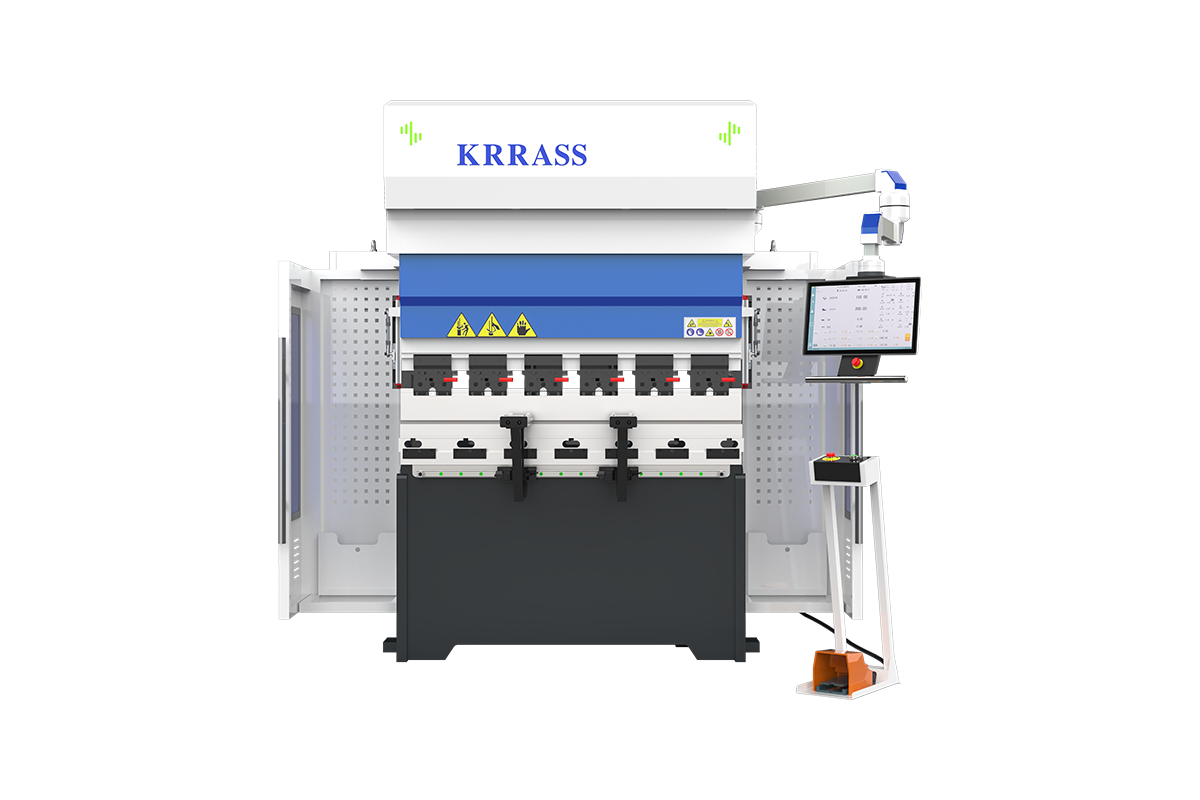

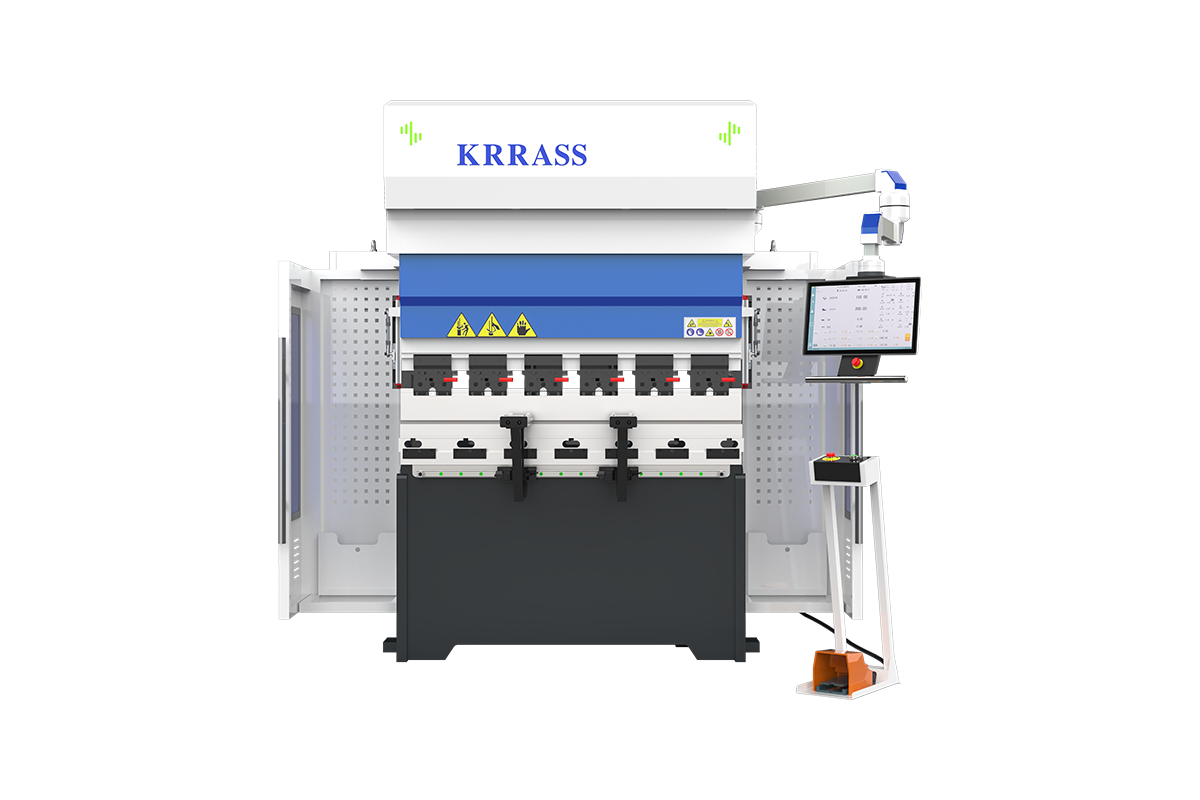

Electric Press Brake

The benchmark of precision bending

Our specialization in developing hybrid technology allows you to achieve energy savings between 55% and 78% compared to a conventional bending press brake. This EPP Series hybrid CNC press brake for sales reduces the need for hydraulic oil and energy consumption without impacting the bending performance.

Simple and solid press brake

Work area can be customized and all types of tool clamping can be installed

Tailored-made sheet metal press brake

Fully-electric press brake

for simple to complex sheet

metal bending.

Bending Force Range

44 to 276

tons for any application

Bed Length Range

4-17 feet

for all production requirements

Every detail covered

The innovative, modular design of the Hybrid CNC Press Brake Series has been achieved through adept engineering methods, collective industry experience, and high-standard manufacturing processes.

The result is a highly precise, reliable, and high-speed production system coupled with energy efficient and noise-reduced operation.

The benchmark of precision bending

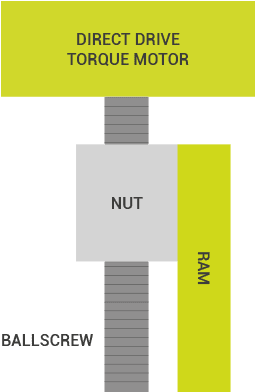

Direct-drive technology for all-electric operation

The hybrid CNC press brake for sales patented Direct Drive Electric Motor maximizes efficiency, repeatability, and reliability as a result of its design, connecting the ball screw in direct synchronization with the torque motor.

Besides reducing maintenance costs significantly, the absence of gear boxes eliminates backlash.

Complete Process Control

The EPP Series hybrid CNC press brake for sales has an intuitive control interface, advanced functions, and a step-by-step guide designed to accommodate operators’ varying skill levels for fast and efficient loading, programming, and editing of jobs.

The state-of-the-art multi-touch control is ergonomically mounted on a moveable arm for ease of access and placement at various positions of the machine, based on the operator’s needs.

Electric Press Brake Technical Parameter

| Bending Pressure (KN) | Bending Length(mm) | Column Distance(mm) | Throat Depth(mm) | Slider Stroke(mm) | Max. Opening Height(mm) | Main Motor Power(kw) | Average Power(kw) | X-axis Max. Distance(mm) | R-axis Max. Distance(mm) | Maximum Speed(mm/s) | Weight (kg) | |||

| Drive in | Bending | Return | ||||||||||||

| EPP-35/1350✭ | 350 | 1350 | 1300 | 0 | 180 | 430 | 2X7.5 | 1.1 | 600 | 120 | 200 | 0-30 | 200 | 3500 |

| EPP-50/1650✭ | 500 | 1650 | 1300 | 210 | 200 | 470 | 2×18 | 2.4 | 600 | 120 | 200 | 0-30 | 200 | 4800 |

| EPP-70/2050✭ | 600 | 2050 | 1700 | 210 | 200 | 470 | 2×23 | 2.6 | 600 | 150 | 200 | 0-30 | 200 | 5400 |

| EPP-70/2500 | 700 | 2500 | 2000 | 210 | 200 | 470 | 2×23 | 2.7 | 600 | 150 | 200 | 0-30 | 200 | 6800 |

The model workbench with ★ in the upper right corner does not have a mechanical compensation device.

Reviewed by 6 users

This electric press brake is an essential tool for our metal fabrication shop, and thoroughly impressed with the performance of this particular model.

Nice press brake

I recently purchased a press brake from KRRASS and it’s perfect