Laser cutting is a precise and efficient manufacturing process widely used in various industries for cutting and shaping materials. It utilizes a focused laser beam to melt, burn, or vaporize material, creating clean and accurate cuts. This method offers numerous advantages over traditional cutting techniques, including high precision, speed, and the ability to cut complex shapes. In this article, we will explore the principle of laser cutting, its different types, key characteristics, and its application for metals.

The principle of laser cutting

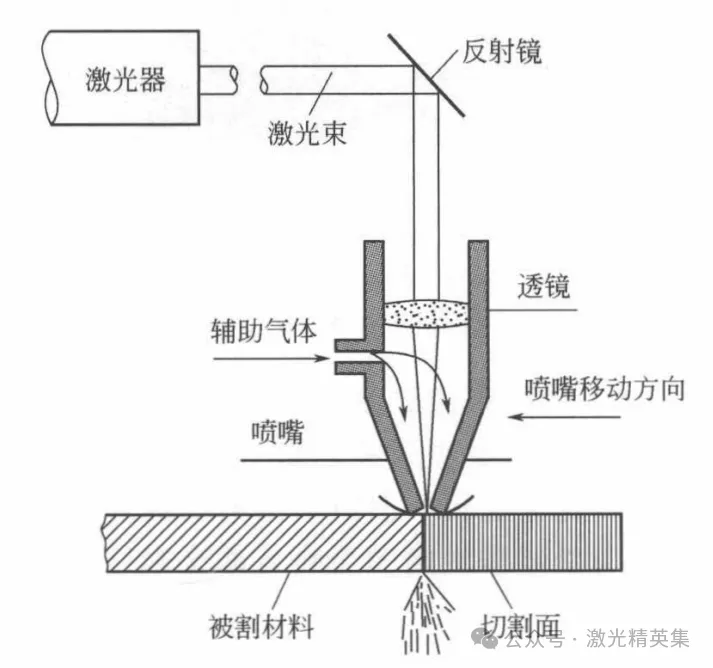

Laser cutting uses a focused high-power density laser beam to scan the surface of the workpiece, locally heating the material to several thousand to tens of thousands of degrees Celsius in a very short time, so that the irradiated material quickly melts, vaporizes, ablates or reaches the ignition point, and at the same time uses a high-speed airflow coaxial with the beam to blow away the molten material and cut the workpiece to achieve the purpose of cutting the material. If the blown gas and the cut material produce a thermal reaction, this reaction will provide additional energy required for cutting; the airflow also has the function of cooling the cutting surface, reducing the heat-affected zone and ensuring that the focusing mirror is not contaminated. Laser cutting is a thermal cutting process.

Whether using CO2 laser or Nd:YAG laser for cutting, the principle is basically the same. In practical applications, a lens is installed in the laser cutting head to focus the laser to a very small focal point (spot), where the power density is extremely high, and the focus is adjusted to the surface of the workpiece to melt or vaporize the material being cut.

The laser cutting process occurs on the surface at the end of the cut, which is called the ablation front. The laser and airflow enter the cut at this point, and part of the laser energy is absorbed by the ablation front, and part passes through the cut or is reflected to the cut space through the ablation front. The ablation front is heated, melted or vaporized by the absorbed laser and the exothermic reaction during the cutting process, and is blown away by the airflow. Part of the heat is transferred to the base material through heat conduction, or is carried away by the airflow through radiation loss and convection heat transfer.

An important factor in laser cutting is the absorption of the incident laser at the ablation front of the workpiece cut, which is the basis for effective laser cutting. The absorption of the laser is determined by the polarization, mode, and convergence angle of the laser, as well as the shape and inclination of the ablation front, the properties of the material, and the degree of oxidation.

Laser cutting uses high-energy lasers to melt or vaporize the material at the cut site, and uses a high-speed auxiliary airflow to blow it away to complete the cutting. The power density of laser cutting can reach 10^4~10^5W/cm2. The laser source generally uses a CO2 laser beam with an operating power of 500~2500W. This power level is lower than the power required by many household electric heaters, but the laser is focused on a very small area through lenses and reflectors. The high concentration of energy can quickly heat the material locally and evaporate the material.

In addition, because the energy is very concentrated, only a small amount of heat is transferred to other parts of the material, causing little or no deformation. Complex shapes can be cut very accurately using lasers, and the cut material does not need to be further processed. Although high-energy CO2 lasers can cut carbon steel plates with a thickness of 25mm, if you want to get a high-quality cut, the plate thickness should generally not be greater than 10mm.

Classification of laser cutting

Laser cutting can use auxiliary gas to help remove melted or vaporized materials, or it can be done without auxiliary gas. Depending on the auxiliary gas used, laser cutting can be divided into four categories: vaporization cutting, melting cutting, oxidation flux cutting, and controlled fracture cutting.

(1) Vaporization cutting

The workpiece is heated by a high-energy-density laser beam, causing the surface temperature of the material to rise rapidly and reach the boiling point of the material in a very short time, which is enough to avoid melting caused by heat conduction. The material begins to vaporize, and part of the material evaporates into vapor and disappears. The vapor is ejected very quickly. At the same time as the vapor is ejected, part of the material is blown away from the bottom of the cut by the auxiliary gas flow as ejecta, forming an incision on the material. During the vaporization cutting process, the vapor carries away the molten particles and washes away the debris, forming holes.

During the vaporization process, about 40% of the material disappears as vapor, while 60% of the material is removed by the airflow in the form of molten droplets. The vaporization heat of the material is generally very large, so laser vaporization cutting requires a lot of power and power density. Some materials that cannot be melted, such as wood, carbon materials and some plastics, are cut and shaped by this method. Laser vaporization cutting is mostly used for cutting extremely thin metal materials and non-metallic materials (such as paper, cloth, wood, plastic and rubber, etc.).

(2) Melting cutting

The metal material is melted by heating with a laser beam. When the power density of the incident laser beam exceeds a certain value, the material inside the beam begins to evaporate and form a hole. Once this small hole is formed, it will absorb all the energy of the incident beam as a black body. The small hole is surrounded by the molten metal wall, and then a non-oxidizing gas (Ar, He, N, etc.) is sprayed through a nozzle coaxial with the beam. The strong pressure of the gas is used to discharge the liquid metal around the hole.

As the workpiece moves, the small hole moves synchronously in the cutting direction to form an incision. The laser beam continues to irradiate along the front edge of the incision, and the molten material is blown away from the incision continuously or in a pulsating manner. Laser melting cutting does not require the metal to be completely vaporized, and the energy required is only 1/10 of that of vaporization cutting. Laser melting cutting is mainly used for cutting some materials that are not easy to oxidize or active metals, such as stainless steel, titanium, aluminum and its alloys.

(3) Oxidation flux cutting

The principle is similar to that of oxy-acetylene cutting. It uses laser as a preheating heat source and oxygen or other active gases as cutting gas. On the one hand, the gas ejected reacts with the cut metal to release a large amount of oxidation heat; on the other hand, it blows the molten oxide and melt out of the reaction zone to form an incision in the metal. Since the oxidation reaction during the cutting process generates a large amount of heat, the energy required for laser oxygen cutting is only 1/2 of that for melting cutting, and the cutting speed is much greater than that of laser vaporization cutting and melting cutting.

The basic principles of oxidation flux cutting are as follows:

①Use oxygen or other active gases. The surface of the material is quickly heated to the ignition temperature under the irradiation of the laser beam, and a violent combustion reaction occurs with oxygen, releasing a large amount of heat. Under the action of this heat, small holes filled with steam are formed inside the material, and the small holes are surrounded by molten metal walls.

②The combustion material is transferred into slag to control the combustion rate of oxygen and metal. The higher the oxygen flow rate, the faster the combustion chemical reaction and the removal of slag. The higher the oxygen flow rate, the better, because too fast a flow rate will lead to rapid cooling of the reaction products (i.e., metal oxides) at the kerf exit, which is not good for cutting quality.

③ There are two heat sources in the oxidation flux cutting process, namely, laser irradiation energy and heat energy generated by the chemical reaction between oxygen and metal. When cutting steel, the heat released by the oxidation reaction accounts for about 60% of the total energy required for cutting. Compared with inert gas, using oxygen as an auxiliary gas can achieve a higher cutting speed.

④ In the oxidation flux cutting process with two heat sources, if the burning speed of oxygen is higher than the moving speed of the laser beam. The kerf appears wide and rough; if the moving speed of the laser beam is faster than the burning speed of oxygen, the resulting kerf is narrow and smooth. Laser oxidation flux cutting is mainly used for cutting steel and is the most widely used cutting method.

(4) Controlled fracture cutting

For brittle materials that are easily damaged by heat, a high-energy-density laser beam is used to scan the surface of the brittle material to evaporate a small groove when heated. Then a certain pressure is applied to heat the material and the laser beam is used for high-speed, controllable cutting. The brittle material will crack along the small groove. The principle of this cutting process is that the laser beam heats the local area of the brittle material, causing a large thermal gradient and severe mechanical deformation in the area, resulting in cracks in the material. As long as the heating gradient is kept balanced, the laser beam can guide the crack to generate and expand in any desired direction.

Controlled fracture is to use the steep temperature distribution generated by laser grooving to generate local thermal stress in the brittle material so that the material breaks along the small groove. It should be noted that this controlled fracture cutting is not suitable for cutting sharp angles and corner slits. It is also not easy to successfully cut extra-large closed shapes. Controlled fracture cutting has a fast cutting speed and does not require too high power, otherwise it will cause the surface of the workpiece to melt and damage the slit edge. The main control parameters are laser power and spot size.

Characteristics of laser cutting

Laser cutting technology has obvious advantages over other thermal cutting methods. Its general characteristics are fast cutting speed and high quality. Its specific characteristics can be summarized as follows:

(1) Good cutting quality

Due to the small laser spot, high energy density and fast cutting speed, laser cutting can achieve good cutting quality. The laser cutting incision is narrow and the dimensional accuracy of the cut parts can reach ±0.05mm. The cut surface is smooth and beautiful, with a surface roughness of only tens of microns (generally Ra is 12.5~25um). Laser cutting can even be used as the last process. The cut seam generally does not need to be processed again before welding, and the parts can be used directly. After the material is laser cut, the width of the heat-affected zone is very small, and the performance of the material near the cut is almost unaffected. In addition, the workpiece deformation is small, the cutting accuracy is high, the geometric shape of the cut seam is good, and the cross-sectional shape of the cut seam presents a relatively regular rectangular shape.

(2) High cutting efficiency

Due to the transmission characteristics of laser, laser cutting machines are generally equipped with multiple CNC workbenches, and the entire cutting process can be fully CNC controlled. During operation, you only need to change the CNC program to apply it to the cutting of parts of different shapes, and can perform both two-dimensional cutting and three-dimensional cutting.

(3) Fast cutting speed

When cutting a 2mm thick low-carbon steel plate with a laser power of 1.2kW, the cutting speed can reach 600cm/min; when cutting a 5mm thick polypropylene resin plate, the cutting speed can reach 1200cm/min. When cutting an 8mm thick carbon steel plate with a laser power of 2kW, the cutting speed is 1.6m/min, and when cutting a 2mm thick stainless steel plate, the cutting speed is 3.5m/min. The heat-affected zone is small and the deformation is extremely small. The material does not need to be clamped and fixed during laser cutting, which can save both tooling and fixtures and auxiliary time for loading and unloading.

(4) Clean, safe, and pollution-free

During laser cutting, the cutting torch does not contact the workpiece, and there is no tool wear. To process parts of different shapes, there is no need to change the "tool", just change the output parameters of the laser. The laser cutting process has low noise, low vibration and no pollution, which greatly improves the working conditions of operators.

(5) A wide variety of cutting materials

Compared with oxy-acetylene cutting and plasma cutting, laser cutting can cut a wide variety of materials, including metals, non-metals, metal-based and non-metal-based composite materials, leather, wood, and fiber. Different materials have different laser cutting adaptability due to their own thermophysical properties and different absorption rates of lasers.

The disadvantage of laser cutting is that it can only cut medium and small thickness plates and pipes due to the limitation of laser power and equipment volume, and the cutting speed decreases significantly as the thickness of the workpiece increases. Laser cutting equipment is expensive and requires a large one-time investment.

In terms of cutting accuracy and surface roughness of the cut, CO2 laser cutting does not exceed electrical machining; in terms of cutting thickness, it is difficult to reach the level of flame and plasma cutting. However, the above significant advantages are sufficient to prove that CO2 laser cutting has and is replacing some traditional cutting methods, especially the cutting of various non-metallic materials. It is an advanced processing method that is developing rapidly and is increasingly widely used.

Application scope of laser cutting

In industrial production, laser cutting technology is one of the most widely used processing methods for laser processing, accounting for about 60% of the entire material laser processing application.

Most laser cutting machines are controlled by CNC programs or made into cutting robots. As a precision processing method, laser cutting can cut almost all materials, including two-dimensional or three-dimensional cutting of thin metal plates. Laser cutting is widely used in electrical manufacturing, transportation machinery, petrochemicals, automobile manufacturing, engineering machinery, medical equipment, decoration, packaging, etc. In the field of automobile manufacturing, laser cutting technology for spatial curves such as car top windows has been widely used. Volkswagen of Germany uses a 500W laser to cut complex body panels and various curved parts.

In the field of aerospace, laser cutting technology is mainly used for cutting special aviation materials, such as titanium alloys, aluminum alloys, nickel alloys, chromium alloys, stainless steel, beryllium oxide, composite materials, plastics, ceramics and quartz. Aerospace parts processed by laser cutting include engine flame tubes, titanium alloy thin-walled casings, aircraft frames, titanium alloy skins, wing lengths, tail wing panels, helicopter main rotors, space shuttle ceramic insulation tiles, etc.

Laser cutting technology is also widely used in the field of non-metallic materials. The power required for laser cutting is relatively low. Generally, a continuous CO2 laser below 1kW is sufficient to cut thin workpieces. It can not only cut materials with high hardness and high brittleness, such as silicon nitride, ceramics, quartz, etc., but also cut flexible materials such as cloth, paper, plastic plates, rubber, leather, etc. For example, using lasers for clothing cutting can save 10% to 12% of clothing materials and improve efficiency by more than 3 times.

The energy density of the laser beam is slightly lower than that of the electron beam, and the cutting capabilities of these two energy beams are basically the same. Compared with electron beam cutting, laser cutting can cut metals up to 25mm thick in atmospheric atmosphere, and can be cut at a very high speed using automatic cutting equipment. The incision is very narrow, the incision angle is almost vertical, and the incision quality is excellent.

In addition to the above applications, laser cutting is also continuously expanding its application areas, as follows:

① Use 3D laser cutting system or configure industrial robot to cut space curves, and develop various 3D cutting software to speed up the process from drawing to cutting parts.

② In order to improve production efficiency, various special cutting systems, material conveying systems, linear motor drive systems, etc. are studied and developed. At present, the cutting speed of the cutting system has exceeded 100m/min.

③ In order to expand the application of engineering machinery, shipbuilding industry, etc., the thickness of cutting low-carbon steel plates has exceeded 30mm, and the process technology of cutting low-carbon steel plates with nitrogen is specially studied to improve the cutting quality of thick plates.

Expanding the application field of CO2 laser cutting and solving some technical problems in new applications are still important topics for engineering and technical personnel.

Laser cutting of different metal materials

(1) Laser cutting of metal materials Although almost all metal materials have high reflectivity to infrared wave energy at room temperature, CO2 lasers that emit beams in the far infrared band (10.6um) are successfully used for laser cutting of many metals. Metal materials have poor absorption of 10.6um laser beams, with an initial absorption rate of only 0.5% to 10%. The absorption rate of most metals in the molten state rises sharply, generally increasing by 60% to 80%.

① Carbon steel. The thickness of laser-cut carbon steel plates can reach 25mm. The slit of carbon steel plates cut by oxidation flux cutting machines can be controlled within a satisfactory width range, and the slit of thin plates can be as narrow as about 0.1mm.

② Alloy steel. Most alloy structural steels and alloy tool steels can achieve good cutting edge quality by laser cutting. When oxygen is used as the processing gas, the cutting edge will be slightly oxidized. For plates up to 4mm thick, nitrogen can be used as the processing gas for high-pressure cutting. In this case, the cutting edge will not be oxidized. For plates with a thickness of more than 10 mm, better results can be achieved by using special plates in the laser and applying oil to the workpiece surface during processing. For high-strength steel, as long as the process parameters are properly controlled, straight, slag-free cutting edges can also be obtained. However, for high-speed tool steel and hot forging die steel containing tungsten, melting and slag are prone to occur during laser cutting.

③ Stainless steel. Laser cutting is an effective processing method for the manufacturing industry that mainly produces stainless steel thin plates. Under strict control of laser cutting heat input, the width of the heat-affected zone of the cutting edge can be limited, thereby ensuring the good corrosion resistance of stainless steel. Oxygen can be used when edge oxidation is not a problem, and nitrogen can be used to obtain an oxidation-free and burr-free edge, and no further treatment is required. Applying a layer of oil film on the surface of the plate will obtain a better perforation effect without reducing the processing quality.

④ Aluminum and its alloys. Laser cutting of aluminum and its alloys belongs to the melting cutting mechanism. The auxiliary gas used is mainly used to blow away the molten product from the cutting area, and usually a good incision quality can be obtained. For some aluminum alloys, care should be taken to prevent the generation of intergranular microcracks on the cutting surface. Although aluminum alloys have high reflectivity and good thermal conductivity, laser cutting can still be used to cut aluminum materials with a thickness of less than 6 mm, depending on the alloy type and laser power. When oxygen is used, the cutting surface is rough and hard; when nitrogen is used, the cutting surface is smooth. Pure aluminum is very difficult to cut. It can only be cut when a "reflection absorption" device is installed on the system, otherwise the reflection will destroy the optical components.

⑤ Copper and its alloys. Pure copper (red copper) cannot be cut with a CO2 laser beam due to its high reflectivity. Brass (copper alloy) should be cut with a higher laser power. Air or oxygen is used as the auxiliary gas, and thinner plates can be cut. Both pure copper and brass have high reflectivity and very good thermal conductivity. Brass plates with a thickness of less than 1 mm can be cut with nitrogen; copper plates with a thickness of less than 2 mm can be cut, and oxygen must be used as the processing gas. Pure copper and brass can only be cut when a "reflection absorption" device is installed on the system, otherwise the reflection will destroy the optical components.

⑥Titanium and its alloys. Pure titanium can couple the heat energy converted by the focused laser beam very well. When oxygen is used as the auxiliary gas, the chemical reaction is violent and the cutting speed is fast, but it is easy to generate an oxide layer at the cutting edge, which may also cause overburning. Using air as the auxiliary gas can ensure the cutting quality. The titanium alloy laser cutting quality commonly used in the aircraft manufacturing industry is good. Although there will be a little sticky slag at the bottom of the cut, it is easy to remove. Titanium plates are cut with xenon and nitrogen as processing gases.

⑦ Nickel-based alloys. Also known as high-temperature alloys, there are many varieties, most of which can be laser-oxidized and flux-cut

The incision quality is good. Laser cutting equipment can cut stainless steel plates below 4mm, and adding oxygen to the laser beam can cut 25mm thick carbon steel plates, but a thin oxide film will be formed on the cutting surface after oxygen cutting. The maximum thickness of laser cutting can reach 30mm, but the dimensional error of the cut parts is large

The absorption rate of the material to the laser beam plays an important role in the initial stage of heating. Once the small hole inside the workpiece is formed, the black body effect of the small hole makes the material absorb the beam close to 100%. In laser cutting practice, the influence of the material surface state on the beam absorption rate can be used to improve the cutting performance of the material. For example, coating a layer of absorbing material on the aluminum surface can significantly increase the cutting speed.