In the world of laser cutting, ensuring your machine performs at its absolute best requires consistent maintenance for laser cutting machines. Regular upkeep helps you identify and address potential issues before they evolve into major problems. By handling these minor issues during routine maintenance, you can avoid the costly repairs associated with letting problems escalate, while also extending the lifespan of your reliable laser cutting machine.

Understanding the intricacies of maintenance for laser cutting machines is key to establishing a long-lasting, productive relationship with your equipment. This regular maintenance ensures your machine maintains peak performance, safeguarding the precision and accuracy of your cuts. For industries where tight tolerances and consistent quality are essential, well-maintained lasers run more efficiently, helping to reduce operating costs and conserve energy.

Ultimately, performing maintenance for laser cutting machines guarantees that your shop operates smoothly, sticking to production schedules and optimizing resource allocation. It’s the difference between a chaotic, unpredictable work environment and a well-organized, high-performing operation.

Now, let's take a closer look at the key machine components within a laser cutting machine that require our tender loving care. Many machine tool suppliers specify when you should conduct certain maintenance processes. The basic building blocks of a laser cutting table include the physical machine tool itself, the laser source (the heart and soul of the operation), the chiller (the cooling maestro), the pallet changer (the behind-the-scenes organizer), and the dust collector (the unsung hero that keeps things clean). You must consider each of these components carefully when it comes to maintenance.

The Machine Tool: The Mechanical Marvel

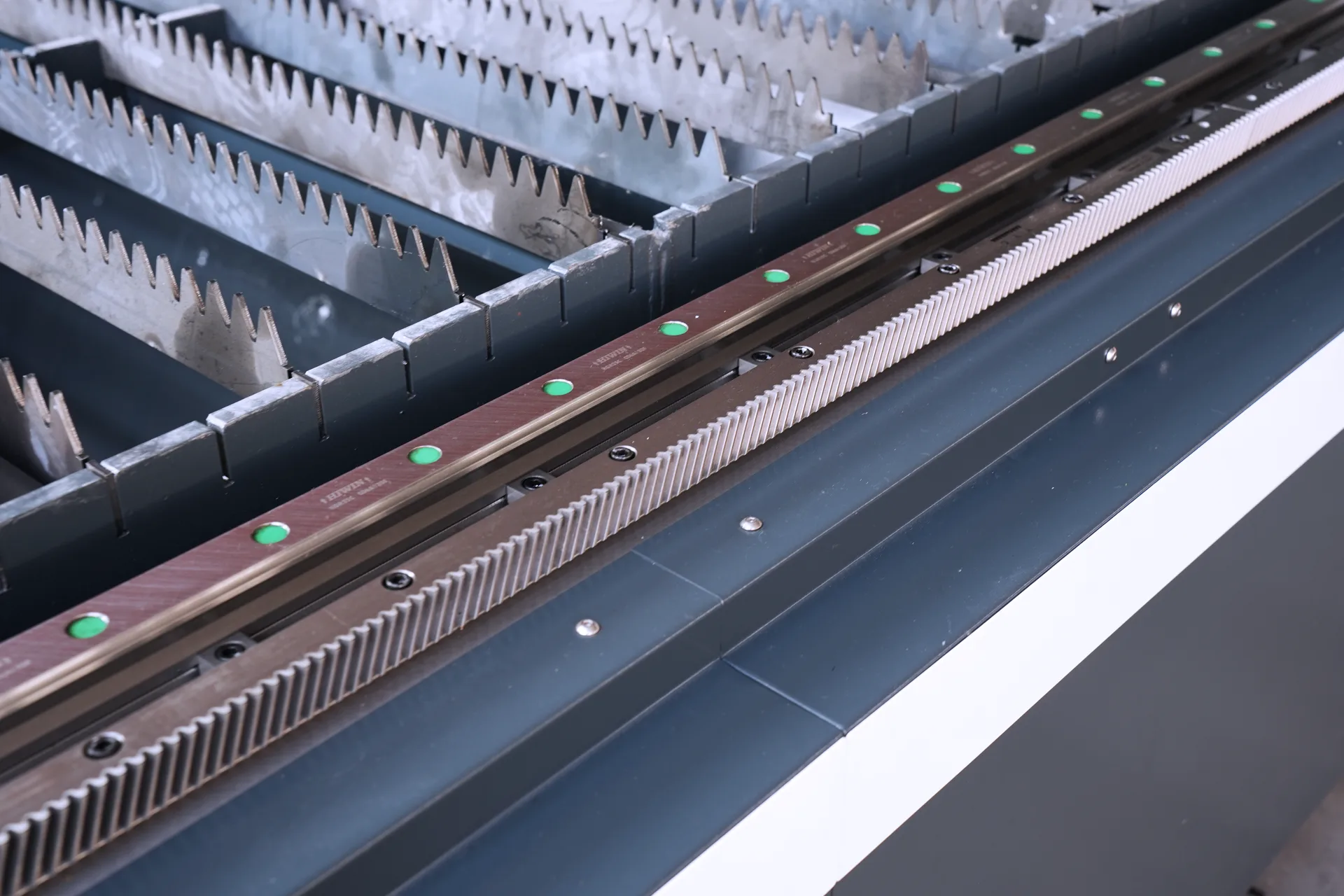

When we talk about the machine tool, we refer to the intricate mechanical parts that bring the machine to life, excluding the laser source. Picture the rack and pinion X, Y, and Z axes, and the guide rails as the smooth movers and shakers of the machine. You need to lubricate these parts regularly. Your machine tool supplier, the oracle of maintenance, likely provides a lubrication schedule based on how much you use the machine. You must double-check this schedule as if it were a precious treasure map.

Over time, wear and tear can cause the axis limits of the machine to change. This can lead to program functionality problems that are as annoying as a persistent mosquito. You should regularly review these axis limits to ensure you're still on the right path.

Don't forget to visually inspect the bellows of the rack and pinion system regularly. You should ensure it's free from any chance of dirt invasion. You also need to scrutinize water connections for any signs of cracks or kinks that could disrupt the flow.

You must change the cooling water filters as per the manufacturer's instructions (usually an annual affair), just like changing the air filters in your car. The same goes for the gas filters of the laser. And here's a pro tip: you should install a 0.01-µm filter in the nitrogen supply line to safeguard the laser system from potential contaminants. Lasers are sensitive to the air they intake, which can carry dust, dirt, oil, and moisture. Without those yearly filter changes, these contaminants can enter the machine's internal components, causing wear, corrosion, and a sluggish performance.

Safety first! You should check the emergency stops, reset, and pause buttons regularly to ensure they're in perfect working order. And don't overlook the warning lamps; a quick visual inspection can save you from potential disasters.

For the sake of your precious eyes, you need to check the protective windows on a fiber laser and all possible points of egress for light from the cutting area. In a dark room, use a flashlight to explore all possible escape routes for light and make sure they're secure.

The Laser: The Shining Star

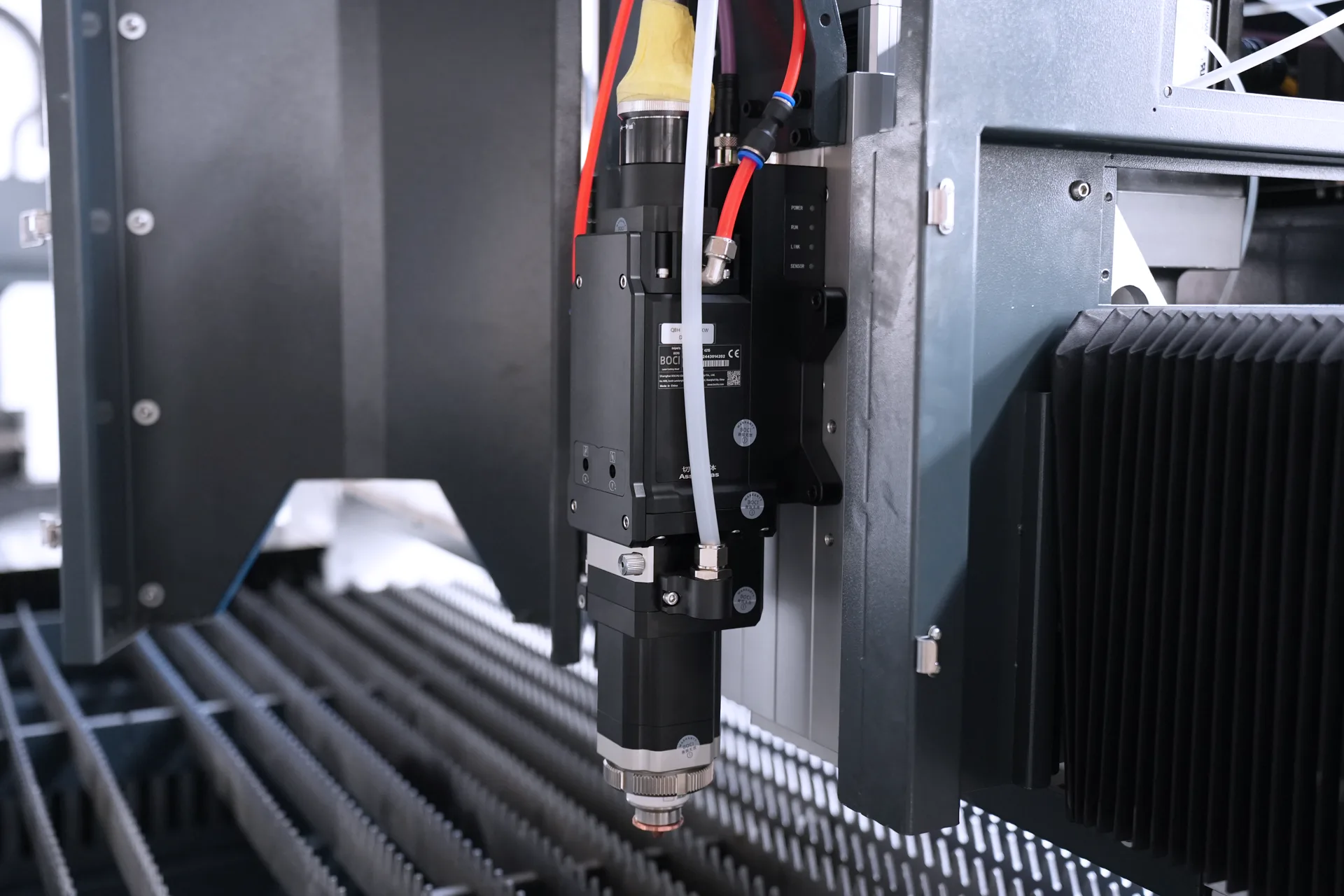

The laser itself is the prima donna of the laser cutting machine, but you still need to review the essential checkpoints. The nitrogen input to a fiber laser is the magic ingredient that affects the kerf and cleanliness of your cuts. You must ensure new, or well-maintained gas regulators are in place to deliver the correct pressure. Old regulators can leak, leading to costly gas escapes. You should keep an eye on the lateral air blast nozzle, making sure it's clean and not clogged with spatter. If you don't check the nozzle, cutting issues can pop up like unwanted weeds.

You need to regularly clean the nozzle changer and check the alignment of the head to the nozzles during a change. You should also ensure the calibration plate stays clean.

You can perform a visual inspection of the laser while it's running to catch any issues before they turn into a full-blown drama.

Finally, you must remember to call in your service engineer to check the internal fans for cleanliness. Proper airflow is crucial for the machine, and if it's compromised, it can disrupt all other components.

The Pallet Changer: The Smooth Operator

The pallet changer is the unsung hero that keeps the machine running smoothly. There are several items that require your regular attention.

First, you should check the lateral guideways, the tracks that guide the pallet wheels into the pallet changer. You must ensure no scrap is lurking in there, as any obstruction could cause the wheels to go off the rails and create a chaotic mess.

You need to check the oil level and the rest of the hydraulic system. Leaks can steal the efficiency of your machine. Also, find out how often the hydraulic oil needs a change. Depending on the manufacturer, it could be every three to five years. And remember, you should bring the table down gently before changing the oil.

You should check the motor chains to see that they're snug and lubricate them if needed. The chain deflection is specified in your machine's maintenance manual.

You need to inspect the wheels on the pallet changer for any chips. After installations, the machine can settle, causing misalignment between the pallet and the machine tool. This can wear the wheels out prematurely. A good preventive maintenance practice is to check and realign or level beds to ensure a smooth ride.

You should measure the step between A/B pallet rails and the processing machine and make sure it's within the tolerance value. If there's no step but you hear an abnormal sound, you need to look under the table for any obstacles or damaged sections on the wheel.

Dust collector maintenance involves keeping up with filter changes and regularly checking the dust bin. You should consider replacing filters instead of cleaning them, as they can be harmful. The gauges on the dust collector will let you know if it's clogged.

You must also check the suction hose attachments regularly for leaks.

Chiller: The Cool Companion

Water conductivity is crucial for fiber laser systems as it directly affects the laser's performance. Fiber lasers generate a significant amount of heat during operation, and this heat needs to be efficiently dissipated to keep stable and reliable laser performance.

You should respect the factory's recommended water conductivity to reduce corrosion of metal parts, which can otherwise degrade the performance of the laser system.

Factory manuals are your guiding stars, usually recommending water and filter changes every six to 12 months. Some machine tool builders prefer regular water, while others recommend deionized or distilled water, and some even suggest additives. You should refer to your factory-supplied manual for the best water and filter change advice.

You need to clean condenser fins and replace external filter mats to give the laser a breath of fresh air to cool the water. This is especially crucial during the sizzling summer months when temperature fluctuations can affect laser output power and beam quality. Correct cooling water helps keep a stable operating temperature and ensures a predictable laser performance.

CO2 Laser Maintenance: The Vintage Treasure

Although fiber lasers are popular in the modern laser cutting world, there are still many CO2 workhorses that deserve special attention.

One of the rewards of fiber lasers is that they don't require mirror maintenance. But for CO2 lasers, you need to clean or replace the bend mirrors annually. Upward-facing mirrors get dirty quickly due to gravity, so you should pay extra attention to them.

Bend mirror alignment and mode checks are essential for a well-performing CO2 laser, but these are usually done by factory-trained service specialists. You should check with your supplier to ensure you're following the necessary schedule.

You need to replace and align the internal resonator mirror based on hours of use. The requirements vary widely depending on your machine, ranging from 4,000 to 20,000 hours of use. Your machine tool supplier can guide you.

The cutting head's processing lens needs to be cleaned and checked for thermal distortion. If it's spattered or scratched, it can shatter, so you should replace it when needed. And never try to manage a shattered lens on your own; call a trained laser engineer to clean the system for you. You should check the head for looseness by gently pushing and pulling it.

You need to conduct regular focus checks to keep your laser cutting precise. Also, check the nozzle center adjustment screws for smooth movement as they can wear out over time.

On an older CO2 machine, you should look for gas leaks in the lines and at the cutting head. Water lines can rot internally from years of acidity, so you need to check the flexibility of these hoses and change them one at a time when an issue arises.

Maintenance for Laser Cutting Machines Schedules: The Rhythm of Care

The frequency of maintenance checks varies depending on the nature of the check, your cutting volume, and the materials your shop is slicing through.

You should perform a quick and simple daily cleaning and visual inspection. Keeping lenses clean and the nozzle clear of debris are daily essentials for superior performance.

Weekly and monthly checks include cleaning optical components. You also need to check coolant levels and hoses and cables on chiller components to ensure the smooth circulation of the lifeblood of the machine.

Annual or periodic maintenance for laser cutting machines involves a detailed inspection of the laser source and all electrical connections, switches, and control panels.

It's always a good idea to check with your machine tool supplier for detailed preventive maintenance advice. Having a checklist of what to check and when is like having a trusty recipe book in your shop, ensuring that you keep your equipment at the perfect intervals.

And when complex repairs or major malfunctions occur, don't hesitate to call in a qualified technician. They're the superheroes who can save the day.

It's easy to think that as long as your laser is cutting cleanly, all is well. But without proper maintenance of the laser head, the machine tool's mechanical components, the pallet changer, and the dust collector, a failure could be lurking around the corner.

In today's world of just-in-time delivery, no one can afford downtime. So, give your laser the love and attention it deserves, and it will reward you with maximum productivity and a long, happy life of cutting perfection.