Introducing the Heavy-duty Pure Electric Servo CNC press brake: A New Era of Energy-saving and Environmentally Friendly press brakes Arrives.

According to a report by a certain company on October 24, 2021, titled "Opinions of Relevant Units in Our Country on Fully Implementing the New Development Concept and Doing a Good Job in Carbon Peaking and Carbon Neutrality," the targets for 2025, 2030, and 2060 are outlined:

By 2025, a preliminary formation of an economic system based on green, low-carbon, and circular development will be achieved, with a significant improvement in energy efficiency in key industries. Energy consumption per unit of GDP will decrease by 13.5% compared to 2020; carbon dioxide emissions per unit of GDP will decrease by 18% compared to 2020; the proportion of non-fossil energy consumption will reach around 20%; forest coverage will reach 24.1%, and forest stock volume will reach 18 billion cubic meters, laying a solid foundation for achieving carbon peaking and carbon neutrality.

By 2030, comprehensive green transformation in economic and social development will yield significant results, and energy efficiency in key energy-consuming industries will reach international advanced levels. Energy consumption per unit of GDP will decrease significantly; carbon dioxide emissions per unit of GDP will decrease by over 65% compared to 2005; the proportion of non-fossil energy consumption will reach about 25%, with a total installed capacity of wind and solar power exceeding 1.2 billion kilowatts; forest coverage will reach about 25%, and forest stock volume will reach 19 billion cubic meters. Carbon emissions will peak and begin to decline.

By 2060, a comprehensive economic system based on green, low-carbon, and circular development, along with a clean, low-carbon, safe, and efficient energy system, will be fully established. Energy utilization efficiency will reach international advanced levels, and the proportion of non-fossil energy consumption will exceed 80%. The goal of carbon neutrality will be successfully achieved, and fruitful results will be obtained in the construction of an ecological civilization, ushering in a new era of harmonious coexistence between humans and nature.

New Model

In line with the objectives set by the "Carbon Peaking and Carbon Neutrality" work proposal, KRRASS Machinery has developed and manufactured the highly anticipated pure electric servo CNC press brake. This model combines four key characteristics of "energy-saving, environmentally friendly, high efficiency, and high precision," effectively solving the cost issues faced by previous large-tonnage pure electric servo CNC press brakes.

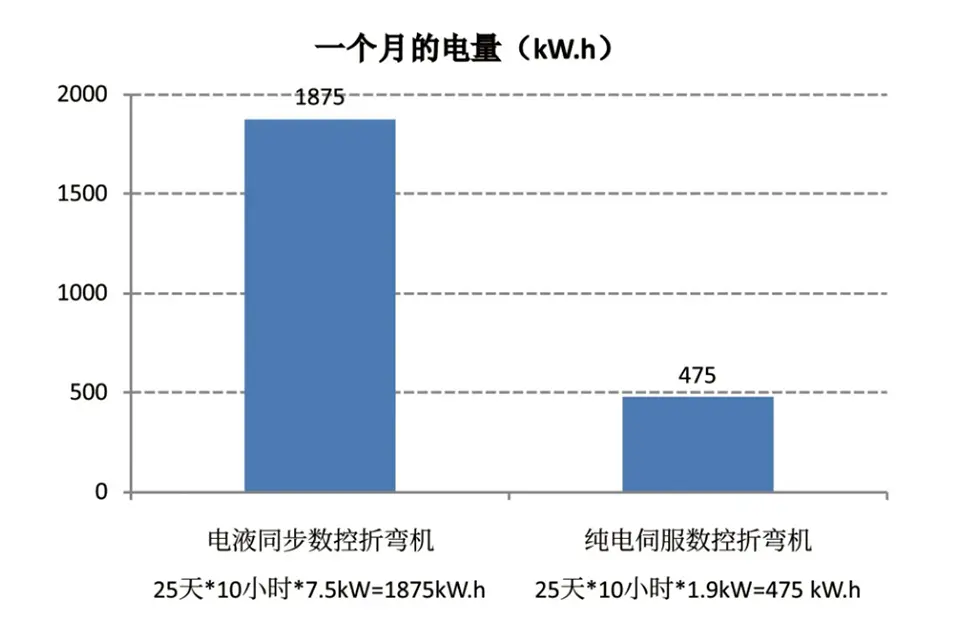

Energy-saving, 80% power reduction

Taking the same type of electro-hydraulic machine as a reference, the pure electric servo model consumes only 25% of the electricity used by the electro-hydraulic servo model in a month.

Environmentally friendly, no oil change required

The pure electric servo CNC press brake does not require hydraulic oil and does not need regular oil changes, eliminating the pollution caused by oil leakage and keeping the workshop clean and tidy.

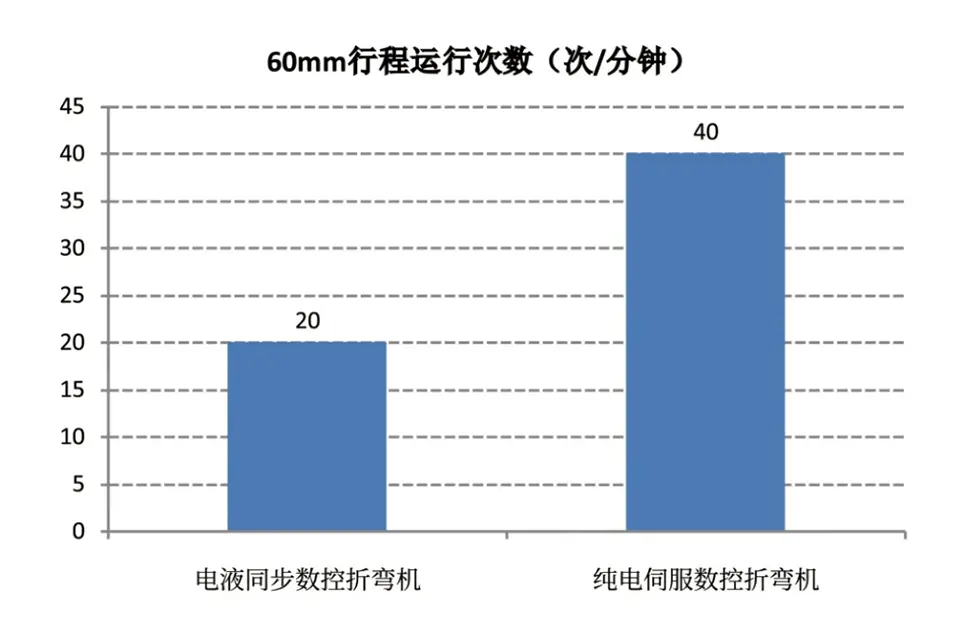

Efficient, doubled productivity

The quick full-speed conversion and dead-point positioning of the pure electric servo CNC press brake are controlled by servo motors and lead screws, making the entire cycle much faster than hydraulic press brakes. Compared to the same type of electro-hydraulic machine, the efficiency is doubled.

Precision, consistently accurate

The pure electric servo CNC press brake relies on servo motors and lead screw transmission to achieve the up and down movement and positioning of the slider, and its positioning accuracy can be maintained even after long-term use. On the other hand, the electro-hydraulic machine relies on hydraulic pressure for the up and down movement of the slider, and the positioning accuracy of the slider will decrease with changes in oil temperature, making it difficult to guarantee consistent precision.

From a long-term perspective, the introduction of KRRASS machine's pure electric servo CNC press brake is a significant step towards entering the "new energy era" in the domestic CNC press brake field. If the equipment we produce is not accepted by the market or customers, even the best machines cannot enter factories and play a role on the production line. Therefore, good technology alone would be merely an embellishment and devoid of substance.

KRRASS machine has always adhered to the production philosophy of creating more durable and reliable sheet metal processing equipment. We hope that the newly introduced pure electric servo CNC press brake model can enter more factories and faithfully carry forward the principles that we consider our belief.