The adoption of high-power, large-torque servo motors and drive technology has led to the increasing use of electric servo drive systems in CNC bending machines. While pure electric servo systems are emerging, hydraulic bending machines remain dominant in the sheet metal industry due to their mature technology and efficiency. This article highlights the advantages of hydraulic bending machines in terms of energy efficiency, environmental impact, production efficiency, bending accuracy, and maintenance costs.

1. Energy Efficiency

Modern hydraulic bending machines are designed to minimize energy consumption by utilizing variable displacement pumps and advanced control systems that only draw power when needed.

In comparison, pure electric servo systems consume power in proportion to the load, drawing more energy during bending operations and less when idle. However, the hydraulic system continuously runs even when the machine is not bending. Hydraulic bending machines, while not as efficient as electric systems, still offer reliability and cost-effectiveness.

For example, a 100-ton hydraulic bending machine consumes about 60 kW per day, while a pure electric servo machine consumes approximately 12 kW. Despite this, hydraulic systems are still preferred for their long-standing reliability.

2. Environmentally Friendly

Hydraulic bending machines have made significant strides in reducing their environmental impact. While pure electric machines eliminate the need for hydraulic oil and its associated maintenance, hydraulic systems now feature improved designs that minimize leaks and waste.

3. Increased Production Efficiency

Hydraulic bending machines offer high production efficiency, with fast response times and high-speed operation. While servo systems can reach faster speeds, hydraulic machines are highly reliable, even in environments with fluctuating temperatures.

A 100-ton hydraulic bending machine, for example, achieves backstroke speeds up to 120 mm/s, while a pure electric system can reach up to 200 mm/s. Despite the speed difference, hydraulic systems offer stability and consistency.

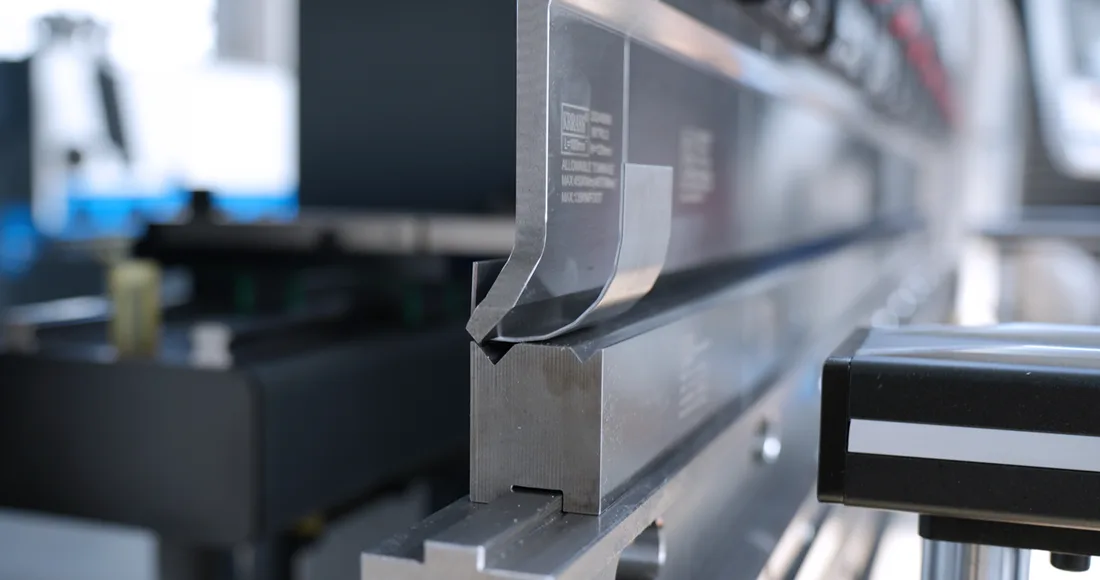

4. Bending Accuracy

Hydraulic bending machines are capable of achieving high bending precision, with angle errors typically within 1 degree. While electric servo machines can achieve finer precision, hydraulic systems are equipped with advanced compensation systems that ensure consistent accuracy over time.

5. Low Maintenance Costs

Hydraulic machines require regular maintenance, such as oil changes and component inspections. However, advancements in hydraulic technology have improved durability and reduced maintenance frequency. Although electric servo systems have lower maintenance requirements, hydraulic machines remain a cost-effective solution for many manufacturers.

6. Safety Features

Hydraulic bending machines are equipped with essential safety features to protect operators. These include light curtains, safety guards, and emergency stop buttons, ensuring the machine halts instantly in case of an emergency.

- Light Curtains: Invisible safety barriers stop the machine when interrupted.

- Safety Guards: Physical barriers prevent accidental contact with moving parts.

- Two-Hand Control: Requires both hands to activate, keeping operators safe.

- Foot Pedal with Guard: Prevents accidental activation.

- Hydraulic Overload Protection: Prevents excessive force from damaging the machine.