In the process of using CNC press brake, it is inevitable that there will be more or less problems. For example, when it makes abnormal noise, what are the problems and how should we adjust them? In fact, there is no need to worry about it. This problem can be eliminated according to the driver parameters and mechanical precision.

1. Drive parameter problem

Adjust the control precision of the bending machine motor with the manual operator, in which the motor parameters KP, KFF and TVI and so on, reduce the values of the first two items respectively, but this operation will reduce the accuracy of the construction machinery design work. Therefore, we need to adjust the value, as long as the value is moderate, do not just pursue the mute effect and affect the accuracy of the analysis.

2. Mechanical precision

When carefully identifying the gear noise or the sharp noise at the end of the motor, check whether the spring machine has loose parts. If possible, check whether there is clearance between the gears. Generally, when adjusting the motor, as long as the motor is loosened with the fixed screw, it needs to be tightened a little.

- The components of CNC bpress brake include synchronous system, slide block, blocking mechanism and worktable. The synchronous system is composed of torsion shaft, swing arm, spherical plain bearing and so on. The overall structure is simple, the performance is stable and reliable, and the synchronous precision is high.

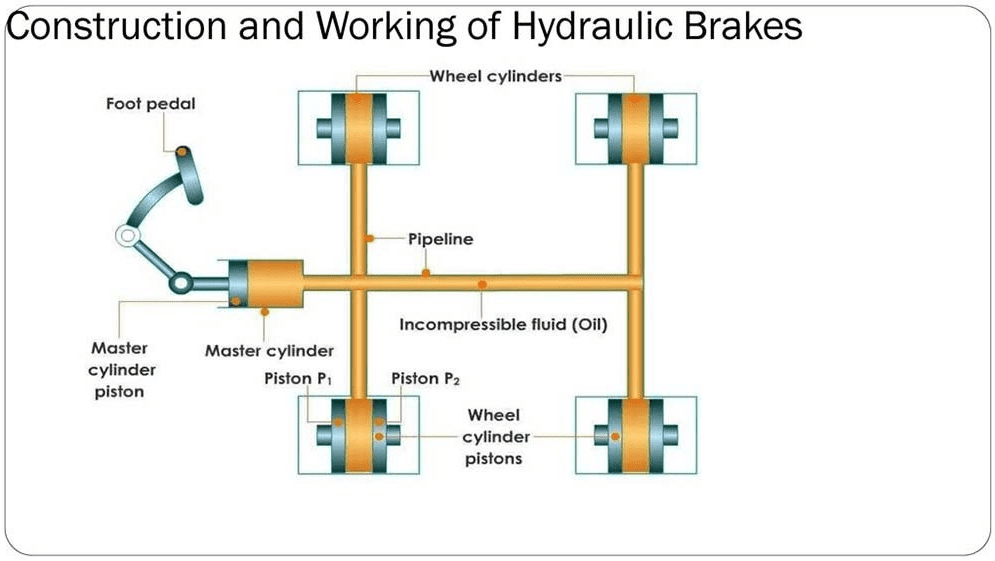

- Because the numerical control bending machine adopts the hydraulic transmission mode, its slider part is composed of slider, oil cylinder and mechanical block fine-tuning structure; The left and right cylinders of the CNC press brake are fixed on the frame, the piston moves up and down through the hydraulic drive slider, and the mechanical stop is controlled and adjusted by the CNC system.

- The CNC press brake is driven by a motor. The motor drives two screws to move synchronously through chain operation. The CNC system controls the size of materials. The worktable is operated by the button box, so that the motor of the numerical control bending machine drives the baffle frame to move forward and backward, and the moving distance is controlled by the numerical control system.

Maintenance skills of CNC press brake

- Add smooth oil to slide block, eccentric pulley, belt pulley and rotating parts once a week. Inject smooth oil into the oil hole every day to keep the parts of the bending machine smooth.

- The maintenance personnel of the bending machine shall check one by one according to the requirements of the point inspection and maintenance items of the bending machine every day to ensure the normal operation of the bending machine and make records.

- Regularly check whether the screws and fasteners of each part of the bending machine are locked and not loose; Check whether the power cord is damaged or aging, whether the socket contact is good and reliable, and repair and replace it in time.

- Every operator must understand the repair and maintenance of the bending machine. If the CNC press brake is not used for a long time, it should be sorted out first, covered with a protective cover and kept properly. Every half a year, idling for a short period of time, should be completely stable.

Learn more about our products, please visit and subscribe to our Youtube channel