Before starting a cnc press brake, there are several preparations that need to be done to ensure the safe and proper operation of the hydraulic press brake. Here are some common preparations:

Securing the press brake

Placing and securing a new cnc press brake is an important step in ensuring the safety and effective use of the equipment. Here is a simple procedure to guide first-time users on how to properly position and secure the press brake:

- Select a suitable location: Choose a stable and stationary location to place the press brake. Ensure that the area has enough space for you to freely operate and maintain the equipment. Additionally, ensure proper ventilation in the surrounding environment to prevent overheating and machine malfunctions.

- Prepare a firm and stable ground: Ensure that the surface where the equipment will be placed is hard, flat, and stable. Prioritize concrete floors or metal surfaces as they provide better stability. If the ground is not sufficiently sturdy, consider adding a thick metal plate or wooden board as a foundation.

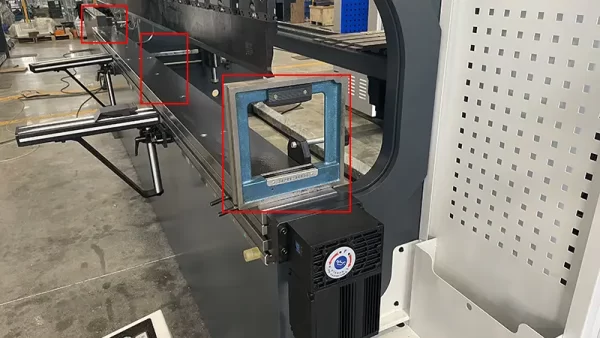

- Use shims and leveling bolts: Before placing the press brake, use shims and leveling bolts to ensure the equipment is stable and level. This will help balance the machine and prevent issues caused by uneven ground. Gradually adjust the bolts according to the installation guide of the equipment until the machine is stable and balanced. Each press brake manufactured by KRRASS is equipped with leveling bolts at the four corners of the machine frame.

- Secure the press brake: After placing the press brake in the appropriate position and leveling it, it needs to be secured to the ground to prevent any movement or shaking during operation. Use suitable bolts or anchoring devices to secure the base or feet of the press brake to the ground.

- Check for fixation and stability: Once the press brake is secured to the ground, carefully inspect the stability of the equipment. Ensure that all fixation points are tight and secure. Try to move the equipment by gently pushing or shaking it to ensure it doesn't have any noticeable movement or shaking.

About the horizontal correction of the fuselage

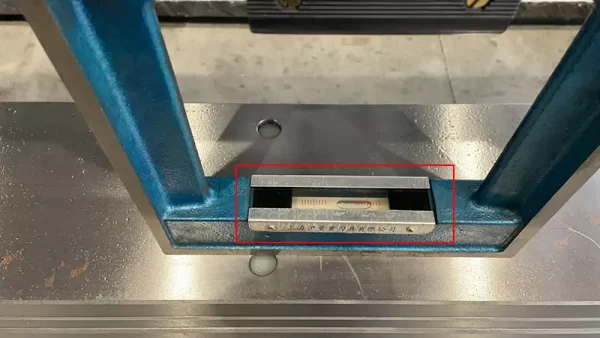

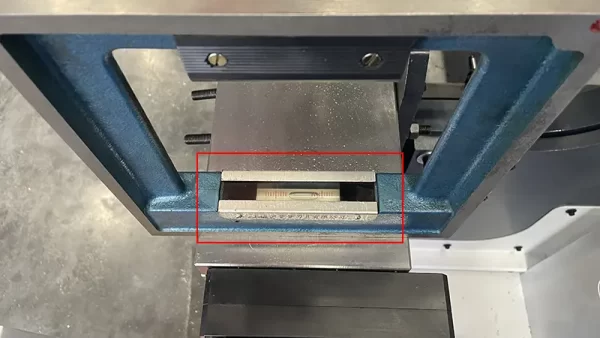

If you want to correct the horizontal position of the press brake, you need to use a spirit level or a spirit level. The specific calibration process is as follows:

1. Use a level ruler and place it in the middle and both sides of the press brake workbench in turn for horizontal correction;

2. The level ruler is placed in the middle of the workbench of the press brake and placed horizontally to correct the horizontal position of the left and right sides of the press brake;

3. The level ruler is placed longitudinally at both ends of the press brake workbench, and is used to correct the horizontal position of the front and rear sides of the press brake;

Please note that this is just a basic procedural guide, and the specific installation process may vary depending on the model of the press brake. To ensure proper installation and operation, always refer to the installation guide and user manual of the equipment, and consult technical service personnel if needed.

Adding Hydraulic Oil

Adding hydraulic oil to the hydraulic press brake is an important step to ensure its proper operation and use. Here is a simple procedure on how to correctly add hydraulic oil to the hydraulic press brake:

- Prepare the required materials: Before adding hydraulic oil, ensure that you have the following materials ready:

- Hydraulic oil suitable for your hydraulic press brake (refer to the equipment manual or consult service personnel for recommendations)

- Hydraulic oil filter (if applicable)

- Funnel or manual pump (for adding hydraulic oil)

- Locate the hydraulic oil filling port: Locate the hydraulic oil filling port on the hydraulic press brake. Typically, the filling port is located above the hydraulic oil tank of the equipment. Refer to the press brake user manual or the guidance provided by service personnel to ensure you find the correct filling port.

- Clean the work area: Before starting to add hydraulic oil, it is essential to clean the area around the hydraulic oil filling port. Use a clean cloth or tissue to wipe the filling port to prevent any impurities or dirt from entering the hydraulic system.

- Install the hydraulic oil filter (if applicable): If the hydraulic press brake is equipped with a hydraulic oil filter, properly install it on the filling port. The hydraulic oil filter helps remove impurities and contaminants from the oil, maintaining the cleanliness and normal operation of the hydraulic system.

- Add hydraulic oil: Slowly pour the hydraulic oil into the filling port, using a funnel or manual pump to avoid spillage. Determine the required hydraulic oil capacity based on the equipment's user manual or manufacturer's recommendations. Gradually add the hydraulic oil and monitor the oil level using the hydraulic system of the equipment.

- Monitor oil level and pressure: During the hydraulic oil filling process, always monitor the oil level and pressure of the hydraulic oil. Ensure that the hydraulic oil is within the appropriate range and close the filling port once the oil is added.

Please note that the above process is a basic guideline. To ensure proper hydraulic oil addition and avoid potential damage, always refer to the press brake's user manual and follow the guidance provided by service personnel. If you are uncertain or lack experience with this process, it is best to seek assistance from professional technicians or experienced personnel.

Connecting Power Supply

Connecting the power supply for a newly purchased hydraulic press brake is an important step to ensure its proper operation and use. Here is a simple procedure on how to correctly connect the power supply for a hydraulic press brake:

- Confirm power requirements: Before connecting the power supply, first confirm the power requirements of the hydraulic press brake. Refer to the press brake's specifications, user manual, or information provided by service personnel to understand the required voltage, phase, and frequency for its operation.

- Prepare the power cord: Based on the power requirements of the hydraulic press brake, select a suitable power cord. Ensure that the rated current and voltage of the power cord align with the equipment's requirements. If necessary, purchase a standard-compliant power cord.

- Check the power socket: Check if the power socket used for the power connection meets the requirements of the hydraulic press brake. Ensure that the voltage, phase, and frequency of the socket match the equipment's requirements. Additionally, ensure that the socket's grounding is reliable to provide a safe electrical connection.

- Connect the power cord: Connect the selected power cord to the power socket in the correct sequence. Ensure that the end of the power cord is fully connected to the socket and check that the plug is securely inserted into the socket.

- Inspect the power connection: Once the power cord is connected to the socket, carefully inspect the power connection. Ensure that the power cord doesn't have any obvious damage or looseness. Verify that the power cord is properly connected to the power input port of the hydraulic press brake.

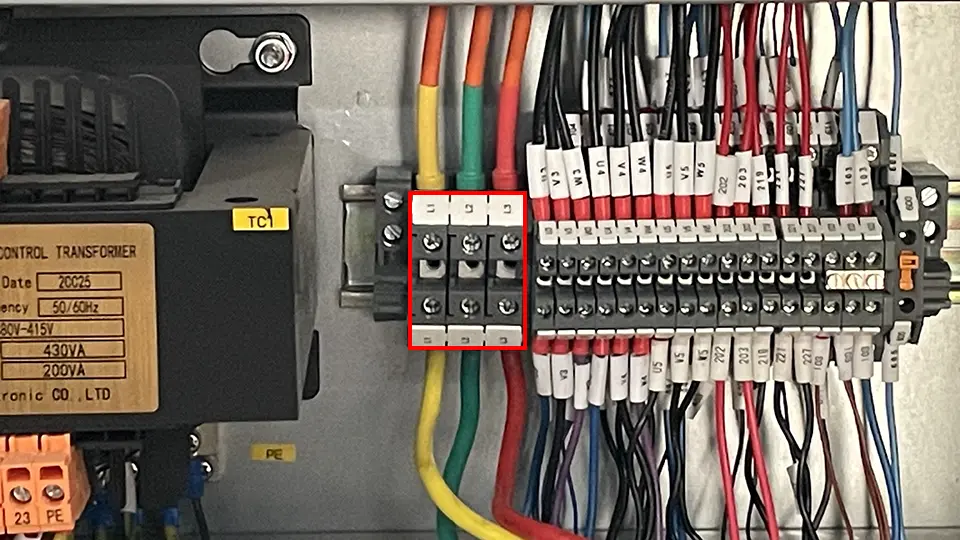

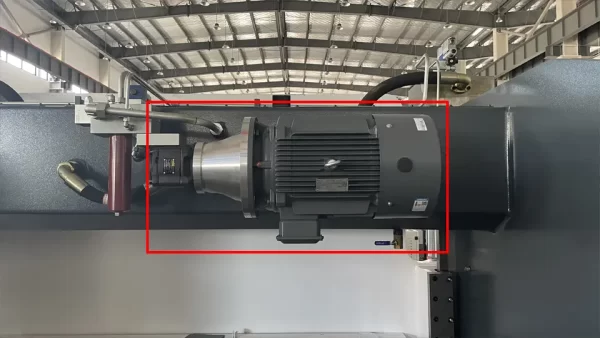

- Power-on test: After connecting the power supply, perform a power-on test to check if the main motor of the hydraulic press brake operates correctly (this step can be skipped if you have purchased a press brake with a servo-hybrid power system). Turn on the power switch and observe the direction of rotation of the fan blades at the end of the main motor:

- If the fan blades of the main motor rotate clockwise, it indicates that the power phase sequence is connected correctly, and you can proceed with the next steps.

- If the fan blades of the main motor rotate counterclockwise, it indicates that the power phase sequence is connected incorrectly, and you need to interchange any two phases of the three-phase power line in the socket.

After confirming the power phase sequence, observe the display screen or indicator lights of the equipment to ensure that it starts up and operates normally.

Please note that the above process is a basic guideline. To ensure proper power supply connection and avoid potential hazards, always refer to the press brake's user manual and follow the guidance provided by service personnel. If you are uncertain or lack experience with this process, it is best to seek assistance from professional electricians to complete the power connection task.

These are the preparations that need to be done before starting a press brake. We hope this information has been helpful. If you have completed these steps, you can continue reading our next article:

DELEM DA53T china press brake installation(Tool configuration)