The advent of plasma cutting in the 1960s brought a revolutionary transformation to the way metal plates were cut. In the pre-plasma cutting era, fabricators predominantly depended on metal-on-metal cutting and oxy-fuel cutting. These traditional methods were associated with significant drawbacks as they generated copious amounts of sparks and debris. Such by-products of the cutting process not only created a messy work environment but also posed a serious safety threat to the personnel involved. However, with the emergence of plasma cutting, the scenario changed drastically.

Plasma cutting, with its advanced technology, manages to minimize the generation of sparks and metal shavings remarkably. This reduction in hazardous by-products makes it a far safer option in comparison to the earlier techniques. Moreover, plasma cutting is renowned for producing edges that are cleaner and devoid of any burn marks on the material, thereby enhancing the overall quality of the cut metal plates.

Plasma Cutting Basics

Plasma cutting has emerged as a significant process in the field of metalworking. It functions by using an accelerated jet of hot plasma to cut through electrically conductive materials. A wide range of materials such as steel, stainless steel, aluminum, brass, and copper can be cut with a plasma torch, and other conductive metals are also within its cutting capabilities. This technique finds extensive application in fabrication shops, automotive repair and restoration, industrial construction, as well as salvage and scrapping operations. Its combination of high speed, precision, and relatively low cost has made it popular from large-scale industrial computer numerical control (CNC) applications to small hobbyist workshops.

The Plasma Cutting Process Unveiled

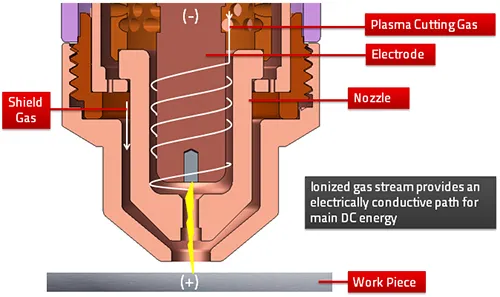

The fundamental mechanism of plasma cutting is quite intricate. Firstly, an electrical channel of superheated and electrically ionized gas, known as plasma, is generated from the plasma cutter. This plasma travels through the workpiece that needs to be cut, and then a completed electric circuit is formed back to the plasma cutter via a grounding clamp. This is achieved by a compressed gas (which can be oxygen, air, inert gases, or others depending on the material being cut). The gas is blown at high speed through a focused nozzle towards the workpiece.

Subsequently, an electrical arc is created within the gas, between an electrode near or integrated into the gas nozzle and the workpiece. This electrical arc ionizes a portion of the gas, giving rise to an electrically conductive plasma channel. When electricity from the cutter torch passes through this plasma, it generates enough heat to melt the workpiece. Concurrently, the high-velocity plasma and compressed gas expel the hot molten metal, effectively cutting through the workpiece.

Advantages and Applications of Plasma Cutting

The advantages of plasma cutting are numerous. It offers high cutting speeds and remarkable precision, allowing for detailed and accurate cuts. The reduction in sparks and metal shavings compared to traditional cutting methods enhances safety in the workplace. Moreover, the clean edges it produces without burn marks on the material contribute to a superior finish. In terms of applications, it is widely utilized in various industries.

Fabrication shops rely on it for creating custom metal components. In automotive repair and restoration, it helps in cutting and shaping metal parts. Industrial construction projects use plasma cutting for erecting structures and installing metal fixtures. Salvage and scrapping operations also benefit from its ability to efficiently cut through large pieces of metal for recycling or disposal purposes.

The Drawbacks of Plasma Cutting

Despite the numerous advantages that plasma cutting offers in comparison to other fabrication techniques, it is not without its limitations.

Material Limitation: Plasma cutting is restricted to conductive materials only. This means that non-conductive substances cannot be processed using this method, which may require alternative cutting processes for certain projects.

Thickness Constraint: It is not the most suitable option for metals thicker than 150mm (approximately 6 inches). As the thickness increases, the efficiency and quality of the cut may decline, and other cutting tools might be more appropriate for such heavy-duty tasks.

Eye Hazard: The bright flashes that occur during the cutting process can have a harmful impact on the eyes. Without proper eye protection, operators are at risk of eye damage, making the use of appropriate safety eyewear essential.

Noise Pollution: The operation of a plasma cutter tends to be noisy. This necessitates the use of hearing protection for the safety and comfort of the operator, as prolonged exposure to high levels of noise can lead to hearing impairment.

Fume Emission: Typically, plasma cutting generates fumes. Consequently, it should be carried out in a well-ventilated area to prevent the inhalation of harmful substances by the operator and to maintain a healthy working environment.

Cost Consideration: When using consumables with a short lifespan, such as nozzles and electrodes, the cost can be relatively high. This requires careful management of consumables and an understanding of the associated expenses to ensure cost-effective operation.

How Does a Plasma Cutter Work?

Plasma cutting employs heat to melt metals rather than relying on mechanical methods. The process operates by transmitting an electric arc through a specific gas, allowing for precise cutting

Plasma cutting involves using heat (typically over 20,000 degrees C) to melt metal rather than cut it mechanically. The plasma arc cutter sends an electric arc through a plasma-cutting gas before passing it through a constricted opening called a nozzle.

As the gas squeezes through the restricted nozzle opening, it picks up speed and elevates the temperature, forming plasma.

The gas is ejected under such high pressure that it melts the workpiece material and forces it from the cut.

In the intricate world of plasma cutting, the role of compressed air cannot be understated. By channeling compressed air through an air compressor, the plasma cutter efficiently generates the necessary heat to slice through metals with remarkable precision.

It’s this reliance on compressed air, paired with the capabilities of modern air compressors, that allows for the numerous advantages of plasma cutting.

Yet, like any tool, understanding its strengths and limitations is essential for optimal results.

However, not every cutter machine works the same.

lasma cutting employs heat to melt metals rather than relying on mechanical methods. The process operates by transmitting an electric arc through a specific gas, allowing for precise cutting

Three Types of Plasma Cutting Processes

High-Frequency Contact: This method is cost-effective but can’t be used with CNC plasma equipment. High-frequency contact cutting involves a high-frequency spark and high voltage that risks interfering with the CNC control and causing issues. The spark forms when the plasma torch contacts the metal, closing the circuit, initiating the spark, and creating the plasma.

Pilot Arc: This process creates the spark inside the torch using a low current circuit and high voltage. The spark creates the pilot arc, and contact with the workpiece creates the cutting arc.

Spring Loaded Plasma Torch Head: Pressing the torch against the workpiece creates a short circuit, which starts the current to flow. The operator releases the pressure to establish the pilot arc.

What Can a Plasma Cutter Cut Through?

Because plasma cutters use high-velocity ionized gas to create a flame, they can cut any electrically conductive metal. Examples include:

- Mild steel

- Stainless steel

- Carbon steel

- Expanded steel

- Aluminum

- Copper

- Brass

- Other ferrous (iron-containing) and non-ferrous materials

Heavy-duty plasma cutters can process metal plates ranging in size from 1 millimeter to 1 inch. Anything larger would require a more powerful plasma cutting machine.

Which Gases are Involved in Using Plasma Cutter Technology?

The gas type depends on the cutting method, material, and thickness. The most common gases used for plasma cutting include the following:

Argon is an inert gas with a stable plasma arc, meaning it reacts very little with most metals at high temperatures. However, argon gas has cutting limitations because of its low plasma arc and slag issues caused by higher surface tension. These problems result in argon being rarely used for plasma cutting.

Nitrogen has better plasma arc stability and a higher energy jet than argon. It forms minimal slag, even when cutting metals like nickel-base alloy and stainless steel with high viscosity. It works as a standalone gas or in combination with other gases, facilitating the high-speed cutting of carbon steel.

Air contains 78% nitrogen and 21% oxygen by volume and is appropriate for plasma cutting. The oxygen constituent of air makes it one of the fastest gases for cutting low-carbon steel and the cheapest. On the negative side, electrodes and nozzles used with air typically have a short service life, and air as a standalone gas causes slag hanging and cut oxidation.

Oxygen, like air, increases the cutting speed on low-carbon steel, although using it with high-temperature and oxidation-resistant electrodes produces better results.

Hydrogen is mainly used as an auxiliary gas to mix with other plasma-cutting gases. The most oft-used combination is hydrogen and argon, which produces a potent plasma-cutting gas.

How to Plasma-Cut Various Materials

As mentioned, the plasma cutting process works on any conductive material, and here are the most common:

- Aluminum being conductive makes it ideal for plasma cutting, and the process offers advantages with thicker metals compared to other methods. It can cut aluminum thicknesses up to 160mm (6-3/8″) cost-effectively.

- Mild steel is inexpensive, versatile, and weldable, lending to plasma cutting and metal fabrication.

- Stainless steel is corrosion and rust-resistant, and plasma cutting works on plates up to 30mm (1-3/16″) thick and in various grades.

- Brass is another metal easily fabricated using plasma cutting because it’s highly conductive. However, the process should occur in a well-ventilated area since brass contains zinc, and inhaling burning zinc’s fumes is detrimental to health.

- Copper has excellent electrical conductivity and essential qualities, including corrosion resistance, high ductility, and weldability. However, like brass, it must be cut in areas with adequate ventilation.

- Cast iron is popular for its low cost and malleability. It is very conductive, with high compressive strength and low melting temperature making it ideal for plasma cutters.

Choosing the Right Plasma CNC Machine for Your Shop

Due to their powerful cutting technology and automated controls, CNC plasma cutting tables can be used for numerous applications, from shaping parts for custom cars to processing oversized materials for shipbuilding. Finding the right plasma CNC machine for your shop depends on what materials you specialize in and how often you’ll be using the burn table. You’ll want an extra-powerful model if you mass produce your parts and run the machine throughout the day, whereas a less powerful table can handle occasional and short cutting sessions. A good rule to follow is to choose a CNC plasma cutter that can process twice the thickness of the materials you work with.

Reviewed by 1 user

the plasma-cutting process works on any conductive material and affordable price