Laser cutting is an innovative technique that cuts through materials with unparalleled efficiency and precision by using focused laser beams. When working with metals, polymers, or even wood, laser cutting machines offer a flexible way to produce complex patterns and superior surfaces.

However, what is the operation of a laser cutting machine? From the fundamentals of laser generation to the detailed cutting process, this essay delves deeply into the mechanics underlying this sophisticated process.

Knowing how these laser machines work not only proves their usefulness in contemporary production but also opens new avenues for industry-wide innovation. Come with me as we investigate the intriguing realm of laser cutting technology!

Table of Contents

Principles of Laser Cutting

What is a Laser?

Light Amplification by Stimulated Emission of Radiation, or laser, is a unique light source that has the following specific qualities:

- High energy density: By focusing energy on a tiny focal point, the laser beam produces enough heat to melt or evaporate materials.

- Monochromaticity: The laser's single wavelength of light ensures stability and great energy concentration.

- Directionality: Long-distance transmission with little energy loss is made possible by the laser beams extremely constant propagation path.

Lasers are perfect for industrial applications like industrial cutting and welding because they are brighter, more coherent, and have stronger directionality than regular light sources.

How Do Laser Cutters Work

How does laser cut run? The method known as laser cutting creates a cut edge by vaporizing materials with a laser. A laser source (also known as a laser generator), such as a CO2, Nd:YAG, or fiber laser, produces a highly concentrated beam of light to start the laser processing process. The substance of the workpiece absorbs the concentrated laser beam and transforms it into heat energy.

Laser cutting heats and cuts materials locally by converting light energy into thermal energy. The following elements are part of its fundamental operating mechanism:

Thermal Effect Principle

When a substance is exposed to a high-intensity laser beam, its energy is quickly absorbed and transformed into thermal energy, changing the material physically in the ways listed below:

- Melting: To produce a clean cut, the material melts and is impressed by a high-pressure gas jet.

- Vaporization: Which is often used to thin materials, is the direct conversion of a solid into a gas.

- Burning: Materials can occasionally catch fire and burn, particularly when an oxygen jet is used to speed up the cutting process.

For a variety of applications, laser cutting produces remarkable results because to its precise control and concentrated energy.

Energy Conversion Process

When photons in the laser beam interact with particles on the material's surface, they impart their kinetic energy to the particles, generating strong vibrations that ultimately produce heat. By quickly raising the local temperature, this method boosts the material's melting or vaporization point.

Physical Changes During the Cutting Process

The following physical phenomena cooperate to finish the machining during the cutting process:

- Localized Heating and Melting: A tiny, hot spot on the workpiece surface is produced by the concentrated laser beam, which quickly melts or vaporizes the region.

- Assist Gas Action: To blast the evaporated or molten material out of the kerf, oxygen, nitrogen, or inert gas is provided through a nozzle. This cools the workpiece and stops oxidation.

- Kerf Formation: A precise kerf is created when the laser head travels through the high-temperature zone, which constantly melts or removes material in its path.

Key Components of a Laser Cutting Machine

To conduct correct and effective cutting, laser cutting machines are made up of a number of essential parts. These elements and their purposes are broken down in depth below.

The Laser Source

The machine's center is the laser source, which produces the cutting laser beam. The many laser types used in laser cutting each have their own benefits, limitations, and operating principles:

CO2 Laser

- Principle: The lasing medium is a combination of gases (CO₂, N₂, and He). The wavelength of infrared light emitted by excited CO₂ molecules is 10.6 μm.

- Benefits:

- High power output (15 kW) that works well with thin metals and non-metals.

- Long operating life (up to 20,000 hours) and low cost per watt.

- Drawbacks:

- Heat production needs a cooling system.

- 10% to 20% less efficient than fiber lasers.

Laser Fiber

- Principle: The lasing medium is a doped optical fiber. Light is released at 1.06 μm.

- Benefits:

- minimal maintenance needs and high efficiency (30–35%).

- faster rates of cutting, particularly for thin metals.

- Drawbacks:

- more expensive initially than CO₂ lasers.

Nd:YAG Laser

- Principle: Uses an yttrium aluminum garnet crystal doped with neodymium as the lasing medium. functions at 1.06 μm.

- Benefits:

- Ideal for reflective materials like copper and aluminum as well as precise micromachining.

- Drawbacks:

- Slower processing for thicker materials and low efficiency (1%–4%).

| Type | Wavelength | Power Range | Applicable Materials | Photoelectric Efficiency |

|---|---|---|---|---|

| CO₂ Laser | 10.6 μm | 1-15 kW (up to 50 kW) | Non-metal/thin metal sheets | 10%-20% |

| Fiber Laser | 1.06 μm | 1-12 kW (up to 30 kW) | Highly reflective metals (e.g., aluminum, copper, brass) | 30%-35% |

| Nd:YAG Laser | 1.06 μm | 50 W-7 kW | Precision micromachining and specialized applications | 1%-4% |

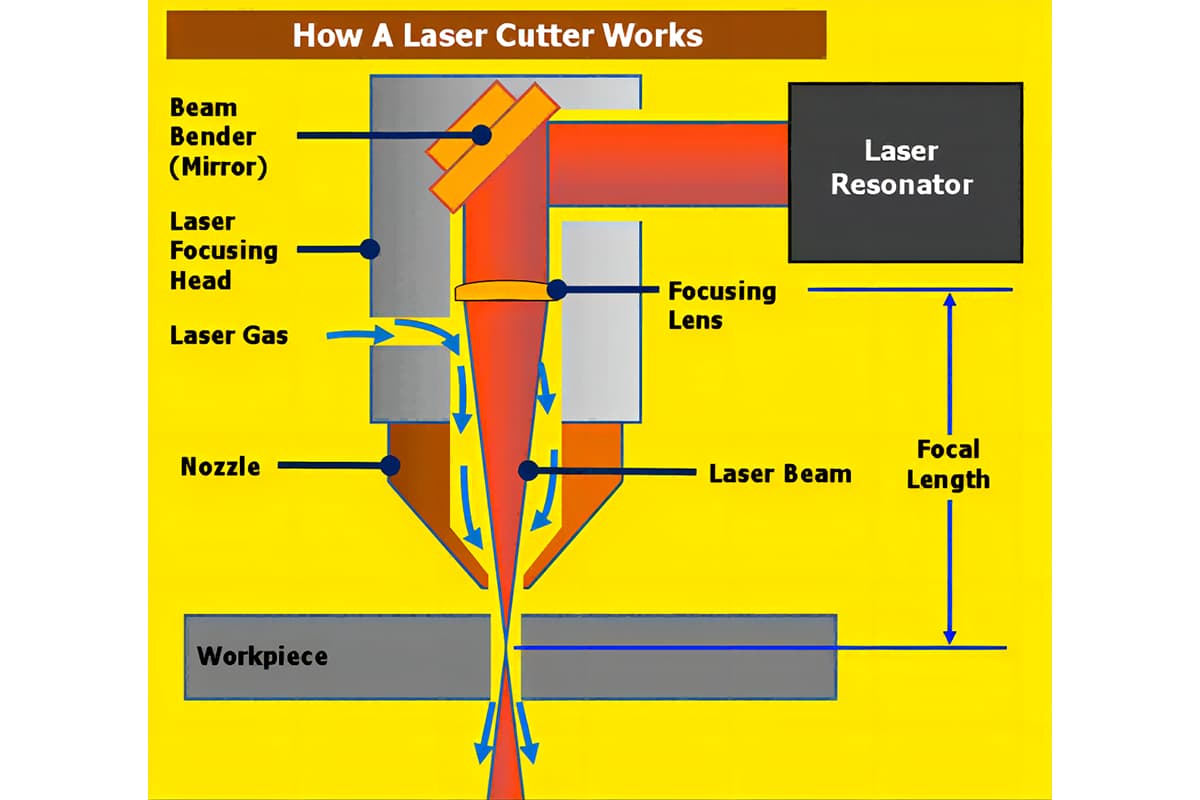

Beam Delivery and Focusing

The laser beam needs to be properly focused on the cutting zone and sent from the source to the workpiece with the least amount of energy loss possible.

Path of Beam Transmission

- Fiber lasers rely on flexible optical fibers for simpler integration, while CO₂ lasers use mirrors to guide the beam.

Concentrating on Optics

- Precision cutting is made possible by lenses and mirrors, which concentrate the laser beam into a tiny area with a high energy density.

- Alignment is crucial because improper alignment might result in part damage or poor cut quality.

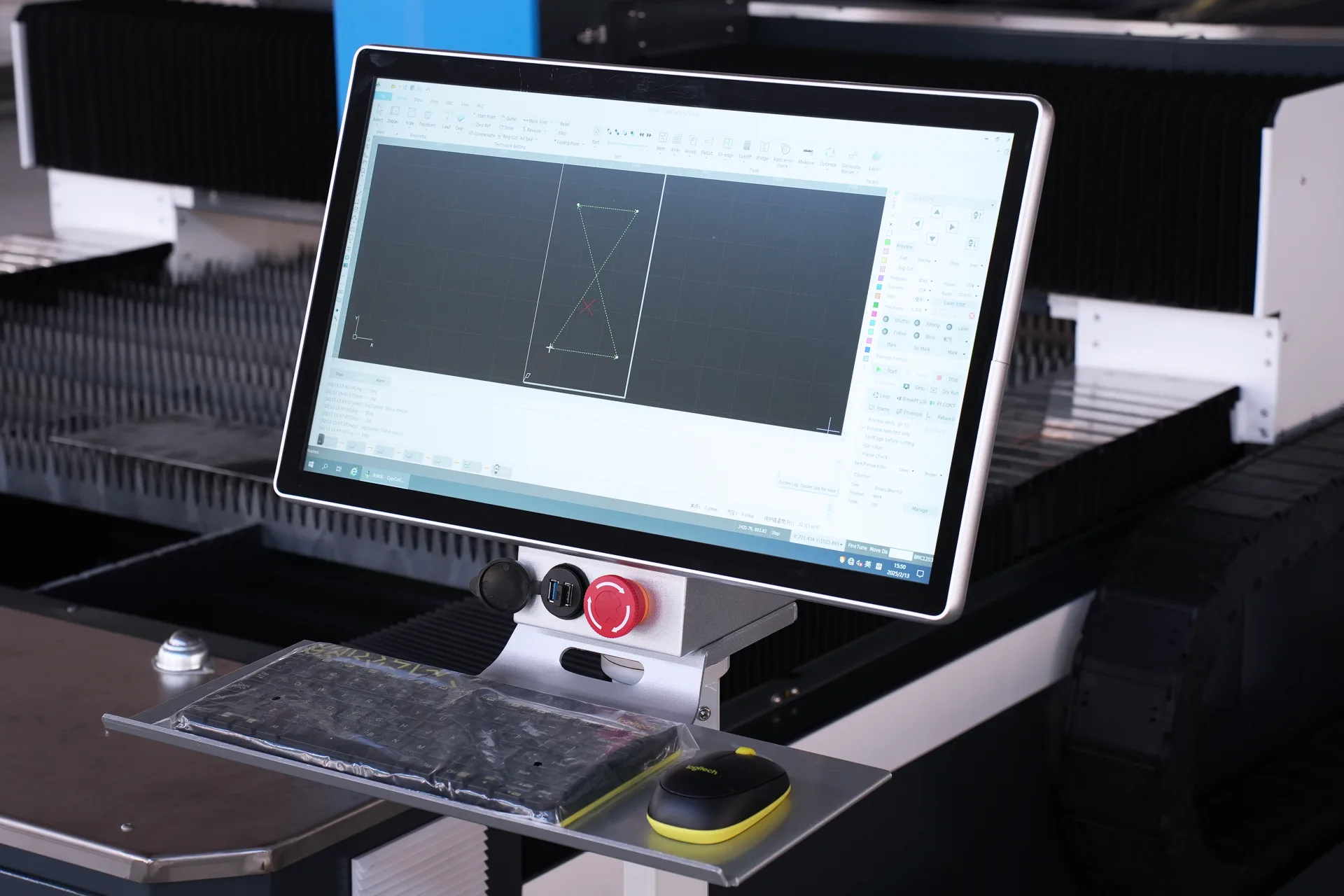

The Control System

The control system regulates motion, power, and cutting settings to guarantee correct operation.

CNC System

- Creates G-code from CAD/CAM drawings so they may be executed by machines.

- Precisely regulates the cutting head's movement.

Servo Control System

- For precise placement and fluid motion during cutting operations, servo motors are used.

Cutting Head and Nozzle

The focusing lens and nozzle, which are in the cutting head, are essential components for guiding the laser beam and auxiliary gas.

Functions of Nozzles:

- Controls the flow of auxiliary gases (nitrogen, oxygen) to clear the cut path of molten material.

- Prevents optical components from becoming contaminated by debris.

Types of Nozzles:

- Single-layer nozzles for nitrogen and other inert gases.

- Double-layer nozzles for high-speed cutting with oxygen aid.

Software/Control Panel

Through control software that manages design input, parameter adjustments, and real-time monitoring, operators communicate with the machine.

Examples include proprietary control software for effective cut execution and CAM software for toolpath development.

Auxiliary Systems

System of Cooling

- Prevents thermal damage by keeping the laser source and optics at constant operating temperatures.

The Exhaust System

- Cuts smoke, fumes, and debris produced during cutting to preserve cut quality and guarantee safety.

Supplementary Gases

- Oxygen: Promotes combustion and speeds up cutting (used to cut carbon steel).

- Nitrogen: Used on stainless steel, it stops oxidation for superior surfaces.

- Air: An affordable choice for simple uses.

Laser Cutting Process

Step 1 Design Preparation and Programming

CAD/CAM Software Use

- CAD (Computer-Aided Design): Use programs like SolidWorks, AutoCAD, or Fusion 360 to create intricate 2D or 3D models. With the use of these tools, designers may guarantee dimension correctness and assign material qualities.

- Computer-Aided Manufacturing (CAM): To specify cutting parameters like speed, laser power, and route, import CAD files into CAM software. Toolpaths that are customized for the material and cutting requirements are then produced using CAM software.

G-Code Conversion

Toolpaths are transformed into G-code, the programming language that CNC machines can understand, using the CAM software. The cutting head and laser beam's motion along the X, Y, and Z axes is managed using G-code. Use a USB driver or Wi-fi connection to send this G code to the laser cutting machine's controller. Setting the process's ideal parameters comes after the design phase.

Step 2 Set the Machine

Place the items to be cut into the laser cutting machine, adjusting the position based on the thickness and kind of material. This configuration allows you to adjust the laser's power, movement speed, and beam focus.

The model of the laser cutting equipment and the kinds of materials being cut decide the ideal parameter.

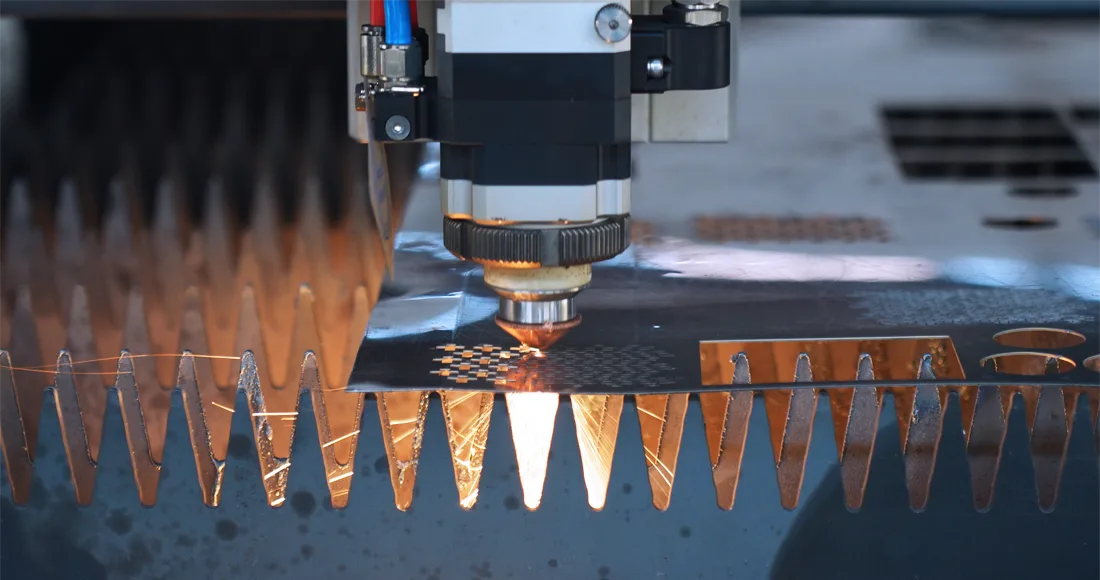

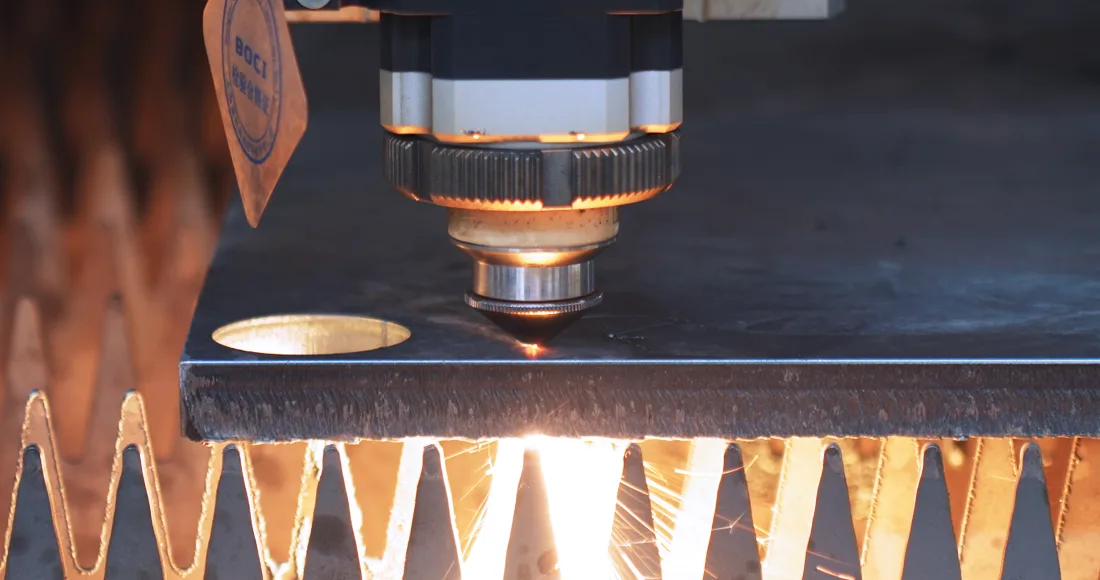

Step 3 Cutting and Engraving Process

You may begin cutting and engraving after setting everything up and starting up. It all starts with the laser resource, which produces steady, solid light.

A solid beam is sent to the cutting head via the mirror system by a laser resonator, which is the source of the laser resource. The lens on the cutting head concentrates the laser into a narrow, concentrated beam.

To cut or raster the raw material, this beam can be directed on the material following the path that the digital device specifies. You will understand the theory better if you ignite a fire with sunlight and a magnifying glass.

The substance will be melted, burned, or vaporized as the light travels along the route, producing correct cutting and engraving.

By using a gas jet, the laser-cutting machine may also remove excess material. The gantry, a mechanical device, is typically where the cutting head is fixed.

This device is often driven by a belt or chain, which enables precise movement of the cutting head inside a designated rectangular area (the working bed's size).

The gantry enables the cutting head to accurately cut at any location on the bed by moving back and forth on the workpiece. To get the best cutting condition, the laser should be focused on the material being cut.

To guarantee a superb laser-cutting effect, all laser cutting equipment must focus the program before cutting. The laser cutting machine has an auxiliary gas in addition to the laser's own function.

During the cutting operation, this gas is ejected from the cutting head and helps to cool the materials and clean the melted metals. As a result, the laser cutting machine can keep a smooth and clean cutting surface in addition to providing precise cutting.

Step 4 Post-Cutting Processes and Inspection

Checks for Quality Control

- Using instruments like calipers or deburring machines, check cut edges for burrs, roughness, verticality, and dimensional correctness.

Steps After Processing

- Deburring: Use sanding or grinding tools to smooth out sharp edges or flaws.

- Surface Treatment: To enhance appearance or stop corrosion, apply painting, anodizing, or polishing.

The last examination

- Before packing or assembling, check each part against the design parameters to guarantee quality and uniformity.

Characteristics of Laser Cutting for Different Materials

Metals and non-metals alike can receive help from the accuracy and adaptability that laser cutting provides. An extensive examination of each category's features, laser settings, and factors is provided below.

1. Metal Materials

Relevant Laser Power and Types

- CO₂ Laser: Good for thin metal sheets, although it needs help gasses to cut well.

- Fiber Laser: Because of its high efficiency and shorter wavelength (1.06 μm), this laser is perfect for metals, particularly highly reflective ones like copper and aluminum.

- Nd: YAG Laser: Less often used in industrial scale cutting, this laser is used for precise metal micromachining.

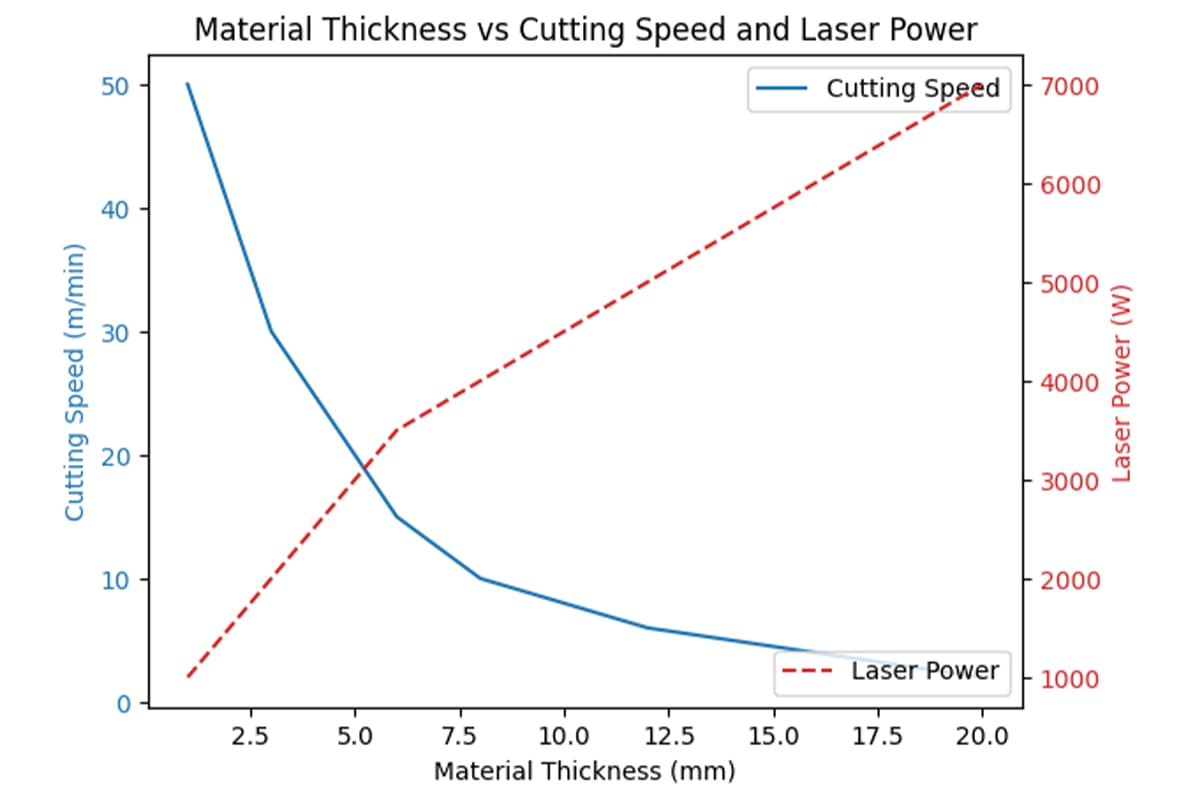

Depending on the material thickness, different power settings are informed:

| Material Thickness | Power Range (watts) |

|---|---|

| Thin sheets (up to 1 mm) | 500–1000 |

| Medium thickness (1–5 mm) | 1000–2000 |

| Thick materials (over 5 mm) | 2000–4000 |

Crucial Cutting Elements

- Power: To guarantee penetration, thicker materials require higher power.

- Speed: To preserve edge quality, slower speeds are needed for thicker metals.

- Help Gas:

- Cutting through oxidation is accelerated by oxygen (used for carbon steel).

- Nitrogen keeps edges clean and stops oxidation (used for stainless steel).

Comparing Typical Metals

| Metal Type | Characteristics | Challenges |

|---|---|---|

| Carbon Steel | Cost-effective, strong, easy to cut. | Prone to rust; requires protective coatings |

| Stainless Steel | Corrosion-resistant, durable. | Reflective surface requires careful settings |

| Aluminum | Lightweight, corrosion resistant. | High reflectivity; risk of warping during cutting |

| Copper & Brass | Excellent thermal and electrical conductivity. | Reflective surfaces require higher power |

| Titanium & Nickel | High strength and corrosion resistance; used in aerospace and medical applications. | Expensive; requires precise control |

Non-Metal Materials

Qualities

Non-metal materials have special qualities that allow them to be used in a variety of ways:

- Wood: Perfect for crafts and furnishings, it cuts cleanly and burns little.

- Acrylic is used extensively in ornamental objects and signs because of its high accuracy and smooth edges.

- Fabric/Textiles: Suitable for both creative and industrial patterns; cuts free of frays.

- Paper/Cardboard: Accurate cuts with little fire hazards when settings are properly adjusted.

Configuring Parameters

| Material Type | Power (%) | Speed (mm/s) | Focus Position |

|---|---|---|---|

| Wood | 30–50% | 50–150 | 1–2 mm above material |

| Acrylic | 40–70% | 100–200 | Optimal focus ensures polished edges |

| Fabric/Textiles | 30–50% | 50–150 | Prevent fraying with precise focus |

| Paper/Cardboard | 10–30% | 200–400 | Avoid burning with lower power |

Comparing Cutting Quality and Material Thickness

- Because thinner materials have less heat effect, they can cut more quickly and cleanly.

- Slower rates and more force are needed for thicker materials to penetrate completely without burning or warping.

Techniques of Laser Cutting

One benefit of laser cutting over plasma cutting for metals is its increased precision. Heat is produced by the strong laser as it meets the substance, melting or vaporizing the surface. There are four primary categories of laser cutting processes based on the types of aid gas:

Cutting Fusion

The aid gas in infusion cutting doesn't help melt the material; it only acts once the laser has done so. Nitrogen, or inert gas, is typically thought of as a cutting aid gas.

By forcing molten metal out of the kerf, pressurized help gas speeds up cutting and lowers the laser power needed to cut through material. Metal may be sliced via fusion cutting. This method is also known as blow cutting and melting.

Cutting with Flames

In flame cutting, oxygen, the aid gas, takes part in the burning and melting of the material. The substance is heated by the laser beam, and when heated materials react with oxygen, flame is produced. This helps the laser beam cut material by increasing the power input to the material.

To realize cutting, I am simultaneously blowing away burned metal with the high-pressure oxygen flow. Materials made of thick carbon steel are often cut by flame. This method is also known as reactive cutting because of the reaction that occurs between heated materials and oxygen.

Sublimation Cutting

When thin materials (such foils and textiles) are cut without the use of an aid gas, sublimation cutting will become visible. Instead of melting the material, a laser beam vaporizes it at once in this process.

The material on the focus may vaporize because to the intense intensity, creating a thin incision. Vaporization cutting is another name for this type of cutting.

Impact-Cutting

Materials that are challenging to cut with continuous laser beams are sliced using impact cutting. To create overlapping holes in the material, a quick pulse laser beam is applied to its surface.

Impact cutting is typically used to cut fragile materials like glass and ceramics. The materials and real application should decide the type of laser to use. For instance, the fiber laser is often used for metal, while the CO2 laser is typically used for cutting a variety of materials.

To ensure precise and effective cutting of metal materials, the laser cutting machine makes use of the complementary effects of a high-energy laser beam and an aid gas.

It is essential to accept instruction and ability when using the laser cutting equipment. For instance, making sure there is adequate ventilation, avoiding direct eye contact with the laser beam, and using protective eyewear. Therefore, safety and best outcomes are possible. For the equipment to continue running well, routine maintenance is also necessary.

Conclusion

High-power lasers are used by the laser cutting machine to cut precisely and effectively in a variety of sectors. Many cutting methods, including fusion and flame, are becoming increasingly essential for contemporary laser technology and production.

In the metal cutting sector, sheet metal manufacturing, and other mechanical engineering applications, KRRASS's laser cutting machines provide unmatched accuracy and efficiency.

Act right now to revolutionize your production process! To select the ideal machine, go through our inventory, or speak with a salesperson for comprehensive details.

FAQs

How can a laser cutter decide what must be cut?

One kind of CNC (Computer Numerical Controlled) machine is a laser cutter, which is run by a computer. With simply a button click, a designer can create anything using design software and then send it to a laser cutter for automated cutting.

What can a laser cutter not cut?

Substances that emit toxins. Chlorinated plastics, such as vinyl and PVC: Chlorine gas, which is poisonous to people and can damage the laser cutter's parts, is released when PVC is sliced. ABS Plastic: When laser-cut, it releases cyanide vapors. Additionally, it typically results in melting rather than a clean cut.

What is the maximum thickness that a laser cutter can cut?

With a 2000W fiber laser cutting equipment, the maximum cutting thickness of various materials is as follows: Carbon steel may be as thick as 20 mm, stainless steel can be as thick as 8 mm, aluminum can be as thick as 6 mm, and copper can be as thick as 4 mm.