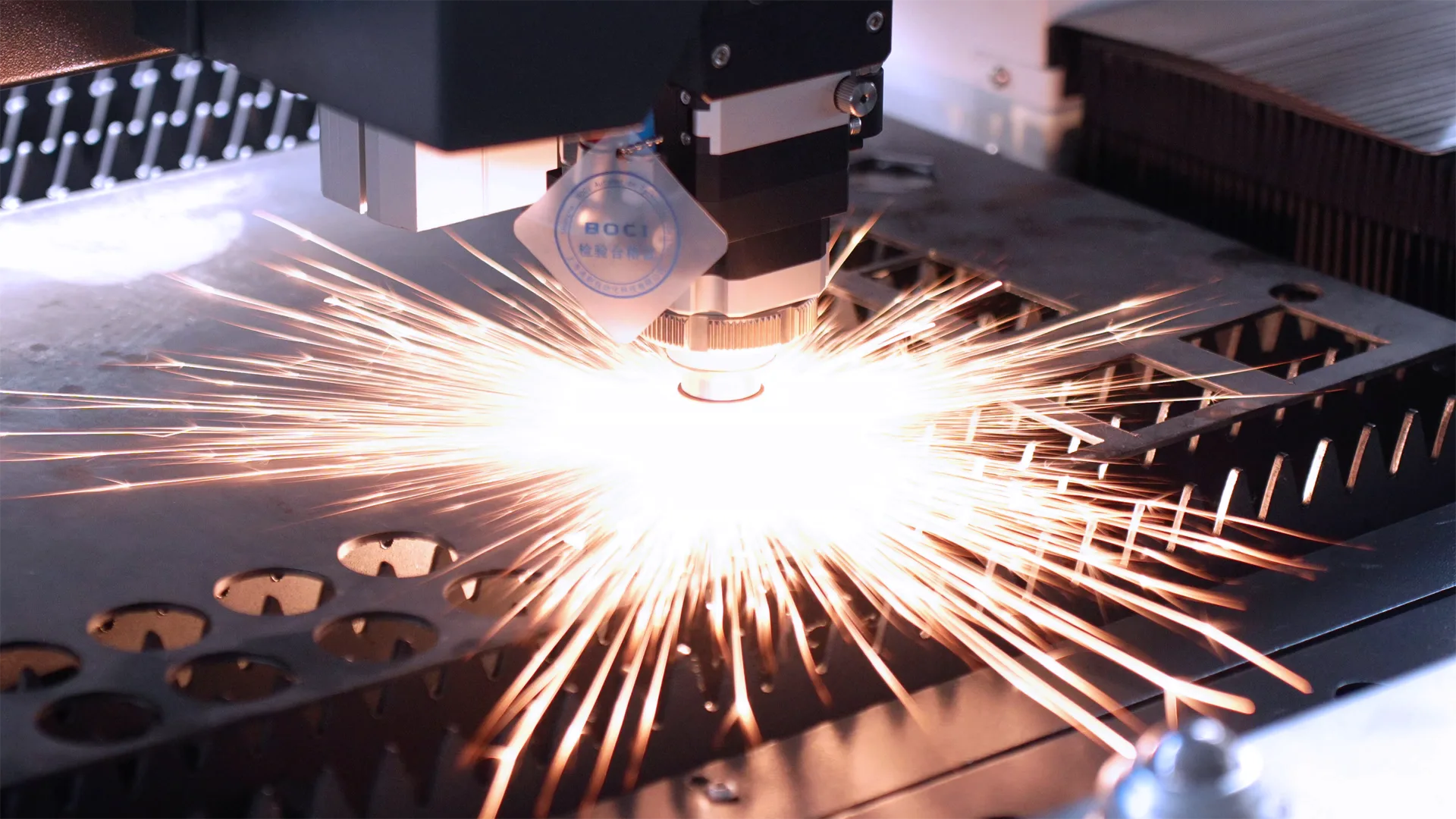

The laser cutting machine market has seen significant growth, driven by the increasing demand for laser-based metal cutting applications. Selecting the appropriate laser power is critical for businesses to optimize productivity, improve cutting quality, and achieve a higher return on investment.

In general, laser cutting machines are categorized based on their power levels:

- High Power (above 6kW) – These machines are suitable for cutting thicker materials and for applications requiring high throughput.

- Medium Power (3kW to 6kW) – Versatile machines capable of cutting a wide range of material thicknesses at efficient speeds.

- Low Power (below 3kW) – Ideal for light materials and thinner sections.

The selection of laser power depends on various factors, including material thickness, metal type, desired cut quality, operating efficiency, and budget. Below are some key considerations when choosing the right laser power for your business:

Factors Influencing Laser Power Selection

- Material Thickness: The power of a laser machine is directly proportional to the thickness of the material it can cut. Thicker metals require higher laser power for effective cutting.

- Metal Types: Different metals reflect laser light to varying degrees. Higher laser power is more effective when cutting high-reflective metals like stainless steel, as it allows the laser beam to penetrate the material more efficiently without being disrupted by back-reflection.

- Operating Efficiency: Higher laser power enables faster cutting speeds, thereby increasing the number of parts produced per hour. Machines with higher power levels can change directions quickly without compromising productivity, enhancing overall operational efficiency.

- Price Considerations: While high-power lasers offer advantages in terms of speed and material thickness capabilities, they come at a higher cost. It’s essential to weigh the increased operational costs with the desired improvements in processing capabilities.

Q&A Section (Using Carbon Steel as an Example)

How Do I Achieve the Best Balance Between Processing Performance and Cost?

To begin, assess your budget for equipment and determine the range of material thicknesses you plan to cut. Common thicknesses include 6mm, 8mm, 12mm, 25mm, 40mm, and beyond.

If your production primarily involves cutting materials between 6mm and 12mm thick, consider two primary factors: cutting quality and efficiency. For those with a limited budget but requiring high precision, a 3kW laser cutting machine would be an ideal choice. Such systems deliver excellent cutting quality for carbon steel sheets up to 8mm thick, providing a mirror-finished cross-section. With a maximum cutting thickness of 20mm, these machines can operate at speeds of 0.3 to 0.5 meters per minute, ensuring both high-quality results and solid performance across medium and thin sheets.

What Power Level Would You Recommend for a Versatile Machine Investment, Considering a Flexible Budget?

For businesses with a larger budget seeking versatility, the 6kW laser cutting machine is an excellent option. When paired with scanning cut technology, the 6kW system significantly boosts the cutting range and speed when processing carbon steel. Capable of cutting 12mm thick carbon steel plates at speeds between 2.5 to 5.2 meters per minute, this system strikes a balance between performance and operational costs. Additionally, it can process carbon steel plates up to 20mm thick at speeds of 0.5 to 0.8 meters per minute, delivering consistent results for both thin and thick plates.

What Is the Best Scenario for High-Power Lasers, Specifically Over 10kW?

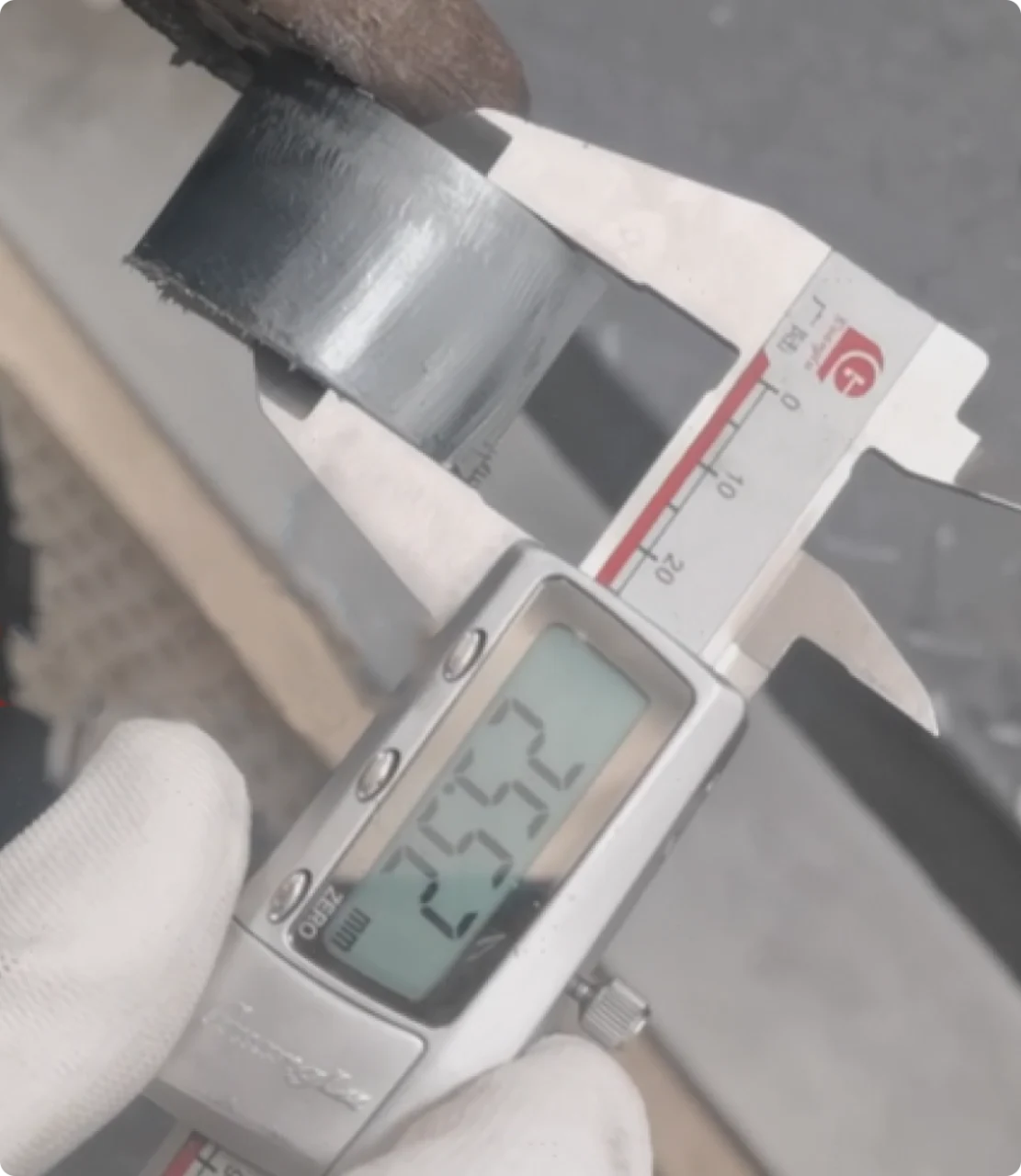

In high-performance scenarios, particularly when cutting thicker materials, a 12kW laser cutting machine excels in delivering excellent cutting quality at moderate efficiencies. For instance, when cutting 25mm thick carbon steel, a 12kW system achieves bright-cut finishes with excellent surface smoothness at speeds ranging from 0.5 to 1.2 meters per minute. The taper angle remains consistently controlled at 20mm, ensuring a high-quality cut.

However, when cutting thicker materials, such as 40mm carbon steel plates, at speeds of 0.5 to 0.9 meters per minute, the cross-section of the cut will exhibit a matte finish, and the efficiency will be slightly reduced compared to thinner materials.

For those seeking a balance of high cutting efficiency without compromising on quality, the 24kW laser cutting system offers unparalleled speed and performance. With air cutting capabilities, this system can handle carbon steel sheets up to 25mm thick at impressive cutting speeds of 1.2 to 2.9 meters per minute—twice as fast as oxygen cutting. This translates to maximum productivity for large-scale operations while maintaining high-quality results. The 24kW system also demonstrates reliable performance when cutting 40mm thick plates, making it ideal for large batch processing with consistent quality.

As a leading provider of laser cutting solutions, KRRASS offers a diverse range of laser cutting machines equipped with various power options. Our experienced sales team is available to assist you in evaluating your specific production requirements, ensuring that you select the optimal laser power to enhance your productivity and quality. Contact us today to discuss your needs and make an informed investment in the right laser cutting technology for your business.