In today’s industrial landscape, modern technology transforms every aspect of manufacturing. Industries constantly evolve with new tools and equipment that drive remarkable achievements. As a business owner in the manufacturing or fabrication sector, you must stay informed about the latest technological advancements. This article focuses on Servo-Electric Press Brakes — innovative machines that deliver precision and efficiency. Read on to gain a deeper understanding of these advanced systems and explore how they can elevate your production capabilities.

What Is A Servo-Electric Press Brake?

Press brakes serve as essential machines that bend and manipulate metal sheets and plates, forming the backbone of many manufacturing processes. Traditional press brakes often produce loud noise and require high energy consumption, making them less ideal in today’s environment where energy conservation and noise reduction have become priorities.

Servo-Electric Press Brakes appear as the superior alternative. Operating entirely on electricity without relying on hydraulic systems, these machines integrate advanced features that enhance eco-friendliness, accuracy, and energy efficiency. Companies like KRRASS have pioneered modern models that not only reduce production costs but also simplify operations through minimal maintenance requirements and faster, more precise results.

How Does A Servo-Electric Press Brake Operate?

A thorough understanding of the operation behind a Servo-Electric Press Brake allows you to maximize its potential and ensure best performance. Traditional press brakes use two main components—the die and the punch—to achieve the desired bending effects. Some models secure the die and move the punch, while others fix the punch and move the die. In both cases, the movable part applies force against the stationary part with the metal workpiece positioned between them. Operators can swap out dies with various angles and shapes to produce customized bends.

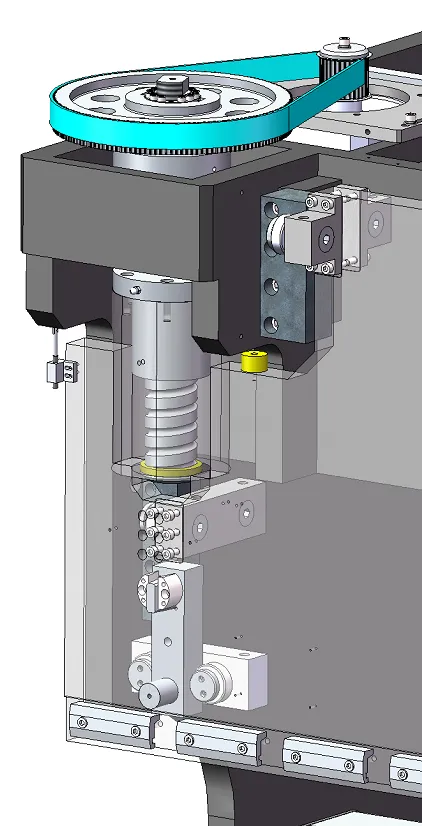

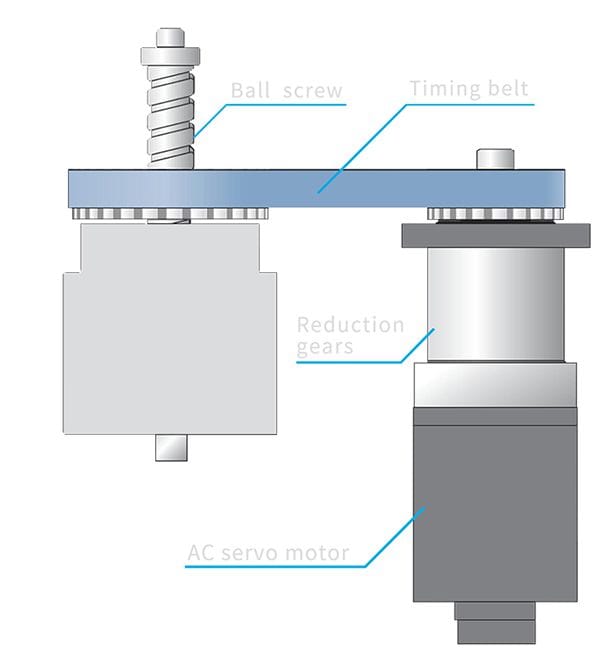

In the case of a Servo-Electric Press Brake, the machine uses electricity to drive the movable parts, replacing the conventional hydraulic pressure system. Two high-precision servo motors deliver the force needed to push the components together, enabling correct metal manipulation. These servo motors work in concert with a system of pulleys that distribute pressure evenly along the material’s length, ensuring consistently precise bends.

Modern machines, such as KRRASS’s CNC Press Brake 4 ~ 6-Axis, incorporate advanced CNC (Computer Numerical Control) systems. These systems allow you to input exact specifications into the machine, which then translates your digital commands into precise mechanical actions. The CNC system coordinates with the servomotors, delivering a level of accuracy and consistency that manual control cannot match. By entering your desired parameters, you receive flawlessly executed bends every time, reducing waste and speeding up production cycles.

Why opt For The Servo-Electric Press Brake?

Servo-Electric Press Brakes dominate the market for several compelling reasons. Understanding these advantages will help you make an informed investment decision:

Less Power Consumption

These advanced machines excel in energy efficiency. While a Servo-Electric Press Brake may require a higher instantaneous power draw to achieve a precise operation, it runs only when needed. In contrast, hydraulic press brakes consume energy continuously throughout the day, making the servo-electric alternative a more energy-conscious choice. This efficient energy use reduces overall operational costs and promotes a greener manufacturing environment.

High Accuracy And Speed

Servo-Electric Press Brakes achieve extraordinary precision—correct to as fine as one micron compared to the ten-plus microns typically saw in hydraulic systems. The integrated servo motors deliver rapid and controlled movements that increase production speed. This enhanced performance not only improves product quality but also boosts your throughput and competitive edge.

Smarter Alternatives

Modern servo-electric machines incorporate intelligent features, including AI-driven controls and robust CNC systems. These smart integrations enable automated adjustments and real-time monitoring, reducing the need for constant manual intervention. You enjoy a seamless production process that enhances productivity and minimizes the risk of human error. This smart technology transforms your operations into a highly responsive and adaptive system.

Sustainable And Environmentally Friendly

Today’s businesses must embrace sustainability and environmental stewardship. Servo-Electric Press Brakes lead the charge in this area. They lower energy consumption, reduce noise levels, and cut risks associated with oil leaks or hydraulic spills. These machines contribute to a safer, cleaner workplace and align your operations with global sustainability standards.

Economical

Servo-Electric Press Brakes offer long-term economic benefits. They need fewer maintenance interventions compared to hydraulic models, which demand regular oil changes, fluid replacements, and seal management. This reduced maintenance translates to lower downtime and reduces running costs, making these machines a financially savvy choice for forward-thinking businesses.

In conclusion, understanding the detailed operation of Servo-Electric Press Brakes and the multiple benefits they offer can transform your manufacturing process. With enhanced precision, energy efficiency, and smart technology integrations, these machines provide a competitive advantage that translates directly into improved product quality and faster turnaround times. If you seek a solution that not only meets but exceeds modern industrial requirements, exploring a Servo-Electric Press Brake could be your next strategic investment. For further consultation and a personalized demonstration, feel free to contact our team. We look forward to helping you drive innovation and efficiency in your production process.