How much do you know about the advantages of Fiber Laser Cutting Machine?

Everyone is no stranger to Fiber Laser Metal Cutting Machine. Today we compare CO2 (carbon dioxide) laser cutting equipment to get a deeper understanding of its advantages.

Meet the Laser Cutting Machine

The fiber laser outputs a laser beam with high energy density and is concentrated on the surface of the workpiece to instantly melt and vaporize the area irradiated by the ultra-fine focus spot. The laser spot is moved by the CNC mechanical system to realize automatic cutting.

Laser Cutting Machine application

Compared with bulky gas lasers and solid-state lasers, fiber laser cutting machines have obvious advantages and have gradually developed into important candidates in high-precision laser processing, lidar systems, space technology, laser medicine and other fields. The Fiber Laser Cutting Machine can be used for plane cutting, pipe cutting, and bevel cutting. The cutting section is neat and smooth to meet the high-precision processing requirements of metal sheets and pipes.

Laser Cutting Machine VS CO2 Laser Cutting

1. Beam quality

Compared with the CO2 laser cutting machine, the fiber laser cutting machine has excellent beam quality, with a smaller focused spot, which makes the cutting lines finer and can achieve better processing.

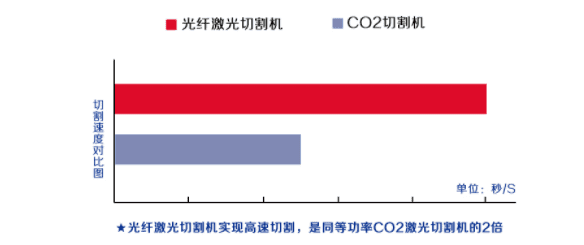

2. Cutting speed and processing efficiency

Compared with the CO2 laser cutting machine, the cutting speed and efficiency of the fiber laser cutting machine are twice that of the same power CO2 laser cutting machine.

3. Equipment stability

The fiber laser adopts a semiconductor modular and redundant design, and there is no optical lens in the resonant cavity, and no start-up time is required. Compared with CO2 lasers, fiber lasers have the advantages of adjustment-free, maintenance-free, and high stability, which are unmatched by other traditional lasers. High-quality fiber laser with stable performance, and the service life of key components can reach 100,000 hours.

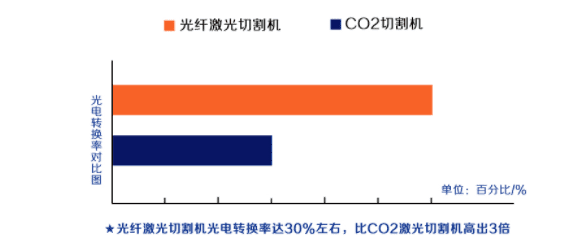

4. Photoelectric conversion efficiency

Laser Cutting Machine has a photoelectric conversion rate of about 30%, which is 3 times higher than that of a CO2 laser cutting machine, which is energy-saving and environmentally friendly, and reduces production costs.

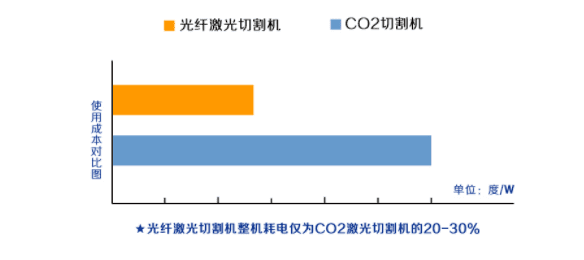

5. Use and maintenance costs

The power consumption of the Laser Cutting Machine is only 20-30% of that of the CO2 laser cutting machine, and the use cost is lower than that of the CO2 laser cutting machine. At the same time, the fiber laser cutting machine does not require laser working gas, fiber transmission, and reflective lenses, saving a large part of the maintenance cost. The fiber laser only needs to provide a constant temperature and humidity environment, clean distilled water or deionized water to cool the laser and stable power output, and it is easy to maintain.

6. Optical path and operation

Compared with the CO2 laser cutting machine, the optical fiber laser cutting machine is transmitted by optical fiber, and does not require complicated light guide systems such as mirrors. The optical path is simple, the structure is stable, and the maintenance is convenient.

If a worker wants to do well, he must first sharpen his tools. The selection of equipment has a key impact on the production efficiency, product quality and even operating costs of an enterprise. Hong Hongxia hopes that every user can choose the right equipment to win every victory in the mall!

Learn more about our products, please visit and subscribe to our Youtube channel