Press Brake is a machine tool for bending metal parts and plates up to 20 millimeters thick. It consists of a V or U-shaped die (according to the required curvature) and a punch. The sheet to be bent is placed on the die, the punch is pressed down, and the sheet is bent to the selected angle. Press brakes are widely used in sheet metal work and manufacturing facilities in a wide range of industries, including automobile and aviation.

How to choose a press brake?

Before you select a press brake, you must know what kind of metal you wish to bend (stainless steel, aluminum sheet, etc.).

You will then have to specify the specific properties to consider in calculating the bending of the component; this includes, for example:

- The tensile strength

- The thickness and length of the metal

- The press brake's folding or bending length

- Width of V

- The inner radius of the parts

Once these properties have been determined, you will have to calculate the weight needed for bending.

Cargo is the compression force of the pressure brake. It determines how much pressure the punch can exert during the bending operation.

- High tonnage makes it possible to bend heavy and hard metals.

- Low weight applies to thin metal.

Warning: Incorrect loading (too high or too low) may damage the press brake or the part that you are bending. Please refer to the Operator's Manual or tonnage table to calculate your pressure brake tonnage.

Which technique would you like to choose for your press brake?

In general, press brake will have three different types of technology:

The hydraulic press brake

- A hydraulic cylinder system moves the punch.

- It has a high bending capacity (bending length up to 8 meters and bending force up to 1500 tons).

- It operates continuously, even if not bending, generating electricity costs.

- It requires significant maintenance regularly.

- It's stronger than an electric press brake.

- It is also cheaper.

- It is suitable for simple bending operations.

The electric press brake

- It is equipped with more energy-efficient servo motors instead of hydraulic cylinders.

- It achieves more significant productivity gains.

- The servo motor only consumes energy when the machine needs to bend.

- There is no need to be more maintenance.

- The machine offers more flexibility.

- It is more expensive than the hydraulic press brake, but operating costs are lower.

The hybrid press brake

- It is a hydraulic press brake equipped with electric motors.

- Having electric motors reduces the use of the hydraulic system.

- It combines the advantages of electric and hydraulic press brakes.

What type of bending should you choose?

There are two types of bending:

- Air bending

- Bottom bending

In what cases should you choose air bending?

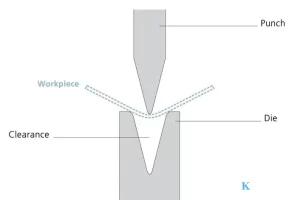

When air bending, the tip of the punch and the two sides of the V permit the bending of the sheet. But this type of bending means the workpiece has a spring-back effect. Because the bending force is less, the metal sheet springs back like an elastic when the punch is removed.

When air bending, the tip of the punch and the two sides of the V permit the bending of the sheet. But this type of bending means the workpiece has a spring-back effect. Because the bending force is less, the metal sheet springs back like an elastic when the punch is removed.

You must therefore adjust the bending angle according to the metal spring back and calculate the margin. As such, for a 90° bend, the punch must go down to 85°, for example.

Calculating this margin should also consider other factors, such as the punch blade's thickness, the fold's length, and the opening of the V.

This type of bending is most commonly used for sheet metal working as it is suitable for machines with reduced capacity, unlike bottom bending, which requires more force.

In what cases should you choose bottom bending?

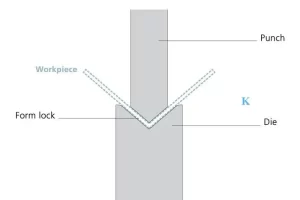

In bottom bending, the punch bends the metal sheet with a high force (3 to 5 times the force of the air bending), which reduces or even prevents the spring-back effect typically associated with the bending of the air. The process begins with air bending and continues with cold forging at the bottom of the V.

This method provides a high degree of angular accuracy.

Applicable to over 2 mm thick sheet metal.

What are the other selection criteria for a press brake?

What other criteria should be taken into account when selecting a press brake?

CNC control system

The CNC control system is the core brain part of the bending machine. It can issue accurate control commands according to various parameters set by the user and multiple data feedback when the bending machine is working. A powerful CNC press brake is inseparable from a powerful CNC control system.

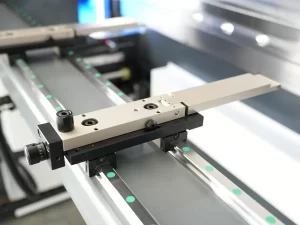

The back gauge

The back gauge

The back gauge is an adjustable gauge used to stop the part by centering the bending line on the V shape of the die. It allows the part to be bent to be in the correct position.

The angle control

It is used to compensate for any inaccuracies in the press brake. We often encounter manual crowning and CNC motorized crowning, etc.

Tools

Using quick clamping allows for shorter tool change times, for example. The clamping length also affects the tool’s accuracy.

Operator safety

In addition to the most commonly used optical safety system, an advanced control safety system is also available for press brakes, a programmable safety controller that simplifies the design process by combining all relevant control, safety, and monitoring functions into one system and eliminates the need for complex integration of third-party components and software. It is designed to improve the performance and safety of press brakes.

KRRASS: the best choice for

all sheet metal processing manufacturers

When considering the overall costs of purchasing, maintaining, and operating a sheet metal equipment setup, a sheet metal fabrication service: KRRASS brand is your best choice. KRRASS has a tremendous reputation in the market due to its focus on consistency and quality at the most competitive price. Whether it's press brake or any other application equipment, our team of experts has the right combination of industry knowledge and the latest tool to provide you with the best products and services on the market. Moreover, we set ourselves apart with our advanced system that is completely online. Just let us know what your product needs, request a quote, and start the process.

Make a request and Get Started Today

Get Instant Quote

Learn more about our products, please visit and subscribe to our Youtube channel