News

Record and deliver news and events related to KRRASS and its products. Welcome to follow and subscribe to KRRASS news to get the latest information.

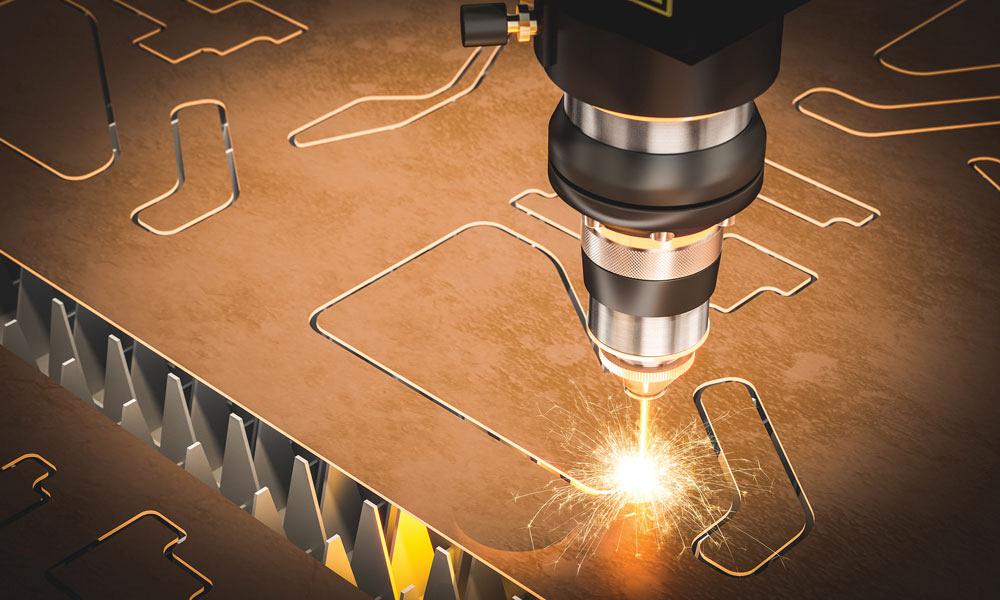

Fiber Laser Cutter for Sale: What to Think and Where to Buy

Are you planning to buy a fiber laser cutter for sale? Selecting laser equipment is never simple. Researching laser types, machine features, technical parameters, and ... Read more

1000W Fiber Laser: Cutting Ability and Paramters

Nowadays, many metal processing companies have begun to replace new processing equipment in order to improve their competitiveness. So, what kind of processing equipment is ... Read more

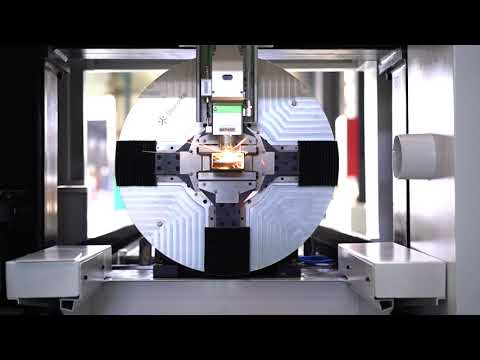

Tube Laser Cutting Machine Prices: Key Factors to Consider

Tube laser cutting machines are advanced tools designed to precisely cut and shape metal tubes and pipes using high-powered lasers. These machines offer unparalleled accuracy, ... Read more

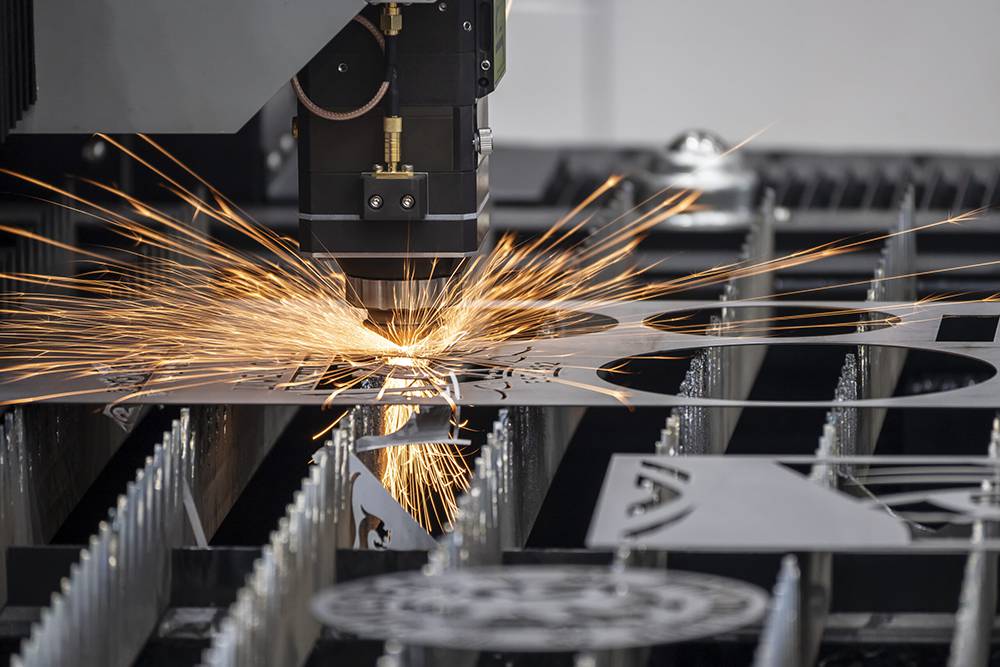

Top Picks for the Best Fiber Laser Cutting Machines in 2024

Choosing the best fiber laser cutting machine is a common concern for many customers. To make an informed decision, several factors need to be considered, ... Read more

Fiber Laser Cutting Machine Price in China: Ultimate Guide

China has emerged as a global leader in manufacturing, particularly in the production of high-quality fiber laser cutting machines. Known for their precision, efficiency, and ... Read more

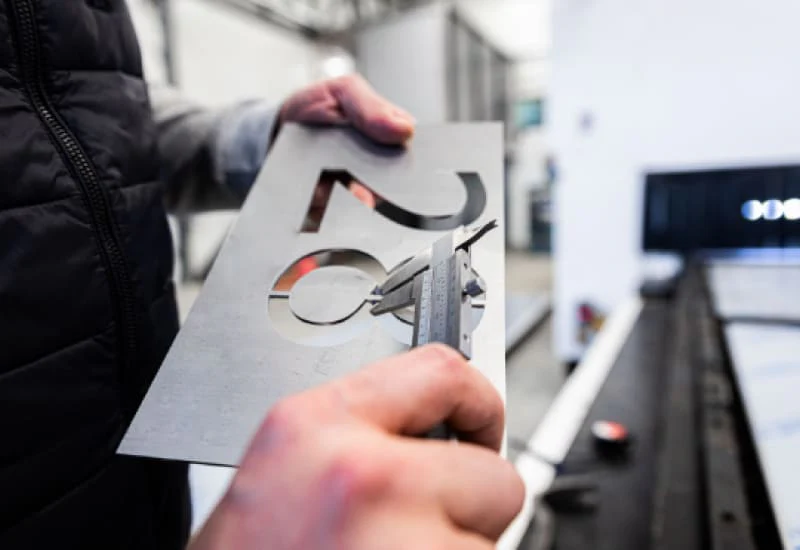

Fiber Laser Metal Cutting Machine: How Materials Suit

When choosing a fiber laser metal cutting machine, material compatibility is a crucial factor. Different metals and alloys have varying properties that affect how they ... Read more

How to Find Best CNC Fiber Laser Cutting Machine

Just like any major investment for your business, selecting the right CNC fiber laser cutting machine demands thorough consideration and research. With the plethora of ... Read more

How to Operate CNC Press Brake Machine

Operating a CNC press brake requires a blend of technical knowledge, precision, and attention to safety. These advanced machines are integral to the metal fabrication ... Read more

2024 China Press Brake Machine Manufactures Guide

Press brakes are fundamental tools in metal forming, essential for various industries from aircraft and automobile manufacturing to home appliances and construction. In China, a ... Read more

100 ton Press Brake Bending Limitis

A 100 ton press brake is a powerful and versatile machine widely used in metalworking industries for bending and shaping metal sheets. Understanding its bending ... Read more

2024 CNC Hydraulic Press Brake Machine Price

In the ever-evolving world of manufacturing and metalworking, CNC hydraulic press brakes have become indispensable tools. These machines, known for their precision, efficiency, and versatility, ... Read more

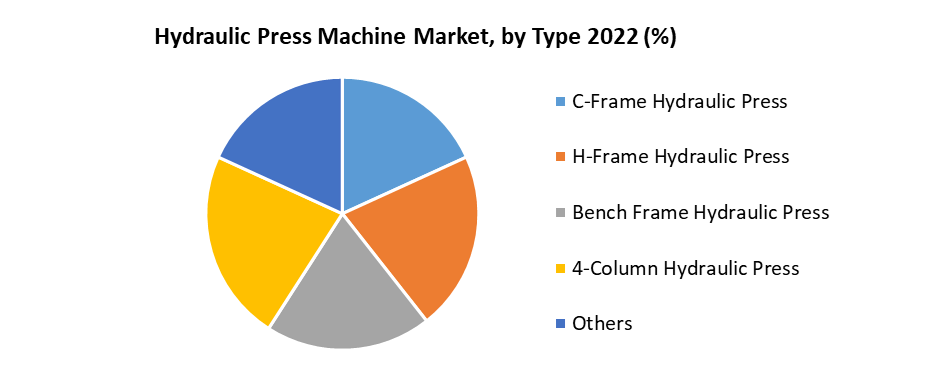

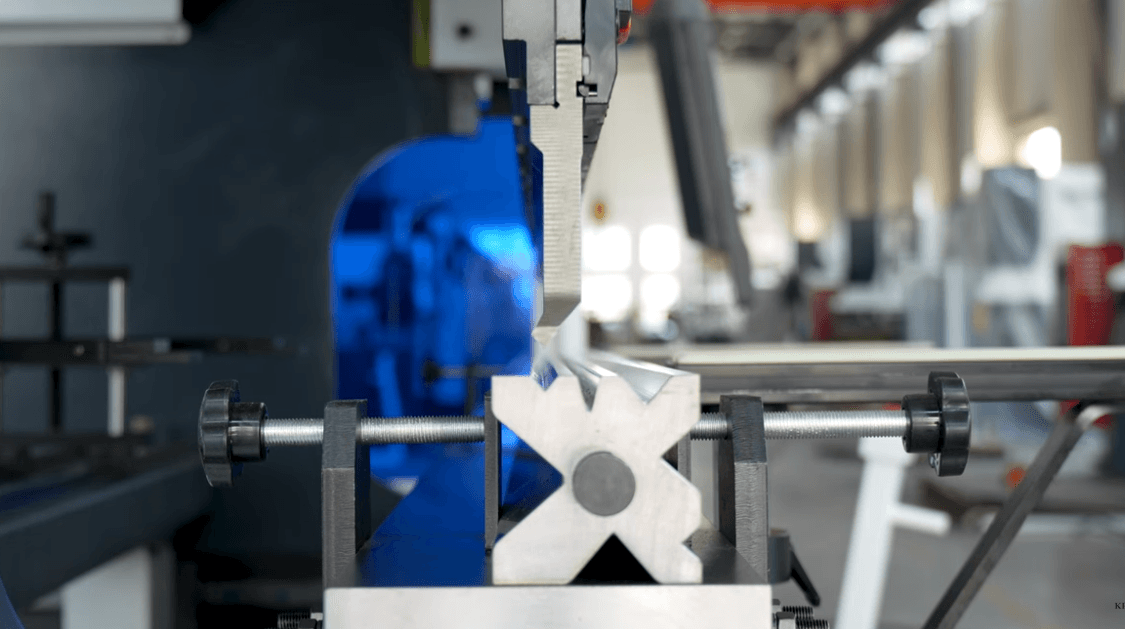

The Ultimate Guide to Hydraulic Metal Brake Presses

Metal press brakes are essential tools in the metalworking industry, utilized to alter the shape, size, or properties of metal materials through the application of ... Read more