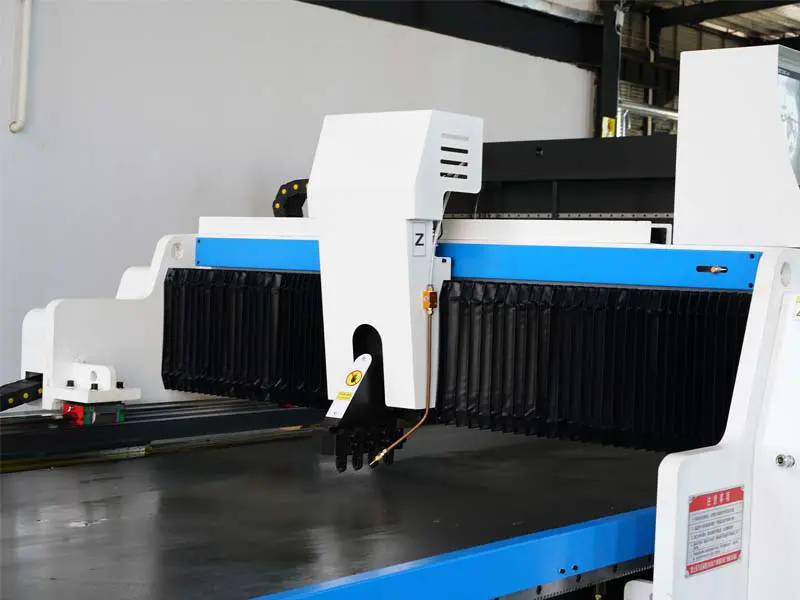

Horizontal V Grooving Machine

Sheet Metal V Groover

Horizontal V Grooving Machine is good at metal sheet accurate grooving,which is good for controling the radius of the bending angle in the subsequent bending process.

Top performances allow to accurately and cost-efficiently V Groov pieces in high volumes.

Proportional oil hydraulic circuit has been completely designed by KRRASS. It is optimized for every V Grooving Machine size, with high-quality and reliable parts.

Horizontal V Grooving Machine is available in a wide range of models and powers. Length and shearing thickness can be customized to the highest levels in the category.

- Controller: HUST CNC Controller - Taiwan

- Serivo Motor: Panasonic - Japan

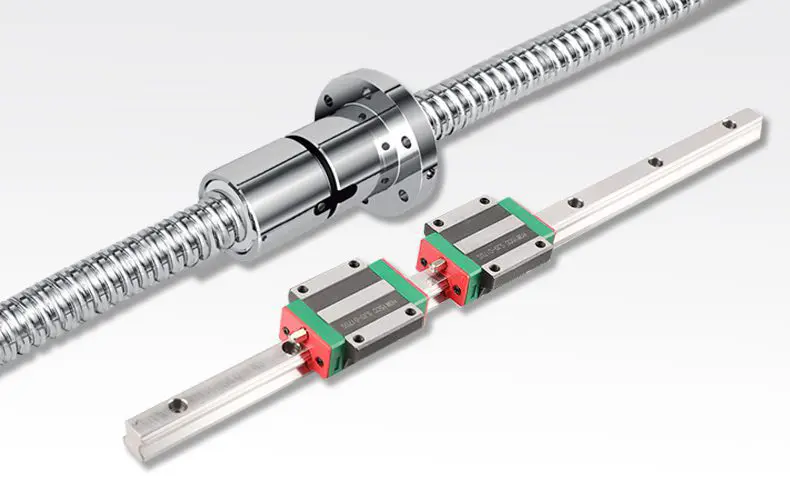

- Hight-Precise Ball Screw: HINWIN - Taiwan

- Hight-Precise Linear Guide Rail: HINWIN - Taiwan

- Gear-rack drive: YYC - Taiwan

- Touching Ball Bearing: NSK - Japan

- Grooving Cutter: KORLOY - Korea

- Electrical Element: AIRTAC - Taiwan

- Air Cylinder: AIRTAC - Taiwan

- Power Cable: IGUS - Germany

Standard Equipment

Introduction to Configuration

Stable Accurate Quiet

The frame structure design is adopted for the machine base and beam, 60mm low alloy high-strength structural steel is used for the worktable, and Q345 steel plate is used for the frame. The overall rigidity of the machine tool is good, firm and durable.

HUST CNC Control System

HUST CNC A60C Control

- 15 inch CNC touch display

- Acceleration / deceleration response time: 0.5US

- With fallback function

- PLC interrupt function: scan time is

- Fixed at 10ms

- Avoid collision

Alloy Blade

- The processing technology of four grooving cutters is adopted, so that each blade during processing can be grooved evenly.

- The blade is made of alloy steel.

- Double nozzle blowing is adopted to clean debris more thoroughly.

More Details of Sheet Metal V Groover

Technical Parameter of Horizontal V Grooving Machine

| NO | Content | Unit | Parameter | |||

|---|---|---|---|---|---|---|

| 1 | type | mm | RAS-1250x3200 | RAS-1250x4000 | RAS-1500x3200 | RAS-1500x4000 |

| 2 | Process plate Thickness | mm | 0.5-6.0 | 0.5-6.0 | 0.5-6.0 | 0.5-6.0 |

| 3 | Process Plate Length x Width | mm | 1250x3200 | 1250x4000 | 1500x3200 | 1500x4000 |

| 4 | Minimum Margin | mm | 8 | 8 | 8 | 8 |

| 5 | Maximum Depth | mm | 0.8 | 0.8 | 0.8 | 0.8 |

| 6 | Maximum grooved Depth | mm | 2.5 | 2.5 | 2.5 | 2.5 |

| 7 | Cut pin speed / variable speed | M/min | 0-90 | 0-90 | 0-90 | 0-90 |

| 8 | Work Table Adjustment | Self-Planing Function | Self-Planing Function | Self-Planing Function | Self-Planing Function | |

| 9 | X Axis Minimum Set Unit | mm | 0.01 | 0.01 | 0.01 | 0.01 |

| 10 | X Axis Positioning Accuracy | mm | ±0.05 | ±0.05 | ±0.05 | ±0.05 |

| 11 | Y Axis Minimum Set Unit | mm | 0.01 | 0.01 | 0.01 | 0.01 |

| 12 | Y Axis Positioning Accuracy | mm | ±0.05 | ±0.05 | ±0.05 | ±0.05 |

| 13 | Z Axis Minimum Set Unit | mm | 0.01 | 0.01 | 0.01 | 0.01 |

| 14 | Z Axis Positioning Accuracy | mm | ±0.03 | ±0.03 | ±0.03 | ±0.03 |

| 15 | X1-X2Axis Motor Power | Kw | 1-1(Total 2KW) | 1-1(Total 2KW) | 1-1(Total 2KW) | 1-1(Total 2KW) |

| 16 | Y Axis Motor Power | Kw | 5.5 | 5.5 | 5.5 | 5.5 |

| 17 | Z Axis Motor Power | Kw | 1 | 1 | 1 | 1 |

| 18 | Work Table Level | mm | ±0.03 | ±0.03 | ±0.03 | ±0.03 |

| 19 | Feeding Mode | Sheet Metal Motionless,Tool Holder Movement | Sheet Metal Motionless,Tool Holder Movement | Sheet Metal Motionless,Tool Holder Movement | Sheet Metal Motionless,Tool Holder Movement | |

| 20 | Work Table Easy Replacement | No Replacement | No Replacement | No Replacement | No Replacement | |

| 21 | The whole machine quenching | Yes | Yes | Yes | Yes | |

| 22 | Hydraulic System | 1.5KW/8L/10Mpa | 1.5KW/8L/10Mpa | 1.5KW/8L/10Mpa | 1.5KW/8L/10Mpa | |

| 23 | Number Of Knives Installed | 4 Alloy Knives | 4 Alloy Knives | 4 Alloy Knives | 4 Alloy Knives | |

| 24 | Outline Size | mm | 5200*2500*1800 | 6000*2500*1800 | 5200*2750*1800 | 6000*2750*1800 |

| 25 | Table parallelism | Mm/M | ±0.02 | ±0.02 | ±0.02 | ±0.02 |

| 26 | Weight | Kg | 8000 | 8500 | 9500 | 10000 |

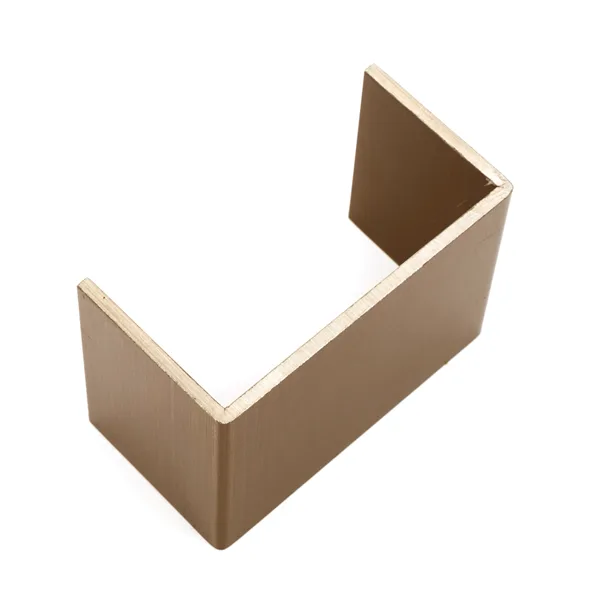

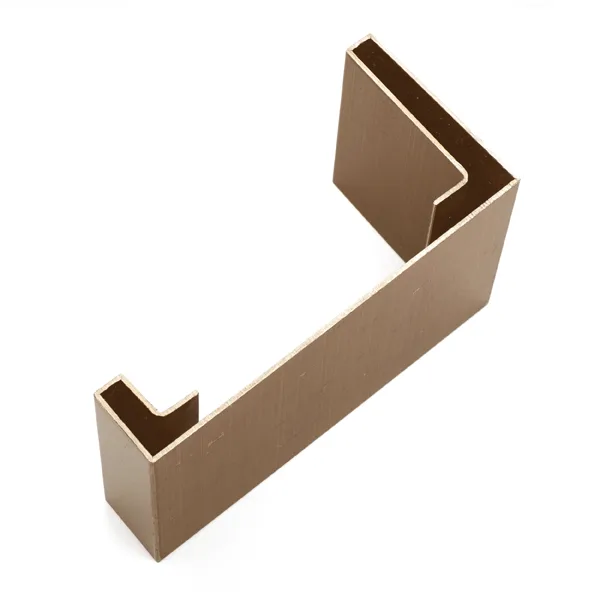

Slotting Case of Sheet Metal V Groover

Reviewed by 7 users

my 1250*4000 is good grooving machine. The quality is good, very smooth after grooving

my grooving machine is 1500*4000. enough for my plate doing groove jobs. Easy to operat.

very good machine. I use this machine make windows, very nice

I need the machine urgent. RAS-1250X4000-Horizontal V Groove Machine came quickly and without any issues. The manufacturing quality appears to be very high. Good company to work with.

I bought RAS1250*3200, grooving machine, the grooving quality is high. Help me a lot.