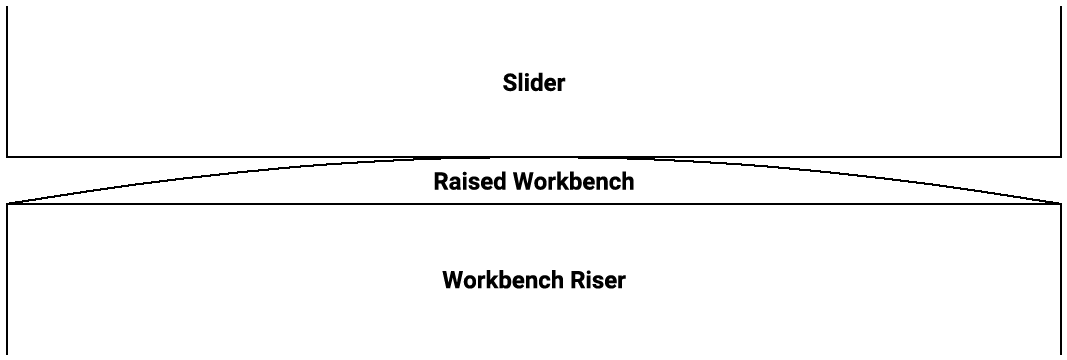

The machine crowning is a device used to compensate for the deflection deformation of a press brake. This deformation can cause the angle of the bend to vary along the length of the workpiece. The convex workbench helps to ensure that the angle is consistent throughout the bending length, which is important for precision bending applications.

Press brake Machine Crowning

The Machine Crowning is a solution to the deflection deformation problem of press brakes. It ensures that the angle of the bend is consistent throughout the bending length, which is important for precision bending applications.

What are the Crowning of deflection deformation?

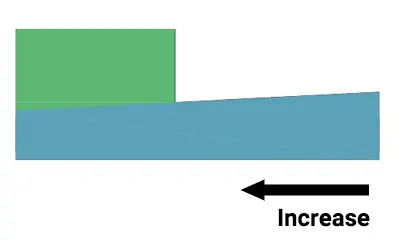

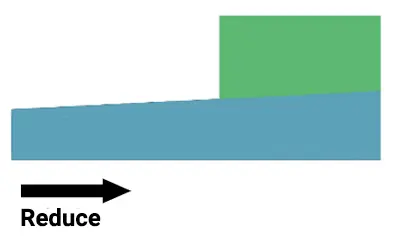

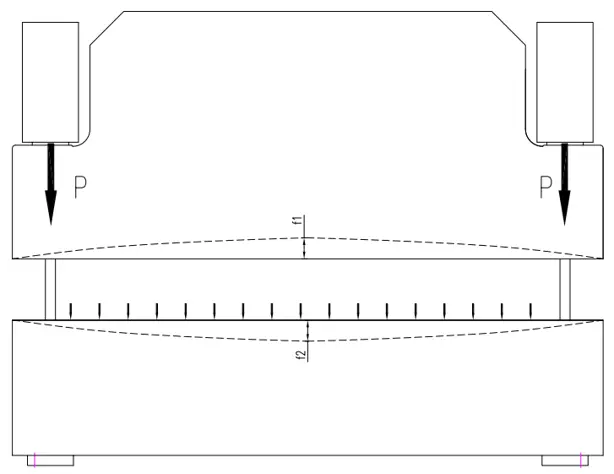

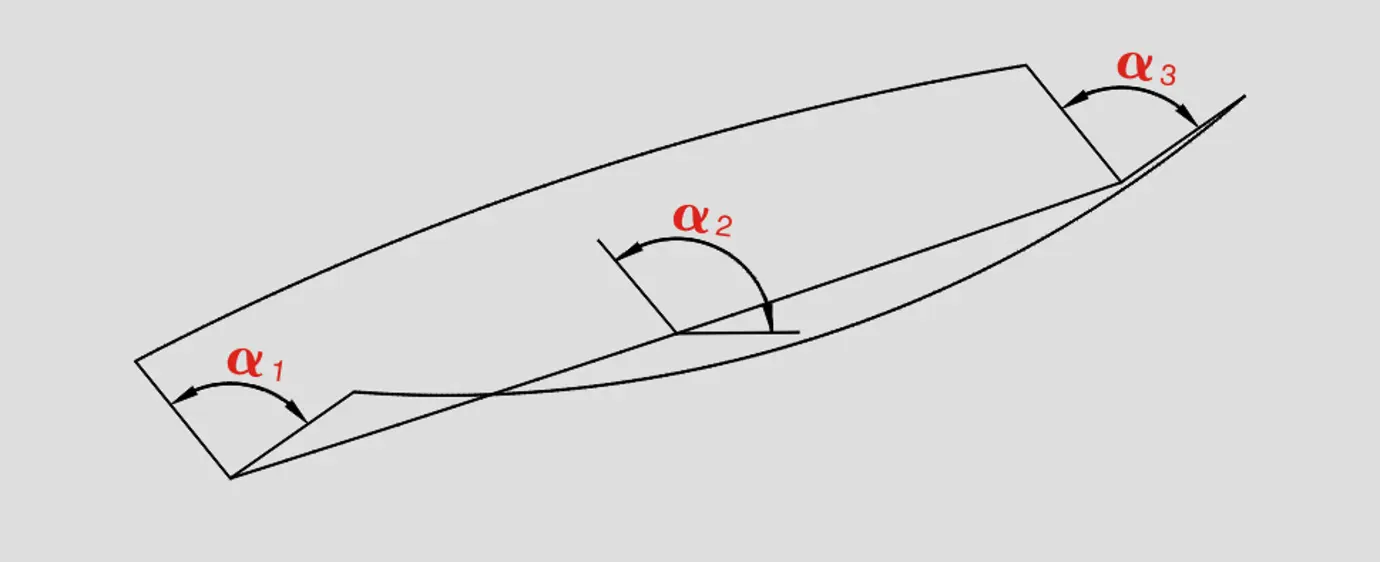

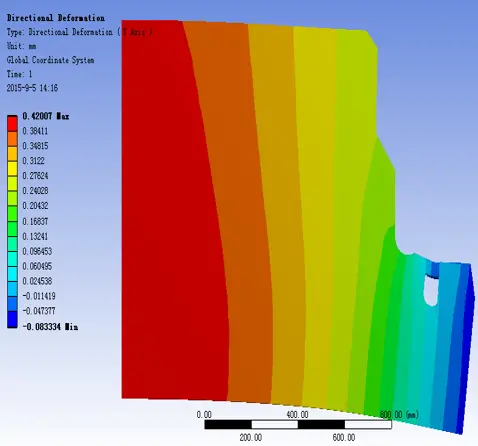

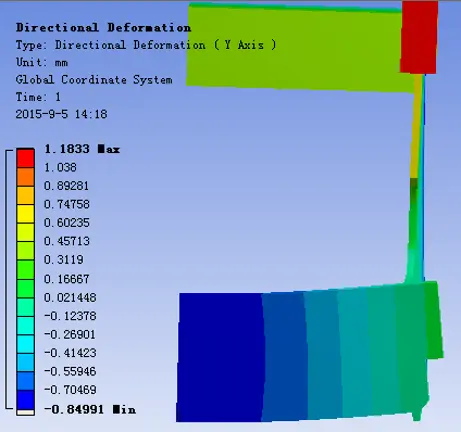

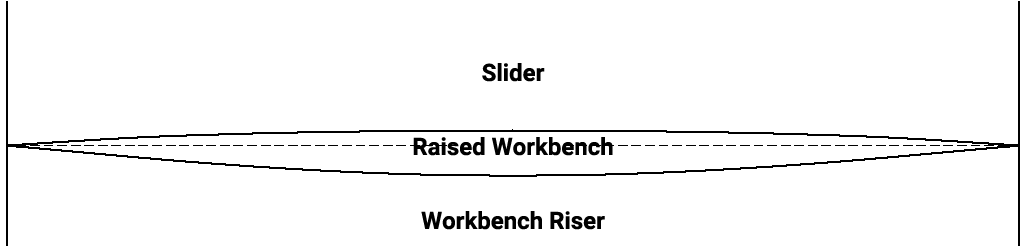

As shown in the figure, the deformation of the middle part of the machine is large, and the deformation of the two ends is small. Therefore, the depth of the two molds entering the lower mold will be deeper. In the absence of compensation, the angles at the two ends of the press brake will be smaller than the angles in the middle.

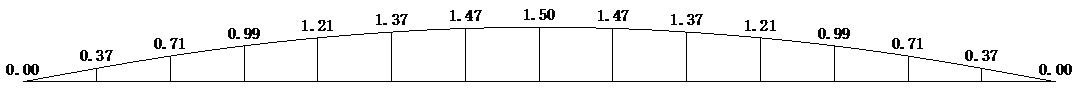

In order to solve the problem of angle errors caused by deflection deformation, we designed a convex workbench to offset the CNC Press Brake Machine Crowning by pre-convexing to ensure a consistent angle throughout the entire bending length.

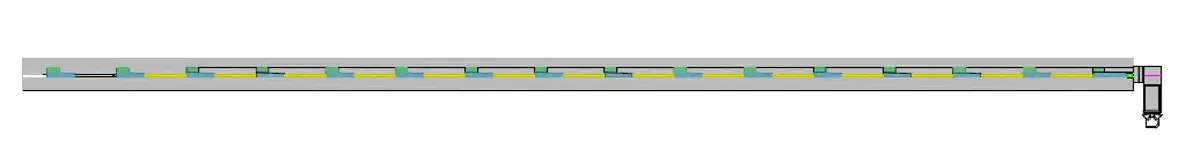

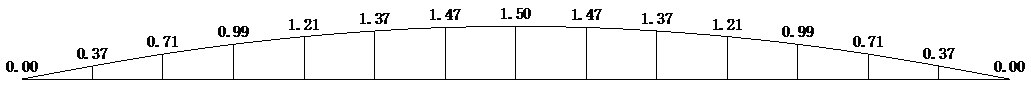

We use finite element analysis to calculate the deflection deformation of the customer's slide block and worktable.

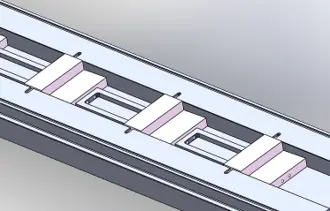

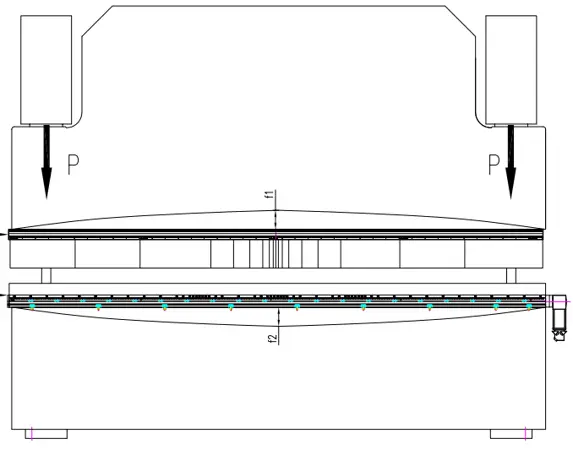

According to this curve, wedge blocks or wave strips are designed and processed. During bending, the convexity of the worktable and the deflection deformation of the machine are offset from each other, which can ensure that the depth of the upper mold entering the lower mold is consistent in the entire length range, and the bending angle is consistent.

The worktable is equipped with precision composite wedges. The wedges are designed and processed according to the deflection deformation curve of the press brake body. Under the drive of the linear push-pull motor at the end of the worktable, the lower wedge moves longitudinally, and the convexity of the worktable increases or decreases accordingly.