The tonnage of the press brake is gradually increasing with the continuous improvement of technology, followed by the increase in the size of the machine itself. This brings a lot of problems for logistics and transportation. In order to solve the problem of large size of the press brake, we usually need to disassemble the machine for transportation during transportation.

However, after the user receives the machine, he needs to reassemble the machine for use. Today, we will teach users how to assemble a brand new press brake:

1. When we receive the press brake, we must first lift the slider of the press brake, as shown in Figure 1:

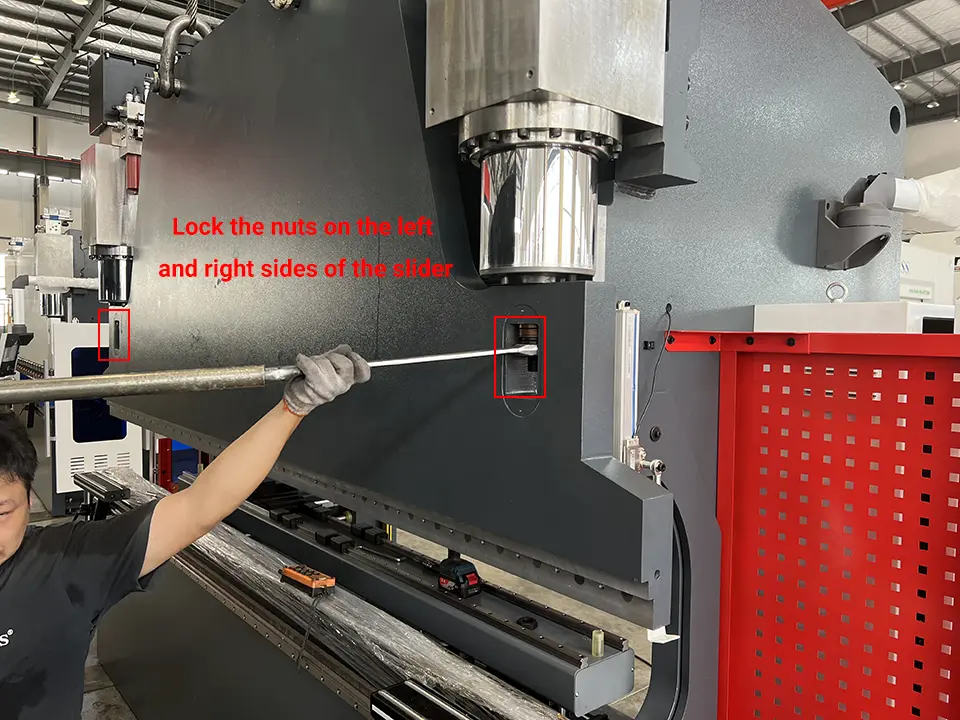

2. Lock the nuts on the left and right sides of the slider, as shown in Figure 2-1 and 2-2:

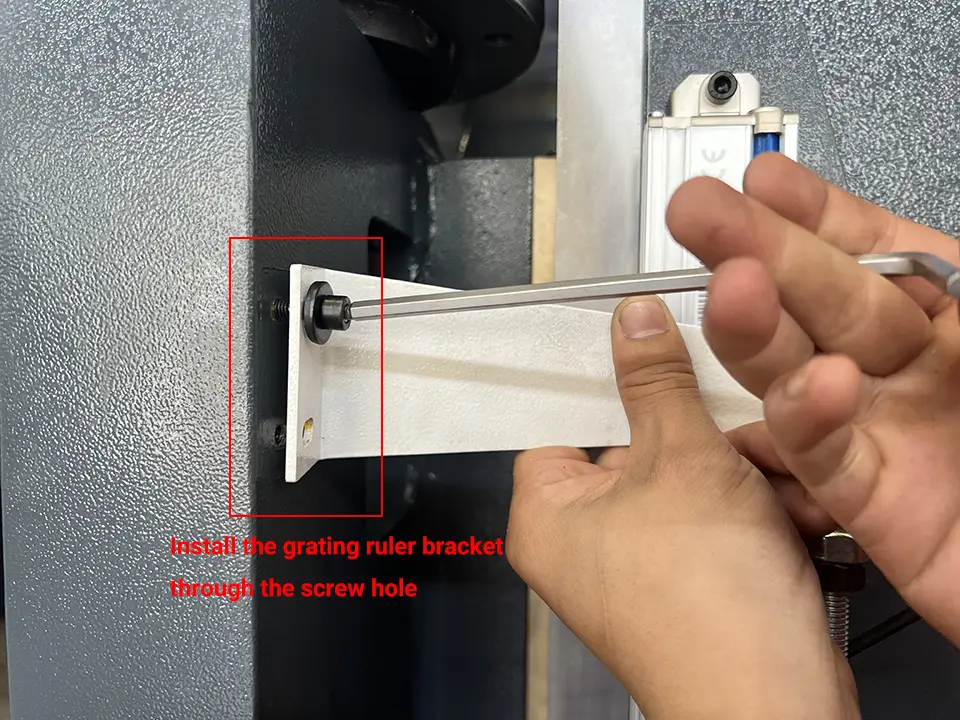

3. Install the grating scales on both sides of the fuselage in sequence, as shown in Figure 3-1 and 3-2: (If the machine has not been disassembled, this step can be skipped, depending on the machine model)

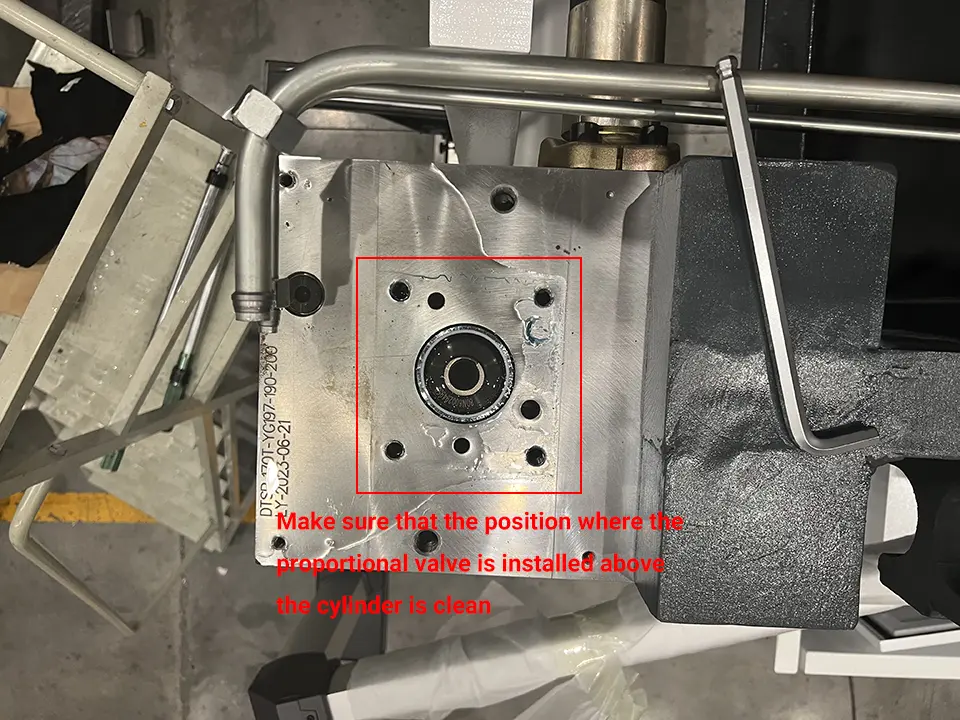

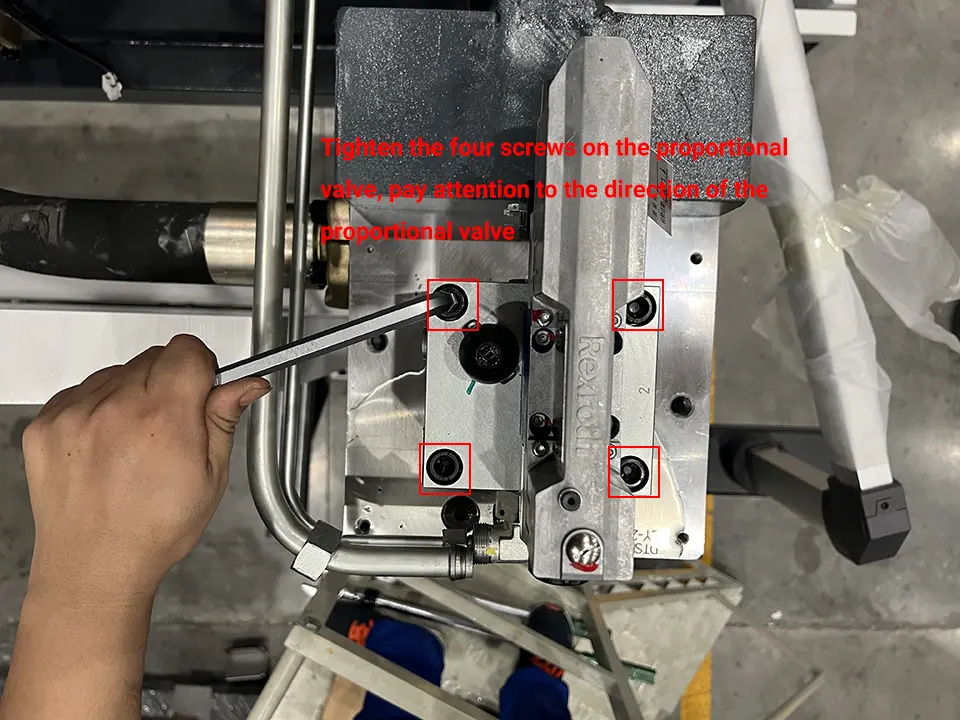

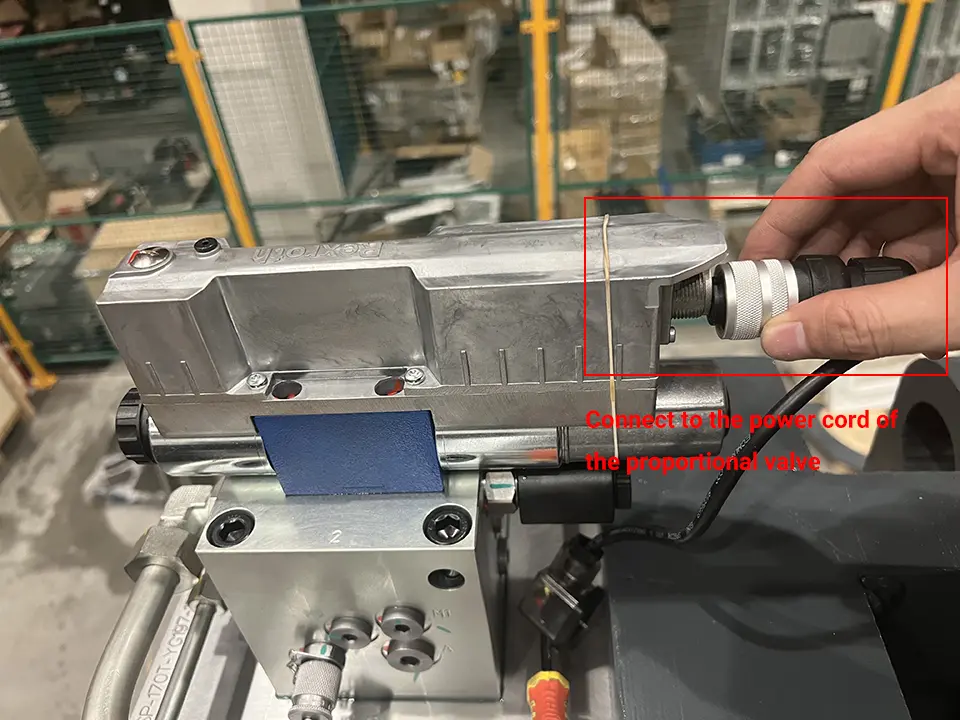

4. Install the proportional valves above the Y1 and Y2 axes in sequence, as shown in Figure 4-1 and 4-2. When installing, ensure that the position where the proportional valve is installed above the oil cylinder is clean and free from any pollutants; if there is any pollution, the proportional valve will be stuck, resulting in the Y1 and Y2 axes falling. Be sure to lock the screws tightly during installation.

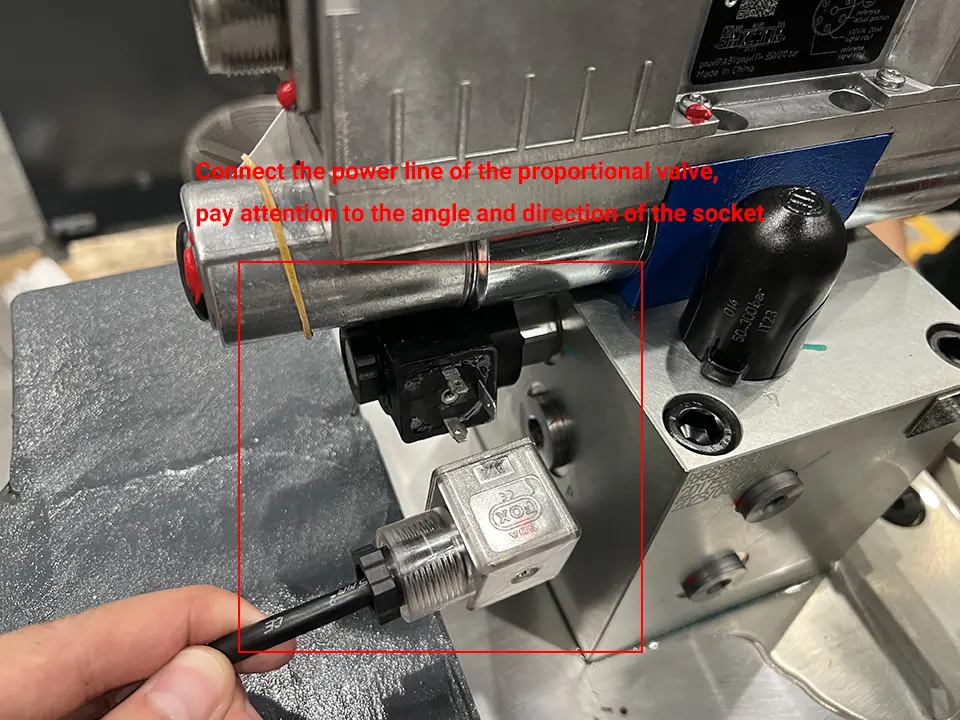

5. Install the power lines of the Y1 and Y2 axis proportional valves, as shown in Figure 5. Be sure to lock the screws tightly during installation.

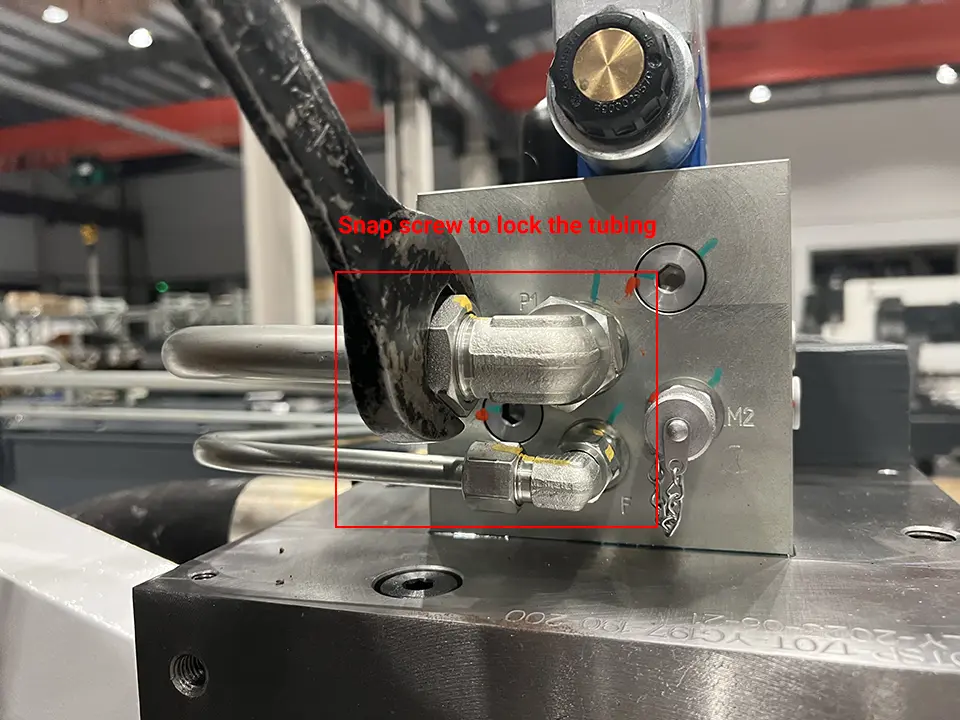

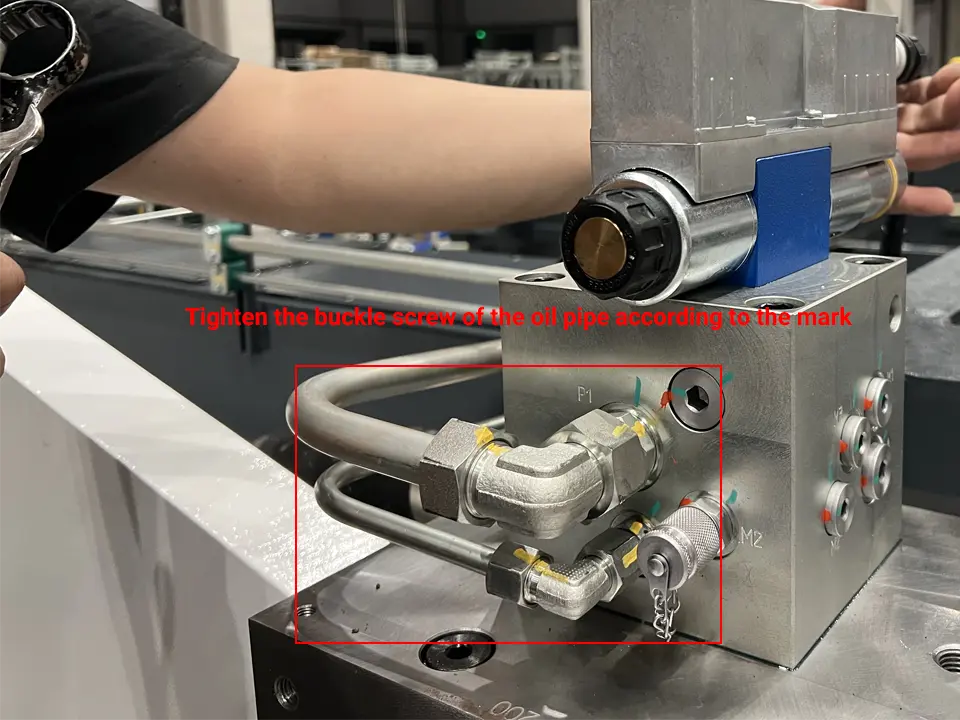

6. To install the oil pipe, make sure that the oil pipe joint is clean, the plane of the oil pipe and the joint should be connected equally, and the buckle screw of the oil pipe should be locked, as shown in Figure 6.

Please install strictly according to the above instructions, and then proceed to the next step of the operation process: