CNC press brakes are indispensable tools in modern metal fabrication. These versatile machines bend sheet metal into precise shapes, enabling the creation of a wide range of components used in industries such as automotive, aerospace, construction, and electronics.

What Are Press Brakes?

Press brakes are machines that form lengths of sheet steel. These sheets are typically utilized in manufacturing, commercial applications, or as additives for other devices. most press brakes are rated by means of their capability to press steel and their usual bending length; that is expressed in numbers (e.g., total PPI, or kilos of strain consistent with inch). they come in many paperwork and frequently are geared up with tooling and add-ons designed to create enormously customized additives. Press brakes fall into primary classes: mechanical and hydraulic. inside the next sectiaccessories, we’ll smash down the difference and explain the distinguished add-ons of each fashion.

Key Components

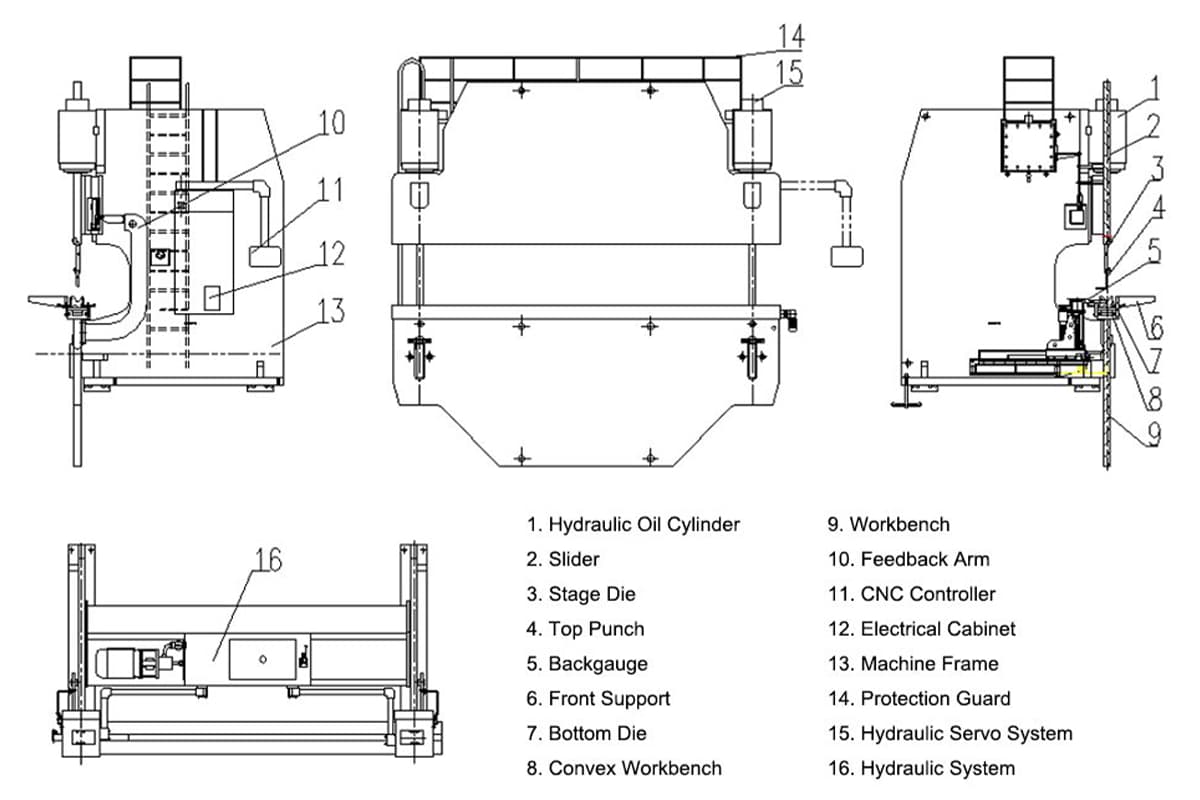

A typical press brake consists of the following key components:

- Frame: The rigid frame provides structural support to the entire machine.

- Ram: The movable part that applies pressure to the sheet metal.

- Slide: The component that guides the ram's movement.

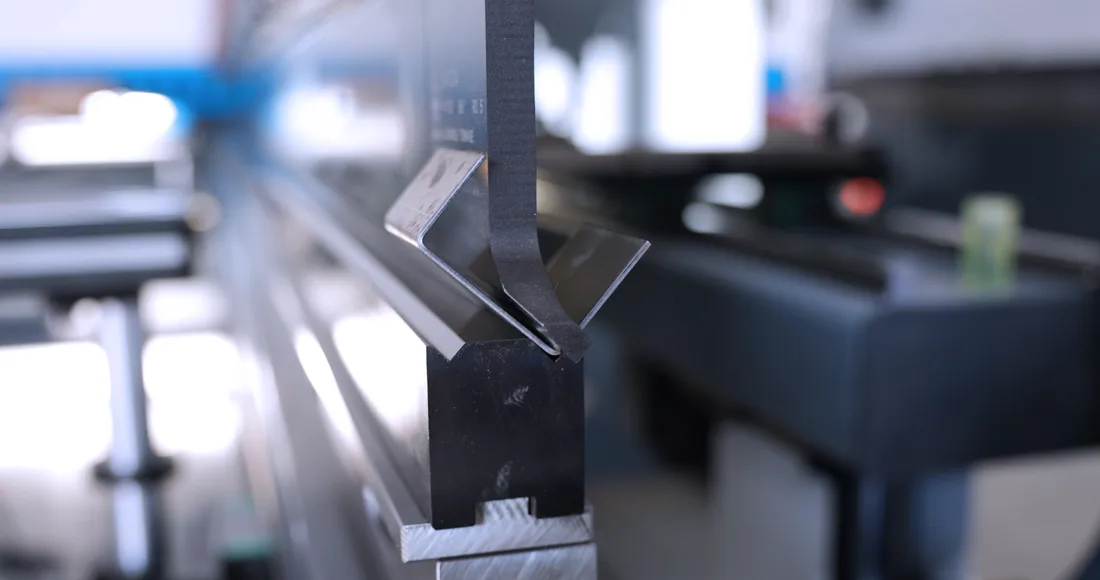

- Tooling: Dies and punches that shape the metal.

- Backgauge: A system that accurately positions the sheet metal.

- CNC Controller: The brain of the machine, controlling all operations.

- Hydraulic Power Unit: Provides hydraulic power to operate the ram.

How It Work

- Sheet Metal Loading: The operator loads the sheet metal onto the machine's bed.

- Program Input: The desired bend angles, lengths, and other parameters are input into the CNC controller.

- Backgauge Positioning: The backgauge accurately positions the sheet metal relative to the tooling.

- Ram Descent: The hydraulic cylinder drives the ram downward, applying pressure to the sheet metal.

- Bending Process: The sheet metal is bent to the desired angle between the punch and die.

- Ram Ascent: The ram returns to its original position.

- Sheet Metal Removal: The operator removes the bent sheet metal.

Types of CNC Press Brakes

The press brakes are classified into different types based on their ram design and control system:

- Mechanical Press Brakes: These use a mechanical flywheel system to generate bending force. While less precise than hydraulic press brakes, they are more cost-effective and suitable for lower-volume production.

- Hydraulic Press Brakes: These use hydraulic cylinders to generate bending force. They offer greater precision, flexibility, and control over the bending process, making them ideal for complex shapes and high-volume production.

Key Features

- High Precision: CNC control ensures accurate and repeatable bends.

- Flexibility: Easily programmable for a wide range of shapes and materials.

- Efficiency: Automated operations reduce cycle times and labor costs.

- Safety: Advanced safety features protect operators from potential hazards.

- Tooling Versatility: A variety of tooling options for different bending applications.

- Remote Diagnostics: Remote monitoring and troubleshooting capabilities.

Selecting the Right Press Brake

When choosing a press brake, consider the following factors:

- Tonnage: The maximum bending force required for your applications.

- Bending Length: The maximum length of sheet metal that can be bent.

- Stroke Length: The maximum distance the ram can travel.

- Accuracy: The desired level of precision for your bends.

- Speed: The required production rate.

- Control System: The complexity of your bending operations.

- Tooling Compatibility: The availability of suitable tooling for your needs.

By carefully considering these factors, you can select the ideal CNC press brake to meet your specific manufacturing requirements.

Conclusion

CNC press brakes are essential tools for modern metal fabrication. Their precision, flexibility, and efficiency enable manufacturers to produce high-quality components at competitive costs. By understanding the key features and factors to consider when selecting a CNC press brake, you can make informed decisions to optimize your production processes.

There’s no denying that press brakes are one of the most useful tools an industrial-grade metalworker can have. Does your practice need an excellent press brake? KRRASS has everything your business needs to succeed.