Hydraulic shearing machine Interpretation on Faults May Encountered in Production

1)A series of questions about the hydraulic system running status you should learn from the machine operator, such as: whether the Hydraulic shearing machine hydraulic system works normally? Hydraulic pump is with abnormal phenomenon? Hydraulic oil detection time and results, filter cleaning and replacement, failure before to adjust: hydraulic components ever replace the sealing element: before and after shearing machines hydraulic system failure to present what abnormal phenomenon: what past the system failure, how to eliminate the and so on, the understanding should be carried out one by one.

2)Observe the actual working condition of the hydraulic system of the shearing machines, and observe whether there are problems in the system’s pressure, speed, oil, leakage, vibration, etc.

3)Listen to the sound of the hydraulic system of the shearing machines, such as impact sound: pump noise and abnormal sound: judge whether the hydraulic system works normally.

4)The working condition of the moving parts of the hydraulic system of the shearing machine is determined by the elastic level at the temperature rise, vibration, crawling and connection.

Shearing machine of Structural Characteristics

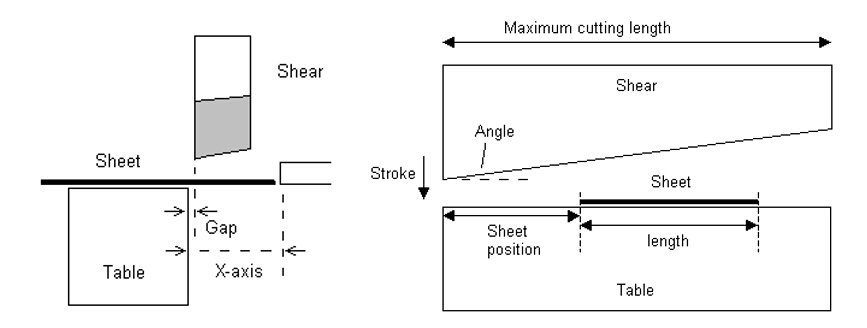

1)Retraction function avoids interference between the backstop device and the work pieces. The range of rear baffle adjustment is 10-600mm (special specifications can also be customized as required); Shear counting device, easy to understand the number of field shear plate.

2)Hydraulic drive, swing tool holder, nitrogen return; Ensure the smooth running of machinery; QC12Y series machine with ESTUN E21S NC controller ensure mechanical performance

3)All steel plate welded frame, vibration elimination of internal stress, with enough strength and rigidity

4)Hydraulic pressure device, reliable safety guard guarantee cutting safety

5)Light aligning device, easy to linear cutting

6)Regularly check the repair switch, safety and handle regularly during the use of the Hydraulic shearing machine to ensure its reliable operation. The back gauge adopts synchronous bar (traditional link type) to improve the precision of back gauge. Quick adjustment device for blade clearance, adjustable tool frame stroke and high production efficiency when cutting narrow material

Learn more about our products, please visit and subscribe to our Youtube channel