In the dynamic realm of modern manufacturing, laser cutting machines have emerged as a cornerstone, enabling the creation of a vast array of products. However, one persistent challenge that often accompanies slag hanging in laser cutting of metal plates is the vexing issue of residue that can impact the quality and functionality of the final product.

What is Slag Hanging?

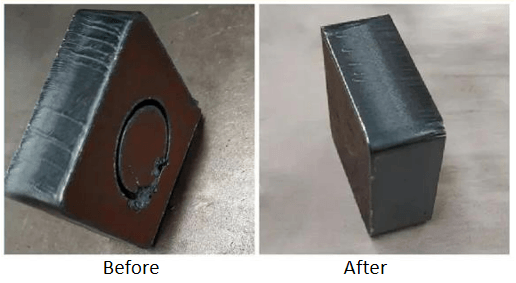

Slag hanging is the unwelcome residual metal melt that clings to the cutting back of workpieces after the laser cutting process. It not only mars the visual allure of the final product but can also potentially impede its functionality.

Reasons for Slag Hanging

- When Cutting Small Hole Workpieces: During laser cutting, a significant amount of heat is generated. In the case of small hole workpieces, while the exterior of the hole can cool relatively efficiently, the interior faces a constraint in heat dissipation space. This leads to a build-up of heat and, so, the formation of slag hanging.

- When Cutting Thick Plates: For thick plates, the molten metal that accumulates on the surface during perforation, combined with heat accumulation, can disrupt the auxiliary air flow. This perturbed air flow, along with excessive heat input, gives rise to the troublesome slag hanging.

Types of Slag Hanging

The nature of slag hanging can vary depending on the specific metal being cut. Different metals produce distinct forms of residue. Some may result in a more oxidized slag, while others yield a slag with a more prominent metallic composition. Understanding the characteristics of the slag is crucial as it guides the choice of the proper cleaning method.

How to Solve Slag Hanging

- Laser Output Power: When dealing with thick plates and meeting slag hanging, it is essential to assess the laser output power. If the power is insufficient to melt the entire plate, an adjustment may be necessary. In some cases, a more powerful laser might be needed. Our company's fiber laser cutters, which offer a power range from 1500W to 20000W, provide the flexibility to precisely control the power. This ensures that the plate is melted uniformly, significantly reducing the likelihood of slag formation.

- Deviation of Laser Beam Focus: The correct focus of the laser beam is vital for a clean cut. If the focus is too close or too far from the workpiece, it can lead to subpar cutting quality and slag hanging. Our fiber laser cutters are equipped with advanced focus adjustment systems that keep the best focus distance throughout the cutting process. This cuts the guesswork and potential errors associated with focus deviation.

- The Air Pressure of Auxiliary Gas: The auxiliary gas plays a pivotal role in laser cutting. It serves to expel the slag and cool the heat-affected zone. If the air pressure is inadequate, residue may remain on the workpiece, leading to slag hanging. Our machines feature a meticulously calibrated auxiliary gas system that delivers the precise air pressure needed to ensure efficient slag removal and proper cooling.

- Cutting Speed: The cutting speed is another critical factor. If it is too rapid, the workpiece may not be cut cleanly, resulting in slag in the lower half area. Conversely, if it is too slow, over-melting can occur, leading to a rough overall section and slag in the upper half. Our fiber laser cutters are endowed with intelligent speed control mechanisms that automatically adapt the cutting speed based on the material thickness and other parameters, ensuring a smooth and slag-free cut.

Tools Needed to Solve Slag Hanging

- Power Adjustment Tools: Our fiber laser cutters come with user-friendly interfaces that allow for effortless adjustment of the laser output power.

- Focus Adjustment Equipment: The built-in focus adjustment tools in our machines are designed for precision and ease of use, enabling operators to quickly and accurately correct any focus deviations.

- Air Pressure Gauge and Regulator: The advanced air pressure monitoring and regulation system in our cutters ensures that the auxiliary gas pressure is always at the best level, easing effective slag removal.

FAQ

Can I use any degreaser to clean the slag hanging?

It is advisable to use a degreaser specifically formulated for metal surfaces. However, with our fiber laser cutters, the occurrence of slag hanging is minimized, reducing the need for extensive degreasing.

What if I don't have the right tools to adjust the laser focus?

Our fiber laser cutters are engineered with simplicity in mind. The focus adjustment tools are intuitive and integrated into the machine, making it accessible even for those new to laser cutting.

How often should I check the auxiliary gas pressure?

Our machines are equipped with sensors that continuously check the auxiliary gas pressure. Nevertheless, a routine check before beginning major cutting projects is a prudent practice.

In conclusion, while slag hanging can pose a significant obstacle in laser cutting metal plates, understanding its causes and implementing the appropriate solutions is key. Our company's fiber laser cutters, with their advanced features and capabilities, offer an effective means of not only addressing slag hanging but also enhancing the overall quality and efficiency of the laser cutting process. By choosing our reliable and innovative fiber laser cutters, you can take your manufacturing endeavors to new levels of excellence.