Welcome to the world of precision metal fabrication, where Electric Press Brakes and CNC Press Brake technology take center stage. In this comprehensive guide, we delve into the sophisticated realm of these powerful machines, exploring how they transform sheets of metal into intricate parts with unparalleled accuracy. Join us as we unfold the layers of innovation behind electric press brakes and reveal how they are revolutionizing the industry.

- What Is an Electric Press Brake?

- Core Components of an Electric Press Brake

- How Electric Press Brakes Stand Apart from Hydraulic and Mechanical Models

- Comparative Analysis: Electric Press Brakes vs. Hybrid Models

- Applications of Electric Press Brakes

- Advantages of Electric Press Brakes

- What to Look for When Purchasing an Electric Press Brake

- Vendor Selection: Finding the Right Supplier for Electric Press Brakes

- Customization and Scalability: Matching Your Needs

- Electric Press Brake and CNC

1. What Is an Electric Press Brake?

In the realm of metal fabrication, the Electric Press Brake stands as a paragon of efficiency and precision. Far from the traditional, manual methods of shaping metal, an electric press brake is a high-tech tool that marries the power of electric motors with the finesse of computer-controlled mechanisms. It's a cornerstone in the toolkit of fabricators who demand exacting standards and high throughput.

The key distinction of an Electric Press Brake lies in its drive system. Unlike hydraulic press brakes that rely on fluid dynamics, the electric variant harnesses the simplicity and reliability of electric servomotors. These motors directly power the ram, resulting in a responsive, energy-efficient, and maintenance-light operation. It’s the go-to equipment for businesses looking to reduce their carbon footprint while enhancing their production capabilities.

But what sets the CNC Press Brake apart? CNC, or Computer Numerical Control, transforms an ordinary electric press brake into a master of metalwork precision. With CNC technology, operators can program the machine to perform complex bends with remarkable accuracy. This programming capability makes the CNC Press Brake a highly adaptable tool, able to tackle a variety of tasks with ease and consistency.

2. Core Components of an Electric Press Brake

Diving deeper into the anatomy of an Electric Press Brake, it's essential to understand its core components. Each part works in harmony to deliver the unparalleled efficiency and precision that these machines are known for.

At the heart of the electric press brake is the servomotor. This component is responsible for the precise control of the ram, dictating the force and speed of the bend. Thanks to the servomotor's capabilities, operators can achieve consistent results with minimal energy waste.

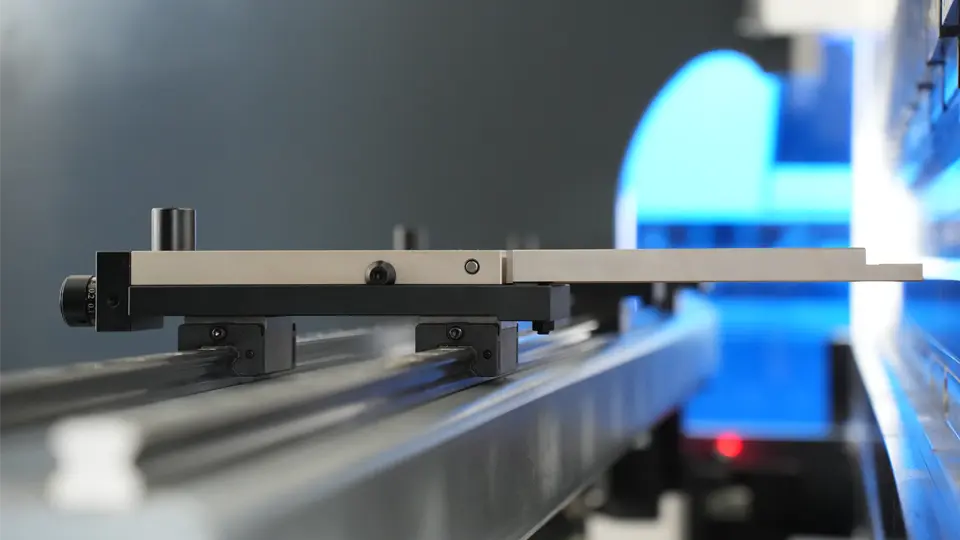

Next, we have the backgauge system. This crucial feature accurately positions the metal sheet for bending. With advancements in CNC technology, the backgauge can move along multiple axes, allowing for complex part bending with minimal handling.

The ram, which applies the actual force to bend the metal, works with unparalleled precision. The ram's movement is guided by the servomotor, following the programmed instructions to the letter.

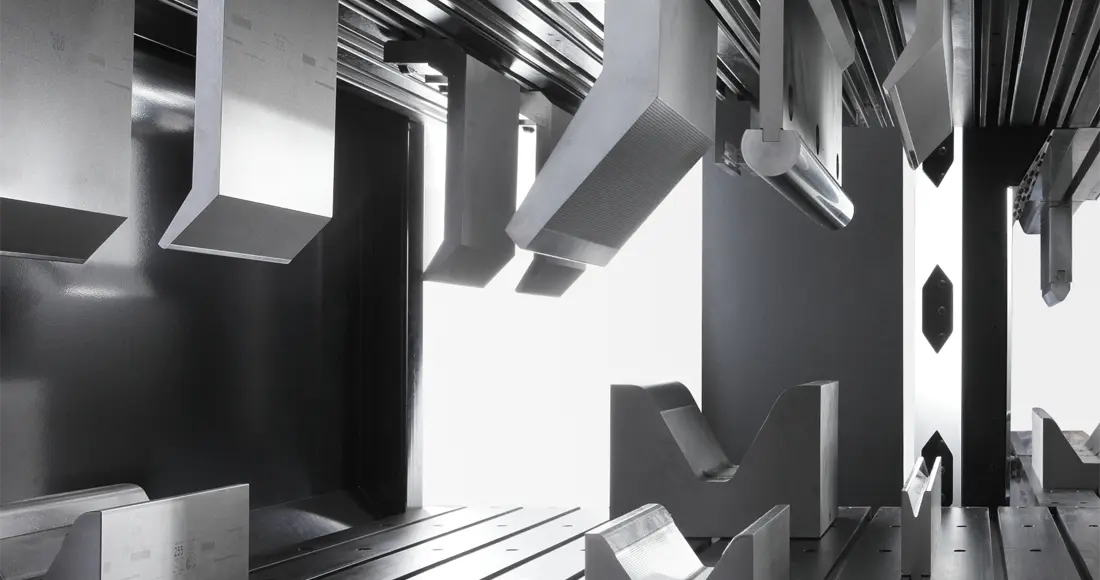

Then there’s the tooling. High-quality dies and punches are integral to the electric press brake's functionality, shaping the metal as it's bent. The variety of tooling options available allows for an impressive range of bending possibilities.

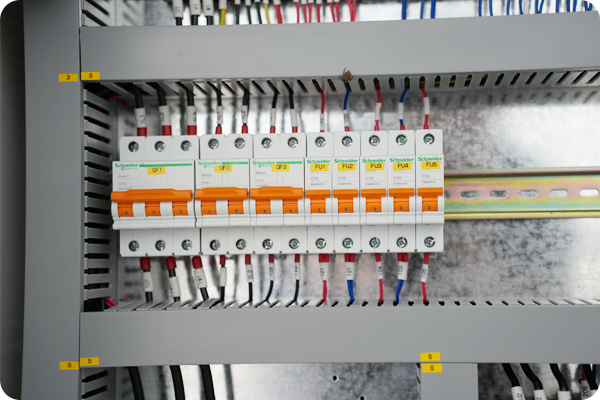

The control system is where the magic happens. It's the interface where the operator inputs data, and the CNC takes over, turning digital blueprints into physical parts. The sophistication of the control system defines the capabilities of the press brake.

Lastly, the safety systems, including light curtains and laser systems, ensure that operation is not only efficient but also safe for the users.

3. How Electric Press Brakes Stand Apart from Hydraulic and Mechanical Models

When it comes to choosing the right press brake, understanding the distinctions between electric, hydraulic, and mechanical models is pivotal. Electric Press Brakes offer several advantages that set them apart in the modern fabrication landscape.

Firstly, the precision of an Electric Press Brake is unparalleled. The direct drive of the servomotor provides a level of control that hydraulic systems can struggle to match. This results in higher precision bends, repeatable outcomes, and less waste due to errors.

Energy efficiency is another standout feature. Electric press brakes consume power only during the bending process, unlike hydraulic models that require constant power to maintain pressure. This not only reduces energy consumption but also lowers operational costs significantly.

The speed of operation is a game-changer. Electric press brakes can achieve faster cycle times due to the swift movement of the servomotors. This efficiency is not at the expense of power, as these machines can handle demanding tasks with ease.

Maintenance requirements for electric press brakes are also reduced. Without hydraulic fluids or numerous mechanical parts, the need for regular servicing is diminished, ensuring higher uptime and productivity.

Moreover, the quiet operation of electric press brakes makes for a more pleasant work environment, which can contribute to improved operator satisfaction and focus.

Finally, the environmental aspect cannot be ignored. The absence of hydraulic oil means there's no risk of leaks or contamination, making electric press brakes a cleaner, more sustainable option for eco-conscious businesses.

In comparison to their mechanical counterparts, which rely on a complex system of gears and clutches, electric press brakes provide smoother operation and improved safety features. The advancements in CNC technology further enhance their capabilities, allowing for complex, multi-axis bending that mechanical models simply cannot achieve.

4. Comparative Analysis: Electric Press Brakes vs. Hybrid Models

In the sphere of metal fabrication, the debate between the use of Electric Press Brakes and Hybrid models is ongoing. While electric press brakes are celebrated for their efficiency and precision, hybrid models also present a compelling case, merging the strengths of hydraulic and electric systems.

Hybrid press brakes typically utilize an electric motor to power a hydraulic pump, only engaging the hydraulic system when necessary. This approach can offer energy savings over traditional hydraulic systems, but how do they stack up against fully electric models?

Energy consumption is a key factor. While hybrids are more efficient than purely hydraulic systems, they still fall short of the energy efficiency of Electric CNC Press Brakes. The latter uses energy directly for the bend, without the need for conversion through hydraulic components.

Precision is another battleground. The direct control that electric press brakes have over the ram movement allows for more precise bends. Hybrid models improve upon the precision of hydraulic brakes but may not achieve the same level of control as a fully electric system.

Speed and productivity are also up for comparison. Electric press brakes often offer faster cycle times due to the rapid response of the electric servomotors. Hybrids try to match this with quicker pump engagement, but they still involve the mechanical process of converting electric power into hydraulic force.

Maintenance requirements present a significant divergence. The simplicity of electric press brakes means fewer moving parts, less wear and tear, and thus, lower maintenance needs. Hybrid models, while requiring less maintenance than traditional hydraulic brakes, still involve complex hydraulic systems that need regular servicing.

Environmental considerations favor electric press brakes. Without reliance on hydraulic fluids, they pose a lower risk of environmental contamination and align better with green manufacturing practices.

5. Applications of Electric Press Brakes

5.1 Where Precision Meets Durability: Industrial Applications

The Electric Press Brake shines in industrial settings where both precision and durability are non-negotiable. These machines are integral in producing large-scale components for automotive, aerospace, and shipbuilding industries. The need for consistent and repeatable bending processes in these sectors makes electric press brakes invaluable. The CNC capabilities allow for the programming of complex patterns necessary for manufacturing intricate parts, like aircraft fuselages or car bodies, with tight tolerances and high strength requirements.

5.2 Small Scale Operations: Electric Press Brakes in Boutique Manufacturing

In the realm of boutique manufacturing, Electric Press Brakes provide the flexibility required for small batch production with varied designs. Custom furniture makers, specialized vehicle modifiers, and creators of bespoke metal art find the precision of electric press brakes perfect for their unique production needs. These operations often require quick setup changes and fine adjustments, which are easily managed via the CNC control systems of electric press brakes.

5.3 Custom Fabrication: Tailoring with Electric Press Brakes

Custom fabrication shops that cater to tailored client specifications benefit immensely from Electric CNC Press Brakes. The ability to quickly program the machinery for one-off designs or limited runs is critical. Whether it's creating specialized architectural elements or prototyping new product designs, the versatility and programmability of electric press brakes make them a key asset in custom fabrication settings.

6. Advantages of Electric Press Brakes

6.1 Enhancing Efficiency: The Speed of Electric Press Brakes

In the fast-paced world of fabrication, the Electric Press Brake emerges as a leader in efficiency. The immediate response and rapid movement of electric servomotors reduce cycle times substantially. This speed, combined with the quick setup enabled by CNC controls, allows shops to increase throughput and respond swiftly to changing production demands.

6.2 Accuracy and Precision: Quality Outputs with Electric Press Brakes

Quality is paramount, and the Electric Press Brake delivers with exceptional accuracy and precision. The direct control and feedback from the servomotors ensure that each bend is executed flawlessly, adhering to exact specifications. This translates to reduced waste, fewer reworks, and a superior end product, meeting the stringent quality standards of industries like aerospace and medical device manufacturing.

Environmental Benefits: The Eco-Friendly Choice

Sustainability is not just a buzzword; it's a critical component of modern manufacturing. Electric Press Brakes are the eco-friendly choice, as they eliminate the need for hydraulic oil and reduce energy consumption. This not only cuts operational costs but also aligns with environmental regulations and green initiatives, making it a responsible choice for the planet.

6.3 Operator Safety: The Safeguards of Modern Electric Press Brakes

Safety is a top priority, and modern Electric Press Brakes are equipped with advanced safeguards. Light curtains, laser systems, and safety software are designed to protect operators from injury. The inherent precision and control of electric press brakes also reduce the chance of accidents, providing a safer work environment and peace of mind.

7. What to Look for When Purchasing an Electric Press Brake

Investing in an Electric Press Brake is a significant decision for any fabrication business. Here are the key factors to consider ensuring you select the right machine for your needs:

Firstly, assess the tonnage capacity. This determines the amount of force the press brake can exert and is crucial to match with the materials and thicknesses you'll be working with.

Next, consider the working length. The length of the machine needs to accommodate the largest pieces you plan to bend. Also, account for the distance between the side frames, known as the 'throat depth,' to ensure you have enough space for your parts.

The control system is the brain of the press brake. Look for a user-friendly interface with powerful software that can store multiple programs and offer detailed control over the bending process.

Evaluate the accuracy of the machine. Check the specifications for repeatability and precision, which are critical for producing consistent high-quality parts.

Investigate the tooling compatibility. Make sure that the press brake can accommodate the range of tooling you need for your bending operations, including any special dies or punches.

Consider the speed of the machine, not just in terms of bending but also the rapid approach and retraction speeds. A faster machine can significantly increase your shop's output.

Don’t overlook the importance of service and support. The availability of technical support, maintenance services, and spare parts can keep your press brake running smoothly and reduce downtime.

Lastly, factor in the overall cost of ownership, including the initial purchase price, operating costs, maintenance expenses, and potential energy savings. A more expensive machine might offer lower long-term costs due to higher efficiency and reliability.

8. Vendor Selection: Finding the Right Supplier for Electric Press Brakes

Choosing a supplier for your Electric Press Brake is as crucial as the machine itself. The right vendor can ensure a smooth purchase, reliable operation, and support throughout the machine's life. Here's what to consider when selecting a supplier:

Look for a supplier with a reputation for quality. Research their history, customer feedback, and the performance of their machines in the field. A reputable supplier should be known for durable and reliable press brakes.

Assess their technical expertise. A supplier should have a deep understanding of their machinery and be able to offer insights and solutions tailored to your specific needs.

Evaluate their customer support. Post-sale support is essential for addressing any issues that arise. Check if they provide prompt service, maintenance assistance, and easily accessible spare parts.

Consider the availability of training. Proper operation of a CNC press brake is key to its performance. Ensure the supplier offers comprehensive training for your operators.

Check their inventory of tooling. The supplier should offer a wide range of tooling options and the ability to source or manufacture custom tooling as required.

Investigate their financial stability. A stable supplier is likely to be around for the long term for ongoing support and service.

Finally, visit their facility if possible. Seeing a supplier’s operation first-hand can give you a better sense of their capabilities and the quality of their electric press brakes.

9. Customization and Scalability: Matching Your Needs

When integrating an Electric Press Brake into your production line, the ability to customize and scale the machine to your specific requirements is essential. This flexibility ensures that your investment can adapt to changing demands and varying projects. Here's what to look for in terms of customization and scalability:

Customization options are paramount. Your chosen press brake should offer a range of features that can be tailored to your operation. This includes adjustable tonnage, variable-length beds, multi-axis backgauges, and specialized tooling. The right configuration will enhance your ability to produce complex parts with precision.

Scalability is equally important. As your business grows, your press brake should be able to keep pace. Look for machines that can be easily upgraded with additional features or higher capacities. Some electric press brakes allow for modular upgrades, which means you can enhance functionality as needed without investing in an entirely new system.

Software plays a critical role in both customization and scalability. Advanced CNC systems can be updated with new programs and can adapt to new manufacturing processes. Ensure that the software is user-friendly and offers strong technical support.

Lastly, consider the manufacturer's ability to provide custom solutions. A vendor that can offer bespoke modifications to their standard machines can be a valuable partner in addressing your unique manufacturing challenges.

10. Electric Press Brake and CNC: Precision Engineering at Its Finest

The combination of Electric Press Brakes with Computer Numerical Control (CNC) technology represents the pinnacle of precision engineering. CNC integration elevates the capabilities of electric press brakes to new heights, enabling operators to execute complex bending tasks with ease and accuracy. Here's how CNC complements the function of electric press brakes:

CNC technology brings a level of automation that is transformative. With CNC, electric press brakes can perform a variety of bends with precise control over angles, depths, and forces. The programmable nature of CNC systems allows for the storage and recall of bending programs, which is invaluable for repeat jobs and consistent production quality.

The integration also ensures a high degree of repeatability. Once the details of a job are programmed into the CNC system, the electric press brake can replicate the process with minimal variance, ensuring uniformity across large production runs.

Moreover, CNC-controlled electric press brakes offer enhanced efficiency. The ability to quickly switch between programs and automate part of the workflow reduces setup times and increases throughput, particularly beneficial for job shops dealing with multiple short-run jobs.

Another significant advantage is the reduction in manual calculations and adjustments. CNC systems can automatically calculate the required bend allowances and bend sequences, reducing the potential for human error and material waste.

Furthermore, the advanced software used in CNC press brakes often includes simulation capabilities, allowing operators to foresee potential problems before actual bending begins. This predictive approach saves time and materials by avoiding mistakes.

Choosing the Best Press Brake

Selecting the right press brake is critical to the success of your metal fabrication endeavors. With the insights provided in this guide, you’re well-equipped to make an informed decision. Embrace the future of fabrication with Krrass, China's leading Press Brake manufacturer, where innovation meets performance. Discover our range of high-precision Electric CNC Press Brakes designed to elevate your manufacturing capabilities. Visit us now at www.krrass.com and step into a world where metal bends to your will.

Read More:

Press Brake Bending: Basics & Tips

What Is a CNC Press Brake Machine and How Does It Work?

Electric Press Brake VS Hydraulic Press Brake: Which One Right for You?