How to choose the valve group for cnc press brake?

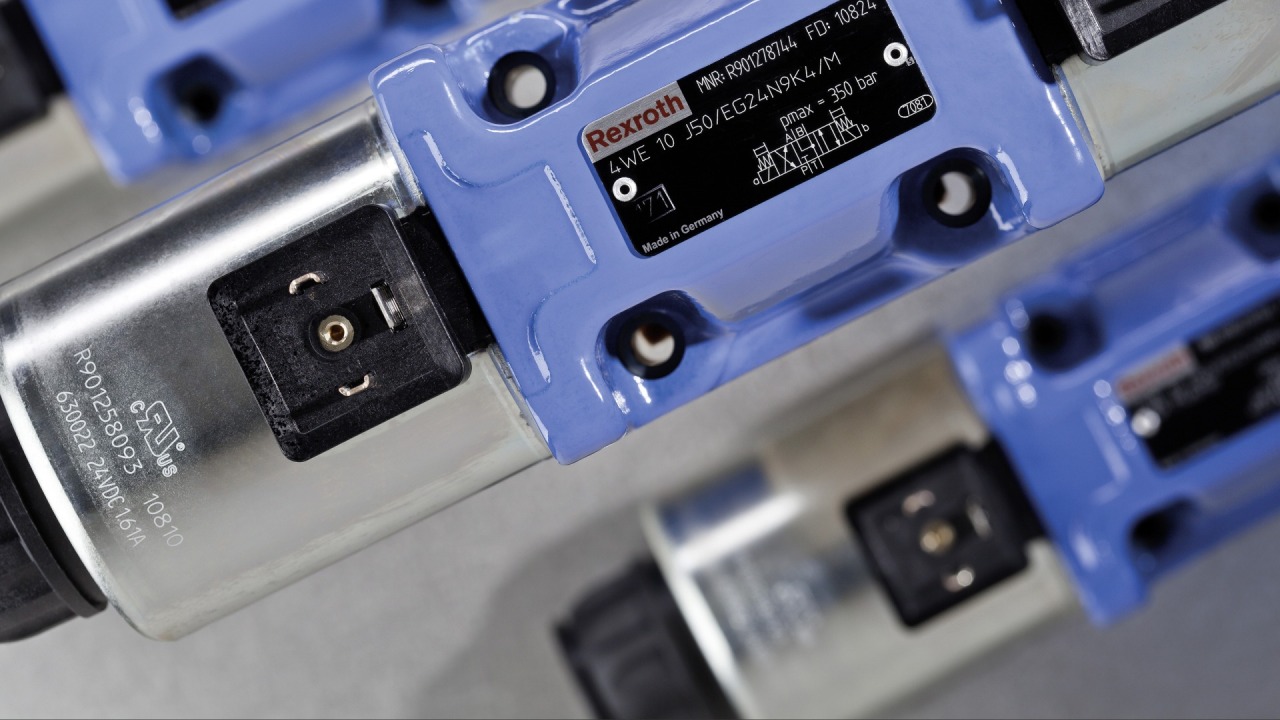

When we choose CNC Press Brake, we often pay attention to the configuration of the machine, such as: CNC system? Hydraulic system? Machine frame? These points are one of the most concerned configurations. So in this issue, we will introduce the differences between Rexroth valve group and Chinese valve group and their respective advantages:

- Brand and technology: As a German brand, Rexroh may have a longer history and more advanced technology accumulation, and may have higher precision and reliability in the design and manufacture of hydraulic valve groups. Chinese valve group brands may have started late, but they may have made technological progress in recent years, but there may still be gaps in some core components or processes.

- In terms of materials: German products may use higher quality alloy materials with better resistance to high temperature and high pressure, while Chinese products may use ordinary materials, which may have lower costs but may not be as long-lasting and stable as imported ones.

- In terms of manufacturing technology:Germany's manufacturing technology may be more sophisticated, with strict quality control and advanced testing methods, while China may have technological deficiencies, resulting in poor product consistency.

- In terms of performance parameters: Rexroh valve groups may perform better in flow control, response speed, pressure stability, etc., and are suitable for high-precision, high-load application scenarios. Chinese ones may perform well in conventional applications, but may not be as good as imported ones under extreme conditions.

- In terms of price: Rexroh is obviously more expensive, while China's products are more cost-effective and suitable for users with limited budgets.

- After-sales service: German brands may have a global service network, but the cost is high and the response may be slow. China may have more timely local services, but the technical support capabilities may vary.

- Customization capabilities: Rexroh may be more flexible and can customize solutions according to needs, while Chinese brands may perform well in standardized products and have limited customization capabilities.

- Application areas: Rexroh is suitable for high-end industry, engineering machinery, and precision control, while Chinese brands may be in the mid- and low-end markets, such as general manufacturing, construction machinery, etc.

- In terms of user feedback: Germany's Rexroth may have a better reputation. Chinese brands may have polarized reviews, with some users satisfied but also reporting unstable quality, depending on the customer's processing accuracy requirements.

- Market trends: China's trend of replacing imports, as well as the situation of technology introduction and independent research and development. For example, whether China's progress in hydraulic technology in recent years has narrowed the gap with German Chinese products.

- Standards and cycles: Factors that users may be concerned about include the supply cycle, the convenience of parts supply, and whether it complies with international standards. For example, whether Rexroh products comply with CE and ISO certifications, and whether China also has corresponding certifications.

There are significant differences between the German Bosch Rexroth valve group and the Chinese brand valve group in many dimensions. The following is a systematic comparison from the perspectives of technology, performance, cost, etc:

1.Technology accumulation and R&D capabilities

- Bosch Rexroth:Rexroth has accumulated a century of technology and is rich in core patent technologies, especially in the fields of precision machining, dynamic response and intelligent control.With high R&D investment and fast product iteration, it can adapt to the needs of high-end industrial scenarios (such as engineering machinery and aerospace).

- China Brand:In recent years, technological progress has been significant. Some leading companies (such as Hengli Hydraulics and Eddie Precision) have achieved mid-to-high-end breakthroughs, but the core design and material technology are still far behind imports. R&D is mostly focused on cost-effectiveness optimization, with less original technology, and relying on imitation or improvement of foreign mature products.

2.Materials and manufacturing processes

- Bosch Rexroth:The use of high-strength alloy, surface hardening treatment (such as PVD coating) and precision casting technology has strong wear resistance and corrosion resistance. The processing accuracy reaches the micron level, and the key components such as valve cores and seals have high stability.

- China Brand:Medium carbon steel or ordinary stainless steel is commonly used, the coating technology is relatively basic, and it is easy to wear under long-term high pressure. The processing equipment of some enterprises is not accurate enough, resulting in large fluctuations in sealing and life.

3.Performance(Bosch Rxroth)

- Dynamic Response:Bosch Rexroth (such as proportional servo valves) have a response time of up to milliseconds, which is suitable for high-frequency, high-precision control. The response speed of Chinese valve groups is mostly above 10ms, which is suitable for conventional industrial scenarios.

- Pressure and flow control:Rexroth has low pressure drop and low internal leakage rate under high pressure (>350bar) and large flow conditions. Chinese valve groups are stable below 200bar, but are prone to vibration, noise and other problems under high pressure.

4.Reliability and lifespan

- Bosch Rexroth:The mean time between failures (MTBF) can reach over 10,000 hours, and it can adapt to harsh environments (high temperature, high humidity, and dust).

- China Brand:MTBF is usually between 3,000 and 5,000 hours. Long-term high-load operation may cause problems such as seal aging and valve core sticking.

5.Cost and performance

- Bosch Rexroth:The unit price is usually 3 to 5 times that of China, but the full life cycle cost (maintenance, energy consumption) may be lower.

- China Brand:The price advantage is significant and it is suitable for budget-sensitive or short-cycle projects, but frequent replacement may increase hidden costs.

6.Service and adaptability

- Bosch Rexroth:The global service system is well-developed and provides customized solutions (such as integrated sensors and intelligent diagnosis), but the after-sales response cycle is relatively long.

- China Brand:The localized service is fast and supports small-batch customization, but its adaptability to complex working con

- Bosch Rexroth:Pursuing extreme reliability, long life or high-end technical requirements (such as intelligent control).

- China Brand:The localized service is fast and supports small-batch customization, but its adaptability to complex working conditions is limited.

- Trend: China's valve group has become more competitive in the mid-range market. Some companies (such as the Rexroth joint venture) have achieved import substitution, but they still need to rely on imports in the high-end field.