Fully Electric CNC Steel Tube Bender With Rotative Head - EB-RH Series

Advanced CNC Steel Tube Bender

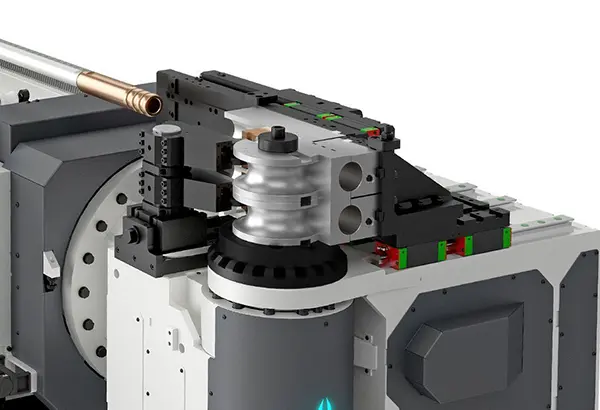

Our fully electric EB-RH series steel tube benders, with rotating heads, contain the most advanced Electric Motion technology on the market with 11 fully electric drive shafts. This range of machines can bend pipes and profiles from 6 to 53 mm with even radii up to 1D with minimal marking when equipped with the booster system. The bending head moves 360º on a radial axis and horizontal and vertical axes. This system offers complete freedom of movement and allows the production of very complex parts in an automatic bending cycle.

100% electric drive of all 11 axles.

Bending head with 360 ° radial axis and horizontal and vertical linear axis.

Bending of multiple fixed and variable radii in the same cycle.

Main Features EB-RH Series

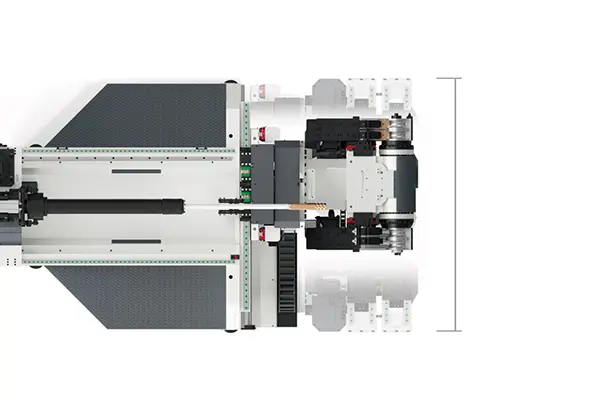

The cycle speed and low energy consumption make these steel tube benders ideal for high-volume and consistent production. Because the level of automation is so advanced, they are easy to integrate into automatic production lines or combine with automatic loading and unloading elements. Thanks to advanced 3D software, the steel tube bender has become an Industry 4.0 machine.

- 100% electric drive of all 11 axles.

- Bending head with 360 ° radial axis and horizontal and vertical linear axis.

- Bending clockwise and counter clockwise in automatic cycle.

- Bending of multiple fixed and variable radii in the same cycle.

- Quick tool change, without having to readjust.

- High working speed and low power consumption.

- Axis movements controlled by servo motors with absolute encoder feedback.

- Simplified synchronisation and optimisation of bending cycles.

- Compact and ergonomic design for optimal operating comfort and maintenance.

- Powerful and intuitive 3D software with anti-collision simulation.

- Easily program or import files from the cloud or from the network.

Freedom Of Movement…

The EB-RH series bending head drive system provides complete freedom of movement. The 360° rotation, combined with the vertical and horizontal axes, allows a quick positioning for the production of very complex bending work. The solution chosen by KRRASS for the rotation is extremely compact and maintenance-free.

It is structurally robust yet lightweight and with a low inertia, allowing for high bending speeds and rapid tool selection adjustments. This unique design dramatically reduces the cycle time of complex bending workpieces.

Easy Integration

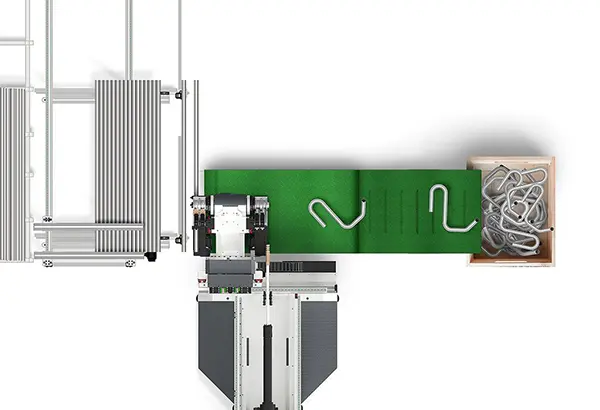

The 360º rotation system, together with the vertical and horizontal movements, contributes to the wide range of movement of the bending head and, if necessary, deflecting the head so that the positioning carriage advances beyond its normal limits.

This feature is particularly important to facilitate integration with automatic loading and unloading systems.

Easy Integration

The EB-RH series bending head drive system provides complete freedom of movement. The 360° rotation, combined with the vertical and horizontal axes, allows a quick positioning for the production of very complex bending work. The solution chosen by KRRASS for the rotation is extremely compact and maintenance-free.

It is structurally robust yet lightweight and with a low inertia, allowing for high bending speeds and rapid tool selection adjustments. This unique design dramatically reduces the cycle time of complex bending workpieces.

The EB-RH series of semi-automatic fixed radius steel tube benders are very versatile, powerful and easy to program and operate. They are intended for sectors that choose versatility and bending quality in terms of speed and productivity. Sectors such as urban furniture, agriculture, prototyping, chemical industry and ship repair.

Steel Tube Bender Technical Parameter

| Model Specification | DW18CNC | DW25CNC | DW38CNC | DW50CNC | DW63CNC | DW75CNC | DW89CNC | DW100CNC | DW114CNC | DW130CNC | DW168CNC | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Maximum bending diameter x thickness(steel) | Φ18 x 1.6mm | Φ25 x 1.6mm | Φ38 x 2mm | Φ50 x 3mm | Φ63 x 3mm | Φ75 x 4mm | Φ89 x 6mm | Φ100 x 8mm | Φ114 x 10mm | Φ130 x 10mm | Φ168 x 14mm | |

| Maximum bending radius (1) | R80mm | R100mm | R180mm | R250mm | R250mm | R250mm | R250mm | R350mm | R350mm | R400mm | R500mm | |

| Minimum bending radius (2) | According to pipe diameter | |||||||||||

| The largest bending angle | 190 ° | 190 ° | 190 ° | 190 ° | 190 ° | 190 ° | 190 ° | 190 ° | 190 ° | 190 ° | 190 ° | |

| Maximum feeding length (3) | 1500mm | 2000mm | 2500mm | 3000mm | 3000mm | 3000mm | 3000mm | 3000mm | 3000mm | 3500mm | 3600mm | |

| Feeding method | Direct feeding Clamping feeding | |||||||||||

| Working speed | Bending speed | Max 200°/s | Max 200°/s | Max 150°/s | Max 85°/s | Max 85°/s | Max 40°/s | Max 30°/s | Max 30°/s | Max 30°/s | Max 30°/s | Max 25°/s |

| Rotary speed | Max 200°/s | Max 200°/s | Max 200°/s | Max 200°/s | Max 200°/s | Max 160°/s | Max 160°/s | Max 160°/s | Max 160°/s | Max 160°/s | Max 160°/s | |

| Feeding speed | Max 1000mm/s | Max 1000mm/s | Max 1000mm/s | Max 1000mm/s | Max 1000mm/s | Max 800mm/s | Max 800mm/s | Max 800mm/s | Max 800mm/s | Max 800mm/s | Max 600mm/s | |

| Accuracy | Bending precision | ±0.1° | ±0.1° | ±0.1° | ±0.1° | ±0.1° | ±0.1° | ±0.1° | ±0.1° | ±0.1° | ±0.15° | ±0.15° |

| Rotary precision | ±0.1° | ±0.1° | ±0.1° | ±0.1° | ±0.1° | ±0.1° | ±0.1° | ±0.1° | ±0.1° | ±0.1° | ±0.1° | |

| Feeding precision | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | |

| Data entry mode | ①Axis( X Y Z ) ②Working value( Y B C ) | |||||||||||

| Bend way (4) |

|

|

|

|

|

|

|

|

|

|

| |

| Power of ratary servo motor (5) | 400W | 400W | 750W | 750W | 750W | 1KW | 1.5KW | 1.5KW | 2KW | 2KW | 3.5KW | |

| Power of feeding servo motor (6) | 750W | 750W | 1KW | 1KW | 1.5KW | 1.5KW | 2KW | 3.5KW | 3.5KW | 5KW | 5KW | |

| Max ellbow bending pipe | ① 18 pieces (PLC type) ②33 pieces (industrial computer type) | |||||||||||

| Max storable sections | ① 200 groups (PLC type) ②1 million groups (industrial computer type) | |||||||||||

| Motor power | 3kw | 3kw | 4kw | 5.5kw | 5.5kw | 7.5kw | 11kw | 15kw | 22kw | 22kw | 22kw | |

| Max hyraulic pressure | 10MPa | 12MPa | 12MPa | 12MPa | 12MPa | 12MPa | 14MPa | 14MPa | 14MPa | 14MPa | 16MPa | |

| Weight of machine | 800Kg | 1000Kg | 1500Kg | 2500Kg | 3000Kg | 4500Kg | 5500Kg | 6000Kg | 7000Kg | 12000Kg | 20000Kg | |

| Measurement | 2760x690x1000mm | 3000x780x1100mm | 3860x780x1200mm | 5000x1350x1230mm | 5200x1350x1230mm | 5200x1350x1360mm | 5650x1350x1360mm | 5700x1350x1400mm | 6120x1460x1400mm | 6630x1860x1400mm | 8100x1965x1660mm | |

Note: (1) (3) According to customer requirements (2) According to the pipe diameter (4) (5) (6) According to the actual product, the final interpretation right belongs to our company.

Reviewed by 10 users

Comprei um bom dobrador de tubos da Krrass. É a primeira vez que compro da China, bom começo.

I want to commend Krrass’s customer support team for their prompt assistance. They responded swiftly to our queries regarding the setup process, which significantly reduced our downtime,great tube bender

CNC pipe bending machine helps a lot to expand production range in full auto

Nous devions plier un tuyau de 2500 mm et nous avons demandé à l’entreprise krrass de nous recommander une cintreuse de tuyaux appropriée, qui convenait parfaitement.

Gran calidad DW38 CNC máquina curvadora de tubos . Y servicio personalizado y mejor imposible.