In the competitive world of manufacturing, every dollar counts. Companies are constantly seeking ways to optimize their operations while minimizing costs. One area where significant savings can be realized is in the acquisition of essential machinery, such as CNC press brakes. While new equipment offers the latest technology and features, a used CNC press brake can provide similar benefits at a fraction of the cost. This article will explore the various advantages of choosing a used CNC press brake, helping you make an informed decision that maximizes value and enhances your production capabilities.

Introduction

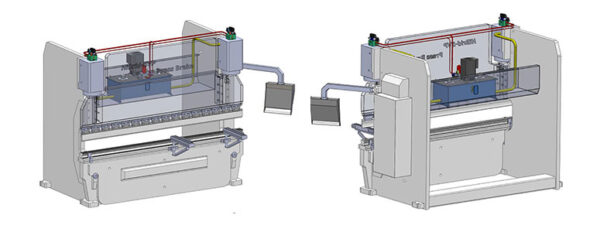

CNC press brakes, integral machines for bending and shaping metal sheets, play a crucial role in achieving these goals. These sophisticated machines utilize computer numerical control (CNC) to automate the bending process, ensuring high accuracy and repeatability. They are essential in industries ranging from automotive to aerospace, enabling the production of complex parts with tight tolerances.c

However, acquiring high-quality equipment can be a significant investment. The importance of cost-effective solutions in manufacturing cannot be overstated. Companies constantly seek ways to balance the need for advanced machinery with budget constraints. This is where the option of purchasing a used CNC press brake becomes particularly attractive.

Opting for a used CNC press brake can offer substantial cost savings while still providing the performance and reliability needed for efficient production. This approach allows businesses to access high-end technology without the hefty price tag associated with brand-new machines. In the following sections, we will delve into the specific benefits of choosing a used CNC press brake, guiding you through the factors to consider and highlighting the potential for maximizing value in your manufacturing operations.

What Is A CNC Press Brake

A CNC press brake is a type of industrial machine used for bending sheet metal into precise, predefined shapes. "CNC" stands for Computer Numerical Control, which means the machine's movements are controlled by a computer program. This technology allows for high precision, consistency, and efficiency in metal forming processes. Here’s a closer look at what makes a CNC press brake an essential tool in manufacturing:

Key Features of a CNC Press Brake: Detailed Overview

1. Frame

The frame is the backbone of a CNC press brake, providing the necessary strength and stability for the entire machine. Typically made of high-quality steel, the frame supports all other components and withstands the significant forces generated during the bending process. A well-constructed frame ensures the machine operates smoothly and maintains accuracy over time.

2. Ram

The ram is the movable upper part of the press brake that exerts pressure on the metal sheet. It moves vertically and is powered by hydraulic, mechanical, or electric systems. The precision of the ram’s movement is crucial for accurate bending. Advanced CNC press brakes often feature a synchronized dual ram system, ensuring even pressure distribution and consistent bends across the entire length of the sheet.

3. Bed

The bed is the stationary lower part of the press brake where the metal sheet is placed. It works in conjunction with the ram to form the bends. The bed supports the die, and its alignment with the ram is essential for achieving precise results. Some CNC press brakes feature a crowning system in the bed to compensate for any potential deflection, ensuring uniform bends.

4. Back Gauge

The back gauge is a critical component for positioning the metal sheet accurately before bending. It consists of adjustable stops that move horizontally, guided by the CNC system. The back gauge ensures that each bend occurs at the correct location on the sheet, maintaining consistency and accuracy. Modern CNC press brakes often come with multi-axis back gauges, allowing complex bend sequences and increased flexibility in production.

5. Control Unit

The control unit is the heart of the CNC press brake, where operators input the bending parameters and programs. It features a user-friendly interface, often with a touchscreen display, for easy programming and operation. The control unit allows for the storage and recall of multiple programs, making it convenient for repetitive tasks and reducing setup times. Advanced control units offer simulation features, helping operators visualize the bending process and avoid errors.

6. Punch and Die

The punch and die are the tools that shape the metal sheet during the bending process. The punch, attached to the ram, presses the metal into the die, which is mounted on the bed. There are various types of punches and dies, each designed for specific bending operations. For example:

- V-dies: Commonly used for general bending tasks.

- U-dies: Suitable for creating U-shaped bends.

- Offset dies: Used for making stepped bends. Selecting the right punch and die combination is crucial for achieving the desired bend angles and shapes.

7. Hydraulic System

Many CNC press brakes use a hydraulic system to power the ram’s movement. The hydraulic system provides the force necessary for bending, with adjustable pressure settings to accommodate different materials and thicknesses. Advanced hydraulic systems feature proportional valves for precise control of the ram’s speed and position, enhancing accuracy and repeatability.

8. Safety Features

Safety is paramount in any industrial machine, and CNC press brakes are no exception. Modern press brakes are equipped with various safety features to protect operators, such as:

- Light curtains: Infrared beams that stop the machine if interrupted.

- Safety guards: Physical barriers that prevent access to moving parts.

- Emergency stop buttons: Allowing operators to quickly halt the machine in case of an emergency.

- Foot pedals: Used to control the ram’s movement, often featuring a two-step operation for added safety.

9. Crowning System

A crowning system is a feature that compensates for any deflection in the bed or ram during bending, ensuring uniform pressure distribution. This system can be manual or automatic, with automatic crowning systems adjusting in real-time based on the bending force. Crowning is particularly important for long sheets, as it prevents inconsistencies in the bend angle across the length of the material.

10. Tool Clamping System

The tool clamping system allows for quick and easy changes of punches and dies. This system can be manual, hydraulic, or pneumatic, with hydraulic and pneumatic clamping offering faster and more efficient tool changes. Quick tool changes reduce downtime and increase productivity, especially in setups requiring multiple different bends.

Understanding these key features of CNC press brakes highlights their importance in achieving precise and efficient metal bending operations. When considering the purchase of a used CNC press brake, it’s essential to evaluate these features to ensure the machine meets your production needs and maintains high performance.

Advantages of CNC Press Brake Over Traditional Press Brake

1. Precision and Accuracy

- CNC Press Brake: Utilizes computer numerical control (CNC) to automate and precisely control the bending process. The CNC system ensures consistent accuracy by following programmed instructions for each bend, reducing the likelihood of human error. This results in high-precision bends that meet tight tolerances.

- Traditional Hydraulic Press Brake: Relies on manual adjustments and operator skill for bending operations. While skilled operators can achieve accurate bends, the process is more susceptible to variability and inconsistency.

2. Repeatability

- CNC Press Brake: Capable of storing multiple programs and recalling them for repetitive tasks. This ensures that each part produced is identical to the previous one, which is crucial for large production runs and maintaining quality standards.

- Traditional Hydraulic Press Brake: Requires manual setup for each bend, leading to potential variations between parts. Achieving consistent results can be challenging, especially for complex or high-volume tasks.

3. Efficiency and Speed

- CNC Press Brake: Automates the bending process, significantly reducing setup times and increasing production speed. The CNC system optimizes the sequence of bends, minimizes downtime between operations, and allows for faster transitions between different jobs.

- Traditional Hydraulic Press Brake: Slower setup and operation times due to manual adjustments. Changing between different jobs or bend sequences can be time-consuming, reducing overall production efficiency.

4. Complex Bending Operations

- CNC Press Brake: Capable of performing complex bending operations with ease. The multi-axis back gauge system and advanced programming capabilities allow for intricate bend sequences and geometries that would be difficult or impossible to achieve with traditional methods.

- Traditional Hydraulic Press Brake: Limited in its ability to perform complex bends. Achieving intricate shapes requires extensive manual intervention and high operator skill, often leading to increased error rates and longer production times.

5. User-Friendly Interface

- CNC Press Brake: Features a user-friendly interface, often with touchscreen controls, making it easier for operators to program and control the machine. Advanced simulation features allow operators to visualize the bending process and detect potential issues before production.

- Traditional Hydraulic Press Brake: Relies on manual controls and adjustments, which can be more challenging and time-consuming for operators. There is no built-in simulation feature, increasing the risk of errors during setup and operation.

Benefits of Used CNC Press Brake

Cost Savings: One of the primary advantages of purchasing a used CNC press brake is cost savings. Compared to buying a new machine, a used press brake typically comes at a lower initial cost. This allows businesses to acquire advanced machinery at a more affordable price point, freeing up capital for other operational needs or investments.

Immediate Availability: Used CNC press brakes are readily available on the market, often with shorter lead times compared to ordering a new machine. This allows businesses to quickly integrate the equipment into their production line and ramp up operations without extended waiting periods.

Proven Performance: Many used CNC press brakes have a track record of performance and reliability. By choosing a machine that has been previously used and maintained, businesses can benefit from proven technology and functionality. This reduces the uncertainty associated with new equipment and ensures that the press brake is capable of meeting production demands.

Lower Depreciation: Unlike new machinery that typically depreciates quickly in the initial years, used CNC press brakes may already have undergone significant depreciation. This stabilizes the asset's value and can result in more predictable long-term costs for the business.

Environmental Sustainability: Opting for a used CNC press brake supports environmental sustainability by extending the lifecycle of industrial equipment. Reusing machinery reduces the demand for new manufacturing resources and contributes to overall resource conservation efforts.

Comparison Between New and Used CNC Press Brakes

1.Cost

When deciding whether to invest in a new or used CNC press brake, cost is crucial. New CNC press brakes from manufacturers like KRRASS come with a significant upfront cost due to their advanced technology and comprehensive warranties. This high initial investment can lead to long-term savings through lower maintenance costs and potential tax benefits.

Conversely, used CNC press brakes from reputable brands like KRRASS are much more affordable, typically ranging from $30,000 to $60,000 depending on the model and condition. These immediate savings allow companies to allocate capital to other areas while still benefiting from KRRASS's proven quality and reliability.

2. Technology

Technology and features also play a significant role in this decision. New CNC press brakes incorporate the latest advancements, offering improved performance, efficiency, and ease of use. These machines may include enhanced automation, better energy efficiency, and higher precision. While used CNC press brakes may lack the newest features, they often still provide reliable performance with proven technology. Additionally, some used machines can be upgraded with newer controls and software, enhancing their capabilities and extending their usefulness.

3. Reliability and condition

Reliability and condition are other critical considerations. New CNC press brakes come with a warranty, ensuring reliability and peace of mind regarding the machine’s performance and condition. These machines typically experience minimal maintenance issues initially, as all components are new and covered by the warranty. On the other hand, the condition of used CNC press brakes can vary widely depending on their age, usage, and maintenance history. Thorough inspection and verification of the machine’s condition are essential before purchase, as older machines may require more frequent maintenance and parts replacement.

When Do You Need To Buy An Used Press Brake

1. Budget Constraints

If your business is operating under a tight budget, a used CNC press brake provides a cost-effective alternative to purchasing a new machine. The lower initial investment allows you to acquire essential equipment without compromising on quality, enabling you to allocate funds to other critical areas of your operations.

2. Short-Term Projects

For companies engaged in short-term projects or temporary contracts, investing in a used CNC press brake can be a practical choice. It provides the necessary functionality without the significant financial commitment of a new machine. Once the project is completed, you can sell the machine with minimal depreciation loss.

3. Expanding Production Capacity

When expanding your production capacity, adding a used CNC press brake can help meet increased demand quickly. Used machines are typically available for immediate purchase and deployment, reducing lead times and allowing you to ramp up production faster compared to waiting for a new machine to be delivered and installed.

4. Supplementing Existing Equipment

If you need to supplement your existing equipment to handle peak periods or specific tasks, a used CNC press brake can be a valuable addition. It can serve as a backup machine or take on overflow work, ensuring your primary equipment remains focused on critical production tasks.

5. Testing New Processes

For businesses looking to test new bending processes or materials, a used CNC press brake offers a cost-effective way to experiment without significant financial risk. You can explore different techniques and workflows to determine the best approach before investing in new, specialized equipment.

6. Entry into CNC Technology

If your business is transitioning from manual or traditional hydraulic press brakes to CNC technology, starting with a used CNC press brake can be an excellent way to familiarize your team with the new system. It allows your operators to gain experience and build proficiency without the higher cost of a new machine.

7. Limited Usage Requirements

For operations that only require occasional use of a press brake, a used CNC machine is a practical option. The lower investment makes sense for equipment that won’t be in constant use, providing the necessary capability without tying up significant capital.

8. Proven Reliability

Opting for a used CNC press brake from a reputable manufacturer like KRRASS ensures you’re getting a machine with proven reliability and performance. These machines are built to last and, with proper maintenance, can continue to deliver high-quality results for many years.

In conclusion, a used CNC press brake can be an excellent investment for businesses in various situations, offering cost savings, flexibility, and reliability. By carefully assessing your specific needs and circumstances, you can determine if a used machine is the right choice for your operations.

When Do You Need To Buy A New Press Brake

High Precision and Accuracy Requirements: If your manufacturing processes demand consistent accuracy and precise control over bending angles and tolerances, a new CNC press brake is ideal. Modern machines incorporate advanced CNC controls and precision hydraulic systems to meet stringent quality standards.

Increased Production Capacity: When expanding your production capacity to meet growing demand, a new CNC press brake offers the reliability and throughput required for high-volume production. These machines are designed for continuous operation, minimizing downtime and optimizing productivity.

Customization and Specialization Needs: For businesses requiring specialized bending applications or custom tooling configurations, a new CNC press brake provides flexibility. Manufacturers offer customization options to tailor the machine to specific production requirements, enhancing overall efficiency and versatility.

Compliance with Industry Standards: New CNC press brakes meet the latest industry standards for safety, environmental impact, and performance. They are equipped with advanced safety features and ergonomic designs to ensure operator safety and compliance with workplace regulations.

Integration with Advanced Technologies: If your business aims to integrate with advanced manufacturing technologies, such as IoT connectivity and data analytics, a new CNC press brake facilitates seamless integration. These machines enable real-time monitoring of performance metrics, predictive maintenance, and optimization of production processes.

Long-Term Return on Investment (ROI): Purchasing a new CNC press brake offers long-term ROI. It comes with comprehensive warranties, technical support, and access to replacement parts, reducing maintenance costs and extending the machine's lifespan. KRRASS cnc pres brake machines are known for their durability and reliability, ensuring continued performance and efficiency over years of operation.

Key Factors to Consider When Purchasing An Used CNC Press Brake

When evaluating a used press brake for purchase, it's essential to delve deeper into several critical factors to ensure it aligns with your business's operational requirements and expectations:

1. Condition Assessment:

Thoroughly inspect the physical condition of the press brake. Look beyond surface appearances for signs of wear and tear, such as corrosion, dents, or worn-out components. Pay attention to critical areas like the bending mechanism, hydraulic system, and control panel. Request detailed maintenance records to understand the machine's history of servicing and repairs. If possible, arrange for a demonstration or test run to assess its operational performance firsthand.

2. Age and Usage History:

Consider both the age of the press brake and its usage history. While newer models may offer updated features and technological advancements, older machines with proper maintenance can still provide reliable service. Evaluate the total hours of operation and the types of tasks it has been used for—whether it has handled light-duty or heavy-duty jobs. Machines with a documented history of consistent maintenance and moderate usage often indicate better reliability and longevity.

3. Brand Reputation and Model Reliability:

Research the reputation of the brand and the specific model of press brake you're interested in. Reputable manufacturers are known for producing durable and high-performance machinery. Investigate if the brand offers comprehensive support, including readily available spare parts and technical assistance. Review customer feedback and industry reviews to gauge reliability and customer satisfaction with the particular model you're considering.

4. Seller's Reputation and Trustworthiness:

Assess the credibility and reputation of the seller from whom you're purchasing the used press brake. Look for established dealers or sellers with a proven track record of supplying quality machinery. Check references, read online reviews, and seek recommendations from industry peers. A trustworthy seller should provide transparent information about the machine's history, offer warranties or guarantees, and be responsive to your inquiries and concerns.

5. Price and Overall Value Proposition:

Evaluate the pricing of similar used cnc press brakes in the market to determine a fair and competitive price range. Beyond the initial purchase cost, consider the overall value proposition. Assess factors such as the machine's condition, age, included accessories or tooling, and the potential for future maintenance costs. Calculate the return on investment (ROI) based on the machine's expected lifespan and its contribution to your production capabilities and efficiency.

By meticulously evaluating these factors, you can make a well-informed decision when purchasing a used cnc press brake. This thorough approach ensures that you not only acquire a cost-effective machine but also one that meets your operational needs reliably and efficiently.

How To Inspect An Used CNC Press Brake

When planning to purchase a used press brake for your business, conducting a meticulous inspection is essential to verify its condition and suitability. Here’s a detailed guide on what to focus on during the inspection process:

1. Physical Examination:

- Overall Condition: Begin by visually inspecting the entire machine. Look for any signs of physical damage such as dents, scratches, or rust. Check the structural integrity of the frame and ensure that all components are securely mounted.

- Hydraulic System: Examine the hydraulic system for leaks, visible wear on hoses, and the condition of hydraulic cylinders. Ensure that there are no unusual stains or puddles of hydraulic fluid around the machine.

- Electrical Components: Inspect the control panel, switches, buttons, and electrical wiring for signs of wear, corrosion, or loose connections. Test each control to verify responsiveness and functionality.

- Tooling and Accessories: Check the condition of the tooling and any accessories that come with the press brake, such as punches, dies, and back gauges. Ensure they are compatible with your production requirements and in good working order.

2. Operational Testing:

- Power On and Initialization: Power on the press brake and observe the initialization process. Check for any error messages or warnings displayed on the control panel.

- Control Panel and Interface: Test the functionality of the control panel and interface. Navigate through different menus and settings to ensure all functions are accessible and operational.

- Bending Performance: Perform test bends on various materials and thicknesses to assess the machine's bending capabilities. Measure the accuracy of the bends using precision instruments to ensure they meet your quality standards.

- Noise and Vibration: Listen for unusual noises or vibrations during operation, as these can indicate mechanical issues or worn-out components.

3. Maintenance and Service History:

- ocumentation Review: Request maintenance records and service history from the seller or previous owner. Review records of routine maintenance, repairs, and any upgrades performed on the machine.

- Scheduled Maintenance: Check if the press brake has undergone regular scheduled maintenance according to manufacturer recommendations. Machines with a documented maintenance history are more likely to have been well-maintained and could offer better reliability.

- Major Repairs: Inquire about any major repairs or replacements of key components such as the hydraulic system, control system, or structural parts. Understand the reasons for these repairs and ensure they were carried out by qualified technicians.

4. Safety and Compliance:

- Safety Features: Verify the functionality of safety features such as emergency stop buttons, light curtains, interlocks, and guarding. Ensure that these safety mechanisms are in place and operational to protect operators during use.

- Compliance with Standards: Confirm that the press brake meets relevant safety standards and regulatory requirements applicable to your industry. Check for certification labels or documentation indicating compliance with safety regulations.

5. Brand Reputation and Support:

- Manufacturer and Model: Research the reputation of the press brake’s manufacturer and the specific model. Established brands known for quality and reliability, such as KRRASS, often provide better support and access to spare parts.

- Customer Feedback: Look for reviews, testimonials, or feedback from other users of the same press brake model. This can provide insights into common issues, user satisfaction, and the overall reliability of the machine.

6. Price Evaluation and Negotiation:

- Fair Market Value: Compare the asking price of the used CNC press brake with similar models in the market. Consider factors such as age, condition, included accessories, and the seller’s reputation.

- Negotiation: Use the findings from your inspection to negotiate a fair price that reflects the machine’s condition and potential longevity. Consider any necessary repairs or upgrades that may impact the overall cost.

By following this comprehensive inspection guide, you can thoroughly evaluate a used CNC press brake to ensure it meets your operational needs, performs reliably, and represents a sound investment for your business. Taking the time to inspect the machine’s physical condition, operational performance, maintenance history, safety features, and overall value will help you make an informed decision and avoid potential issues in the future.

Where To Buy A Used CNC Press Brake

- Specialized Machinery Dealers

- Online Marketplaces

- Industrial Auctions and Liquidations

- Trade Shows and Expositions

- Local Machinery Suppliers and Resellers

When looking to purchase a used CNC press brake, exploring reputable sources is key to ensuring quality and reliability. Consider established industrial machinery dealers, authorized KRRASS dealers for certified options, online marketplaces like eBay or Machinio, and industry-specific auctions. Each avenue offers distinct benefits—from comprehensive service and support to competitive pricing. By prioritizing thorough inspections and choosing trusted sellers, businesses can confidently acquire a used CNC press brake that meets their production needs while benefiting from cost savings and operational efficiency.

Reviewed by 1 user

press brake

High-quality KRRASS bending machines, excellent quality, are purchased by many friends in our country.