Hydraulic Guillotine Shearing Machine

Sheet Metal Hydraulic Guillotine Shears

Sheet metal hydraulic guillotine shears, precise and high-quality cutting with automatic gap adjustment, excellent cutting, and perfect speed. KRRASS QC11K Hydraulic Guillotine Shears can cut metal sheets to maintain the highest production capacity with maximum precision and quality.

Top performances allow to accurately and cost-efficiently cut pieces in high volumes

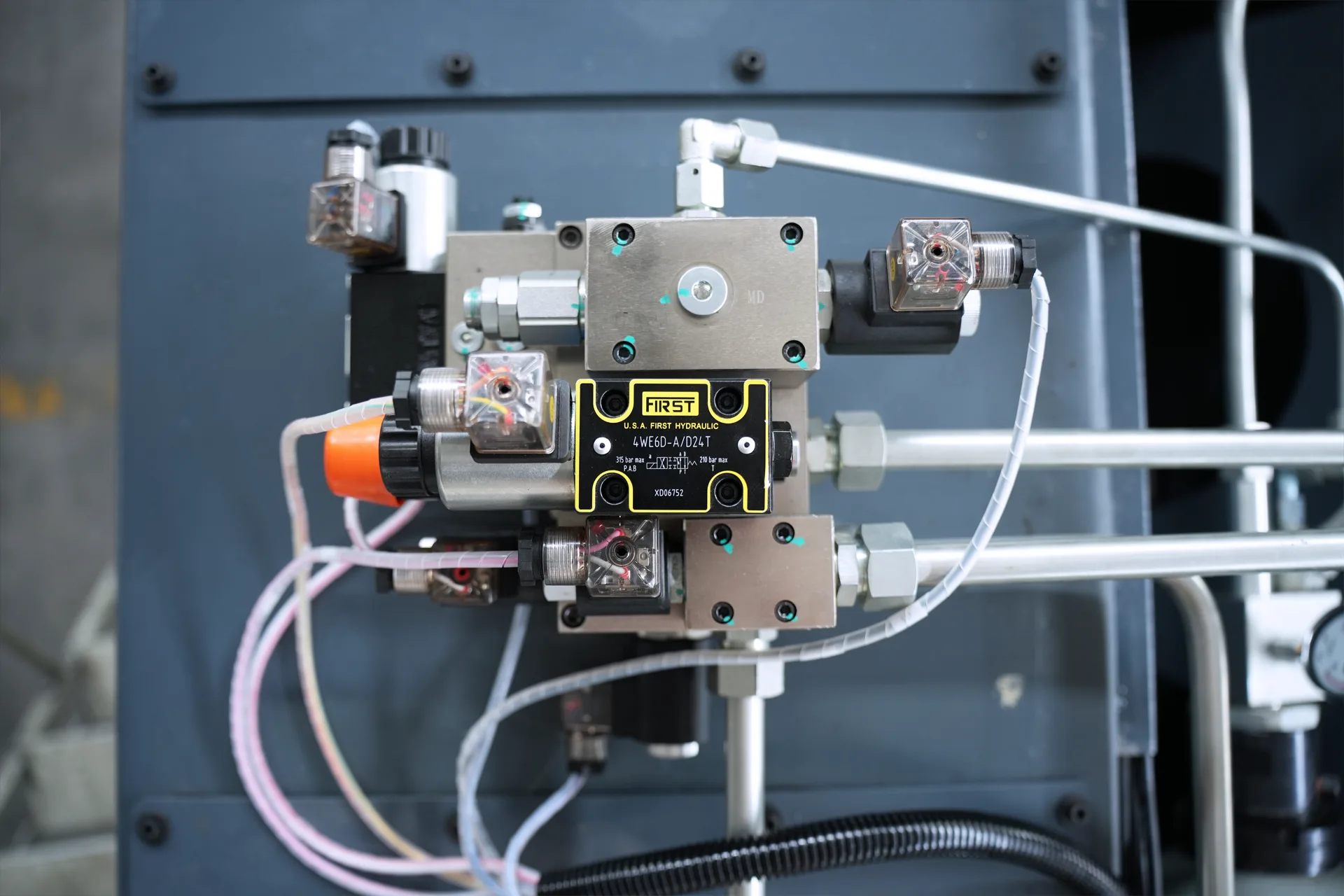

We has entirely designed the proportional oil hydraulic circuit. It is optimized for every swing beam shear size, with high-quality and reliable parts

QC11K-Cut Hydraulic Guillotine Shears are available in many models and powers. Hydraulic Guillotine Shears can customize length and shearing thickness to the highest levels in the category.

- Controller: ESTUN E21S

- Electrics: Schneider Electric - France

- Main Motor: Siemens Motor - Germany

- Frequency Converter: Shihlin-Taiwan

- Foot Switch: KACON - South Korea

- Hydraulic System: Bosch Rexroth - Germany

- Oil Pump: First- USA

- Sealing Ring: PARKER - America

- High Efficiency Motor - Class IE3

- Tube Connector: EMB - Germany

- Backgauge: SACH-Taiwan

Standard Equipment

Introduction to Configuration

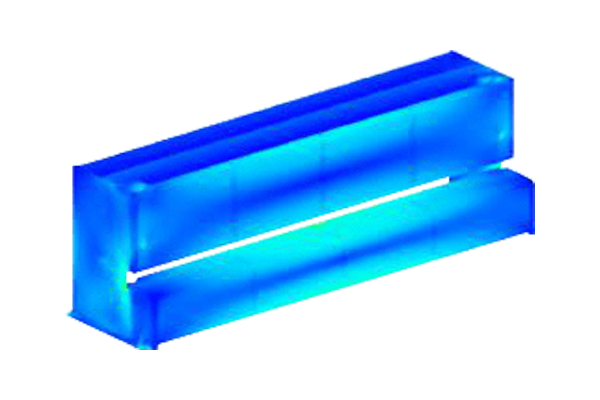

FEA & Stress Analysis

Stress Analysis & Finite Element Analysis

The CAE software SOLIDWORKS used as the method to analyze the linear static construction, stress and deformation for press break and laser cutting machine frames. So for complicated structures, highly complex loading’s, transient modelling and combination of the above, FEA makes sense.

ESTUN NC Control System

ESTUN E21S Control

- High-definition hydraulic display

- Control common motors and frequency converters

- X-axis intelligent positioning

- Multi-step programming, 40 programs, each program 25 steps

- Built-in time relay function

- One-button function switching

- Unilateral positioning function

- A key backup and restore of parameters

- Chinese and English

- Metric system

Why KRRASS Hydraulic Guillotine Shears?

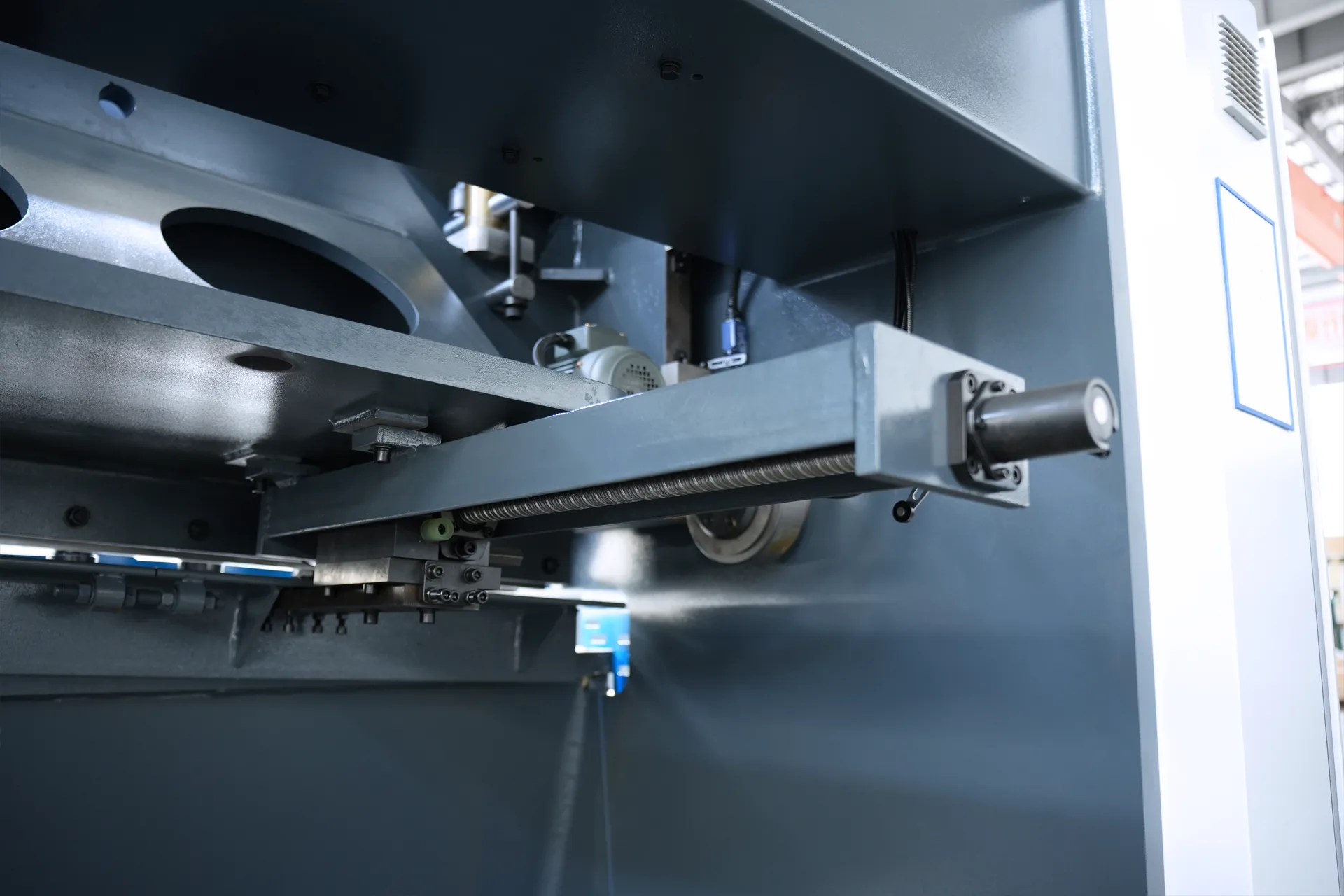

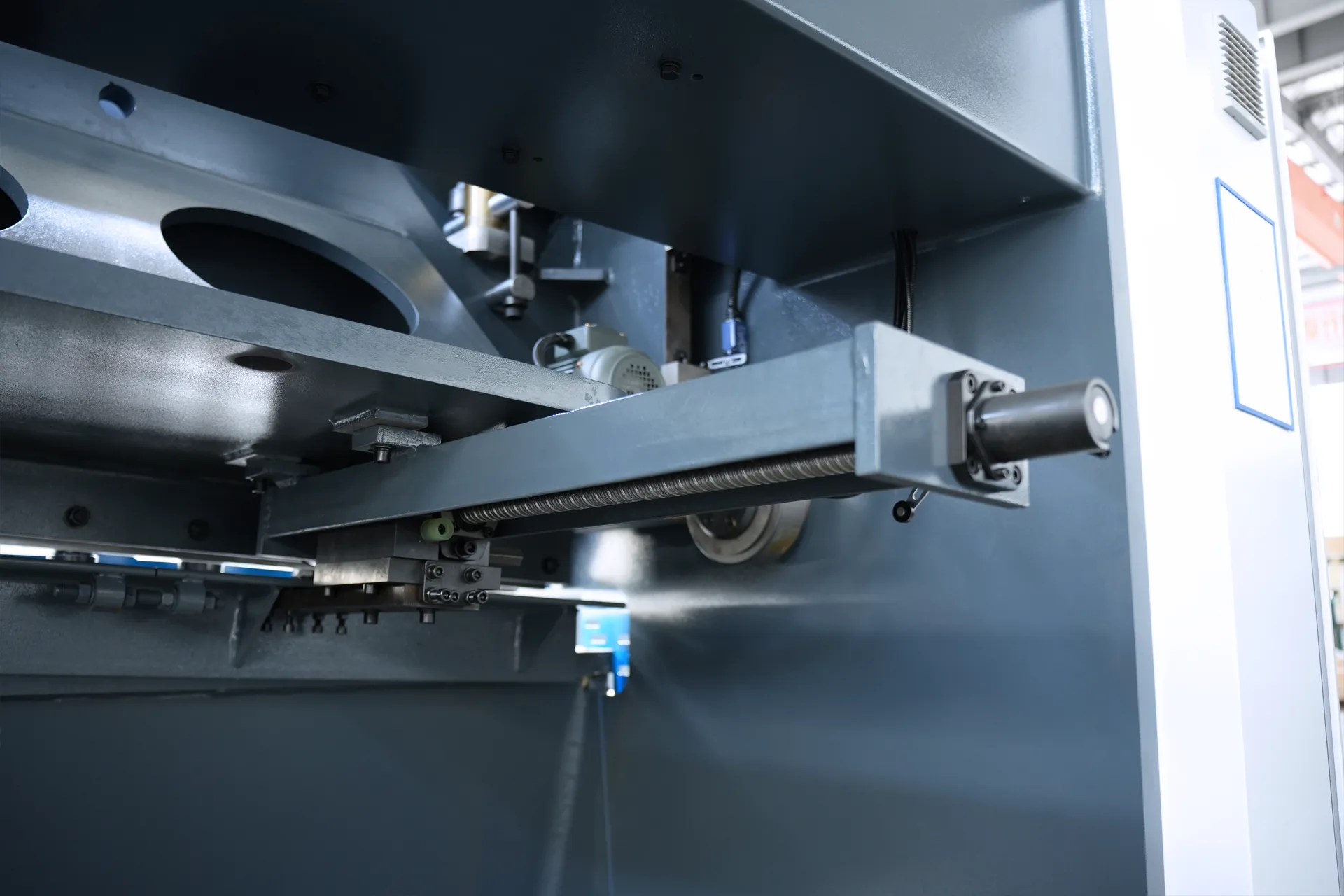

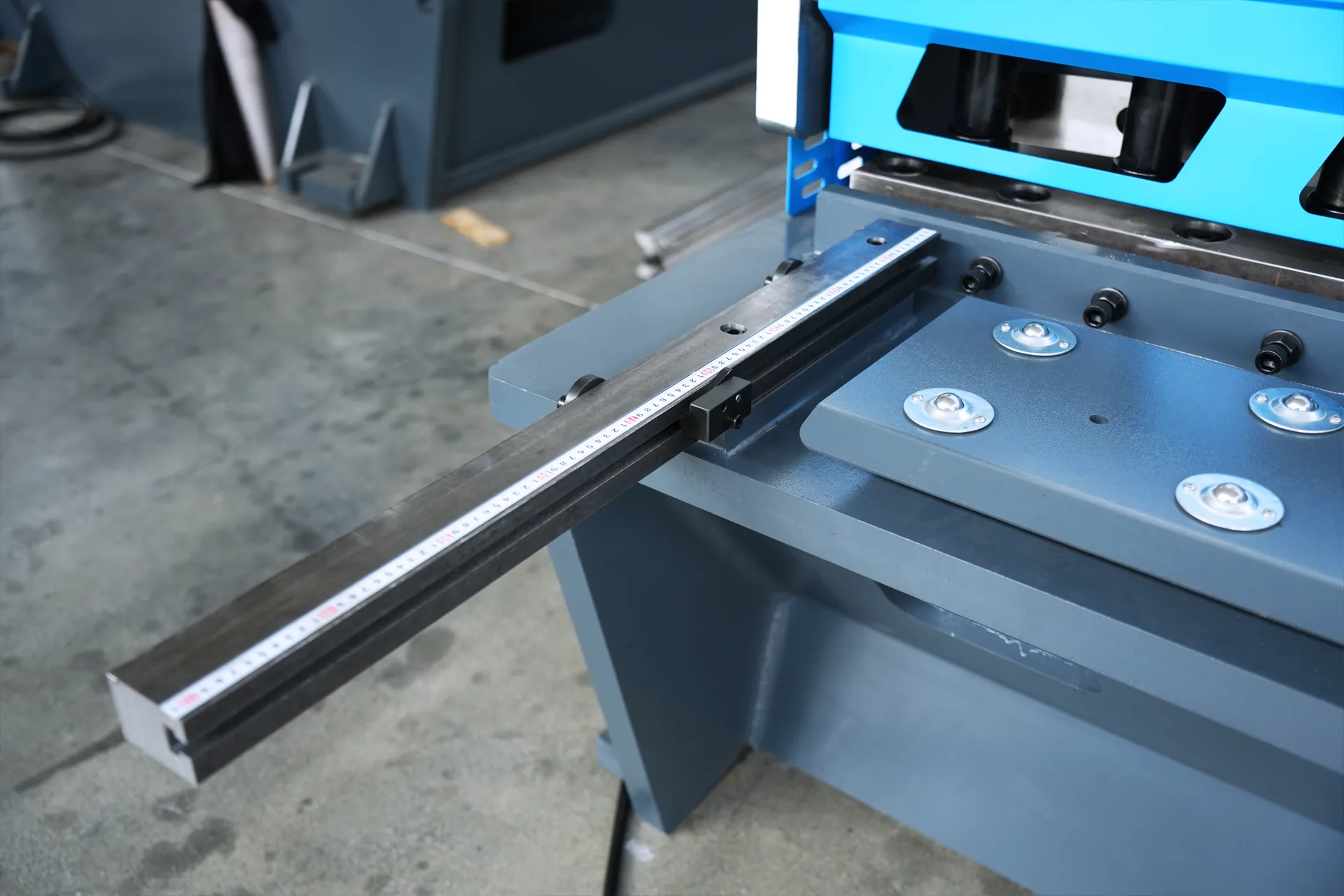

Sheet Metal Guillotines Back Gauge System

One of the most important factor for bending capacity is the design of back gauge and stability. Quality cutting is possible with perfect product, stabilty and precision back gauge.

The high speed ballscrew back gauge system movement is also supported with linear guides, which helps the back gauge achieve long life, greater sensitivity and strengthens against any collisions.

Sheet Metal Hydraulic Guillotine Shears

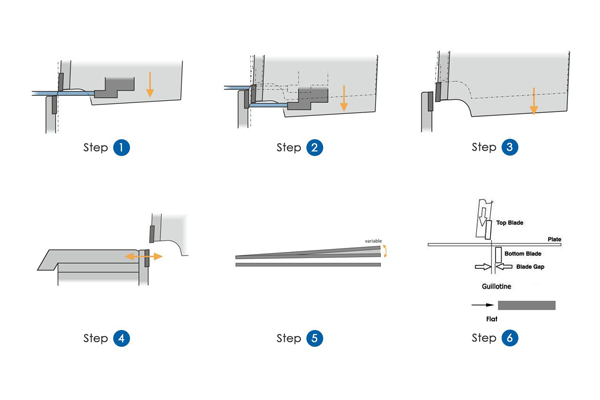

Principle: The hydraulic guillotine shearing machine uses a hydraulic system to provide cutting power. During operation, the upper and lower blades achieve relative movement through hydraulic cylinders to complete the cutting of the workpiece.

Characteristics:

- Typically used in large workshops and situations requiring mass production.

- Suitable for high-precision and efficient cutting of medium-thick sheet materials.

- High cutting force, suitable for various thicknesses of metal sheets.

- Capable of continuous and automated cutting operations, with high production efficiency.

* Reference: Wikipedia - Shear_(sheet_metal)

More Details of Hydraulic Shearing Machine

Optional Equipment

- Front Photoelectric Protection

- Back Photoelectric Protection

- Oil Cooler

- Back Photoelectric Protection

- Electric gap adjustment

Hydraulic Guillotine Shears Technical Parameter

| Model | Max Thickness (mm) | Cutting Length (mm) | Throat Depth (mm) | Angle-Cutting Range (°) | Blade Length (mm) | Shearing Speed (Cuts/min) | Back Gauge Specification | Motor Power (kw) | Oil Tank Capacity (L) | Weight (T) | ||

<450 N/mm2 | <700 N/mm2 | Speed (mm/sec) | Speed (mm/sec) | |||||||||

| 6X2500 | 6 | 4 | 2500 | 100 | 1-3 | 2600 | ≥15 | 750 | 180 | 7.5 | 220 | 4.2 |

| 6X3200 | 6 | 4 | 3200 | 100 | 1-3 | 3300 | ≥15 | 750 | 180 | 7.5 | 290 | 5.7 |

| 6X4000 | 6 | 4 | 4000 | 100 | 1-3 | 4100 | ≥15 | 750 | 180 | 11 | 290 | 8.5 |

| 8X2500 | 8 | 5 | 2500 | 100 | 1-3 | 2600 | ≥15 | 750 | 180 | 11 | 220 | 4.4 |

| 8X3200 | 8 | 5 | 3200 | 100 | 1-3 | 3300 | ≥15 | 750 | 180 | 11 | 290 | 6 |

| 8X4000 | 8 | 5 | 4000 | 100 | 1-3 | 4100 | ≥6 | 750 | 180 | 11 | 290 | 8.9 |

| 10X2500 | 10 | 6.5 | 2500 | 100 | 1-3 | 2600 | ≥12 | 750 | 180 | 11 | 320 | 6.5 |

| 10X3200 | 10 | 6.5 | 3200 | 100 | 1-3 | 3300 | ≥12 | 750 | 180 | 15 | 420 | 8 |

| 10X4000 | 10 | 6.5 | 4000 | 100 | 1-3 | 4100 | ≥12 | 750 | 180 | 15 | 420 | 12 |

| 12X2500 | 12 | 8 | 2500 | 100 | 1-3 | 2600 | ≥12 | 750 | 180 | 15 | 360 | 8.5 |

| 12X3200 | 12 | 8 | 3200 | 100 | 1-3 | 3300 | ≥12 | 750 | 180 | 18.5 | 500 | 10 |

| 12X4000 | 12 | 8 | 4000 | 100 | 1-3 | 4100 | ≥12 | 1000 | 180 | 18.5 | 500 | 13.5 |

| 16X2500 | 16 | 10.5 | 2500 | 100 | 1-3 | 2600 | ≥10 | 1000 | 180 | 22 | 360 | 13 |

| 16X3200 | 16 | 10.5 | 3200 | 100 | 1-3 | 3300 | ≥10 | 1000 | 180 | 22 | 500 | 15 |

| 16X4000 | 16 | 10.5 | 4000 | 100 | 1-3 | 4100 | ≥10 | 1000 | 180 | 22 | 500 | 16.5 |

| 20X2500 | 20 | 13 | 2500 | 100 | 1-3.5 | 2600 | ≥8 | 1000 | 180 | 37 | 540 | 17 |

| 20X3200 | 20 | 13 | 3200 | 100 | 1-3.5 | 3300 | ≥8 | 1000 | 180 | 37 | 800 | 20 |

| 20X4000 | 20 | 13 | 4000 | 100 | 1-3.5 | 4100 | ≥8 | 1000 | 180 | 37 | 800 | 22 |

| 30X2500 | 30 | 20 | 2500 | 100 | 1-3.5 | 2600 | ≥8 | 1000 | 180 | 37 | 800 | 29 |

| 30X3200 | 30 | 20 | 3200 | 100 | 1-3.5 | 3300 | ≥8 | 1000 | 180 | 37 | 800 | 38 |

| 40X3200 | 40 | 26.5 | 2500 | 100 | 1-3.5 | 2600 | ≥8 | 1000 | 180 | 37 | 800 | 38 |

Reviewed by 14 users

our DA360S is very good. very helpful for my 8*3200 shearing machine

Tôi đã mua được 3 năm

Наконец получил машину мне нужно, машина 12X4000MM стрижки очень хорошо

my QC11K-16*3200 working very good. QC11K is designed for thick metal plate.

QC11K 10*4000mm guillotine shearing machine , i like it