CNC press brakes are critical components in modern manufacturing, offering precision and efficiency in bending and shaping metal sheets. As technological advancements continue to enhance their capabilities, these machines become even more indispensable across various industries. This article aims to guide you through finding the best deals on top CNC press brake for sale in 2024, ensuring you make an informed and cost-effective purchase.

Understanding CNC Press Brakes

What Is CNC Press Brake

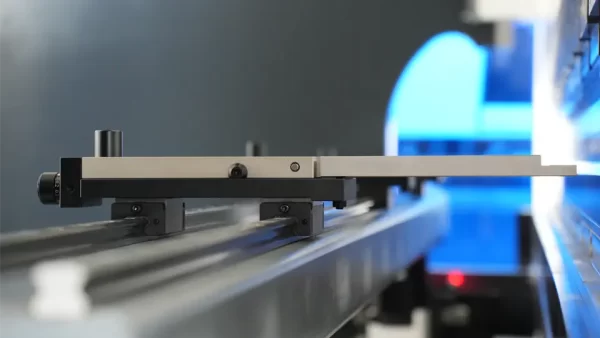

A CNC press brake is a machine tool used for bending sheet and plate material, most commonly sheet metal. It uses a combination of a punch and die to form predetermined bends by clamping the workpiece between a matching punch and die. CNC technology automates the control of the press brake, providing high precision and repeatability.

Key Features and Benefits

Precision

CNC press brakes are renowned for their exceptional accuracy, which is crucial for producing high-quality components. The precision of these machines is attributed to their advanced control systems and high-quality mechanical components. This level of accuracy is essential in industries where even the slightest deviation can lead to significant issues, such as in aerospace or medical device manufacturing. CNC press brakes can achieve tolerances within a few microns, ensuring that every bend and cut is precisely as programmed, leading to less waste and higher-quality end products.

Efficiency

Automation is one of the standout features of CNC press brakes, drastically reducing the need for manual intervention. This automation leads to increased production speed and efficiency, as the machine can operate continuously with minimal downtime. The CNC system can quickly switch between different programs, allowing for rapid setup changes and reducing the time between production runs. Additionally, advanced features such as automated tool changing and adaptive bending capabilities further enhance the efficiency of CNC press brakes, enabling manufacturers to meet tight deadlines and increase overall productivity.

Versatility

CNC press brakes are highly versatile machines, capable of performing a wide range of bending operations. They can handle complex bends, including multi-step processes, with ease. This versatility allows manufacturers to perform multiple operations in one setup, reducing the need for additional equipment and manual handling. CNC press brakes can work with various materials, from thin sheets of aluminum to thick steel plates, making them suitable for diverse applications in industries such as automotive, construction, and electronics. The ability to quickly adapt to different production requirements makes CNC press brakes a valuable asset in any manufacturing facility.

Consistency

One of the key advantages of CNC press brakes is their ability to ensure consistency across large production runs. The computerized control system ensures that each part is produced to the same specifications, eliminating the variations that can occur with manual operations. This uniformity is critical in industries where parts need to fit together precisely or meet stringent quality standards. Consistent production not only improves the overall quality of the products but also reduces the need for rework and inspection, saving time and costs. With CNC press brakes, manufacturers can confidently produce high volumes of parts that meet exacting standards, enhancing their reputation for quality and reliability.

Common Applications

CNC press brakes are utilized in various industries, including:

- Automotive: Manufacturing car panels, chassis components, and other parts.

- Aerospace: Creating precise and durable components for aircraft.

- Construction: Producing structural elements and custom metalwork.

- Electronics: Fabricating enclosures and brackets.

- Furniture: Forming metal frames and decorative elements.

CNC Press Brake Vs Traditional Press Brake: What's the Biggest Difference

The biggest differences between CNC press brakes and traditional press brakes lie in their control systems, precision, versatility, and efficiency. CNC press brakes offer advanced automation, high precision, and the ability to perform complex bends, making them ideal for high-volume, high-precision manufacturing.

Traditional press brakes, while suitable for simpler bending operations, rely heavily on manual control and adjustments, leading to potential variations in accuracy and consistency. Ultimately, the choice between CNC and traditional press brakes depends on the specific needs of the manufacturing process, including the complexity of bends, required precision, and production volume.

Current Market Trends and Pricing Overview

The market for CNC press brakes in 2024 is highly competitive, with numerous manufacturers offering a variety of models to meet the diverse needs of the industry. Prices for CNC press brakes can vary significantly based on specifications, brand, and features. Understanding current market trends and pricing can help you make an informed decision and find the best deals.

Market Trends

1. Technological Advancements

Innovations in CNC technology, such as improved control systems and automation features, are driving demand for newer models. These advancements enhance precision, efficiency, and ease of use, making them attractive to manufacturers looking to upgrade their equipment.

- A prominent automotive parts manufacturer adopted the latest Amada HFE3i 2204 CNC press brake, which features advanced control systems and automation. This upgrade reduced their setup times by 30% and increased production efficiency by 20%, allowing them to meet tighter production schedules with higher precision.

2. Energy Efficiency

With a growing emphasis on sustainability, many manufacturers are developing CNC press brakes that consume less energy and have a lower environmental impact. This trend is particularly important for companies aiming to reduce operational costs and meet regulatory requirements.

- An aerospace company invested in the Trumpf TruBend 3100, known for its energy-efficient design. By switching to this model, the company reduced its energy consumption by 15%, aligning with their sustainability goals and significantly lowering operational costs.

3. Customization and Flexibility

The demand for customizable press brakes that can be tailored to specific production needs is increasing. Manufacturers are offering machines with adjustable tonnage, bending lengths, and advanced software options to provide greater flexibility.

- A custom metal fabrication shop required a press brake with versatile capabilities to handle various projects. They selected the Krrass WC67K 80/2500, which allowed them to adjust settings easily and handle a wide range of materials and bending requirements. This flexibility improved their service offering and customer satisfaction.

4. Global Supply Chain

Global supply chain disruptions have affected the availability and pricing of CNC press brakes. Manufacturers are focusing on localizing their supply chains to mitigate these challenges and ensure timely delivery.

- A large-scale manufacturer faced delays due to supply chain disruptions and decided to switch to Durma, which had more localized production and supply networks. This change minimized downtime and ensured consistent machine availability, keeping their production schedule on track.

Pricing Overview

The price of a CNC press brake depends on several factors, including tonnage, bending length, brand, and additional features. Here's a general pricing overview based on these factors:

| Brand | Model | Tonnage | Bending Length | Price Range (USD) | Key Features |

|---|---|---|---|---|---|

| Trumpf | TruBend 3100 | 100 tons | 3 meters | $150,000 - $200,000 | High precision, energy-efficient, user-friendly interface |

| Amada | HFE3i 2204 | 220 tons | 4 meters | $180,000 - $250,000 | Advanced automation, versatile applications, strong support |

| Krrass | WC67K 80/2500 | 80 tons | 2.5 meters | $50,000 - $80,000 | Cost-effective, robust construction, user-friendly |

| Durma | AD-S 30175 | 175 tons | 3 meters | $100,000 - $150,000 | Customizable, durable, high precision |

Tips for Finding the Best Deals

- Monitor Market Trends: Stay updated with the latest technological advancements and market shifts. Subscribe to industry newsletters and follow reputable sources.

- Compare Prices: Use online platforms and industry reports to compare prices across different manufacturers and models.

- Look for Promotions: Manufacturers often have sales and promotions, especially during industry trade shows or at the end of the financial year.

- Consider Total Cost of Ownership: Evaluate not just the initial purchase price but also the long-term costs, including maintenance, energy consumption, and potential downtime.

CNC Press Brake For Sale: TOP 10 Suppliers in 2024

Choosing the right CNC press brake is crucial for any manufacturing operation. To help you make an informed decision, here are the top 10 suppliers of CNC press brakes in 2024, known for their quality, innovation, and customer support.

1. Trumpf

Overview: Trumpf is a leading name in CNC press brakes, known for their high precision and energy-efficient models.

Key Models: TruBend 3100, TruBend 5085

Strengths: Advanced automation, robust build quality, and excellent customer service.

2. Amada

Overview: Amada offers a range of CNC press brakes that combine innovation with reliability.

Key Models: HFE3i 2204, HG 1003 ATC

Strengths: High precision, versatile applications, and strong support network.

3. Krrass

Overview: Krrass provides cost-effective CNC press brakes without compromising on quality.

Key Models: WC67K 80/2500, MB8-200T/3200

Strengths: Affordable pricing, robust construction, user-friendly interface.

4. Durma

Overview: Durma is known for its durable and customizable CNC press brakes.

Key Models: AD-S 30175, AD-R 125/30

Strengths: Customizable options, strong build, high precision.

5. Accurpress

Overview: Accurpress is a well-established brand offering a range of reliable press brakes.

Key Models: Accell E 150-10, Edge 1025

Strengths: Durability, precision, extensive service network.

6. Bystronic

Overview: Bystronic focuses on innovation and high-performance CNC press brakes.

Key Models: Xpert 150, Xpert Pro 100

Strengths: High precision, advanced technology, energy efficiency.

7. LVD

Overview: LVD offers a comprehensive range of CNC press brakes for various industries.

Key Models: Dyna-Press 40/15, Easy-Form 135/30

Strengths: Versatility, advanced control systems, robust build.

8. Prima Power

Overview: Prima Power is known for its innovative and efficient CNC press brakes.

Key Models: eP Genius 1030, BCe Smart

Strengths: Automation, energy efficiency, high precision.

Common Mistakes to Avoid When Buying a CNC Press Brake for Sale

1. Ignoring Maintenance Needs

Mistake: Neglecting to factor in maintenance requirements and costs can lead to unexpected downtime and increased operational expenses.

Detailed Explanation:

- Maintenance Costs: CNC press brakes require regular maintenance to ensure optimal performance and longevity. This includes routine inspections, lubrication, and potentially more extensive servicing.

- Service Availability: Consider the availability of qualified technicians and the responsiveness of the manufacturer’s service network. Lack of timely maintenance can disrupt production schedules and increase repair costs.

Preventative Action:

- Plan for Maintenance: Include maintenance costs in your budget and negotiate service agreements with clear terms.

- Scheduled Inspections: Implement a schedule for routine inspections and follow manufacturer-recommended maintenance procedures to extend machine lifespan.

2. Overlooking Training

Mistake: Failing to provide adequate training for machine operators can result in inefficient use of the CNC press brake and potential safety hazards.

Detailed Explanation:

- Operator Competence: Proper training ensures operators understand machine capabilities, safety protocols, and efficient operation practices.

- Software Proficiency: Training should cover CNC programming, tool setup, and troubleshooting to maximize productivity and minimize errors.

Preventative Action:

- Training Program: Invest in comprehensive training programs provided by the manufacturer or third-party experts.

- Ongoing Education: Encourage continuous learning to keep operators updated on new features and best practices.

3. Underestimating Specifications

Mistake: Selecting a CNC press brake that does not meet your current or future production requirements can limit operational efficiency and growth potential.

Detailed Explanation:

- Tonnage and Bending Length: Ensure the press brake can handle the maximum force (tonnage) and accommodate the largest workpieces you typically handle.

- Bend Complexity: Consider the types of bends (e.g., straight bends, box bends, complex shapes) and the variety of materials (e.g., steel, aluminum, stainless steel) you work with.

- Production Capacity: Assess the machine’s speed, accuracy, and flexibility to meet production demands now and in the foreseeable future.

Preventative Action:

- Detailed Assessment: Conduct a thorough analysis of your production requirements, including expected growth and new project types.

- Consultation with Experts: Seek advice from engineers or consultants to ensure the chosen machine aligns with your specific operational needs.

5. Additional Considerations

- Budget Constraints: While cost is important, prioritize long-term value and operational efficiency over initial savings.

- Environmental Impact: Evaluate energy efficiency ratings and sustainability features to minimize operational costs and comply with environmental regulations.

- Supplier Reputation: Choose a reputable supplier with a track record for quality products, reliable support, and responsive customer service.

By avoiding these common mistakes and taking proactive measures to understand your operational needs, invest in training, and evaluate machine specifications thoroughly, you can make a confident decision when purchasing a CNC press brake. This approach ensures your investment enhances productivity, meets safety standards, and supports long-term business growth.

Conclusion

In conclusion, selecting the right CNC press brake is pivotal for enhancing manufacturing precision and efficiency. By navigating through detailed specifications, considering maintenance needs, and ensuring adequate training for operators, businesses can avoid common pitfalls and maximize their investment. With a wide array of CNC press brake for sale from reputable manufacturers, each offering unique features and capabilities, it's essential to align your purchase with long-term production goals and operational requirements.

Reviewed by 1 user

Good machine

I purchased a KRRASS210TON CNC Press Brake, which has stable quality and professional online guidance for debugging.