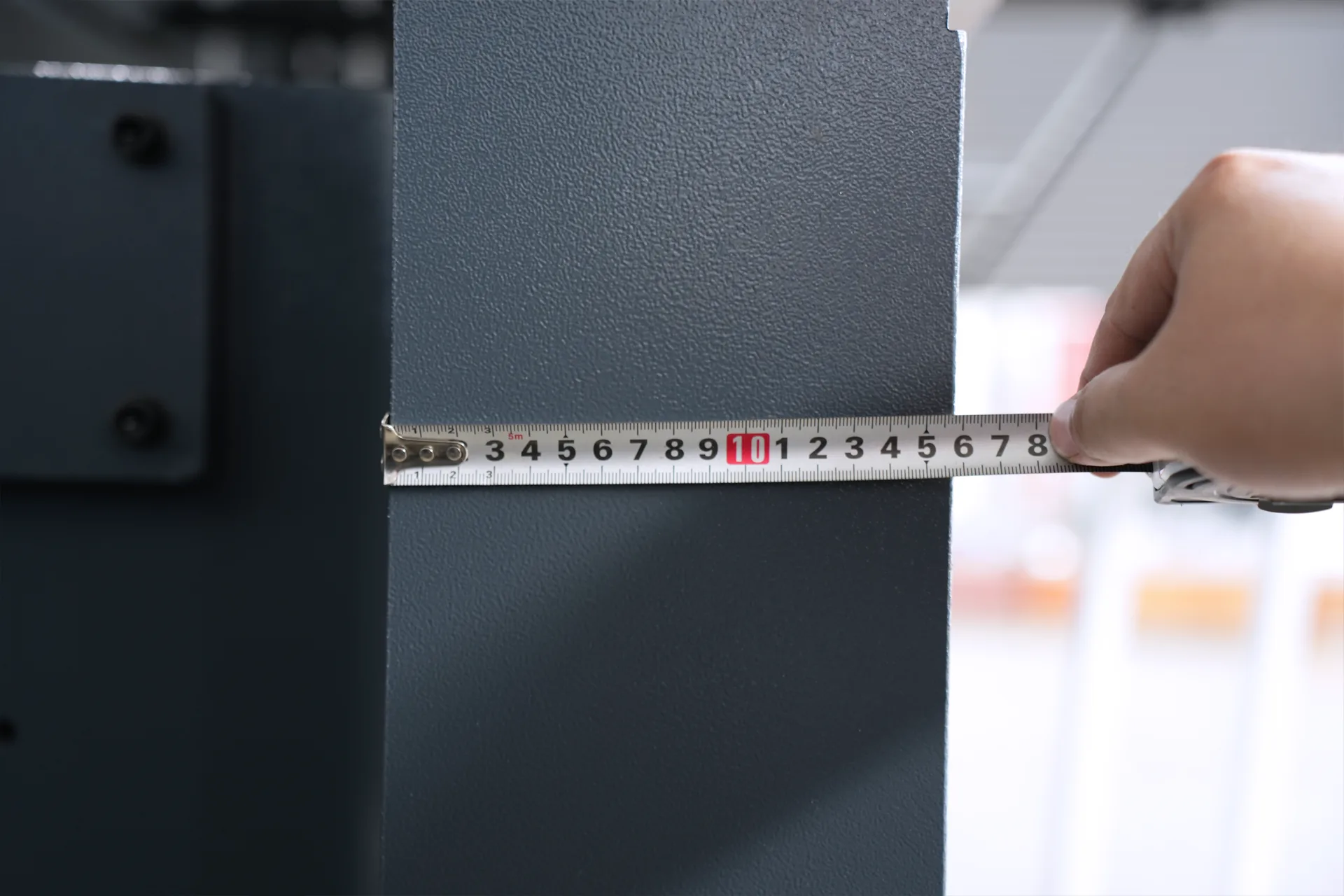

Thickness of workbench (160mm)

Thickness of side panel (80mm)

Thickness of slider (80mm)

Tooling (Optional)

Standard tooling

Non-Standard tooling

Gooseneck tooling

Double-V Concentric Mold

Four-V Concentric Mold

Multi-V Mold

Warranty

30-DAY MONEY BACK GUARANTEE

You should feel completely satisfied with your KRRASS Press Brake purchase, and your peace of mind is a significant part of that process. We want you to feel the same confidence in your new KRRASS machine that we do, which is why every Press Brake purchase includes our Hassle-Free KRRASS 30-Day Return option in order to fully experience and evaluate their new KRRASS machine. It allows you to return or exchange your KRRASS purchase, for any reason, within 30 days of initial purchase. Refunds are simple and are issued once the original machine and all accompanying accessories have been returned. The refund or exchange will be issued minus the 15% restocking fee for items & accessories, 25% KRRASS Press Brake Machine Series customization fee, and shipping or handling costs are not included. Click here for details

2-YEAR LIMITED MACHINE WARRANTY

2 years Bumper to Bumper machine warranty for all machine mechanical and electrical components. (Except consumables parts) The Company represents and warrants that the KRRASS All Series of products will perform according to the warranty policy stated above from date of invoice. Products will be free from defects in materials and workmanship under normal use and service for the stated period. KRRASS has the responsibility to offer a timely solution and/or repair if deemed inoperable or defective by KRRASS Repair & Support Specialists. Clients are obligated to show proof of any such claims of machine parts or operational defects. Click here for details

Related products

Related products

-

Sale!

Sale!

210Ton Press Brake Machine for Sale, 4 Meter Hydraulic Metal Brake

5.00 out of 5$35,299.00Original price was: $35,299.00.$32,699.00Current price is: $32,699.00. Add to cart -

Sale!

Sale!

135Ton Hybrid Press Brake for Sale, PBE-135T3200 DA69T 8+1 Hybrid Press Brake Machine

5.00 out of 5$80,800.00Original price was: $80,800.00.$76,300.00Current price is: $76,300.00. Add to cart -

Sale!

Sale!

2025 New Hybrid CNC Press Brake, 175Ton Sheet Metal Press Brake, DELEM DA58T 2D Controller

5.00 out of 5$32,999.00Original price was: $32,999.00.$30,299.00Current price is: $30,299.00. Add to cart -

Sale!

Sale!

250Ton Hybrid Press Brake for Sale, PBE-250T4000 DA53T 4+1 Hybrid Press Brake Machine

0 out of 5$44,100.00Original price was: $44,100.00.$40,900.00Current price is: $40,900.00. Add to cart

Leave feedback about this