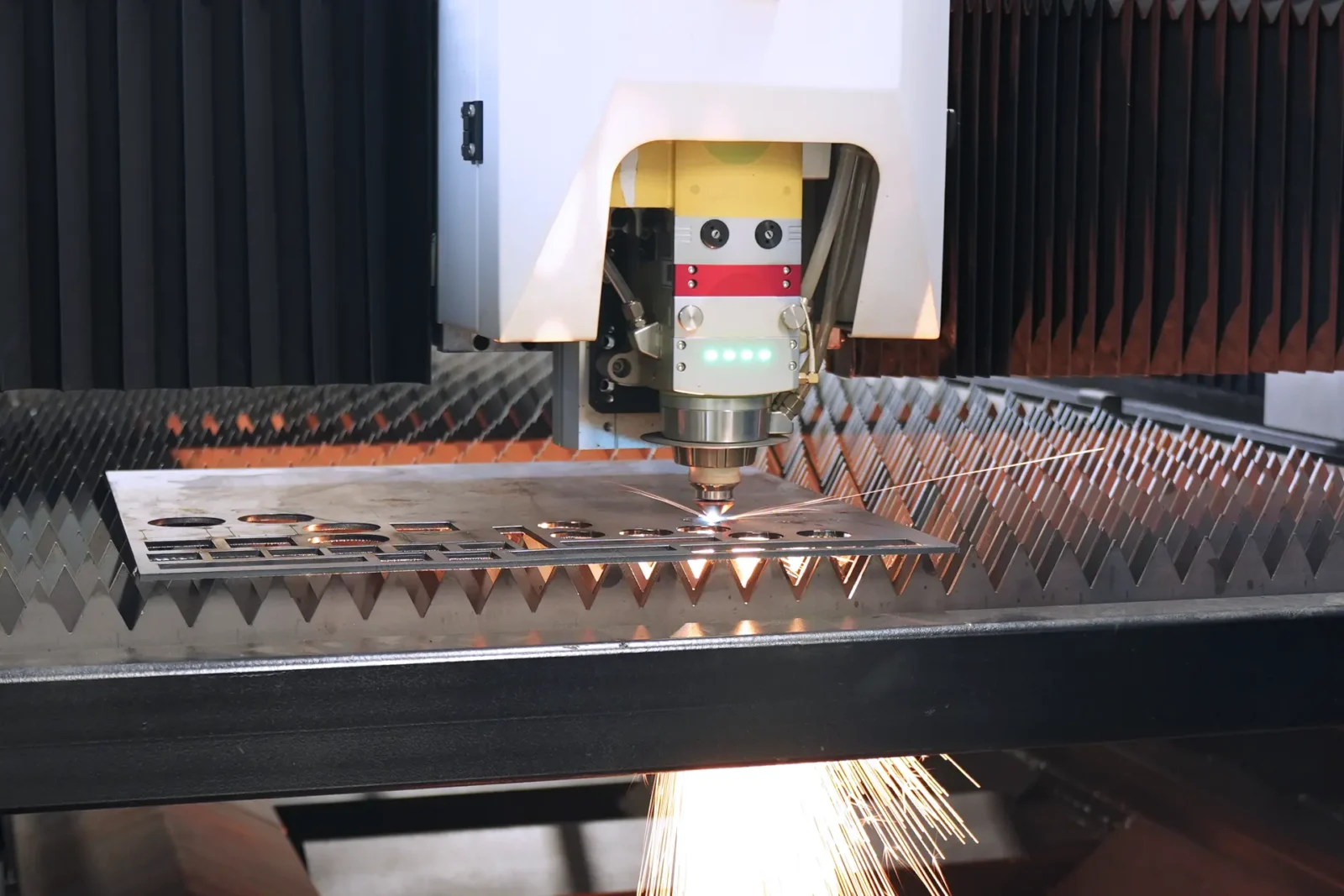

Choosing the right laser cutting power is crucial for effectively cutting metal in 2025. The laser cutting power level influences the speed, accuracy, and energy efficiency of the cutting process. For instance:

- At 6 mm thick, the speed ranges from 16 units at 12 kW to 33 units at 40 kW.

- At 20 mm thick, the speed increases from 2 units at 15 kW to 12 units at 40 kW.

This demonstrates that higher laser cutting power enhances the quality of the cut. Thicker metals require more powerful lasers. Consider the type of metal, costs, and advancements in technology such as super-strong lasers. The optimal laser cutting power depends on your specific needs, but finding a balance between speed and cost is essential.

Table of Contents

Key Takeaways

- Picking the right laser power helps with speed and accuracy.

- Stronger lasers cut thick metals faster and leave smooth edges.

- Match laser power to metal thickness for the best results.

- Thicker metals need stronger lasers to cut properly.

- Think about the metal type; shiny metals like aluminum need more power.

- Save energy by using smart settings, cutting costs by 30%.

- Choose machines that work with different tasks and materials.

- Buy modern machines with automation to save time and effort.

- Test the machine on your materials before buying to be sure.

Understanding Laser Cutting Power

Definition and Importance

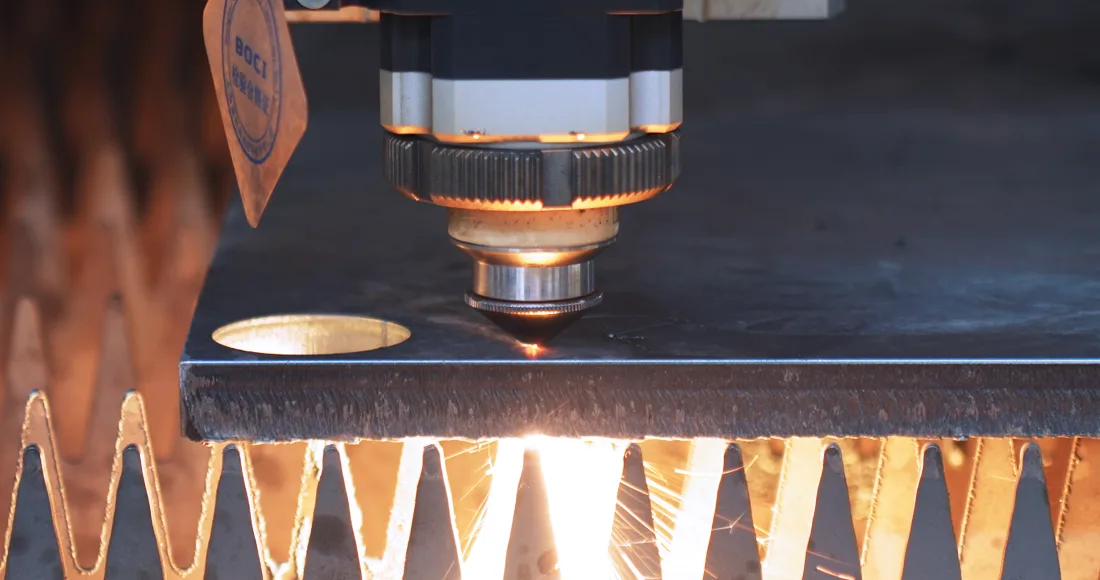

Laser cutting power means the energy a laser machine uses. It is measured in kilowatts (kW). This power shows how well the laser cuts metals. Stronger lasers can cut thicker materials faster and more precisely. For example, a 6kW laser works for tough jobs, while a 3kW laser is better for thin metals. High cutting speeds, improved cutting quality and efficiency are all indicators of a higher power laser cutting machines. Cutting products with high processing efficiency are typically easier to cut with a higher power cutter.

Laser cutting power is important because it affects speed and quality. Machines with higher power cut quicker and make smoother edges. This reduces extra work after cutting. Choosing the right power is key for efficient metal cutting. In addition to being a waste of money, low power laser cutters may reach a specific cutting thicknesses, which impacts cutting speeds and effectiveness. Occasionally, a low-power laser cutting machines may not be able to cutting thicker materials, and medium thick materials are even more difficult to reach. This will impact the timely completion of your cutting tasks.

| Power Level | What It Means |

|---|---|

| High Power | More than 6kW |

| Middle Power | Between 3kW and 6kW |

| Low Power | Less than 3kW |

How Laser Cutting Power Impacts Performance

A laser machine’s performance depends on its power level. Higher power cuts faster and works better on thick metals. For example, a 6kW laser cuts up to 1.25 inches thick efficiently. A 3kW laser is best for thinner metals, up to 0.83 inches.

| Laser Power | Metal Thickness | Cutting Speed | Efficiency Level |

|---|---|---|---|

| 3kW | Up to 0.83 inch | Medium | Best for thin metals |

| 4kW | Up to 1.04 inches | Good | Works for medium thickness |

| 6kW | Up to 1.25 inches | High | Great for tough materials |

Higher power also boosts production. A 6kW laser cuts more pieces per hour than a 3kW one. This makes it ideal for industries needing fast production.

Tip: Match the power level to your material thickness and job needs for better results.

Common Power Ranges for Metal Cutting

Laser machines have different power levels for various tasks. Knowing these helps you pick the right one:

- Low Power (<3kW): Best for thin metals like aluminum or steel. These are cheaper but slower for thick materials.

- Middle Power (3kW - 6kW): Good for medium-thick metals. They balance cost and performance well.

- High Power (>6kW): Perfect for thick and strong metals. They are fast but cost more to run.

| Power Level | Metal Thickness | Cutting Speed (m/min) | Finish Quality |

|---|---|---|---|

| <3kW | <8mm | 0.3 - 0.5 | Smooth Finish |

| 3kW | <20mm | 0.3 - 0.5 | Good Results |

| 6kW | <12mm | 2.5 - 5.2 | Consistent Quality |

| 12kW | <25mm | 0.5 - 1.2 | Bright Finish |

| 24kW | <25mm | 1.2 - 2.9 | Very Efficient |

Think about the metal thickness you cut most often. A 3kW machine handles up to 20mm, while a 6kW machine works well for up to 30mm.

Factors Influencing Fiber Laser Cutting Machine Power Selection

Material Type and Properties

The kind of metal you cut matters a lot. Metals like aluminum and copper reflect light, making cutting harder. These need stronger lasers for clean cuts. Mild steel and stainless steel absorb laser energy better. They need less power for the same thickness.

Stronger metals need more laser power to cut well. For example, titanium or hardened steel needs high-power lasers to cut through. Softer metals like brass can use lower power. Knowing your material helps you pick the right laser machine.

| Factor | Description |

|---|---|

| Types of Metals | Different metals need different power levels for cutting. |

| Material Thickness | Thicker metals need stronger lasers to cut properly. |

| Operating Efficiency | Higher power makes cutting faster and more efficient. |

Thickness of the Material

Thicker metals need more laser power to cut through. Thin sheets can be cut with less power. For example, a 3kW laser cuts up to 0.83 inches thick. Anything thicker might not cut well. A 6kW laser can cut metals up to 1.25 inches thick easily.

More power also means faster cutting for thick materials. This saves time and boosts productivity. But using too much power on thin metals wastes energy and costs more. Matching laser power to material thickness gives the best results.

- Laser power matches the thickness of the metal being cut.

- Higher power cuts faster and works better on thick materials.

Cost Efficiency and Energy Consumption

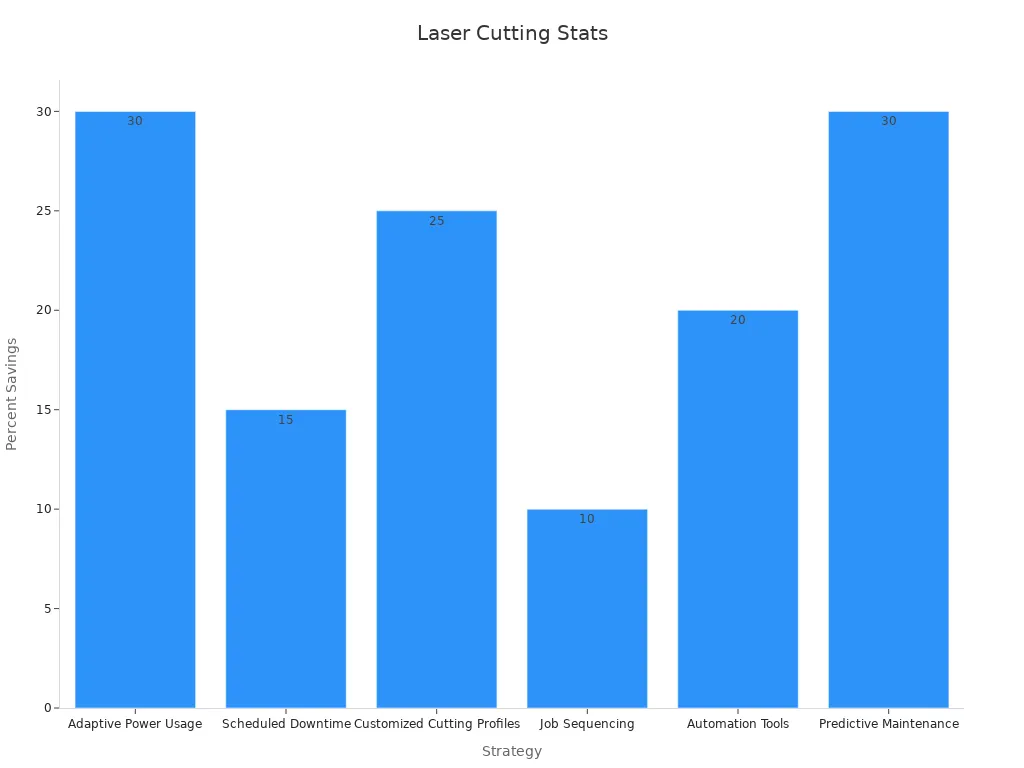

Choosing the right power saves money and energy. High-power lasers cost more to run but cut faster. This reduces extra work after cutting, saving time and money.

Using energy-saving methods can lower costs. For example, adaptive power settings save up to 30% energy. Scheduling breaks and planning jobs well also reduce expenses. Automation tools and regular maintenance improve efficiency and save money.

| Strategy | Energy Savings / Cost Reduction |

|---|---|

| Adaptive Power Usage | Saves up to 30% energy |

| Scheduled Downtime | Cuts energy costs by 15% |

| Customized Cutting Profiles | Boosts efficiency by 25% |

| Automation Tools | Improves efficiency by 20% |

Using energy-smart methods keeps costs low without losing quality. This makes laser cutting both affordable and effective.

Machine Versatility and Adaptability

When picking a fiber laser cutting machine, flexibility is very important. A machine that works with different tasks and materials gives better value. In 2025, advanced machines have features for many uses, saving both time and money.

Modern laser machines are flexible because they support different power levels. Higher power cuts faster and handles thicker materials. For example, a 6kW laser works for medium metals, while a 12kW laser is great for heavy tasks. Machines with adjustable power can easily switch between materials and thicknesses.

| Metric | Description |

|---|---|

| Laser Power Ratings | Higher power means faster cutting and thicker material cutting. |

| Cutting Speed | Faster speeds improve efficiency and make machines more useful. |

| Material Compatibility | Machines that work with many materials are more adaptable. |

Adaptable machines can also combine with other processes. Many now include cutting, drilling, or welding in one system. This makes them more useful and saves time. For example, one machine can cut, engrave, and weld, lowering costs and production time.

Tip: Choose machines that handle many tasks. This saves money on extra equipment.

Highly adaptable machines reduce the need for special tools. They switch between cutting and engraving easily. This is helpful for industries needing precision, like car or airplane manufacturing.

- Works for cutting and engraving tasks.

- Saves money by reducing the need for extra machines.

Machines that handle materials like aluminum and steel show great versatility. One machine can cut thin sheets or thick plates. This helps meet customer needs and stay competitive.

Picking a flexible laser machine prepares your business for the future. You can handle new materials and projects as you grow. This keeps your investment valuable for a long time.

Advancements in Laser Cutting Power Technology

Ultra-High-Power Lasers

Ultra-high-power lasers are changing how metal is cut. These lasers, often over 20kW, work faster and more precisely. They easily cut thick materials, making them great for industries like aerospace. For example, a 24kW laser cuts 30mm steel quicker than weaker lasers. This saves time and boosts productivity.

These lasers also make cleaner cuts with smoother edges. This means less extra work is needed after cutting, saving time and money. However, they use more energy. Think about your needs before buying one. If you often cut thick or tough metals, these lasers might be the best choice.

Fiber Lasers vs. CO2 Lasers

Fiber and CO2 lasers are common for cutting metal. Fiber lasers use optical fibers to create the laser beam. They are energy-saving and need less upkeep. CO2 lasers use gas to make the beam and are better for cutting non-metals like wood.

Fiber lasers are great for reflective metals like aluminum. They also cut thin materials faster. CO2 lasers are versatile but struggle with reflective metals. If you mainly cut metal, fiber lasers are more efficient and cost less to run.

| Feature | Fiber Lasers | CO2 Lasers |

|---|---|---|

| Efficiency | High | Moderate |

| Maintenance | Low | High |

| Material Suitability | Reflective metals, thin sheets | Non-metals, thicker materials |

Pick the laser type based on your material and budget. Fiber laser cutting machine are a modern and efficient choice for cutting metal.

Automation and Smart Features

Automation is improving laser cutting machines. New machines have smart features that save time and effort. For example, automated material loaders reduce manual work. Smart sensors adjust settings automatically for better results.

Some machines also use AI-powered software. This software plans cutting paths to reduce waste. You can even control the machine remotely with a phone or tablet. These features make work faster and more accurate.

Tip: Choose machines with automation to stay ahead in 2025.

Automated laser machines are a smart investment. They improve efficiency and lower costs, making them a great choice for your business.

Recommendations for Laser Cutting Power in 2025

Suggested Power Levels for Common Metals

Choosing the right power depends on the metal type. Each metal needs specific power for clean cutting. For example:

- Carbon Steel: Use a 3kW laser for sheets under 8mm. It gives a shiny finish. For plates up to 20mm, a 6kW laser works faster and better.

- Stainless Steel: A 6kW laser cuts up to 12mm smoothly. For thicker pieces, a 12kW laser ensures steady quality.

- Aluminum: Reflective metals like aluminum need more power. A 12kW laser cuts up to 25mm with a bright edge. A 24kW laser is best for thicker plates.

| Power Level | Material Type | Thickness Range | Cutting Quality |

|---|---|---|---|

| 3kW | Carbon Steel | Up to 8mm | Shiny finish |

| 6kW | Stainless Steel | Up to 12mm | Smooth edges |

| 12kW | Aluminum | Up to 25mm | Bright-cut finish |

| 24kW | High-Reflective | Up to 40mm | High efficiency |

Tip: Match laser power to metal type and thickness for best results.

Power Levels for Different Applications

Different jobs need different power levels. Knowing this helps you pick the right machine.

- Small Businesses: Machines with 20W to 500W are good for engraving or thin sheets. They are affordable and work well for light tasks.

- Industrial Use: For heavy cutting, 500W to 10,000W machines are fast and precise. They suit large-scale jobs.

- Custom Solutions: Special projects may need 20W to 500W, depending on the material and design.

| Application Type | Power Range | Efficiency Level |

|---|---|---|

| Small Business | 20W to 500W | Moderate |

| Industrial Production | 500W to 10,000W | High |

| Custom Projects | 20W to 500W | Variable |

Higher power also means faster cutting. For example, a 6kW laser cuts carbon steel up to 20mm thick at 0.5 to 0.8 meters per minute. This is great for industries needing quick results.

Future-Proofing Your Investment

Buying a laser machine is a long-term choice. To keep it useful, think about these points:

- Scalability: Pick a machine with adjustable power. This lets you cut more materials as your business grows.

- Technology Integration: Look for machines with smart features. These include AI cutting paths and remote controls, which save time and reduce waste.

- Durability: Strong machines last longer and need less fixing. This saves money and avoids delays.

Note: A flexible machine with modern features keeps its value for years.

By choosing the right power and features, you can meet today’s needs and prepare for tomorrow. This keeps your business efficient and competitive.

Common Mistakes When Choosing Laser Cutting Machine Power

Misjudging Power Needs

A big mistake is picking the wrong power level. Using too much power wastes energy and raises costs. For example, cutting thin aluminum with a 6kW laser uses extra energy without better results. Too little power causes bad cuts, slower work, or damaged materials. A 3kW laser struggles with thick or shiny metals, leaving rough edges or incomplete cuts.

To fix this, match power to the metal's thickness and type. Thicker metals need stronger lasers for clean cuts:

| Factor | Description |

|---|---|

| Material Thickness | Thicker metals need higher power for proper cutting. |

| Type of Metal | Reflective metals need more power for smooth results. |

| Operating Efficiency | Higher power boosts speed and production, saving time. |

Think about your needs to pick the right power for better results and lower costs.

Ignoring Material Differences

Each metal reacts differently to laser cutting. Forgetting this can cause bad results. Shiny metals like aluminum and copper need more power to avoid reflection problems. Softer metals like brass need less power to stop rough edges or bending.

Keep these tips in mind for better cuts:

- Metals have unique traits that affect cutting performance.

- Thin metals need less power, while thick ones need more.

- Test new materials to find the best power settings for smooth cuts.

Skipping these steps wastes materials, raises costs, and upsets customers. Always test your machine on the metals you plan to cut.

Forgetting Long-Term Costs

Only looking at the price tag can be a mistake. High-power lasers cost more upfront but save money later by working faster and needing less fixing. Low-power machines are cheaper at first but take longer and use more energy, raising costs over time.

To save money long-term, try these ideas:

- Energy Use: Pick energy-saving machines to lower bills.

- Adjustable Power: Change power settings to fit jobs and save up to 30% energy.

- Breaks: Plan downtime to cut energy use by 15% and keep machines lasting longer.

By thinking about these factors, you can choose a machine that balances cost now with savings later.

Final Checklist for Selecting Laser Cutting Power

Key Questions to Ask

When picking the right laser cutting power, asking smart questions helps. These questions guide you to match your needs with the machine's abilities:

- What is the thickness of the materials you cut most often?

Thicker metals need stronger lasers. For example, a 6kW laser cuts up to 1.25 inches. A 3kW laser is better for thin sheets. - What types of metals do you work with?

Metals like aluminum and copper reflect light and need more power. Softer metals, such as brass, need less power for smooth cuts. - How important is cutting speed for your operations?

Faster cutting comes with higher power. This boosts productivity. If you cut large amounts quickly, a high-power laser is a must. - What is your budget for operating costs?

Stronger lasers cost more to run but save time. Balancing upfront costs with long-term savings is important. - Do you need a machine that can handle multiple tasks?

Machines with adjustable power can cut different materials. They are a smart choice for long-term use.

Answering these questions helps you pick a machine that fits your needs.

Tip: Test the machine on your materials before buying to ensure it works well.

Summary of Factors to Evaluate

To choose wisely, think about key factors. These decide how well the machine works for your tasks. The table below shows the main points:

| Factor | Description |

|---|---|

| Material Thickness | Thicker metals need stronger lasers for clean cuts. |

| Metal Type | Reflective metals like aluminum need more power to avoid issues. |

| Operating Efficiency | Higher power means faster cutting, saving time on big projects. |

| Cost | Stronger lasers cost more but work faster and more precisely. |

Also, keep these in mind:

- Laser Power: Stronger lasers are better for thick materials. For instance, a 12kW laser cuts 25mm aluminum with a shiny finish.

- Metal Characteristics: Each metal reacts differently to lasers. Reflectivity and melting points affect the power needed.

By thinking about these factors, you can pick a machine that fits your goals and budget. A good machine will meet today’s needs and adapt to future ones.

Note: Choose machines with adjustable power. They handle many materials and stay useful as your business grows.

Picking the right laser power helps cut metal well in 2025. Think about the material, thickness, cost, and new technology. For example:

- Plasma cutting is great for metals like steel.

- Laser cutting is better for thin sheets, saving material but costing more.

Talk to experts and try machines to find the best fit. Choose flexible tools that can handle future changes. This keeps your business running smoothly and saves money over time.

FAQ

What is the best laser power for cutting stainless steel?

A 6kW laser is great for cutting stainless steel up to 12mm thick. For thicker sheets, use a 12kW laser for faster and smoother cuts.

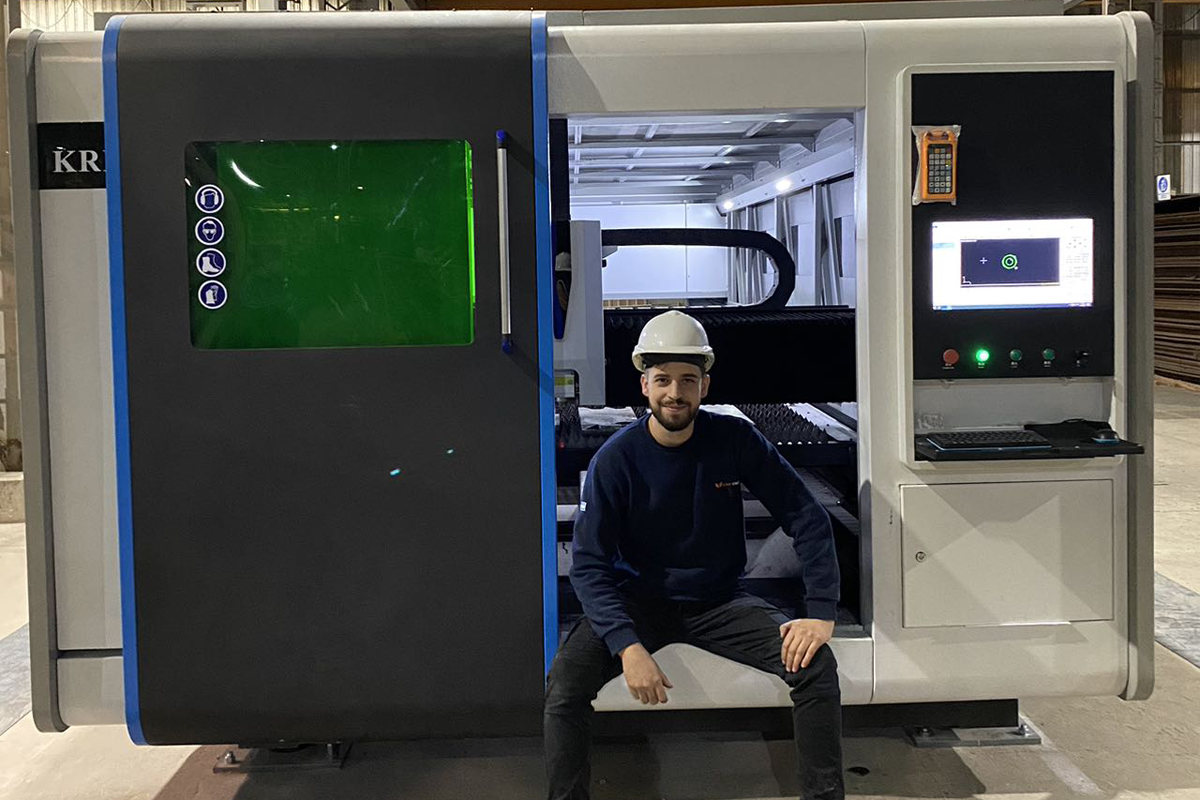

Can one laser machine cut different materials?

Yes, many modern machines, like those from KRRASS, have adjustable power. This lets you cut materials like aluminum, carbon steel, and stainless steel accurately.

How do reflective metals impact laser cutting?

Reflective metals, like aluminum and copper, can reflect the laser beam. Fiber lasers with higher power are better for cutting these materials efficiently.

Is a high-power laser always the best choice?

Not always. High-power lasers are faster for thick materials but use more energy. For thin sheets, a 3kW laser saves energy and still cuts well.

How can I lower the running costs of my laser machine?

Use energy-saving tools like adaptive power settings. Plan breaks to save energy. Regular maintenance keeps the machine efficient and avoids expensive repairs.

What’s the difference between fiber lasers and CO2 lasers?

Fiber lasers are better for cutting metals, especially reflective ones. They need less upkeep and use less energy. CO2 lasers are good for non-metals but struggle with reflective surfaces.

How can I make my laser cutting machine last longer?

Pick a fiber laser cutting machine with adjustable power and smart features like AI cutting paths. These help you handle new materials and projects, keeping the machine useful for years.

Why should I pick KRRASS for laser cutting machines?

KRRASS makes advanced machines that are precise, energy-efficient, and flexible. Their machines meet various needs and provide excellent performance for a long time.

Tip: Test your machine on the materials you plan to cut. This helps ensure it works well and reduces waste.