Selecting the correct power level for a fiber laser cutting machine is key to achieving both high performance and cost-effectiveness. The laser’s power influences critical factors, including cutting speed, material thickness, and compatible materials. Here’s a comprehensive guide to help you make an informed decision.

What is a Fiber Laser Cutting Machine?

A fiber laser cutting machine is an advanced industrial tool designed for cutting various materials with exceptional precision and efficiency using a fiber laser.

Fiber Laser:

- Definition: A fiber laser operates with an optical fiber core, which is infused with rare-earth elements like erbium, ytterbium, or neodymium to amplify light energy.

- Beam Delivery: The laser beam is generated and delivered through flexible fiber optics directly to the cutting head, ensuring stability, flexibility, and reliability.

Cutting Machine:

- Structure: The laser cutting machine comprises a laser source, a precision cutting head, a CNC (Computer Numerical Control) system, a bed to support the material, and typically a cooling system.

- Function: By focusing a high-powered laser beam on the workpiece, the machine melts, burns, or vaporizes the material, allowing precise and efficient cuts.

Understand Your Cutting Needs

Understanding your cutting needs is essential in selecting the right fiber laser cutter for your projects, especially in metal fabrication. Here are key considerations to help you determine your requirements:

- Types of Materials

- Metal Type: Identify the metals you’ll be working with, such as steel, aluminum, or copper.

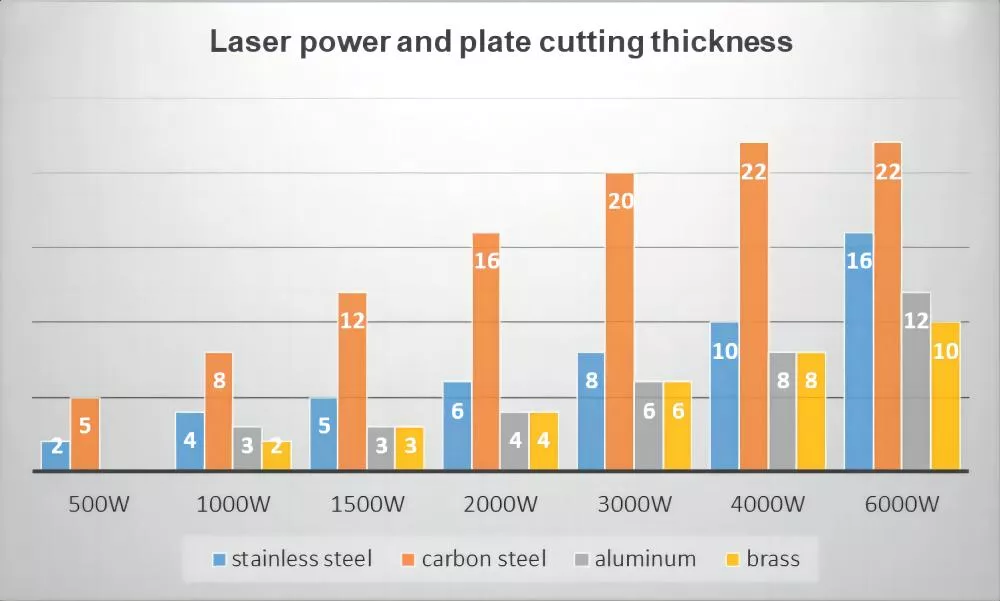

- Thickness: Determine the thickness range of your materials. Lower power (500W–1000W) works well for thin metals like aluminum, copper, and stainless steel, while higher power (2000W+) is required for thicker materials like heavy stainless steel, carbon steel, and other robust metals.

- Cutting Precision

- Tolerance Levels: Define the level of precision needed for your projects. High-precision tasks often demand advanced CNC capabilities.

- Edge Quality: Assess the importance of achieving smooth, clean edges for your applications.

- Volume of Work

- Production Volume: Consider the volume of cutting required. High-volume work benefits from fast, automated machines.

- Batch Size: Smaller batches provide flexibility, while large batches demand consistent, efficient cutting processes.

- Type of Cutting

- Straight Cuts: Ideal for shearing machines or guillotines.

- Complex Shapes: Laser cutters or CNC plasma machines are best for intricate shapes and patterns.

- Speed and Efficiency

- Cutting Speed: Assess your required speed. Faster machines enhance productivity but may come at a higher investment.

- Setup Time: Consider setup and adjustment times for different projects.

- Machine Features

- Automation: Seek features like automatic material feeding, CNC controls, and automated cutting sequences for ease of operation.

- Versatility: Some machines offer multifunctional capabilities—cutting, punching, and bending—adding greater value to your operations.

Power Ranges and Their Applications

Choosing the correct power range for a fiber laser cutting machine is essential to meet your specific cutting needs effectively. Here’s an overview of different power ranges and their typical applications:

Low-Power Fiber Laser Cutting Machines

- Power Range: Up to 500W

- Applications:

- Thin Metal Sheets: Ideal for cutting thin metal sheets like aluminum and steel.

- Intricate Designs: Suitable for detailed, precise cuts in small-scale projects.

- Prototyping: Commonly used in creating prototypes and custom designs.

- Artistic Projects: Popular in jewelry making, decorative items, and crafts.

Medium-Power Fiber Laser Cutting Machines

- Power Range: 500W to 2000W

- Applications:

- General Fabrication: Perfect for small to medium workshops handling general metal fabrication.

- Automotive Parts: Suitable for cutting components for automotive applications.

- Construction Materials: Useful for cutting materials like beams and metal sheets for construction.

- Furniture Manufacturing: Ideal for creating metal parts for furniture and fixtures.

High-Power Fiber Laser Cutting Machines

- Power Range: 2000W to 6000W

- Applications:

- Heavy-Duty Fabrication: Used in high-demand metal fabrication industries.

- Thick Metal Cutting: Capable of cutting thicker metals, such as stainless steel and carbon steel.

- Shipbuilding: Essential for cutting large metal components in shipbuilding.

- Aerospace Components: Used for high-precision, high-strength parts in aerospace manufacturing.

Ultra-High-Power Fiber Laser Cutting Machines

- Power Range: Above 6000W

- Applications:

- Industrial Manufacturing: Suited for large-scale industrial manufacturing processes.

- Heavy Equipment Manufacturing: Ideal for creating parts for heavy machinery.

- Structural Steel Fabrication: Perfect for fabricating structural steel components for buildings and infrastructure.

- Energy Sector: Used for cutting large metal components in energy projects, including oil rigs and wind turbines.

Evaluate Production Volume

Assessing production volume helps ensure you select machinery that aligns with current demands and future growth. Here’s a breakdown of how to evaluate production requirements effectively:

- Understand Current Production Needs

- Daily/Weekly/Monthly Output: Calculate the average number of units produced over set periods to gauge baseline demand.

- Order Sizes: Review typical order sizes and frequency to understand the consistency of demand.

- Project Future Growth

- Sales Projections: Use historical sales data and market trends to forecast upcoming sales.

- Expansion Plans: Factor in potential expansions or new product lines to anticipate growth needs.

- Analyze Production Capacity

- Machine Capacity: Assess the maximum capacity of your machines in units per hour or shift to understand their potential output.

- Utilization Rates: Calculate the actual utilization rate by comparing operating hours with available hours.

- Assess Workflow Efficiency

- Cycle Times: Measure the time taken for each production step to identify efficiency levels.

- Bottlenecks: Pinpoint any bottlenecks slowing production and explore solutions.

- Downtime: Track machine downtime, noting causes such as maintenance or changeovers.

- Calculate Required Capacity

- Peak Demand: Plan for peak periods, ensuring your machinery can meet high volumes without sacrificing quality.

- Buffer Capacity: Include a buffer to handle unexpected demand spikes or production issues.

- Consider Machine Flexibility

- Adaptability: Opt for machines that can handle varying products and volumes.

- Scalability: Choose machinery that supports growth, minimizing the need for frequent upgrades.

| Factor | Evaluation Criteria |

|---|---|

| Current Production | Daily/weekly/monthly output |

| Future Growth | Sales projections, expansion plans |

| Machine Capacity | Maximum units per hour/shift, utilization rates |

| Workflow Efficiency | Cycle times, bottlenecks, downtime |

| Required Capacity | Peak demand, buffer capacity |

| Machine Flexibility | Adaptability, scalability |

| Financial Analysis | Cost per unit, investment costs |

| Technology | Automation, CNC controls |

| Labor and Staffing | Workforce availability, training programs |

| Real-world Examples | Case studies, industry benchmarks |

Final Considerations

When choosing a fiber laser cutting machine, it’s essential to consider budget, future needs, and manufacturer support to ensure a wise investment.

- Budget Considerations

- High-power lasers provide superior cutting capabilities but come with a higher cost. Assess your budget and weigh the return on investment (ROI). If your business requires high precision and speed, a high-power laser may be worth the investment. For smaller operations or less intensive tasks, a lower-power laser could be more economical.

- Future Expansion Plans

- Anticipate future needs. If you foresee increased production or the need to cut thicker materials, investing in a higher-power laser now can save on future upgrades and avoid potential downtime.

- Manufacturer Support and Warranty

- Select a reputable manufacturer that offers robust after-sales support and a comprehensive warranty. Reliable support ensures that your machine operates smoothly and provides assistance if any issues arise.

Conclusion

Selecting the right power for your fiber laser cutting machine requires balancing your current needs, future plans, and budget. By carefully assessing the material types, thicknesses, and production volumes involved in your work, you can choose a laser power that maximizes efficiency and productivity within your budget. Always weigh the long-term benefits and the level of support offered by the manufacturer to make a well-informed investment.

Taking the time to research and understand your specific needs will pay off, ensuring you invest in a fiber laser cutting machine that meets your requirements and supports your business growth.

Reviewed by 1 user

Credi sempre nella qualità delle macchine laser krrass