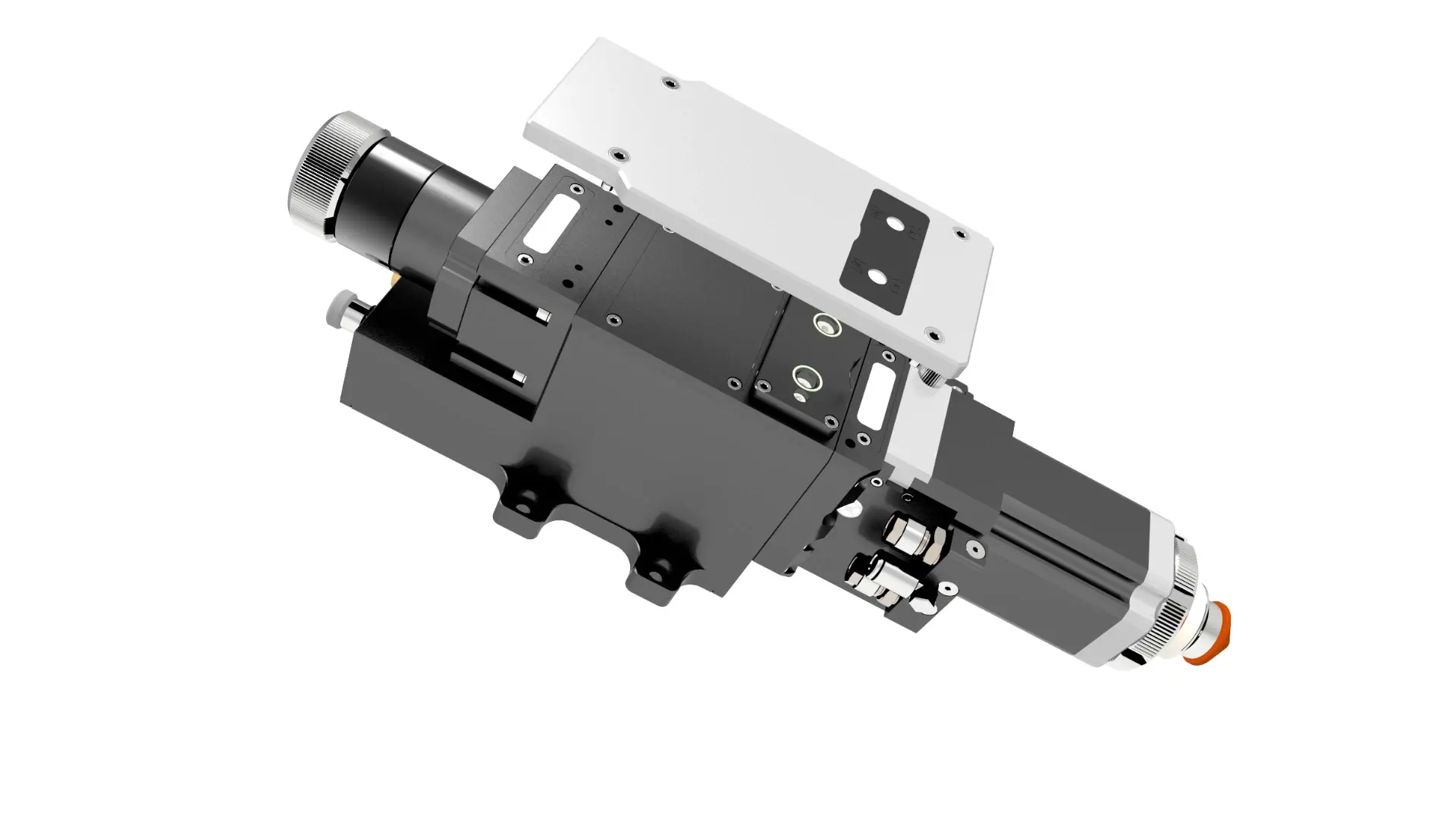

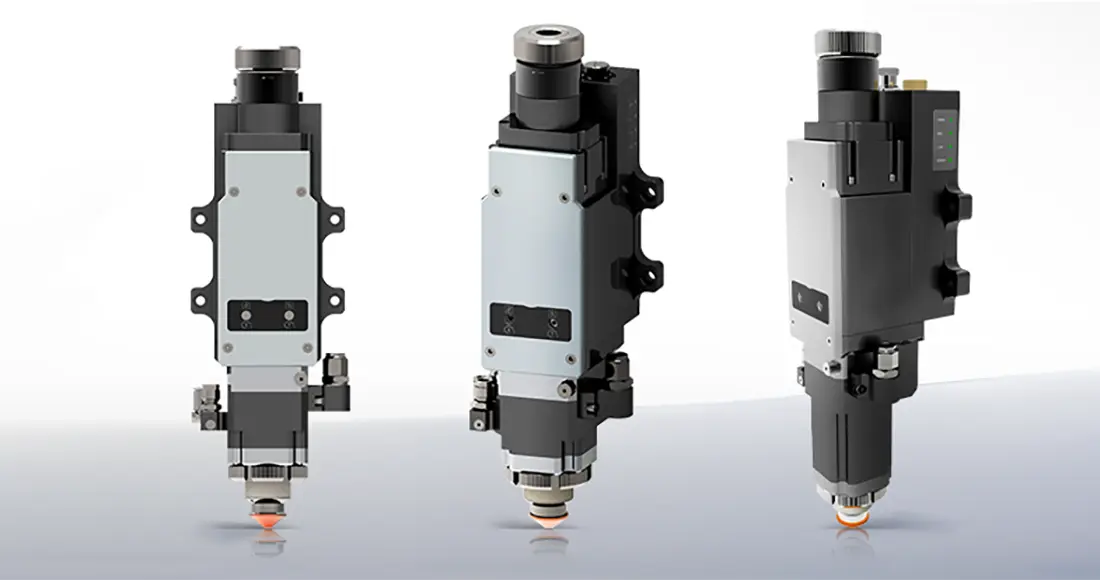

Fiber Laser Cutting Machine Head BLT3 series is a cost-effective intelligent cutting head developed for small and medium-sized power, which is not only small in size and light in weight, but also integrates multiple sets of intelligent sensors inside the cutting head, real-time closed-loop intelligent monitoring, rapid diagnosis and timely warning.

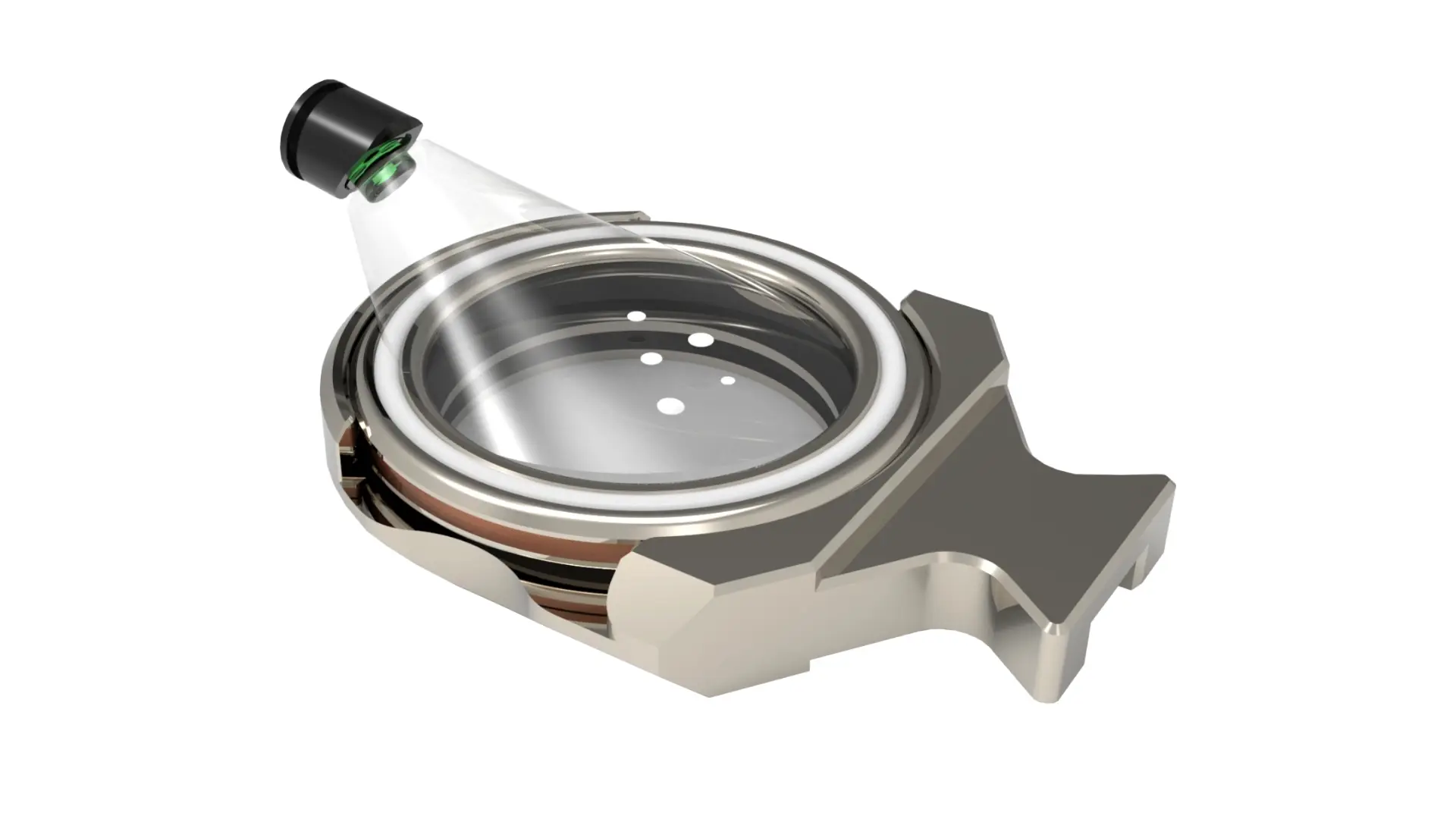

Drawer design of the mirror group

The drawer-type design structure of the lens group is plug-and-play, and the maintenance is more convenient.

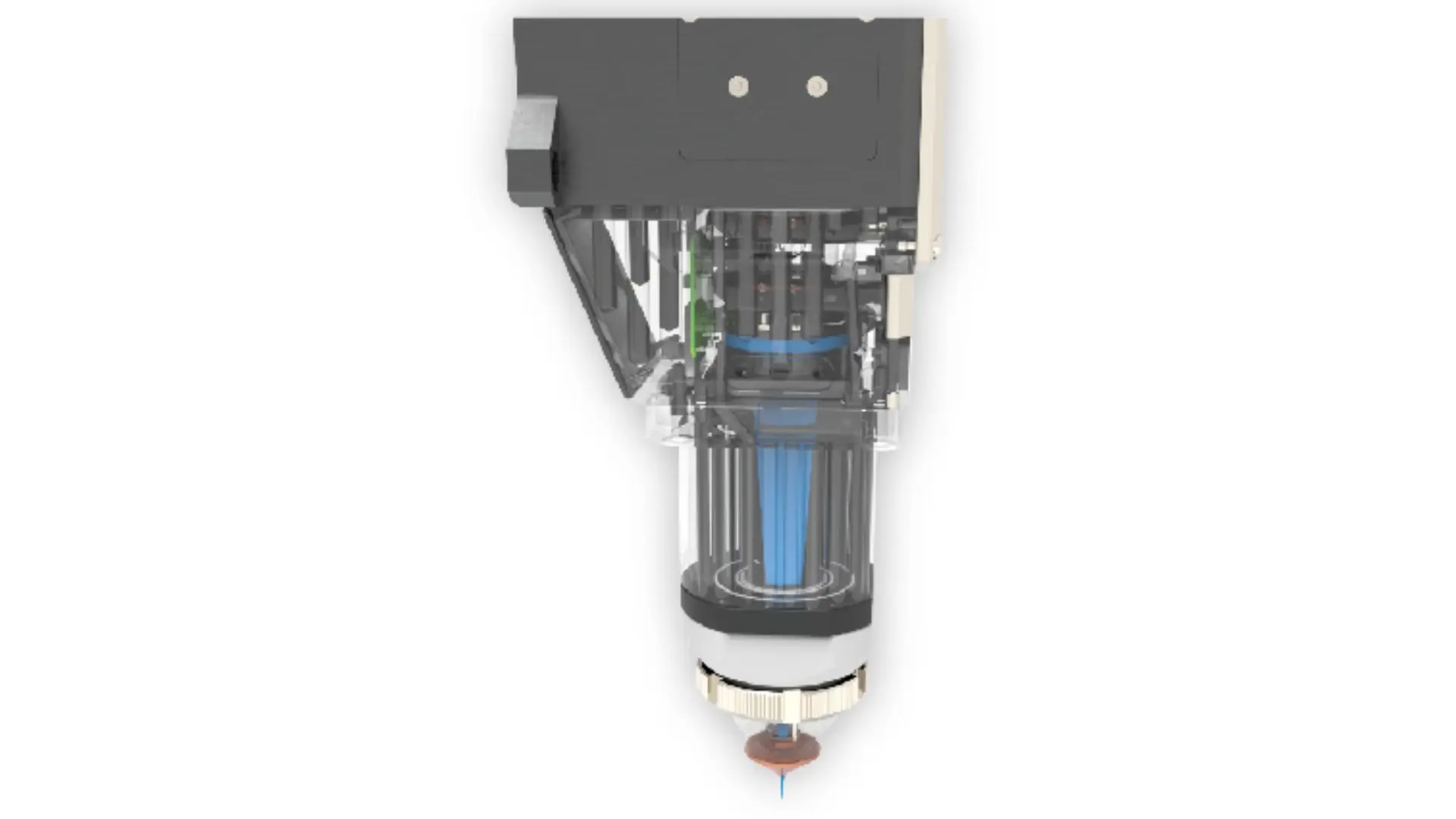

Collision protection

The anti-collision design of the cutting head effectively reduces the probability of returning to the factory, no need for after-sales door-to-door, customers can replace it by themselves, and the maintenance cost is lower.

Protective mirror contamination monitoring

Real-time monitoring of the temperature of the protective mirror during the cutting process, when the protective lens is polluted, the system will stop the light in time to alarm, effectively reducing the cutting defects caused by the contamination of the protective mirror.

Barometric pressure monitoring

Real-time monitoring of the gas flow output during the cutting process, timely warning when the deviation is too large, effectively reduce the poor cutting caused by the excessive deviation of the output air pressure, and the pollution and breakdown of the protective mirror caused by the insufficient pressure of the air supply.

IP64 degree of protection

The new structural design enhances the sealing performance of the cutting body, and the dust cover plate is added to the optical core area, which improves the sealing level of the core chamber and prolongs the service life of the core lens.