The NC Press Brake is to use the equipped mold (general or special mold) to bend the cold metal sheet into various geometric cross-sectional shapes. The press brake generally adopts the special CNC system for the press brake. The coordinate axis of the press brake has been changed from the single.

The axis is developed to 12 axes, and the numerical control system can automatically realize the sliding depth control, the left and right tilt adjustment of the sliding block, the front and back adjustment of the back stopper, the left and right adjustment, the pressure tonnage adjustment and the slider approaching speed adjustment and so on. The press brake can easily realize the actions of slide down, jog, continuous, pressure holding, return stroke and halfway stop, and can bend multiple elbows of the same angle or different angles in one feeding.

What is NC Press Brake?

The technical field of nc press brake specifically relates to a press brake torsion shaft synchronization device. The torsion shaft synchronization device includes a synchronous torsion shaft, a swing arm connected to both ends of the synchronous torsion shaft, and a connecting rod connected to the swing arm.One end of the swing arm is movably connected with the synchronous torsion shaft, the other end of the swing arm is movably connected with the connecting rod, the bottom end of the connecting rod is provided with a swing arm pier, and a slider reinforcement is provided below the swing arm pier.

Ribs, the slider reinforcement ribs are arranged inside the slider and support the slider. The two ends of the synchronous torsion shaft can move synchronously, so that the two ends of the slider can move up and down synchronously to meet the requirements of its balance. The torsion axis servo press brake has the characteristics of reasonable design, simple assembly adjustment, easy parts processing, and improved product quality.

Choice of nc press brake system:

1.ESTUN E21 Control

- The high-definition hydraulic display has two languages, Chinese and English, and one page displays programming parameters, making it faster and more convenient to write programs.

- Intelligent positioning of X and Y axes can also be adjusted manually as required, eliminating the mechanical manual positioning device.

- Built-in pressure holding time, unloading delay setting function, the operation is simpler, and there is no need for a time relay to reduce the cost.

- With parameter one-key backup and restore function, parameters can be restored at any time as needed to reduce maintenance costs.

Support multi-process programming, complex workpieces can be processed at one time, improving production efficiency and processing accuracy. - All the buttons on the panel are micro switches, which have been strictly tested for EMC, high and bottom temperature, and vibration. Ensure product stability and service life.

- Passed CE certification to meet the needs of overseas markets.

2.ESTUN E310P Control

4 axes are supported, viz, X-axis, Y-axis, R-axis and C-axis.

4 axes are supported, viz, X-axis, Y-axis, R-axis and C-axis.- The back gauge can be controlled in a high-accuracy since the servo systems control X-axis and R-axis.

- Automatic calculation of the block position, according to the bending angle, material, thickness and mold parameters.

- The back gauge can be controlled in a high-accuracy since the servo systems control X-axis and R-axis.

- Optional hydraulic or mechanical to control the C-axis.

- Program in absolute value or angle.

- Materials and die informations are programable.

- Language setting and unit setting.

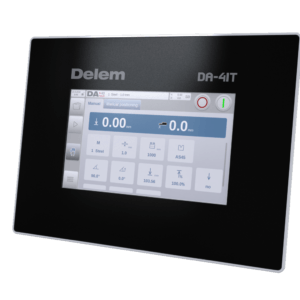

3.Holland DELEM DA41T

- Industrial-grade high-quality touch screen control

- 7″ widescreen high resolution color TFT

- Slider Y axis control

- Backgauge X axis control

- R axis control

- Program memory for 100 programs

- Angular programming

- Tool programming

- Manually move all axes

- USB memory stick interface

4.Switzerland Cybtouch 8

- Large screen, high definition and contrast touch screen system.

- Convenient interface, clear display and large icon buttons.

- The EasyBend page is very convenient for single-step bending.

- Perfect programming can improve the efficiency of batch multi-step bending.

- Online help and pop-up prompts make the software interface very friendly.

- Support multiple languages.

- Use PC or laptop to upgrade and transfer data through wireless software

What is CNC Press Brake?

The cnc press brake does not need to take special measures during the return (up) trip. In the fast-forward phase of the descending stroke, on the basis of parallel synchronization, two one-way throttle valves are used to eliminate the deviation caused by factors such as manufacturing quality, leakage, etc., and to ensure the downward movement with a certain synchronization accuracy. When it enters the work advancement stage but has not touched the workpiece, two correction plunger cylinders installed on the workbench are used for further synchronization correction.

Imagine that one side first comes into contact with the correction plunger, and the larger correction force slows down or stops the movement of that side until the other side catches up and contacts the correction post hydraulic and pneumatic plugs at the same time. The correction force can be set by the overflow valve and read by the pressure gauge. Practice has shown that the synchronization effect is very obvious, this is because various asynchrony factors can be ignored compared with the correction force. In order to make full use of the capacity of the machine, the overflow valve 3 should be unloaded after a period of time.

Imagine that one side first comes into contact with the correction plunger, and the larger correction force slows down or stops the movement of that side until the other side catches up and contacts the correction post hydraulic and pneumatic plugs at the same time. The correction force can be set by the overflow valve and read by the pressure gauge. Practice has shown that the synchronization effect is very obvious, this is because various asynchrony factors can be ignored compared with the correction force. In order to make full use of the capacity of the machine, the overflow valve 3 should be unloaded after a period of time.

Choice of CNC press brake system:

1.Holland DELEM DA53T

- "Hot-key” touch navigation

- 10.1" high resolution colour TFT

- Up to 4 axes (Y1,Y2 + 2 aux. axes)

- Crowning control

- Tool / material / product library

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as

- open-loop valves.

- TandemLink (option)

- USB memory stick interfacing

- Profile-T offline software

2.Holland DELEM DA58Tx

- 2D graphical touch screen programming

- 18.5" high resolution colour TFT

- Bend sequence calculation

- Crowning control

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- USB, peripheral interfacing

- Profile-T offline software

3.Holland DELEM DA66S

- 2D graphical touch screen programming mode

- 3D machine representation, in simulation and production

- 24" high resolution color TFT

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- User specific application support within the control's multitasking environment

- Sensor bending & correction interface

- Profile-S2D offline software

4.Holland DELEM DA69S

- 3D and 2D graphical touch screen programming mode

- 3D visualization, including 3D machine representation, in simulation and production

- 24" high resolution color TFT

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- User specific application support within the control's multitasking environment

- Sensor bending & correction interface

- Profile-S3D offline software

5.Switzerland Cybtouch 12ps

- Large, vivid and high-contrast fully touchscreen.

- Simple pages, clear display, large keys.

- Intuitive user-friendly interface.

- Complete programming for efficient mass-production with multiple bends.

- Easy single bends with EasyBend page.

- On-line help and interactive warning pop-ups.

- Comfortable wireless data backup and software updating using PC or Notebook.

- Large variety of languages available.

6.Switzerland Cybtouch 15ps

- 15” modern streamlined glass surface touch screen that can be used with gloves.

- User friendly HMI thanks to intuitive programming and easy to setup with dedicated wizards (autotuning).

- 2D graphical profile drawing (Touch Profile) and precise 2D program creation.

- Automatic bending sequence calculation.

- Easy single bends thanks to the EasyBend page.

- Wide storage capacity.

- Internal backup and restore functions.

- Wireless communication for extended diagnostics and updates (with laptop).

The biggest difference between nc press brake and cnc press brake:

1. Different structural principles

The design principles of the two models are different, resulting in different structures for ensuring synchronization on both sides of the bending slider. The nc press brake uses a torsion shaft to link the left and right swing rods to form a torsion shaft forcing a synchronization mechanism to move up and down the cylinders on both sides. Therefore, the torsion shaft synchronization press brake is a mechanical forced synchronization method, and the parallelism of the slider cannot be automatically checked and automatically adjusted.

The CNC press brake is to install a magnetic (optical) scale on the slider and the wall plate. The CNC system can analyze the synchronization of the two sides of the slider through the feedback information from the magnetic (optical) scale at any time. If there is an error, the CNC system will pass The proportional electro-hydraulic servo valve is adjusted to synchronize the strokes on both sides of the slider. Numerical control system, hydraulic control valve group and magnetic scale constitute the feedback closed-loop control of cnc press brake.

2. Accuracy

The parallelism of the slider determines the angle of the workpiece. NC press brake is the mechanism to keep the slider synchronized. There is no real-time error feedback, and the machine itself cannot make automatic adjustments. In addition, its partial load capacity is poor (NC press brake uses the torsion shaft to force the synchronization mechanism to move up and down the cylinders on both sides, if the long-term partial load will cause the torsion shaft to deform)

Cnc press brake is the system through the proportional electro-hydraulic valve group to control the slider synchronization, the magnetic (optical) scale real-time error feedback, if there is an error, the system will adjust through the proportional valve after the magnetic (optical) scale feedback to maintain the synchronization of the slider.

3. Speed

There are two points in the work of the machine that determine its operating speed:

- Slider speed,

- Backgauge speed,

- Bending step.

The cylinder of nc press brake is 6:1 or 8:1, which is slow, while the cylinder of cnc press brake is 13:1 or 15:1, which is fast. Therefore, the fast down speed and return speed of cnc press brake are much higher than that of nc press brake.

4. Operation

Because nc press brake is not equipped with a control system and no V-axis compensation, it can only rely on the experience of old workers to do trial bending when processing according to the drawings. If you do not meet the standard, you must continue to try. This process not only produces waste, but also has a small selection range and high wages when recruiting operators.

The cnc press brake is controlled by a professional numerical control system, with V-axis compensation, simple operation, and low requirements for worker experience. There is a simulation bending function, no stakeout is required, only the size of the drawing input step needs to be corrected, and the bending is carried out directly.

5. Strength

Because of its own design, the NC press brake cannot bend under unbalanced load. If it is bent under unbalanced load for a long time, it will cause deformation of the torsion shaft.

The cnc press brake does not have such a problem. The Y1 and Y2 axes on the left and right sides run independently, so they can be eccentrically folded.

Learn more about our products, please visit and subscribe to our Youtube channel

4 axes are supported, viz, X-axis, Y-axis, R-axis and C-axis.

4 axes are supported, viz, X-axis, Y-axis, R-axis and C-axis.

Reviewed by 24 users

Conocimientos muy profesionales, y útil para mí para elegir una máquina de flexión

I run a small factory in Australia,I just bought the CNC press brake MB8-110T3200 from Krrass,I really feel lucky that I chose krrass brand,really perfect machine

My PBS-175T/3200 CNC Press Brake works very well.

Fui a la fábrica de KRRASS y vi mi freno de prensa 200T6000 y estoy muy satisfecho!

perfect machine, the MB8 Press brake is manufactured with high quality.