Hydraulic Punching Machine

Hydraulic Punching Machine

KRRASS Hydraulic Punching machines ranging from 35 to 200 tons of punching capacities, combined with different throat depths to choose from, provides a complete range of models to meet our customer’s wide range of requirements.

Top performances allow to accurately and cost-efficiently cut pieces in high volumes.

We has entirely designed the proportional oil hydraulic circuit. It is optimized for every guillotine shear size, with high-quality and reliable parts.

Hydraulic Punching machines is available in a wide range of models and powers. Ironworker machines can customize parameters to the highest levels in the category.

Standard Equipment

- Electrics: Schneider Electric – France

- Main Motor: Siemens Motor – Germany

- Foot Switch: KACON – South Korea

- Hydraulic System: Bosch Rexroth – Germany

- Oil pump: First/Sunny – USA

- Sealing Ring: PARKER – America

Features

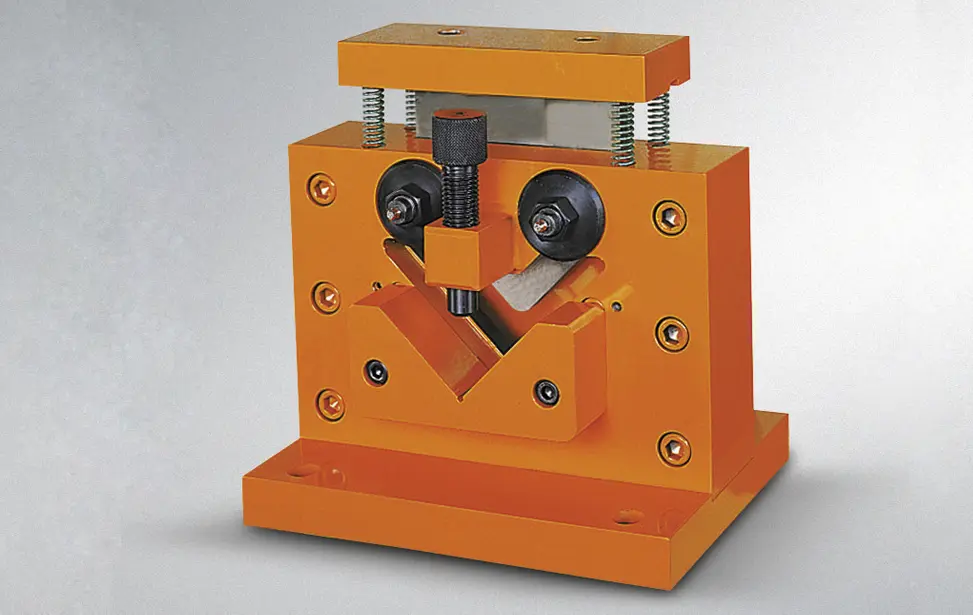

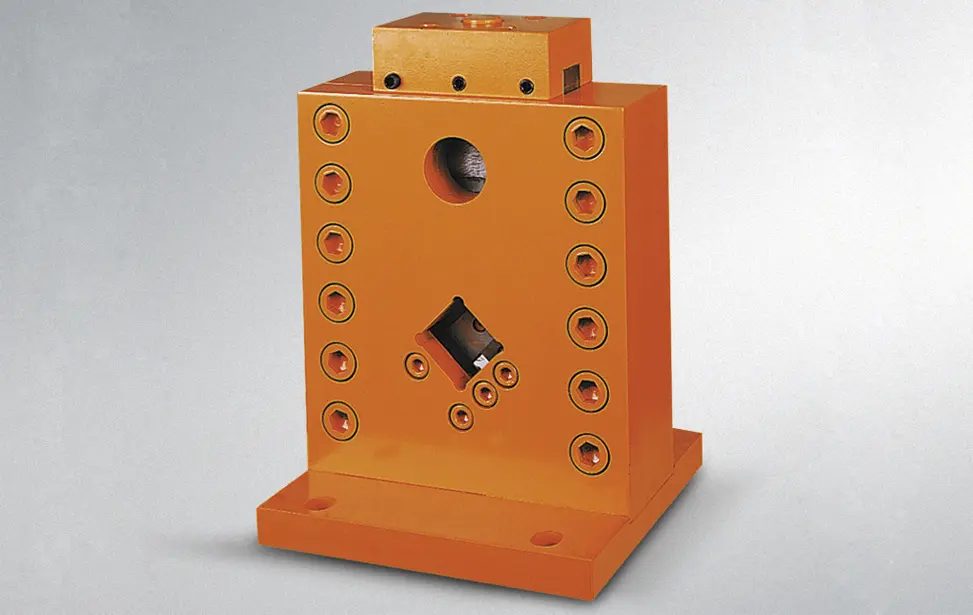

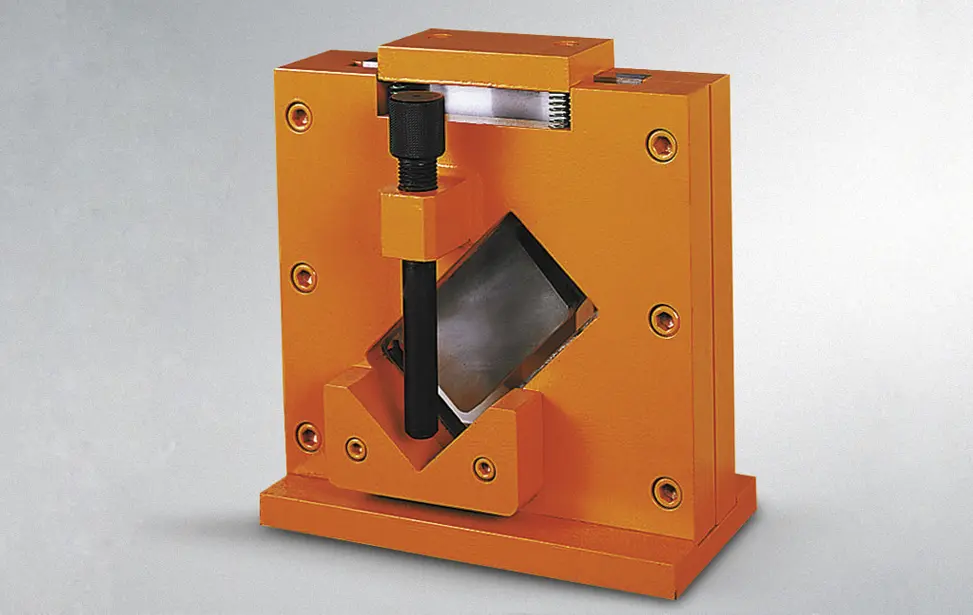

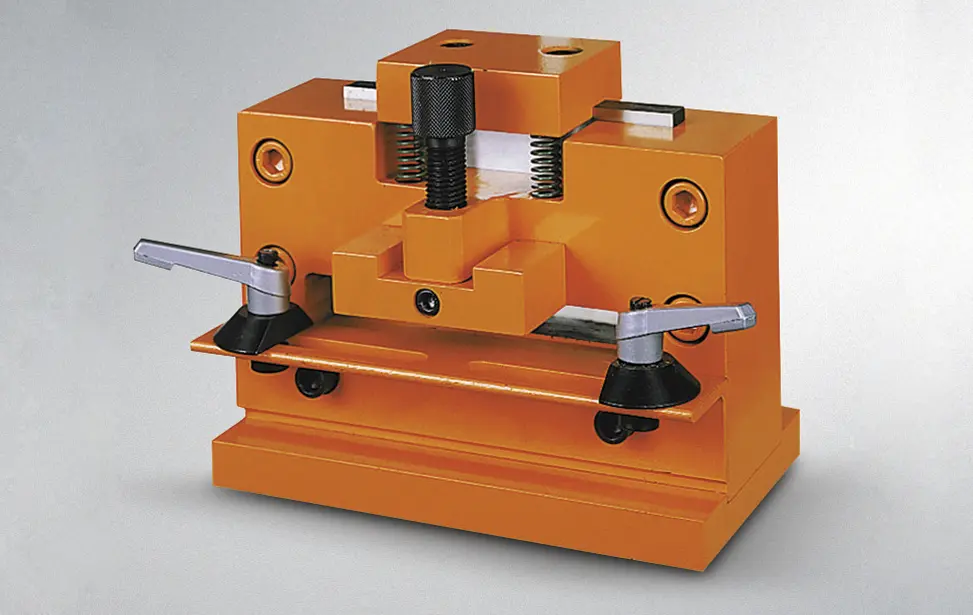

Punching station

All metal punching operations of the ironworker machine are processed using hydraulic power, thus allowing the machine to punch very efficiently and silently. Punching is silent, powerful, and efficient. The device can either be used to hit thick metal or thin materials layered together. The waste materials come off together and in layers. The punching table consists of two parts: the first is the punching flange, and the second is the holder. There are different holders for different materials. The holder is a device that prevents the fabric from coming back with the punch after cutting.

Optional Equipment

- The patented dual-piston hydraulic cylinder enables the machine to retract faster, and also makes our cylinder slimmer, which brings a better appearance to the machine.

- Hydraulic Punching machines ranging from 35 to 200 tons of punching capacities, combined with different throat depths to choose from, provides a complete range of models to meet our customer’s wide range of requirements.

- All optional tooling used on the punching station of S/SD ironworkers can also be used on the PM models, turning the punching machine into a universal machine.

Multipurpose

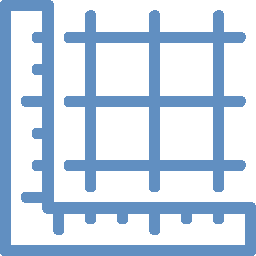

Technical Parameters of Punching Machine

| Model | Unit | Q35YS-16 | Q35YS-20 | Q35YS-25 | Q35YS-30 | Q35YS-40 | Q35YS-50 |

|---|---|---|---|---|---|---|---|

| Pressure | T | 60 | 90 | 120 | 160 | 200 | 250 |

| Plate Strength | N/mm² | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 |

| Slider Stroke | mm | 80 | 80 | 90 | 100 | 110 | 200 |

| Punching Stroke Times | T/min | 10-20 | 12-22 | 8-18 | 6-16 | 6-16 | 6-16 |

| Punching Plate Thickness | mm | 16 | 20 | 25 | 30 | 35 | 40 |

| Max Hole Diameter | mm | 25 | 30 | 35 | 38 | 40 | 45 |

| Throat Depth | mm | 300 | 335 | 480 | 600 | 535 | 600 |

| Main Motor | kw | 5.5 | 7.5 | 11 | 15 | 18.5 | 18.5 |

| Outline Dimension | mm | 1400X700X1700 | 1600X800X1800 | 1800X960X2000 | 2000X1050X2450 | 2200X1050X2450 | 2600X1440X2500 |

Use case of Punching Machine