Choosing the right press brake for your metal processing needs is crucial for efficiency and precision. Among the options available, the hybrid press brake stands out by combining hydraulic power with electric drive systems, offering energy efficiency and faster operation. In this article, we’ll explore the different types of press brakes, including ordinary hydraulic, main motor servo CNC, hybrid, and pure electric models, to help you make the best choice for your specific requirements.

Table of Contents

What are the classifications of press brake?

According to the energy-saving methods of bending machines, they are divided into the following categories:

What is an ordinary hydraulic press brake?

CNC Hydraulic Press Brake: Ordinary hydraulic bending machine is a device used for metal sheet processing. It uses a hydraulic system to provide power to achieve sheet bending. The main motor is an ordinary motor.

Advantages: The requirements for working environment and working voltage are relatively low.

Disadvantages: The noise is relatively loud and the power consumption is relatively high.

What is a main motor servo cnc press brake?

Main motor servo bending machine: The main motor servo bending machine is a device used for metal sheet processing. It uses a hydraulic system to provide power to achieve sheet bending. The main motor is a Servomotor.

Advantages: Very low noise and power saving.

Disadvantages: The requirements for the working environment and working voltage are slightly higher, especially for the ambient temperature, which cannot be too high or too low. If the ambient temperature is high, the servo drive will alarm. When the ambient temperature is below zero, the machine cannot operate when the machine starts in the morning.

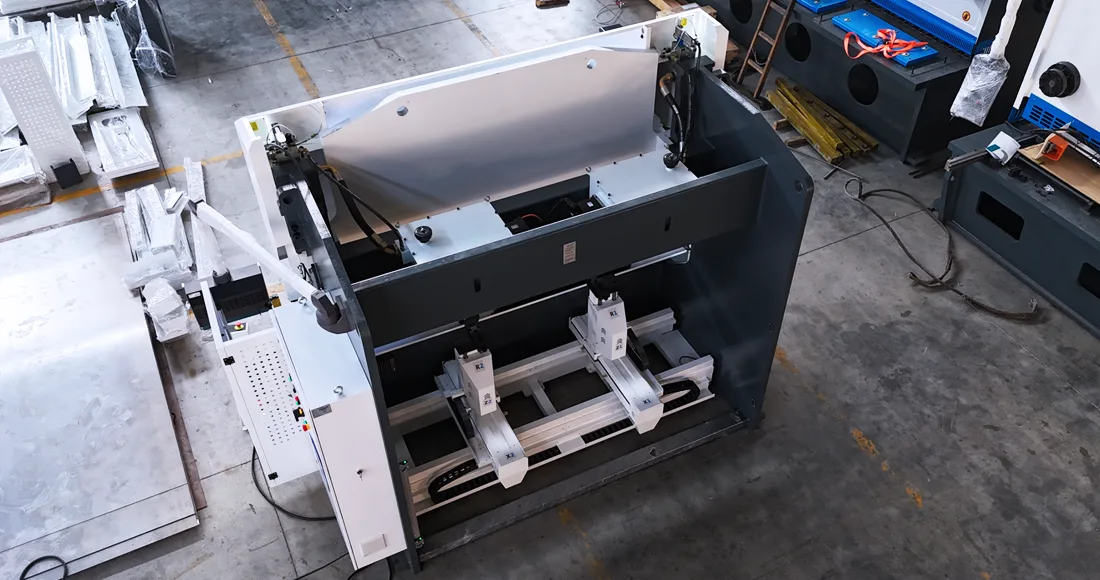

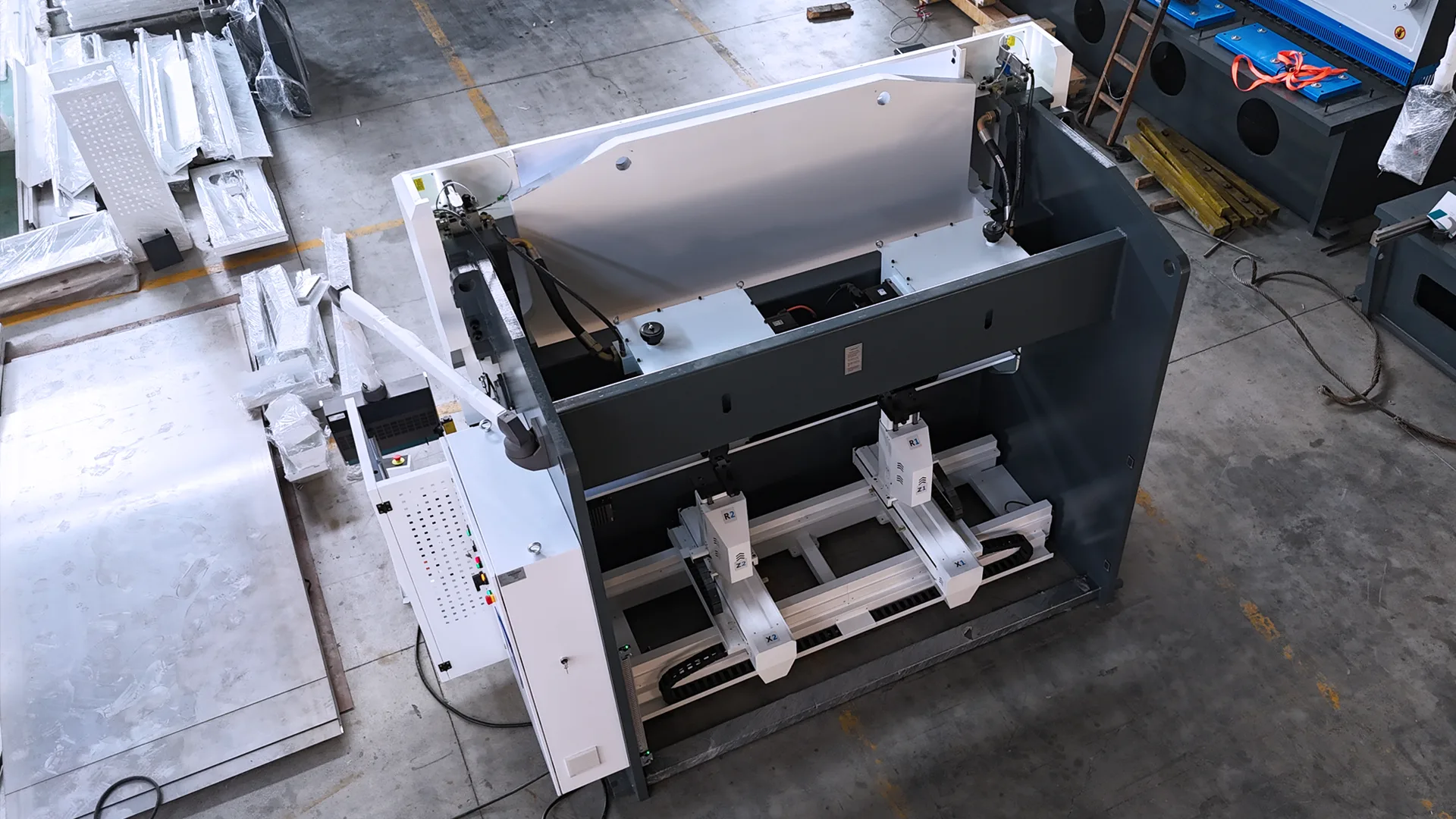

What is a hybrid press brake?

Hybrid press brake: The hybrid press brake is a device used for metal sheet processing. It uses a hydraulic system to provide power to achieve sheet bending. The operation of the machine is controlled by dual motors and dual oil pumps.

Advantages: low noise, less hydraulic oil, power saving, and fast working speed.

Disadvantages: The requirements for the working environment and working voltage are slightly higher, especially for the ambient temperature, which cannot be too high or too low. If the ambient temperature is high, the servo drive will alarm. When the ambient temperature is below zero, the machine cannot operate when the machine starts in the morning.

What is a pure electric press brake?

Pure Electric Press Brake: Pure electric Press Brake is a device used for metal material processing. It uses a servo motor screw nut to provide power to achieve sheet bending.

Advantages: No lubricating oil is used, fast speed, high precision, and more suitable for small parts processing.

Disadvantages: Only suitable for 35T-70T bending machines, high rigidity requirements for the frame, not suitable for large tonnage production, and Japanese brands are recommended for screw rods.

How should I choose when purchasing?

When selecting a press brake, consider the following factors:

- Application Needs: Think about the type of material and thickness you need to bend. Hydraulic press brakes are suitable for heavy-duty applications with thick materials, while electric and hybrid models excel in high-precision bending tasks.

- Precision and Control: If accuracy is critical in your operations, look for CNC-controlled press brakes, especially those with servo-electric or pure electric drives. These machines offer highly repeatable results.

- Energy Efficiency: If reducing energy consumption is a priority, consider servo-electric or hybrid press brakes, which offer better energy efficiency than traditional hydraulic systems.

- Speed and Productivity: For high-speed production, servo-driven and pure electric press brakes can provide faster, more precise movements compared to hydraulic models.

- Maintenance and Operational Costs: Pure electric and hybrid press brakes generally require less maintenance and have lower operational costs than hydraulic models, which need regular fluid changes and can incur higher power costs.

- Budget: Hydraulic press brakes are often more affordable upfront, but electric and hybrid press brakes can offer long-term savings due to their energy efficiency and lower maintenance requirements.

By carefully evaluating these factors, you can select the press brake that best suits your specific needs, balancing cost, efficiency, and performance.

Summary: When purchasing, choose according to the user's environment and product, or contact our sales staff.