When it comes to precision and efficiency, laser cutting technology, especially fiber laser cutting machines, stands out as the top choice for stainless steel cutting. In this comprehensive guide, we’ll dive deep into the intricacies of laser cutting for stainless steel, exploring the best machines, techniques, and tips to optimize your cutting process while keeping the costs in check.

- Can Stainless Steel Be Cut with a Laser?

- How Does Stainless Steel Laser Cutting Work?

- What Are the Different Types of Laser Cutters Used for Stainless Steel Cutting?

- What Are Main Parameters of Laser Cutting Stainless Steel?

- What Are the Types of Stainless Steel Suitable for Laser Cutting?

- What Is the Best Stainless Steel for Laser Cutting?

- What Are the Industries That Utilize Laser Cutting for Stainless Steel?

- What Are the Expected Outcomes of Using a Laser for Cutting Stainless Steel?

- What Are Important Things to Consider When Laser Cutting Stainless Steel?

- How to Laser Cut Stainless Steels?

- Costs Associated with Laser Cutting Stainless Steel

- Which Are the Best Stainless Steel Laser Cutting Machines?

- What Are Alternative Technologies and Machines for Laser Cutting Stainless Steel?

1. Can Stainless Steel be Cut with a Laser?

The answer is a resounding yes! Stainless steel, known for its corrosion resistance and sleek appearance, can indeed be precisely and efficiently cut using laser technology. And when it comes to laser cutting for stainless steel, you have a variety of options to choose from. The most prominent among them is the fiber laser cutting machine, which is renowned for its precision, speed, and flexibility.

But why choose laser cutting over traditional methods? For one, laser cutting machines, including the fiber laser cutting machine, offer a level of precision that is simply unmatched by traditional cutting methods. They can handle complex shapes and intricate designs with ease, making them an ideal choice for customized projects or products that require a high degree of accuracy. Additionally, laser cutting for stainless steel reduces material wastage, ultimately saving costs in the long run.

When considering laser cutting for your stainless steel projects, it’s important to understand that the quality of the cut depends on several factors. These include the type of laser cutting machine used, the thickness and grade of the stainless steel, and the specific settings of the machine. Ensuring that these factors are optimized for your specific project will result in a clean, precise cut that meets your requirements.

2. How Does Stainless Steel Laser Cutting Work?

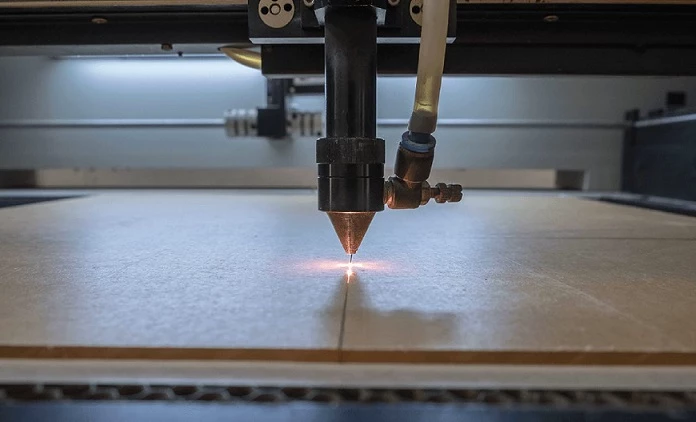

The process of laser cutting for stainless steel is a fascinating blend of science and technology. Essentially, it involves using a focused laser beam to melt, burn, or vaporize the material, resulting in a precise and clean cut. But let’s dive deeper and understand the nitty-gritty of how it all comes together.

Firstly, it all starts with the laser cutting machine. This machine, which could be a fiber laser cutting machine or another type of laser cutter, generates a laser beam that is then focused onto the stainless steel surface. The intensity and heat of the laser beam are controlled and adjusted based on the thickness and grade of the stainless steel being cut.

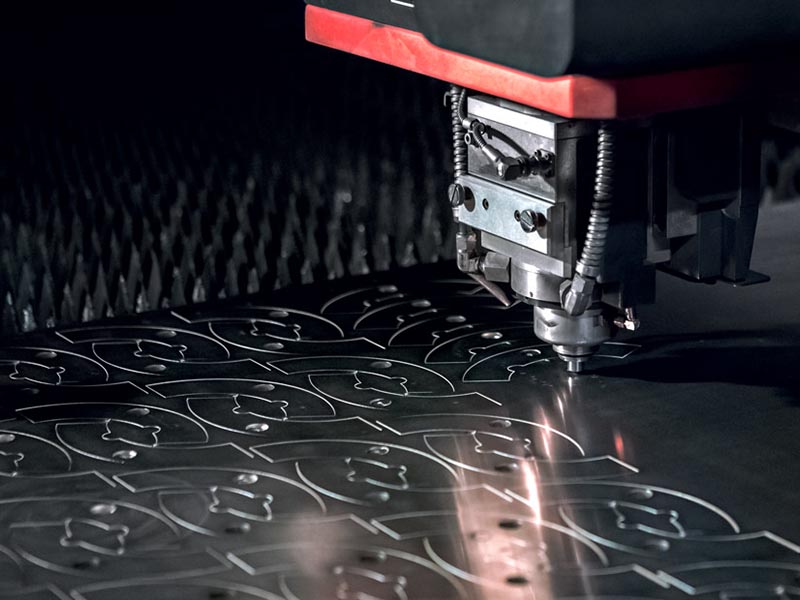

Once the laser beam is focused on the stainless steel, it begins to melt, burn, or vaporize the material along the designated cutting line. As the laser beam moves, it leaves behind a clean and precise cut that perfectly follows the desired pattern or shape. This is why laser cutting is an excellent option for projects that require intricate designs or customized shapes.

In addition to the laser beam itself, the process also involves the use of assist gases. These gases, which could include oxygen, nitrogen, or air, are used to blow away the molten material, leaving behind a smooth and clean cut edge. The choice of assist gas depends on the specific requirements of the project, as different gases can affect the final appearance and quality of the cut.

3. What are the Different Types of Laser Cutters Used for Stainless Steel Cutting?

When it comes to laser cutting for stainless steel, there are primarily two types of laser cutters that are commonly used: fiber laser cutters and CO2 laser cutters. Each type has its own unique set of features and advantages, making them suitable for different applications and requirements. Let’s take a closer look at these two types of laser cutters.

Fiber Laser Cutters

Fiber laser cutters are a popular choice for stainless steel cutting due to their high precision, speed, and flexibility. They use a fiber laser, which is a type of solid-state laser that generates a high-quality laser beam by using a fiber optic cable. The laser beam is then focused onto the stainless steel surface, resulting in a clean and precise cut.

One of the key advantages of fiber laser cutters is their efficiency. They are capable of cutting stainless steel at a faster rate compared to other types of laser cutters, making them an ideal choice for high-volume production. Additionally, fiber laser cutters require less maintenance and have a longer lifespan, resulting in lower operating costs over time.

CO2 Laser Cutters

CO2 laser cutters, on the other hand, use a gas mixture that includes carbon dioxide to generate a laser beam. The laser beam is then focused onto the stainless steel surface, melting or vaporizing the material to create a clean and precise cut. CO2 laser cutters are known for their high power and ability to handle thicker materials.

While CO2 laser cutters are capable of producing high-quality cuts, they generally have a slower cutting speed compared to fiber laser cutters. Additionally, CO2 laser cutters require more maintenance and have a shorter lifespan, resulting in higher operating costs over time. However, they are still a popular choice for applications that require high power and the ability to handle thicker materials.

4. What are Main Parameters of Laser Cutting Stainless Steel?

Laser cutting stainless steel is a precise process that requires careful attention to a variety of parameters to ensure a clean and accurate cut. The main parameters that need to be considered are the laser power, cutting speed, focus position, and assist gas pressure. Let’s delve into each of these parameters to understand their importance in the laser cutting process.

What are the Cutting Tolerances for Stainless Steel Laser Cutting?

The cutting tolerances for stainless steel laser cutting are typically within the range of ±0.1mm to ±0.5mm, depending on the thickness and grade of the stainless steel, as well as the specific settings of the laser cutting machine. Achieving tight tolerances requires precise control of the laser power, cutting speed, and other parameters to ensure a clean and accurate cut.

What is the Thickest Steel that Can be Laser Cut?

The thickness of steel that can be laser cut depends on the power of the laser cutting machine and the specific requirements of the project. In general, fiber laser cutters are capable of cutting steel up to 25mm thick, while CO2 laser cutters can handle thicknesses up to 20mm. However, it is important to note that the quality of the cut may decrease as the thickness of the material increases, so it is crucial to optimize the parameters for the specific thickness of the stainless steel being cut.

5. What are the Types of Stainless Steel Suitable for Laser Cutting?

Stainless steel comes in various grades and types, each with its own unique properties and applications. When it comes to laser cutting, it’s essential to understand the differences between the types of stainless steel to choose the one that best suits your needs. Let’s explore the four main types of stainless steel suitable for laser cutting: Austenitic, Ferritic, Martensitic, and Duplex.

Austenitic Stainless Steels

Austenitic stainless steels are known for their corrosion resistance and excellent formability. They are the most commonly used type of stainless steel and are ideal for laser cutting. The austenitic family includes grades such as 304 and 316, which are often used in the food and pharmaceutical industries due to their corrosion resistance.

Ferritic Stainless Steels

Ferritic stainless steels are known for their good corrosion resistance and magnetic properties. They are typically lower in cost compared to austenitic stainless steels and are used in applications where corrosion resistance and magnetism are required. Common grades of ferritic stainless steel include 409 and 430.

Martensitic Stainless Steels

Martensitic stainless steels are known for their high strength and hardness. They are used in applications where high strength and hardness are required, such as in the manufacture of cutting tools and surgical instruments. Common grades of martensitic stainless steel include 410 and 420.

Duplex Stainless Steels

Duplex stainless steels combine the properties of austenitic and ferritic stainless steels, offering good corrosion resistance, high strength, and excellent formability. They are often used in applications where high strength and corrosion resistance are required, such as in the oil and gas industry. Common grades of duplex stainless steel include 2205 and 2507.

6. What is the Best Stainless Steel for Laser Cutting?

Choosing the best stainless steel for laser cutting involves considering factors such as thickness, grade, and the specific requirements of the project. Each type of stainless steel has its own unique properties and applications, making some types better suited for laser cutting than others.

In general, austenitic stainless steels, such as grades 304 and 316, are considered the best options for laser cutting. They offer excellent corrosion resistance, formability, and are widely available, making them an ideal choice for a variety of applications. These grades are also known for their good cutting performance, producing clean and accurate cuts.

Ferritic and martensitic stainless steels can also be used for laser cutting, but they may not offer the same level of cutting performance as austenitic grades. Duplex stainless steels, which combine the properties of austenitic and ferritic stainless steels, can be a good option for applications that require high strength and corrosion resistance.

Ultimately, the best stainless steel for laser cutting depends on the specific requirements of the project. It’s essential to consider factors such as thickness, grade, and application to choose the stainless steel that best suits your needs.

7. What are the Industries that Utilize Laser Cutting for Stainless Steel?

Laser cutting technology has revolutionized the manufacturing process, and its precision and efficiency have made it a popular choice in various industries. Stainless steel, with its corrosion resistance and durability, is a preferred material in many applications. When you combine the versatility of stainless steel with the precision of laser cutting, you get a match made in industrial heaven. Let’s explore some of the industries that capitalize on this dynamic duo.

1. Automotive Industry: The automotive industry relies on laser cutting for stainless steel to produce precise and intricate components for vehicles. This includes exhaust systems, body panels, and various engine parts. The precision of laser cutting ensures that each part fits perfectly, improving the overall efficiency of the manufacturing process.

2. Medical Industry: The medical field requires precision and cleanliness, which is where laser cutting shines. Stainless steel is commonly used for surgical instruments, implants, and other medical devices. Laser cutting ensures that these critical components meet the strict standards and specifications required in the medical industry.

3. Aerospace Industry: The aerospace industry is known for its stringent requirements and tight tolerances. Laser cutting is used to create precise components for aircraft and spacecraft, where even a small error can have significant consequences. The ability of laser cutting to handle complex shapes and intricate designs makes it an invaluable tool in aerospace manufacturing.

4. Construction Industry: Stainless steel is often used in construction for structural components, roofing, and cladding. Laser cutting is employed to cut and shape these materials to the required specifications, ensuring a perfect fit and a visually appealing finish.

5. Food and Beverage Industry: The food and beverage industry utilizes stainless steel for various applications, including processing equipment, containers, and utensils. Laser cutting is used to create precise components that meet the hygiene standards and regulations of the industry.

8. What Are the Expected Outcomes of Using a Laser for Cutting Stainless Steel?

Laser cutting is a highly advanced technique used in the manufacturing industry to cut and shape materials with precision and efficiency. When it comes to cutting stainless steel, a robust and durable material, the outcomes of using a laser are nothing short of impressive. Here are some expected outcomes you can look forward to:

1. Precision and Accuracy: One of the significant advantages of laser cutting is its ability to produce intricate and precise cuts with tight tolerances. This precision ensures that each piece is cut exactly to specifications, reducing the need for additional processing and finishing.

2. Clean and Smooth Edges: Unlike traditional cutting methods that can leave rough or jagged edges, laser cutting produces clean and smooth edges that often require no additional finishing or polishing. This not only improves the overall aesthetic of the final product but also reduces the time and cost associated with post-processing.

3. Consistency and Reproducibility: Laser cutting allows for consistent and repeatable results, making it an ideal choice for mass production. The precision of laser cutting ensures that each piece is virtually identical, reducing the risk of discrepancies or defects in the final product.

4. Reduced Material Waste: The laser cutting process is highly efficient and produces minimal waste. The ability to make precise cuts means that more parts can be cut from a single sheet of stainless steel, maximizing material utilization and reducing waste.

5. Improved Safety: Laser cutting is a non-contact process, meaning there is no direct contact between the cutting tool and the material being cut. This reduces the risk of accidents or injuries and ensures a safer working environment.

9. What Are Important Things to Consider When Laser Cutting Stainless Steel?

Laser cutting stainless steel is a precise and efficient process, but there are several essential factors to keep in mind to ensure optimal results and maintain the integrity of the material. Here are some crucial considerations when using a laser to cut stainless steel:

1. Type of Stainless Steel: As we’ve discussed earlier, different types of stainless steel possess varying properties. Austenitic, ferritic, martensitic, and duplex stainless steels each react differently under a laser’s influence. Understanding the specific type you’re working with can influence cutting speed, power, and gas settings.

2. Thickness of the Material: The thickness of the stainless steel can impact the laser cutting settings and the overall outcome. Thicker materials may require slower cutting speeds and higher laser power to achieve clean cuts.

3. Laser Power and Cutting Speed: Achieving the perfect balance between laser power and cutting speed is crucial. Too much power or too slow a speed can lead to burn marks or melt the material, while too little power or too fast a speed can result in incomplete cuts.

4. Assist Gas Selection: The choice of assist gas—often nitrogen, oxygen, or compressed air—can affect the cutting quality. Nitrogen, for instance, is used to prevent oxidation, resulting in clean, oxide-free edges. Oxygen can produce a faster cut, but might lead to oxidized edges.

5. Lens and Nozzle Maintenance: Regular maintenance and cleaning of the lens and nozzle are vital. Accumulated debris or a damaged lens can affect the laser’s focus and cutting quality.

6. Material Surface Quality: A clean and smooth stainless steel surface ensures better cutting results. Any contaminants or coatings on the surface can affect the cutting process and quality.

7. Material Handling: To prevent damage or deformation, it’s essential to handle and store the stainless steel sheets properly. Any bends or warps in the material can lead to inconsistent cuts.

10. How to Laser Cut Stainless Steels?

Laser cutting stainless steel is a process that requires precision, patience, and knowledge. Here’s a step-by-step guide on how you can achieve clean, precise cuts on stainless steel with a laser cutting machine:

1. Select the Right Type of Laser Cutting Machine: The type of laser cutting machine you choose can significantly affect the outcome. A fiber laser cutting machine is typically preferred for cutting stainless steel as it offers higher precision and efficiency compared to other types of lasers.

2. Choose the Suitable Stainless Steel: As mentioned before, there are different types of stainless steel available, and each has its own properties and suitability for laser cutting. Select the right type of stainless steel for your project.

3. Prepare the Material: Ensure the surface of the stainless steel is clean and free from any contaminants or coatings. A smooth surface results in better cutting quality.

4. Set Up the Machine: Input the correct settings for the specific type of stainless steel you are cutting. This includes the laser power, cutting speed, and assist gas flow rate. Refer to the manufacturer’s guidelines or consult with experienced operators for the optimal settings.

5. Choose the Right Assist Gas: The type of assist gas you use can affect the cutting quality. Nitrogen is commonly used for stainless steel as it prevents oxidation and produces clean, oxide-free edges.

6. Perform a Test Cut: Before proceeding with the actual cutting, it’s recommended to perform a test cut on a scrap piece of stainless steel to ensure the settings are correct and the machine is functioning properly.

7. Start Cutting: Once everything is set up and you are satisfied with the test cut, you can start the cutting process. Monitor the machine and make any necessary adjustments to the settings if required.

8. Post-Processing: After cutting, inspect the edges and surface quality of the cut pieces. If any additional finishing or polishing is required, carry out these steps as necessary.

By following these steps and considering all the important factors involved, you can achieve clean, precise, and efficient laser cutting of stainless steel, producing high-quality parts for your projects.

11. Costs Associated with Laser Cutting Stainless Steel

When it comes to laser cutting stainless steel, the benefits are clear – precision, speed, and quality. However, like any other industrial process, there are associated costs that you should be aware of. Let’s break them down:

11.1 Initial Investment

The first and most significant cost is the initial investment in a laser cutting machine. The price can range from a few thousand to several hundred thousand dollars, depending on the machine’s size, type, and capabilities. Fiber laser cutting machines, which are ideal for stainless steel, tend to be on the pricier side. Additionally, you need to consider the cost of any additional equipment, such as air compressors, cooling systems, and safety gear.

11.2 Operating Costs

Once the machine is up and running, you’ll need to account for the operating costs. This includes electricity, assist gases (such as oxygen or nitrogen), consumables (like lenses and nozzles), and maintenance costs. Labor costs for machine operators and technicians should also be considered. Additionally, depending on your location and the type of materials you are working with, you may need to invest in air filtration systems to meet environmental regulations.

11.3 Tips for Cost Optimization

While the costs can be high, there are several ways you can optimize them to ensure a good return on investment:

1. Proper Maintenance: Regular maintenance and timely repairs can significantly extend the lifespan of your machine and prevent costly breakdowns.

2. Efficient Operation: Ensuring that the machine is operated efficiently, with the correct settings for each job, can minimize waste and reduce costs.

3. Training: Investing in training for machine operators and technicians can improve efficiency and reduce the likelihood of costly mistakes.

4. Energy-Efficient Equipment: Opt for energy-efficient machines and equipment to reduce electricity costs.

5. Optimize Designs: Optimizing your product designs for laser cutting can reduce material waste and save money in the long run.

12. Which are the Best Stainless Steel Laser Cutting Machines?

When it comes to cutting stainless steel, not just any laser cutting machine will do. You need something that’s powerful, precise, and reliable. Here are some of the best stainless steel laser cutting machines that tick all the right boxes:

1. Fiber Laser Cutting Machines: As we’ve mentioned before, fiber laser cutting machines are the preferred choice for cutting stainless steel. They offer high precision, speed, and efficiency. Some of the top brands in this category include Trumpf, Amada, and Bystronic.

2. CO2 Laser Cutting Machines: While not as popular as fiber lasers for cutting stainless steel, CO2 lasers can still get the job done. Some of the best CO2 laser cutting machines are manufactured by Epilog Laser, Universal Laser Systems, and Trotec.

When choosing a laser cutting machine, consider factors like the thickness of the stainless steel you’ll be cutting, the level of precision required, and your budget. It’s also important to think about the size of the machine and whether it will fit in your workspace. Additionally, look for machines that come with good customer support and warranty options.

13. What are Alternative Technologies and Machines for Laser Cutting Stainless Steel?

While laser cutting is one of the most popular and precise methods for cutting stainless steel, there are alternative technologies and machines that can also be used for this purpose. Let’s explore some of the other options available:

1. Waterjet Cutting: This method uses a high-pressure stream of water, often mixed with abrasive particles, to cut through the stainless steel. Waterjet cutting is known for its ability to cut through thick materials with high precision.

2. Plasma Cutting: In plasma cutting, a jet of hot plasma is used to cut through the stainless steel. This method is faster than laser cutting but may not be as precise.

3. Flame Cutting: Also known as oxy-fuel cutting, this method uses a combination of oxygen and a fuel gas to cut through the stainless steel. Flame cutting is suitable for thick materials but is less precise than laser cutting.

4. Mechanical Cutting: This method involves using tools like shears, saws, or nibblers to cut through the stainless steel. Mechanical cutting is typically less precise and slower than laser cutting but can be more cost-effective for certain applications.

Each of these methods has its own advantages and disadvantages, and the best choice will depend on factors like the thickness of the material, the level of precision required, and the available budget. It’s essential to consider your specific needs and do your research before deciding on the best method for your application.

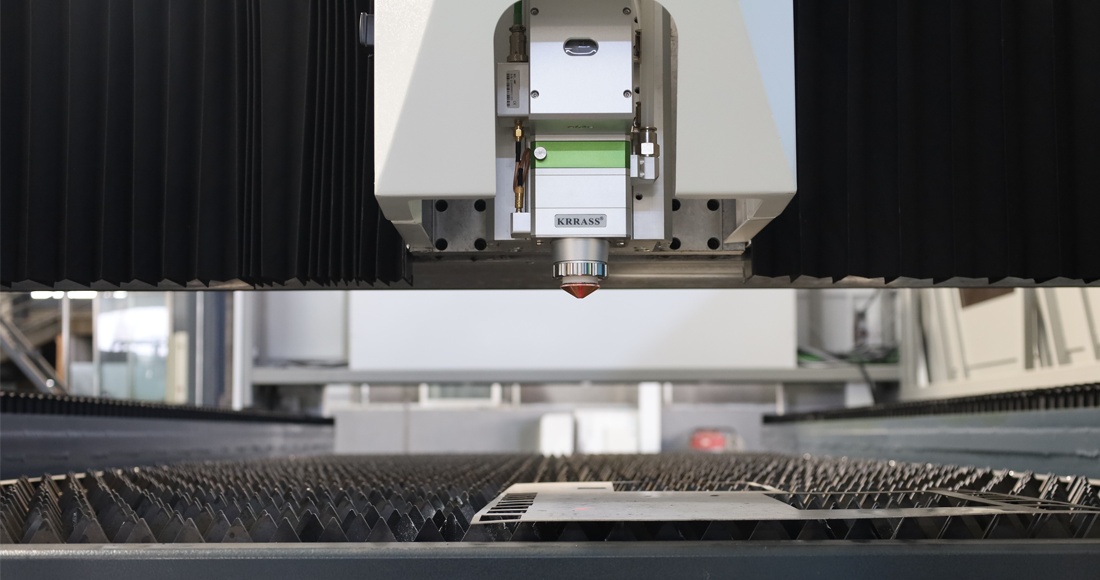

Choosing the Best CNC Laser Cutting Machine

Selecting the right CNC laser cutting machine is crucial for achieving the perfect cut. When it comes to precision, durability, and efficiency, Krrass, China’s leading Fiber Laser Cutting Machine manufacturer, stands out from the competition. Krrass offers a range of top-quality machines tailored to meet your stainless steel cutting needs. Explore the best options and make an informed decision by visiting https://www.krrass.com today.