Embarking on your journey to get started with laser cutting? As a novice, two fundamental questions arise: What is laser cutting, and why should it be your choice? Understanding the core principles, recognizing the benefits, and selecting the right machine are the essential first steps to unlocking the full potential of laser cutting. In this guide, we explore the exciting world of laser cutting machines and provide the insights you need to get started.

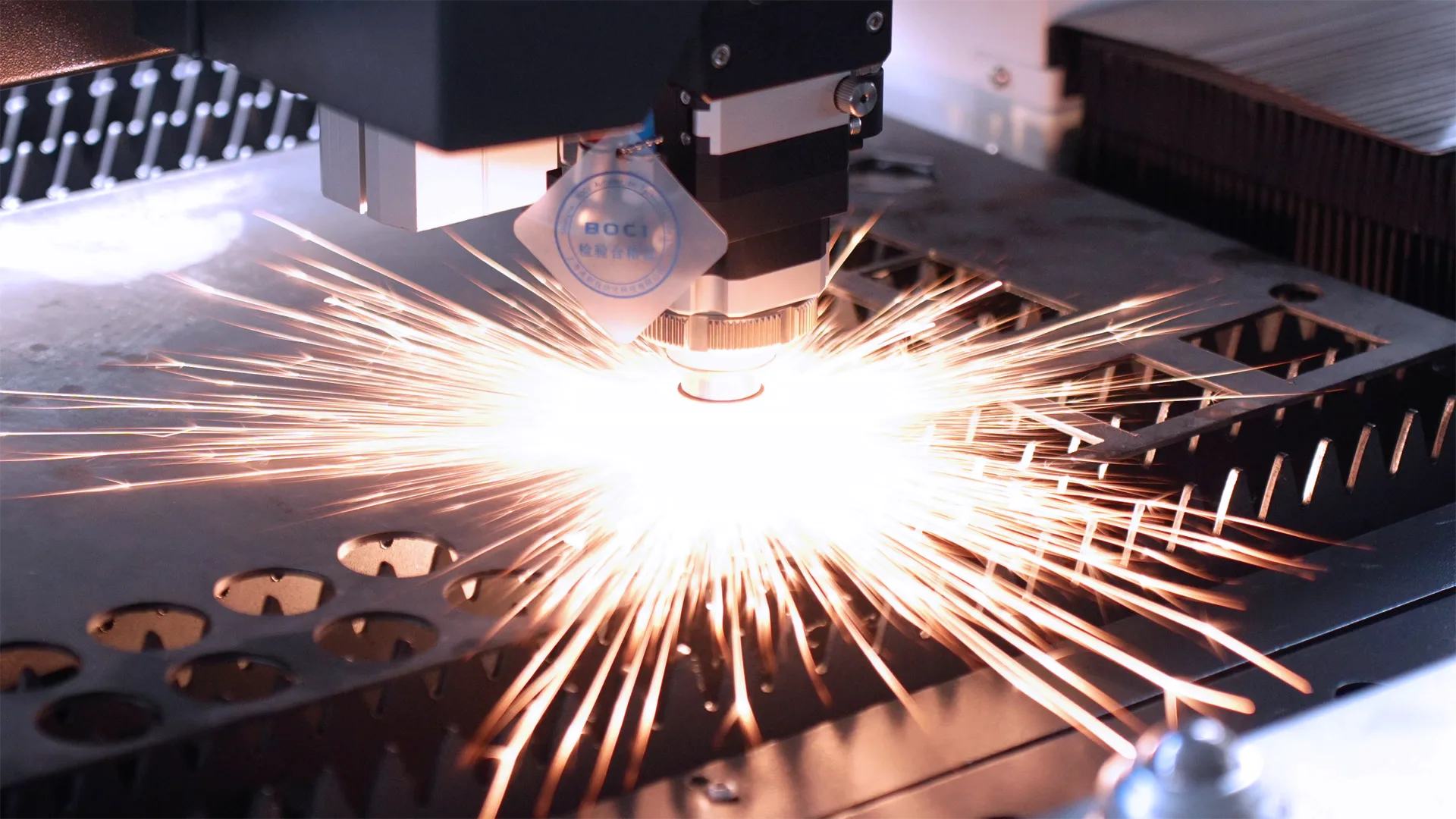

Laser cutting technology, a marvel of modern engineering, utilizes high-power-density laser beams as precision tools. These beams, precisely guided by an optical system, target the material’s surface with surgical accuracy, initiating a process of burning, melting, and evaporating the material. Through this delicate interplay, laser cutting creates flawless cuts with minimal waste.

With its constellation of unique attributes, laser cutting has ascended to the zenith of modern manufacturing preferences. It is the paragon of precision, endowing creations with immaculate cuts and finishes. Its velocity is a boon for mass production, a veritable whirlwind of efficiency. Metals like steel, stainless steel, and aluminum, as well as non-metals such as wood, plastic, and glass, all succumb to its versatile prowess. And in its wake, waste is minimized, with most remnants ripe for recycling, a testament to its eco-conscious charm.

Understanding Laser Cutting Machines

For those treading the first steps in this domain, delving into the essence of laser cutting machines is imperative. Thus, we embark on a voyage to explore the mainstream variants and the vital cogs that are these mechanical marvels.

Types of Laser Cutting Machines

Categorized by laser ilk, laser cutting machines unfurl in three distinct forms, each with its own narrative and niche. Let the ensuing video be your portal to an intuitive encounter.

- CO2 Laser Cutters: These machines, with CO2 gas as their luminous essence, reign supreme in the realm of non-metal sculpting. Wood, plastic, glass, and paper yield to their deft touch. Their engraving finesse is the stuff of legend, a virtuoso's performance in the symphony of craftsmanship.

- Fiber Laser Cutters: Harnessing the power of optical lasers, they are the knights of metal cutting, especially for stainless steel and aluminum. Swift and efficient, they charge through tasks with gusto. Their maintenance demands are a mere whisper, costs slashed, and energy efficiency a resounding anthem.

- YAG Laser Cutters: YAG (Yttrium Aluminum Garnet) laser cutters, with neodymium-doped yttrium aluminum garnet as their spark, are tailored for the rigors of high-strength, high-hardness escapades. Aerospace components and the like find their perfect match in these precision artisans.

Key Components of a Laser Cutting Machine

A laser cutting machine, a complex organism, is an ensemble of numerous parts, each playing a pivotal role in the cutting ballet.

- Laser Source: The beating heart of the machine, responsible for birthing the high-power-density laser beam. CO2 lasers, fiber lasers, or YAG lasers – the choice is a bespoke decision, calibrated to the material's thickness and nature.

- Control System: The maestro conducting the orchestra, the control system choreographs the machine's every move. The CNC system, a digital virtuoso, precisely dictates the laser beam's path and tempo. An advanced iteration ushers in automation and intelligence, a crescendo of productivity.

- Mechanical Bed: The stable stage upon which materials rest, the mechanical bed is the bastion of stability and precision. Its design and composition are the architects of cutting quality, ensuring materials stand unwavering during the cutting overture.

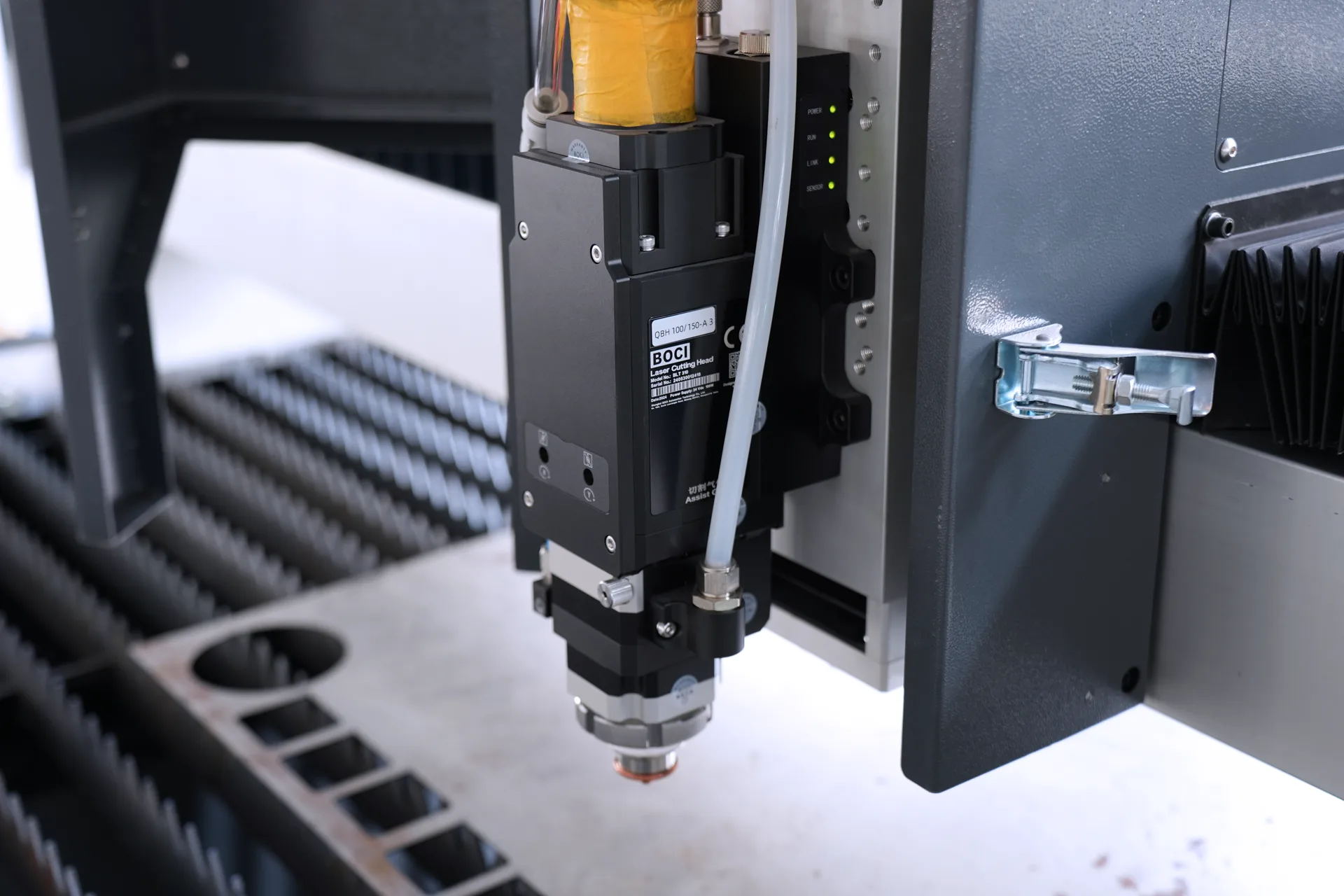

- Cutting Head: The nexus where laser and material converge, the cutting head cradles focusing lenses and a nozzle. Here, the laser beam is focused with pinpoint precision, and with the aid of gaseous allies, the molten and vaporized debris is banished. Its design and upkeep are the keys to unlocking best performance.

- Automatic Lubrication: The unsung hero, automatic lubrication, nurtures the machine's moving parts. Regular anointing banishes wear, extends life, and elevates cutting efficiency and accuracy to new heights.

In sum, laser cutting machines are the vanguard of modern manufacturing. The choice of their type and components is the compass guiding productivity and quality. A profound communion with their working principles and technological nuances is the catalyst for manufacturing's renaissance.

Get Started With Laser Cutting

How to Choose the Right Laser Cutting Machine for Beginners

The quest for the perfect laser cutting machine is a rite of passage for beginners. Herein lie the guiding stars to illuminate your choice.

- Cutting Machines: The arena offers a plethora of contenders, such as CO2 and fiber laser cutting machines. CO2 laser cutters, with their CO2 laser beams, are the artisans for wood, acrylic, leather, and other non-metals. Their dominion spans commercial landscapes, with prices a variable spectrum from hundreds to tens of thousands of dollars. Fiber laser cutters, on the other hand, are the speed demons of metal cutting, their precision and cost-efficiency making them the darlings of industrial manufacturing.

- Cutting Thickness: A table, a guidepost through the labyrinth of cutting thickness.

| Laser Cutter Power | Suitable Materials | Cutting Thickness |

| Low Power Laser Cutter (10W - 100W) | Paper, Thin Plastics | Thin Materials |

| Medium Power Laser Cutter (100W - 500W) | Wood, Acrylic | Up to 1/4 inch |

| High Power Laser Cutter (500W - 2000W) | Metal Materials | Up to 1 inch |

This tableau is your key to unlocking the proper equipment, tailored to your unique needs.

- Budget: The budget, a pragmatic compass. YAG and CO2 laser cutters, more budget-friendly than their fiber counterparts, are the ideal companions for households and small studios.

- Application Scenarios: For home DIY odysseys or petite craft endeavors, low-power YAG and CO2 laser cutters are the trusty sidekicks. Commercial or industrial crusades, however, demand the might of high-power CO2 and fiber laser cutters.

Setting Up Your Laser Cutting Machine

The initiation ritual unfolds in three acts: unboxing and assembly, software installation, and calibration and testing.

- Unboxing and Assembly:

- Unveil the box and conduct a meticulous inventory. Ensure every part, from the machine's core to the laser tube, cooling system, and control screen, is present and accounted for.

- Gently extract each part, safeguarding the delicate, like laser tubes and lenses, from harm's way.

- Follow the script of instructions. Anchor the laser tube firmly, then erect the cooling system. Ensure the cooling water tank and pipes form a seamless circulatory bond, banishing the specter of water flow impediments. Finally, install focus lenses and reflective mirrors, pristine and aligned, to shepherd the laser beam with unerring precision.

- Software Installation:

- Procure the installation elixir from the supplier or summon it from the official website.

- Unleash the installer and heed its prompts. Verify the software's harmony with your operating system.

- As the installation concludes, anoint your desktop with a shortcut, a portal to convenience.

- Open the software and acquaint yourself with its interface and functions. Adjust parameters – power, speed, frequency – in a delicate dance choreographed by the material's essence.

- Calibration and Testing:

- Laser calibration, the cornerstone of cutting efficacy. Align the laser with the cutting plane, a celestial alignment.

- Subject it to the crucible of sample tests. Ensure the laser beam treads the cutting path with pinpoint accuracy.

- Embark on cutting trials, a litmus test of performance and efficiency. Refine laser power, speed, and focus, chasing the elusive zenith of perfection.

- Regularly cleanse laser lenses and reflective mirrors. Let them shine with unblemished clarity and maximal transmission.

- Monitor the cooling system. Ensure the coolant's ceaseless circulation, warding off the feverish embrace of overheating laser tubes.

With these steps, the gateway to laser cutting mastery swings open. You stand poised to embrace the machine, to script your own tales of cutting wizardry.

Laser Cutting Parameters

The alchemy of laser cutting is governed by a pantheon of parameters: power, speed, focal length, and alignment. Their harmonious tuning is the secret incantation for elevating cutting quality and efficiency.

- Power Settings: A power-to-material thickness lexicon.

| Laser Cutter Power | Applicable Materials | Cutting Thickness |

| Low Power Setting (10W - 100W) | Paper, Thin Plastic | Thin Materials |

| Medium Power Setting (100W - 500W) | Wood, Acrylic | Medium Thickness Materials |

| High Power Setting (500W - 2000W) | Thick Materials, Metal | Thick Materials |

- Speed Settings: Cutting speed, a double-edged sword in the cutting saga.

| Speed Setting | Applicable Materials & cutting quality | Advantages | Disadvantages |

| Low-Speed Setting | Thick materials, high-precision cutting | Ensures laser has enough time to penetrate material | It may cause edges to overheat and scorch |

| Medium-Speed Setting | Most of materials, regular cutting | Balances cutting speed and quality, suitable for most applications | Nonsignificant, generally well-balanced |

| High-Speed Setting | Thin materials, fast cutting | Improves production efficiency | It may affect cutting precision and edge quality |

- Focus and Alignment: Focal length and alignment, the architects of cutting precision.

- Focal length adjustment: Tailor the focal length to the material's thickness. A perfect focus on the material surface is the key to unlocking cutting efficiency and quality.

- Laser alignment: Align the laser beam with the cutting path, banishing offsets and errors. Alignment tools and sample tests are your allies in this pursuit of accuracy.

- Material Compatibility: Different materials, a diverse symphony of reactions to laser cutting.

| Material | Applicable Laser Type | Cutting Power | Cutting Speed | Tips |

| Wood | CO2 laser cutter | Medium power | Medium speed | Adjust power and speed according to wood thickness to avoid scorching and deformation. |

| Acrylic | CO2 laser cutter | Medium power | Medium speed | Using low speed settings can achieve smoother edges but requires caution to avoid overheating. |

| Metal | Fiber laser cutter high-power CO2 laser cutter | High power | Low speed | Use proper cooling systems to prevent laser overheating and material deformation. |

| Fabric | CO2 laser cutter | Low power | High speed | Using low power can prevent scorching and ensure smooth cutting edges. |

Mastery of these parameters and material idiosyncrasies is the golden key to optimizing laser cutting, a passport to a world of flawless cuts and boundless creativity.

Beginner Laser Cutting Projects

For novices, laser cutting machines unfurl a canvas of limitless potential, a playground for creative exploration. Here, we unfurl a tapestry of simple project ideas and a step-by-step guide, your compass to navigate the first forays into laser cutting artistry.

Simple Project Ideas

- Custom Keychains: Crafting custom keychains, a petite yet entrancing odyssey. Select from materials like wood and acrylic and let the laser cutter sculpt unique designs. Each keychain, a bespoke masterpiece.

- Personalized Coasters: Fashioning personalized coasters, a beginner's delight. Design shapes and patterns, and with the laser cutter's precision, transform them into tangible art. Wood and acrylic, the mediums of choice.

- Decorative Wall Art: Decorative wall art, a more intricate endeavor, yet one brimming with sense of accomplishment. Sketch floral, animal, or geometric visions, and watch the laser cutter breathe life into them. Wood and acrylic, the conduits of smooth edges and intricate details.

Step-by-Step Project Guide

- Designing Your Project:

- Choose a design software: Adobe Illustrator, CorelDRAW, or Inkscape – the digital ateliers for creating and editing vector graphics. Their file formats, the language understood by laser cutting machines.

- Create your design: Weave your vision into vector graphics. Keep lines clear, patterns uncluttered, for best cutting performance.

- Save files: Enshrine your design in a format the laser cutter reveres, such as SVG or DXF.

- Preparing the Material:

- Choose materials: Let your project's essence guide your material selection. Wood, acrylic, leather, or paper – the palette of possibilities.

- Prepare materials: Affix the material to the workbench, a flat and steadfast foundation. Banish movement during the cutting ballet.

- Executing the Cut:

- Set cutting parameters: Power, speed, focal length – calibrate these according to material thickness and type. The machine's manual, your trusted oracle.

- Load Design File: Upload your design file into the laser cutter's control software. Ensure perfect alignment, a prelude to cutting perfection.

- Start cutting: Ignite the machine and stand vigilant. Monitor the cutting symphony, ready to pause and adjust at the first sign of discord.

- Finishing Touches:

- Clean the workpiece: After the cutting crescendo, retrieve the material. Sandpaper or kindred tools can smooth the edges, erasing the remnants of the cutting process.

- Assembly and Decoration: If assembly beckons, as in keychains or wall art, follow the design blueprint. Add colors or paints, a flourish of aesthetics.

- Check the finished product: Cast a discerning eye over the final creation. Ensure it meets your expectations, unblemished and whole.

With these steps, the threshold of your first laser cutting project is crossed. The machine, a catalyst for creativity, a portal to dreams realized.

Conclusion

This is a guiding star for all laser cutting novices. Through the labyrinth of working principles, machine types, and project guidance, we hope to kindle a deeper affinity for these mechanical wonders.

Welcome to the realm of KRRASS Machine Tool's laser cutting machines! Our creations, the superheroes of the cutting world, stand ready to vanquish any cutting challenge. Metal sheets or tubes, our Dual-use Fiber Laser Cutting Machine and kin will dispatch tasks with speed and precision.

Yearning for more? Traverse our product page and let our laser cutting machines be your chariot into a new era of cutting excellence!